Abstract

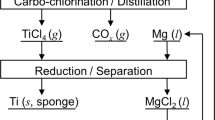

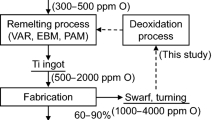

Titanium (Ti) is produced by a multi-step process from Ti ore composed of Ti oxide including chlorination process. However, the smelting cost is a major factor that leads to an increase in the cost of Ti. To lower the cost of Ti, the development of a new technique for the direct production of metallic Ti from an oxide feed material is highly desired. However, owing to the high affinity between Ti and oxygen (O) and the high solubility of O in Ti, it is extremely difficult to produce metallic Ti with low O concentration which meets the level required by the industry. In this study, we developed a new method for producing Ti with a low O concentration directly from TiO2 by using Mg as a reductant, assisted by a rare earth oxychloride formation reaction. The production of Ti with a low O concentration was demonstrated using a magnesiothermic reduction of TiO2 in MgCl2–LaCl3 molten salt via a reduction reaction involving LaOCl formation: (TiO2 (s) + 2 Mg (l) + 2 LaCl3 (l) = Ti (s) + 2 MgCl2 (l) + 2 LaOCl (s)). An electrochemical method that produces metallic Ti from TiO2 with no consumption of rare earth elements and Mg was designed based on the experiment results. This process is expected to replace the current smelting processes of Ti as well as numerous other rare metals produced from raw oxide materials and contribute significantly to a decrease in the price of rare metals.

Graphical Abstract

Similar content being viewed by others

References

Okabe TH (2019) Metallothermic reduction of TiO2. In: Fang ZZ, Froes FH, Zhang Y (eds) Extractive metallurgy of titanium, 1st edn, pp 131–164

Okabe TH, Takeda O (2019) Fundamentals of thermochemical reduction of TiCl4. In: Fang ZZ, Froes FH, Zhang Y (eds) Extractive metallurgy of titanium, 1st edn, pp 65–96

Takeda O, Ouchi T, Okabe TH (2020) Recent progress in titanium extraction and recycling. Metall Mater Trans B 51:1315–1328

Okabe TH, Zheng C, Taninouchi Y (2018) Thermodynamic considerations of direct oxygen removal from titanium by utilizing the deoxidation capability of rare earth metals. Metall Mater Trans B 49:1056–1066

Zheng C, Ouchi T, Iizuka A, Taninouchi Y, Okabe TH (2019) Deoxidation of titanium using Mg as deoxidant in MgCl2-YCl3 flux. Metall Mater Trans B 50:622–631

Perkin FM, Pratt L (1907) Reducing action of metallic calcium and calcium hydride upon metallic oxides, sulphides, and halogen salts. Trans Faraday Soc 3:179–186

Hasegawa M (1950) Production of crude titanium. J Jpn Inst Met A 14:23–26 (in Japanese)

Sibert ME, Steinberg MA (1956) Electrolytic titanium. J Met 8:1162–1168

Henrie TA (1968) Extractive metallurgy of titanium. High Temp Refract Metals 34:139–154

Oki T, Inoue H (1967) Reduction of titanium dioxide by calcium in hot cathode spot. Mem Fac Eng Nagoya Univ 19:164–166

Hayes FH, Bomberger HB, Froes FH, Kaufman L, Burte HM (1984) Advances in titanium extraction metallurgy. JOM 36:70–76

Ono K, Miyazaki S (1985) Study on the limit of deoxidation of titanium and the reduction of titanium dioxide by saturated calcium vapors. J Jpn Inst Met 49:871–875

Ono K, Ogawa M, Okabe TH, Suzuki RO (1990) Production of titanium powders by the calciothermic reduction of TiO2. Tetsu-to-Hagane 76:568–575

Okabe TH (1993) A fundamental study on refining of titanium and its aluminides. PhD thesis, Kyoto University, pp 1–209

Okabe TH, Oda T, Mitsuda Y (2004) Titanium powder production by preform reduction process (PRP). J Alloys Compd 364:156–163

Okabe TH, Waseda Y (1997) Producing titanium through an electronically mediated reaction. JOM 49:28–32

Abiko T, Park I, Okabe TH (2003) Reduction of titanium oxide in molten salt medium. 10th World Conference on Titanium, Humburg

Park I, Abiko T, Okabe TH (2005) Production of titanium powder directly from TiO2 in CaCl2 through an electronically mediated reaction (EMR). J Phys Chem Solids 66:410–413

