Abstract

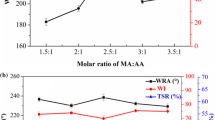

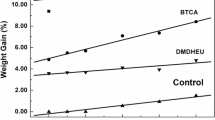

1,2,3,4-Butanetetracarboxylic acid (BTCA) can cause significant strength loss to cotton fabrics, but it has been proven that a flexible molecular structure could benefit the strength in our previous study. In this research, more flexible copolymers [P(IA–AA)] were synthesized with itaconic acid (IA) and acrylic acid (AA) and creatively used as a formaldehyde-free crosslinking reagent for cotton fabrics to replace BTCA. The optimal synthetic conditions of P(IA–AA) were recommended as that the molar ratio of IA:AA and reaction time were 1:1 and 3 h, respectively. The structure of P(IA–AA) was characterized with proton nuclear magnetic resonance spectroscopy, mass spectroscopy and Fourier transform infrared spectroscopy. Results provided evidence that the P(IA–AA) was synthesized with two IA and two AA molecules (molecular weight was 406). Through careful selection, the optimal anti-wrinkle finishing conditions were P(IA–AA) concentration of 160 g/L, pH value of 2.1, curing temperature of 180 °C, and curing time of 2 min. By comparing with IA, BTCA, citric acid (CA), and copolymers of maleic acid (MA) and AA [P(MA–AA)] in the similar conditions, the P(IA–AA)-treated fabrics showed the highest tearing strength retention of 59.30% and whiteness index of 77.60, and the wrinkle recovery angle of the P(IA–AA)-treated fabrics (245.1° ± 0.85°) was comparable with that of the CA-treated ones (244.7° ± 4.30°). Additionally, by separating the strength loss caused by degradation (TSLD) from that caused by crosslinking (TSLC), the P(IA–AA)-treated fabrics presented about 10% less TSLD than P(MA–AA)-treated ones with a comparable TSLC.

Similar content being viewed by others

References

Bajaj P, Paliwal DK, Gupta AK (1993) Acrylonitrile-acrylic acids copolymers. 1. Synthesis and characterization. J Appl Polym Sci 49:823–833

Chen D, Yang CQ, Qiu X (2005) Aqueous polymerization of maleic acid and cross-linking of cotton cellulose by poly(maleic acid). Ind Eng Chem Res 44:7921–7927

Harifi T, Montazer M (2012) Past, present and future prospects of cotton cross-linking: new insight into nano particles. Carbohydr Polym 88:1125–1140

Hu H, Dong X, Tang W, Yao J, He J (2018) Effects of molecular structures of poly-carboxylic acids on crosslinking reaction. Dye Finis 01:0001–0005

Ji B, Tang P, Yan K, Sun G (2015) Catalytic actions of alkaline salts in reactions between 1,2,3,4-butanetetracarboxylic acid and cellulose: II. Esterification. Carbohydr Polym 132:228–236

Ji B, Qi H, Yan K, Sun G (2016a) Catalytic actions of alkaline salts in reactions between 1,2,3,4-butanetetracarboxylic acid and cellulose: I. Anhydride formation. Cellulose 23:259–267

Ji B, Yan K, Sun G (2016b) Investigation on functional properties of 1,2,3,4-butanetetracarboxylic acid cross-linked fabrics impacted by molecular structures and chemical affinity of catalysts. Ind Eng Chem Res 55:5216–5222

Ji B, Zhao C, Yan K, Sun G (2016c) Effects of acid diffusibility and affinity to cellulose on strength loss of polycarboxylic acid crosslinked fabrics. Carbohydr Polym 144:282–288

Ji B, Zhao C, Yan K, Sun G (2018) Effects of divalent anionic catalysts on cross-linking of cellulose with 1,2,3,4-butanetetracarboxylic acid. Carbohydr Polym 181:292–299

Ji B, Tang P, Hu C, Yan K (2019) Catalytic and ionic cross-linking actions of L-glutamate salt for the modification of cellulose by 1,2,3,4-butanetetracarboxylic acid. Carbohydr Polym 207:288–296

Liang T, Yan K, Zhao T, Ji B (2020) Synthesis of a low-molecular-weight copolymer by maleic acid and acrylic acid and its application for the functional modification of cellulose. Cellulose 27:5665–5675

Luo M, Li H, Huang C, Zhang H, Xiong L, Chen X, Chen X (2018) Cellulose-based absorbent production from bacterial cellulose and acrylic acid: synthesis and performance. Polymers 10:702–719

Peng H, Yang CQ, Wang X, Wang S (2012) The combination of itaconic acid and sodium hypophosphite as a new cross-linking system for cotton. Ind Eng Chem Res 51:11301–11311

Qi H (2017) Formaldehyde-free anti-wrinkle finishing on cotton fabrics by polycarboxylic acids. Donghua University, Shanghai

Qi H, Huang Y, Sun G, Qing F, Yan K (2016a) Anti-crease finishing of cotton fabrics based on crosslinking of cellulose with acryloyl malic acid. Carbohydr Polym 135:86–93

Qi H, Pan J, Qing F, Yan K, Sun G (2016b) Anti-wrinkle and UV protective performance of cotton fabrics finished with 5-(carbonyloxy succinic)-benzene-1,2,4-tricarboxylic acid. Carbohydr Polym 154:313–319

Schramm C, Rinderer B, Tessadri B (2014) Non-formaldehyde, crease resistant agent for cotton fabrics based on an organic–inorganic hybrid material. Carbohydr Polym 105:81–89

Tang P, Ji B, Sun G (2016) Whiteness improvement of citric acid crosslinked cotton fabrics: H2O2 bleaching under alkaline condition. Carbohydr Polym 147:139–145

Vadakkekara GJ, Thomas S, Nair CPR (2020) Sodium itaconate grafted nanocellulose for facile elimination of lead ion from water. Cellulose 27:3233–3248

Wan Y (2014) Synthesis and properties of low molecular weight poly(acrylic acid-co-itaconic acid). Zhengzhou University, Zhengzhou

Yang CQ (1991) FT-IR spectroscopy study of the ester crosslinking mechanism of cotton cellulose. Text Res J 61:433–440

Yang CQ, Gu X (2001) Polymerization of maleic acid and itaconic acid studied by FT-Raman spectroscopy. J Appl Polym Sci 81:223–228

Yang CQ, Wang X (1996) Formation of cyclic anhydride intermediates and esterification of cotton cellulose by multifunctional carboxylic acids: an infrared spectroscopy study. Text Res J 66:595–603

Yang C, Wang X, Kang I (1997) Ester crosslinking of cotton fabric by polymeric carboxylic acids and citric acid. Text Res J 67:334–342

Yang CQ, Xu L, Li S, Jiang Y (1998) Nonformaldehyde durable press finishing of cotton fabrics by combining citric acid with polymers of maleic acid. Text Res J 68:457–464

Yang CQ, Hu C, Lickfield GC (2003) Crosslinking cotton with poly(itaconic acid) and in situ polymerization of itaconic acid: fabric mechanical strength retention. J Appl Polym Sci 87:2023–2030

Acknowledgments

This research was funded by the National Natural Science Foundation of China (51803025), the Fundamental Research Funds for the Central Universities (2232020D-21), and the China Postdoctoral Science Foundation Project (2018M641893).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, T., Yan, K., Zhao, T. et al. High strength retention of cellulose fibers crosslinking with synthesized low-molecular-weight copolymers of itaconic acid and acrylic acid. Cellulose 28, 1167–1178 (2021). https://doi.org/10.1007/s10570-020-03574-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03574-z