Abstract

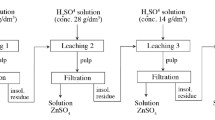

An improved method of (NH4)2SO4 roasting followed by water leaching to utilize zinc oxidized ores was studied. The operating parameters were obtained by investigating the effects of the molar ratio of (NH4)2SO4 to zinc, roasting temperature, and holding time on zinc extraction. The roasting process followed the chemical reaction control mechanism with the apparent activation energy value of 41.74 kJ·mol−1. The transformation of mineral phases in roasting was identified by X-ray diffraction analysis combined with thermogravimetry-differential thermal analysis curves. The water leaching conditions, including the leaching temperature, leaching time, stirring velocity, and liquid-to-solid ratio, were discussed, and the leaching kinetics was studied. The reaction rate was obtained under outer diffusion without product layer control; the values of the apparent activation energy for two stages were 4.12 and 8.19 kJ·mol−1. The maximum zinc extraction ratio reached 96% while the efficiency of iron extraction was approximately 32% under appropriate conditions. This work offers an effective method for the comprehensive use of zinc oxidized ores.

Similar content being viewed by others

References

S.M.C. Santos, R.M. Machado, M.J.N. Correia, M.T.A. Reis, M.R.C. Ismael, and J.M.R. Carvalho, Ferric sulphate/chloride leaching of zinc and minor elements from a sphalerite concentrate, Miner. Eng., 23(2010), No. 8, p. 606.

Z.Y. Ding, Z.L. Yin, X.F. Wu, H.P. Hu, and Q.Y. Chen, Leaching kinetics of willemite in ammonia-ammonium chloride solution, Metall. Mater. Trans. B, 42(2011), No. 4, p. 633.

Z.Y. Ding, Q.Y. Chen, Z.L. Yin, and K. Liu, Predominance diagrams for Zn(II)-NH3-Cl−-H2O system, Trans. Nonferrous Met. Soc. China, 23(2013), No. 3, p. 832.

C.X. Li, H.S. Xu, Z.G. Deng, X.B. Li, M.T. Li, and C. Wei, Pressure leaching of zinc silicate ore in sulfuric acid medium, Trans. Nonferrous Met. Soc. China, 20(2010), No. 5, p. 918.

V. Safari, G. Arzpeyma, F. Rashchi, and N. Mostoufi, A shrinking particle-shrinking core model for leaching of a zinc ore containing silica, Int. J. Miner. Process., 93(2009), No. 1, p. 79.

S. Rao, D.C. Zhang, T.Z. Yang, W.F. Liu, L. Chen, H.B. Ling, and X.W. Zhang, Selective extraction of zinc from refractory hemimorphite using iminodiacetic acid as a complexing agent, JOM, 69(2017), No. 10, p. 1909.

L.Y. Feng, X.W. Yang, Q.F. Shen, M.L. Xu, and B.J. Jin, Pelletizing and alkaline leaching of powdery low grade zinc oxide ores, Hydrometallurgy, 89(2007), No. 3–4, p. 305.

Y. Li, J.K. Wang, W. Chang, C.X. Liu, J.B. Jiang, and F. Wang, Sulfidation roasting of low grade lead-zinc oxide ore with elemental sulfur, Miner. Eng., 23(2010), No. 7, p. 563.

S.H. Yang, H. Li, Y.W. Sun, Y.M. Chen, C.B. Tang, and J. He, Leaching kinetics of zinc silicate in ammonium chloride solution, Trans. Nonferrous Met. Soc. China, 26(2016), No. 6, p. 1688.

H.M. Shao, X.Y. Shen, Y. Sun, Y. Liu, and Y.C. Zhai, Reaction condition optimization and kinetic investigation of roasting zinc oxide ore using (NH4)2SO4, Int. J. Miner. Metall. Mater., 23(2016), No. 10, p. 1133.

X.Y. Shen, H.M. Shao, H.M. Gu, B. Chen, Y.C. Zhai, and P.H. Ma, Reaction mechanism analysis of roasting Zn2SiO4 using NaOH, Trans. Nonferrous Met. Soc. China, 28(2018), No. 9, p. 1878.

Z.L. Yin, Z.Y. Ding, H.P. Hu, K. Liu, and Q.Y. Chen, Dissolution of zinc silicate (hemimorphite) with ammonia-ammonium chloride solution, Hydrometallurgy, 103(2010), No. 1–4, p. 215.

