Abstract

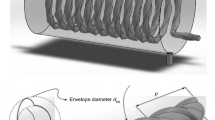

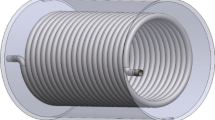

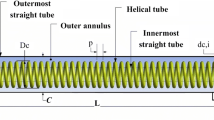

In this study, experimental investigations and exergy analysis on shell and helically coiled tube heat exchanger are carried out for free convection heat transfer. The measured data are totally optimised utilizing thermodynamics rules in which exergy study is performed to investigate the thermal performance of the helical system under different operating conditions. The experimental set-up of apparatus are designed and made for cold water and hot water as a working fluid of both the shell side and helical coil side, respectively. The effects of several parameters such as geometry and operational conditions on the exergy destruction and dimensionless exergy destruction are investigated. The counter flow direction is considered under the steady state flow condition, and the critical Reynolds number was more than 4000 in this study. The main objective of this work was to clarify the effect of the volume flow rates and inlet temperatures of hot water and cold water in the shell and helical coil on exergy efficiency and pressure drop. Results showed that the exergy destruction and dimensionless exergy destruction decrease with the increase of coil pitch and Dean number. In contrast, the exergy destruction and dimensionless exergy destruction are obviously increased with the hot water flow rates or cold water flow rates. These exergy characteristics are also augmented with the values of hot water inlet temperatures and cold water inlet temperatures. The pressure drop is considerably increased with the increase of Dean number and reduced with the increase of coil diameter. While, the exergy efficiency steadily increases with the decrease of the cold water flow rates and with the increase of Dean number.

Similar content being viewed by others

Abbreviations

- T :

-

Temperature (control volume) (K)

- T 0 :

-

Dead state temperature (K)

- P 0 :

-

Dead state pressure (K)

- ρ :

-

Density of water (kg/m3)

- u :

-

Velocity of water (m/s)

- μ :

-

Viscosity (kg/m.s)

- z :

-

Elevation (m)

- g :

-

Specific gravity (−)

- h :

-

Enthalpy of water (kJ/kg)

- s :

-

Entropy of water (kJ/kg.K)

- \( {\dot{W}}_{CV} \) :

-

Control volume work (W)

- Q :

-

Flow rate (LPM)

- \( {\dot{m}}_h\&{\dot{\ m}}_c \) :

-

Mass flow rate of hot and cold water (kg/s)

- ψ :

-

Exergy flow (J/kg)

- \( {\dot{S}}_{gen. HCHE.} \) :

-

Entropy generation of helical coil heat exchanger (W/K)

- Ψ dest. HCHE :

-

Exergy destruction of helical coil heat exchanger (W)

- e :

-

Dimensionless of exergy destruction (−)

- \( {\eta}_{ex_{HCHX}} \) :

-

Exergy efficiency of helical coil heat exchanger (−)

- Cmin :

-

Smaller heat capacity rate (W/K)

- Cp :

-

Specific heat at constant pressure (J/kg.K)

- Re in :

-

Reynolds number inside helical coil heat exchanger (−)

- D e :

-

Dean number (−)

- W:

-

Total uncertainty in the measurement

- X:

-

Independent variable

- 1 and 2:

-

Inlet and outlet sections in coil tube

- 3 and 4:

-

Inlet and outlet sections in shell

- h and c:

-

Hot and cold water

- R+ :

-

Function of the independent variables

- X1, X2, …Xn :

-

Independent variables

- w1, w2, …wn :

-

Independent variables

- din :

-

Inlet diameter (m)

- Dc :

-

Coil diameter (m)

- ΔT:

-

Temperature difference (K)

- L:

-

Length of helical coil (m)

- N:

-

Number of turns of helical coil

- P:

-

Distance between two consecutive coils [1.5* Dc](m)

References

Wu S-Y, Chen S-J, Li Y-R, Li L-J (2008) Numerical investigation of turbulent flow, heat transfer and entropy generation in a helical coiled tube with larger curvature ratio. Heat Mass Transf 45:569–578

Pawar SS, Sunnapwar VK (2013) Studies on convective heat transfer through helical coils. Heat Mass Transf 49:1741–1754

Amori KE (2014) Thermal and hydraulic characteristics of a novel helical coiled tube used as a heat exchanger. Arab J Sci Eng 39:4179–4186

Alimoradi A, Veysi F (2016) Prediction of heat transfer coefficients of shell and coiled tube heat exchangers using numerical method and experimental validation. Int J Therm Sci 107:196–208

Alimoradi A, Olfati M, Maghareh M (2017) Numerical investigation of heat transfer intensification in shell and helically coiled finned tube heat exchangers and design optimization. Chem Eng Process Process Intensif 121:125–143