Chen GZ, Fray DJ, Farthing TW (2000) Direct electrochemical reduction of titanium dioxide to titanium in molten calcium chloride. Nature 407:361–364

Fray DJ (2001) Emerging molten salt technologies for metals production. JOM 53:26–31

Chen GZ, Fray DJ, Farthing TW (2004) Removal of oxygen from metal oxides and solid solutions by electrolysis in a fused salt. United States Patent 20040159559A1

Ono K, Suzuki RO (2002) A new concept for producing Ti sponge: calciothermic reduction. JOM 54:59–61

Suzuki RO, Inoue S (2003) Calciothermic reduction of titanium oxide in molten CaCl2. Metall Mater Trans B 34:277–285

Suzuki RO, Ono K, Teranuma K (2003) Calciothermic reduction of titanium oxide and in-situ electrolysis in molten CaCl2. Metall Mater Trans B 34:287–295

Suzuki RO, Fukui S (2004) Reduction of TiO2 in molten CaCl2 by Ca deposited during CaO electrolysis. Mater Trans 45:1665–1671

Suzuki RO (2005) Calciothermic reduction of TiO2 and in-situ electrolysis of CaO in molten CaCl2. J Phys Chem Solids 66:461–465

Fang ZZ, Middlemas S, Guo J, Fan P (2013) A new, energy-efficient chemical pathway for extracting Ti metal from Ti minerals. J Am Chem Soc 135:18248–18251

Zhang Y, Fang ZZ, Sun P, Zhang T, Xia Y, Zhou C, Huang Z (2016) Thermodynamic destabilization of Ti-O solid solution by H2 and deoxygenation of Ti using Mg. J Am Chem Soc 138:6916–6919

Zhang Y, Fang ZZ, Xia Y, Huang Z, Lefler H, Zhang T, Sun P, Free ML, Guo J (2016) A novel chemical pathway for energy efficient production of Ti metal from upgraded titanium slag. Chem Eng J 286:517–527

Zhang Y, Fang ZZ, Xia Y, Sun P, Devener BV, Free M, Lefler H, Zheng S (2017) Hydrogen assisted magnesiothermic reduction of TiO2. Chem Eng J 308:299–310

Zhang Y, Fang ZZ, Sun P, Xia Y, Free M, Huang Z, Lefler H, Zhang T, Guo J (2017) Kinetically enhanced metallothermic redox of TiO2 by Mg in molten salt. Chem Eng J 327:169–182

Xia Y, Fang ZZ, Zhang Y, Leer H, Zhang T, Sun P, Huang Z (2017) Hydrogen assisted magnesiothermic reduction (HAMR) of commercial TiO2 to produce titanium powder with controlled morphology and particle size. Mater Trans 58:355–360

Lefler H, Fang ZZ, Zhang Y, Sun P, Xia Y (2018) Mechanisms of hydrogen-assisted magnesiothermic reduction of TiO2. Metall Mater Trans B 49:2998–3006

Li Q, Zhu X, Zhang Y, Fang ZZ, Zheng S, Sun P, Xia Y, Li P, Zhang Y, Zou X (2019) An investigation of the reduction of TiO2 by Mg in H2 atmosphere. Chem Eng Sci 195:484–493

Nersisyan HH, Lee JH, Won CW (2003) Combustion of TiO2–Mg and TiO2–Mg–C systems in the presence of NaCl to synthesize nanocrystalline Ti and TiC powders. Mater Res Bull 38:1135–1146

Eshed M, Irzh A, Gedanken A (2009) Reduction of titanium dioxide to metallic titanium conducted under the autogenic pressure of the reactants. Inorg Chem 48:7066–7069

Bolivar R, Friedrich B (2019) Magnesiothermic reduction from titanium dioxide to produce titanium powder. J Sustain Metall 5:219–229

Won CW, Nersisyan HH, Won HI (2010) Titanium powder prepared by a rapid exothermic reaction. Chem Eng J 157:270–275

Ouchi K, Kobayashi Y, Endo R, Susa M (2013) Promotion of solid TiO2 reduction by molten magnesium from the perspective of reaction mechanisms. Tetsu-to-Hagane 99:433–438 (in Japanese)

Nersisyan HH, Won HI, Won CW, Jo A, Kim JH (2014) Direct magnesiothermic reduction of titanium dioxide to titanium powder through combustion synthesis. Chem Eng J 235:67–74