B. Chen, X.Y. Shen, H.M. Gu, H.M. Shao, Y.C. Zhai, and P.H. Ma, Extracting reaction mechanism analysis of Zn and Si from zinc oxide ore by NaOH roasting method, J. Cent. South Univ., 24(2017), No. 10, p. 2266.

S.M. He, J.K. Wang, and J.F. Yan, Pressure leaching of synthetic zinc silicate in sulfuric acid medium, Hydrometallurgy, 108(2011), No. 3–4, p. 171.

Y. Hua, Z. Lin, and Z. Yan, Application of microwave irradiation to quick leach of zinc silicate ore, Miner. Eng., 15(2002), No. 6, p. 451.

Y.C. Zhang, J.X. Deng, J. Chen, R.B. Yu, and X.R. Xing, Leaching of zinc from calcined smithsonite using sodium hydroxide, Hydrometallurgy, 131–132(2013), p. 89.

Y. Sun, X.Y. Shen, and Y.C. Zhai, Thermodynamics and kinetics of extracting zinc from zinc oxide ore by ammonium sulfate roasting method, Int. J. Miner. Metall. Mater., 22(2015), No. 5, p. 467.

X.B. Min, K. Xue, Y. Ke, B.S. Zhou, Y.W.J. Li, and Q.W. Wang, Sulfidation roasting of hemimorphite with pyrite for the enrichment of Zn and Pb, JOM, 68(2016), No. 9, p. 2435.

S. Moradi and A.J. Monhemius, Mixed sulphide oxide lead and zinc ores problems and solutions, Miner. Eng., 24(2011), No. 10, p. 1062.

Z.W. Zhao, S. Long, A.L. Chen, G.S. Huo, H.G. Li, X.J. Jia, and X.Y. Chen, Mechanochemical leaching of refractory zinc silicate (hemimorphite) in alkaline solution, Hydrometallurgy, 99(2009), No. 3–4, p. 255.

W.Q. Qin, W.Z. Li, Z.Y. Lan, and G.Z. Qiu, Simulated small-scale pilot plant heap leaching of low-grade oxide zinc ore with integrated selective extraction of zinc, Miner. Eng., 20(2007), No. 7, p. 694.

M.K. Jha, V. Kumar, and R.J. Singh, Review of hydrometallurgical recovery of zinc from industrial wastes, Resour. Conserv. Recycl., 33(2001), No. 1, p. 1.

H.S. Xu, C. Wei, C.X. Li, G. Fan, Z.G. Deng, M.T. Li, and X.B. Li, Sulfuric acid leaching of zinc silicate ore under pressure, Hydrometallurgy, 105(2010), No. 1–2, p. 186.

S.M. He, J.K. Wang, and J.F. Yan, Pressure leaching of high silica Pb-Zn oxide ore in sulfuric acid medium, Hydrometallurgy, 104(2010), No. 2, p. 235.

I.G. Matthew and D. Elsner, The hydrometallurgical treatment of zinc silicate ores, Metall. Trans. B, 8(1977), No. 1, p. 73.

Z.Y. Ding, Z.L. Yin, H.P. Hu, and Q.Y. Chen, Dissolution kinetics of zinc silicate (hemimorphite) in ammoniacal solution, Hydrometallurgy, 104(2010), No. 2, p. 201.

S. Espiari, F. Rashchi, and S.K. Sadrnezhad, Hydrometallurgical treatment of tailings with high zinc content, Hydrometallurgy, 82(2006), No. 1–2, p. 54.

A.C. Dou, T.Z. Yang, J.X. Yang, J.H. Wu, and A. Wang, Leaching of low grade zinc oxide ores in Ida2−-H2O system, Trans. Nonferrous Met. Soc. China, 21(2011), No. 11, p. 2548.

A.L. Chen, M.C. Li, Z. Qian, Y.T. Ma, J.Y. Che, and Y.L. Ma, Hemimorphite ores: A review of processing technologies for zinc extraction, JOM, 68(2016), No. 10, p. 2688.

A.L. Chen, Z.W. Zhao, X.J. Jia, S. Long, G.S. Huo, and X.Y. Chen, Alkaline leaching Zn and its concomitant metals from refractory hemimorphite zinc oxide ore, Hydrometallurgy, 97(2009), No. 3–4, p. 228.

E. Abkhoshk, E. Jorjani, M.S. Al-Harhsheh, F. Rashchi, and M. Naazeri, Review of the hydrometallurgical processing of nonsulfide zinc ores, Hydrometallurgy, 149(2014), p. 153.