Andrzejczyk R, Muszynski T (2017) Thermodynamic and geometrical characteristics of mixed convection heat transfer in the shell and coil tube heat exchanger with baffles. Appl Thermal Eng 121:115–125

Rahimi M, Ardahaie SS, Hosseini MJ, Gorzin M (2020) Energy and exergy analysis of an experimentally examined latent heat thermal energy storage system. Renew Energy 147:1845–1860

Pandey SD, Nema VK (2011) An experimental investigation of exergy loss reduction in corrugated plate heat exchanger. Energy 36:2997–3001

Akpinar EK (2006) Evaluation of heat transfer and exergy loss in a concentric double pipe exchanger equipped with helical wires. Energy Convers Manag 47:3473–3486

Naphon P (2011) Study on the exergy loss of the horizontal concentric micro-fin tube heat exchanger. Int Commun Heat Mass Transfer 38:229–235

Sadighi Dizaji H, Jafarmadar S, Hashemian M (2015) The effect of flow, thermodynamic and geometrical characteristics on exergy loss in shell and coiled tube heat exchangers. Energy 91:678–684

Alimoradi A (2017) Investigation of exergy efficiency in shell and helically coiled tube heat exchangers. Case Stud Thermal Eng 10:1–8

Dančová P, Hussain A, Fsadni AM, Veselý M (2016) CFD analysis of the two-phase bubbly flow characteristics in helically coiled rectangular and circular tube heat exchangers. EPJ Web of Conferences 114:02044

Mandal MM, Serra C, Hoarau Y, Nigam KDP (2010) Numerical modeling of polystyrene synthesis in coiled flow inverter. Microfluid Nanofluid 10:415–423

Bhuiyan AA, Amin MR, Islam AKMS (2013) Three-dimensional performance analysis of plain fin tube heat exchangers in transitional regime. Appl Therm Eng 50:445–454

Riyandwita BW, Awwaluddin M, Hastuty S (2019) Performance evaluation of helical coil heat exchanger with annulus shell side using computational fluid dynamics. AIP Conference Proc 2193:020039

Emani MS, Ranjan H, Bharti AK, Meyer JP, Saha SK (2019) Laminar flow heat transfer enhancement in square and rectangular channels having: (1) a wire-coil, axial and spiral corrugation combined with helical screw-tape with and without oblique teeth and a (2) spiral corrugation combined with twisted tapes with oblique teeth. Int J Heat Mass Transf 144:118707

Baqir AS, Mahood HB, Kareem AR (2019) Optimisation and evaluation of NTU and effectiveness of a helical coil tube heat exchanger with air injection. Thermal Sci Eng Progress 14:100420

Sharqawy MH, Saad SMI, Ahmed KK (2019) Effect of flow configuration on the performance of spiral-wound heat exchanger. Appl Therm Eng 161:114157

Vocale P, Bozzoli F, Rainieri S, Pagliarini G (2019) Influence of thermal boundary conditions on local convective heat transfer in coiled tubes. Int J Therm Sci 145:106039

Sheeba A, Akhil R, Prakash MJ (2020) Heat transfer and flow characteristics of a conical coil heat exchanger. Int J Refrig 110:268–276

Adrain B (2002) Fundamentals of exergy analysis, entropy generation minimization, and the generation of flow architecture. Int J Energy Res 26:0–43

Sadighi Dizaji H, Khalilarya S, Jafarmadar S, Hashemian M, Khezri M (2016) A comprehensive second law analysis for tube-in-tube helically coiled heat exchangers. Experiment Thermal Fluid Sci 76:118–125

Kline SJ, FA MC (1953) Describing uncertainties in single-sample experiments. Mech Eng 78:3–8

Ali S (2001) Pressure drop correlations for flow through regular helical coil tubes. Fluid Dynamics Res 28(4):295

Kumar R, Chandra P (2019) Thermal analysis, pressure drop and exergy loss of energy efficient shell, and triple meshed helical coil tube heat exchanger, energy sources, part a: recovery, utilization, and environmental effects, 42(8):1026–1039. https://doi.org/10.1080/15567036.2019.1602213

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

High Lights

• Experimental work and exergetic analysis of Shell and helical coil tube heat exchanger are investigated

• Geometrical effect and operational parameters on exergy characteristics and pressure drop are studied.

• Exergy efficiency for different amounts of Dean number and inlet temperatures is evaluated.

Rights and permissions

About this article

Cite this article

Al-Abbas, A.H., Mohammed, A.A. & Hassoon, A.S. Exergy analysis of Shell and helical coil heat exchanger and design optimization. Heat Mass Transfer 57, 797–806 (2021). https://doi.org/10.1007/s00231-020-02993-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02993-9