Okabe TH, Taninouchi Y, Zheng C (2018) Thermodynamic analysis of deoxidation of titanium through the formation of rare-earth oxyfluorides. Metall Mater Trans B 49:3107–3117

Zheng C, Ouchi T, Kong L, Taninouchi Y, Okabe TH (2019) Electrochemical deoxidation of titanium in Molten MgCl2-YCl3. Metall Mater Trans B 50:1652–1661

Kong L, Ouchi T, Okabe TH (2019) Direct deoxidation of Ti by Mg in MgCl2-HoCl3 flux. Mater Trans (JIM) 60:2059–2068

Kong L, Ouchi T, Zheng C, Okabe TH (2019) Electrochemical deoxidation of titanium scrap in MgCl2-HoCl3 system. J Electrochem Soc 166:E429–E437

Iizuka A, Ouchi T, Okabe TH (2020) Ultimate deoxidation method of titanium utilizing Y/YOCl/YCl3 equilibrium. Metall Mater Trans B 51:433–442

Iizuka A, Ouchi T, Okabe TH (2020) Development of a new titanium powder sintering process with deoxidation reaction using yttrium metal. Mater Trans 61:758–765

Tanaka T, Ouchi T, Okabe TH (2020) Lanthanothermic reduction of TiO2. Metall Mater Trans B 51:1485–1494. https://doi.org/10.1007/s11663-020-01860-6

Tanaka T, Ouchi T, Okabe TH (2020) Yttriothermic reduction of TiO2 in molten salts. Mater Trans 61:1967–1973

Kong L, Ouchi T, Okabe TH (2020) Deoxidation of Ti using Ho in HoCl3 flux and determination of thermodynamic data of HoOCl. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2020.156047

Arum-shuppan (2019) The rare metal news. no. 2838, 5

Gupta CK, Krishnamurthy N (2013) Oxide reduction processes in the preparation of rare-earth metals. Mining Metall Explor 30:38–44

Muthmann W, Weiss L (1904) Untersuchungen über die metalle der cergruppe. Justus Liebigs Ann Chem 331:1–46

Muthmann W, Weiss L (1907) Untersuchungen über metallisches vanadin, niob, tantal. Justus Liebigs Ann Chem 351:59–99

Vogel R (1917) About the influence of the titanium on the perlite creation in carbon steel. Ferrum 14:177–197

Okabe TH, Suzuki RO, Oishi T, Ono K (1991) Thermodynamic properties of dilute titanium-oxygen solid solution in beta phase. Mater Trans (JIM) 32:485–488

Barin I (1995) Thermochemical data of pure substance, 3rd edn. Wiley-VCH, Weinheim

Chase MW (1998) NIST-JANAF Thermochemical Tables, 4th edn., American Institute of Physics

Permyakov PG, Korshunov BG, Krokhin VA (1975) Solubility of rare earth and yttrium oxochlorides in molten salts: MCl2 (M: Mg, Ca, Sr, Ba). Zhurnal Neorganicheskoj Khimii 20:2184–2187

Drobot DV, Korshunov BG, Durinina LV (1965) Equilibrium of reaction of lanthanum and praseodymium chlorides with oxygen. Izv. Akad. Nauk SSSR. Neorg Mater 1:2189–2196

Okabe TH, Suzuki RO, Oishi T, Ono K (1991) Production of extra low oxygen titanium by calcium-halide flux deoxidation. Tetsu-to-Hagane 77:93–99 (in Japanese)

Okabe TH, Oishi T, Ono K (1992) Preparation and characterization of extra-low-oxygen titanium. J Alloys Compd 184:43–56

Okabe TH, Nakamura M, Ueki T, Oishi T, Ono K (1992) Preparation of extra-low-oxygen titanium by the calcium-halide flux deoxidation process. Materia Japan 31:315–317 (in Japanese)

Acknowledgements

The authors are grateful to Mr. Akihiro Iizuka and Dr. Lingxin Kong at The University of Tokyo for their effective comments. This work was financially supported by the Japan Society for the Promotion of Science (JSPS) through a Grant-in-Aid for Scientific Research (S) (KAKENHI Grant No. 26220910 and 19H05623).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Hongmin Zhu.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tanaka, T., Ouchi, T. & Okabe, T.H. Magnesiothermic Reduction of TiO2 Assisted by LaCl3. J. Sustain. Metall. 6, 667–679 (2020). https://doi.org/10.1007/s40831-020-00296-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-020-00296-1