Q. Liu, T.C. Zhao, and G.D. Zhao, Production of zinc and lead concentrates from lean oxidized zinc ores by alkaline leaching followed by two-step precipitation using sulfides, Hydrometallurgy, 110(2011), No. 1–4, p. 79.

S.M. Mousavi, S. Yaghmaei, M. Vossoughi, A. Jafari, and R. Roostaazad, Zinc extraction from Iranian low-grade complex zinc-lead ore by two native microorganisms: Acidithiobacillus ferrooxidans and Sulfobacillus, Int. J. Miner. Process., 80(2006), No. 2–4, p. 238.

X.L. Xu, W.Z. Liu, G.R. Chu, G.Q. Zhang, D.M. Luo, H.R. Yue, B. Liang, and C. Li, Energy-efficient mineral carbonation of CaSO4 derived from wollastonite via a roasting-leaching route, Hydrometallurgy, 184(2019), p. 151.

J.P. Hu, W.Z. Liu, L. Wang, Q. Liu, F. Chen, H.R. Yue, B. Liang, L. Lü, Y. Wang, G.Q. Zhang, and C. Li, Indirect mineral carbonation of blast furnace slag with (NH4)2SO4 as a recyclable extractant, J. Energy Chem., 26(2017), No. 5, p. 927.

L. Wang, W.Z. Liu, J.P. Hu, Q. Liu, H.R. Yue, B. Liang, G.Q. Zhang, D.M. Luo, H.P. Xie, and C. Li, Indirect mineral carbonation of titanium-bearing blast furnace slag coupled with recovery of TiO2 and Al2O3, Chin. J. Chem. Eng., 26(2018), No. 3, p. 583.

W.Z. Liu, X.M. Wang, Z.P. Lu, H.R. Yue, B. Liang, L. Lü, and C. Li, Preparation of synthetic rutile via selective sulfation of ilmenite with (NH4)2SO4 followed by targeted removal of impurities, Chin. J. Chem. Eng., 25(2017), No. 6, p. 821.

G.Q. Zhang, D.M. Luo, C.H. Deng, L. Lv, B. Liang, and C. Li, Simultaneous extraction of vanadium and titanium from vanadium slag using ammonium sulfate roasting-leaching process, J. Alloys Compd., 742(2018), p. 504.

Y.C. Li, H. Liu, B. Peng, X.B. Min, M. Hu, N. Peng, Y.Z. Yuang, and J. Lei, Study on separating of zinc and iron from zinc leaching residues by roasting with ammonium sulphate, Hydrometallurgy, 158(2015), p. 42.

W.N. Mu, F.H. Cui, Z.P. Huang, Y.C. Zhai, Q. Xu, and S.H. Shao, Synchronous extraction of nickel and copper from a mixed oxide-sulfide nickel ore in a low-temperature roasting system, J. Clean. Prod., 177(2018), p. 371.

S. Yin, T. Aldahri, S. Rohani, C. Li, D.M. Luo, G.Q. Zhang, H.R. Yue, B. Liang, and W.Z. Liu, Insights into the roasting kinetics and mechanism of blast furnace slag with ammonium sulfate for CO2 mineralization, Ind. Eng. Chem. Res., 58(2019), No. 31, p. 14026.

W.Z. Liu, S. Yin, D.M. Luo, G.Q. Zhang, H.R. Yue, B. Liang, L.M. Wang, and C. Li, Optimising the recovery of high-value-added ammonium alum during mineral carbonation of blast furnace slag, J. Alloys Compd., 774(2019), p. 1151.

Y.X. Hua, Introduction of Metallurgical Process Kinetics, 1st ed., Metallurgical Industry Press, Beijing, 2004.

H.M. Shao, X.Y. Shen, B.B. Zhang, and Y.C. Zhai, Purification of the digestion solution of zinc oxide ores, J. Northeast. Univ. Nat. Sci., 36(2015), No. 6, p. 811.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51774070, 52004165, and 51574084), and the National Key Research and Development Program of China (No. 2017YFB0305401).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, Xy., Shao, Hm., Ding, Jw. et al. Zinc extraction from zinc oxidized ore using (NH4)2SO4 roasting-leaching process. Int J Miner Metall Mater 27, 1471–1481 (2020). https://doi.org/10.1007/s12613-020-2015-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2015-2