Abstract

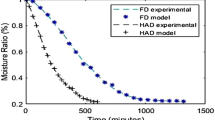

The present work deals mainly with dehydration characteristics of onion slices. Microwave power levels of 100, 350, 550 and 750 W was practiced to dry onion slices with thicknesses of 2.5, 5, 7.5 and 10 mm. The results showed that moisture diffusivity and specific energy consumption of the process increased with both increasing microwave power and the samples thickness, and ranged from 0.82 × 10−8 to 6.13 × 10−8 m2 s−1 and from 0.82 to 5.43 MJ kg−1 water, respectively. The average activation energy varied in the range of 1.28–1.77. Furthermore, for simulation of drying process and to predict the moisture removal behavior of the samples, multi-layer feed-forward (MLF) artificial neural network (ANN) was employed. Practicing different networks and based on statistical parameters, the best topology, transfer functions and training algorithms were determined. The results revealed that, as a powerful tool, ANN modeling could be effectively used to predict drying kinetics and determine the moisture content of the samples.

Similar content being viewed by others

References

Joardder MUH, Brown R, Kumar C, Karim MA (2015) Effect of cell wall properties on porosity and shrinkage of dried apple. Int J Food Prop 18:2327–2337

Torki-Harchegani M, Ghanbarian D, Ghasemi Pirbalouti A, Sadeghi M (2016) Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of pepper mint leaves undergoing microwave and hot air treatments. Renew Sust Energ Rev 58:407–418

Vallespir F, Rodríguez Ó, Eim VS, Rosselló C, Simal S (2018) Freezing pre-treatments on the intensification of the drying process of vegetables with different structures. J Food Eng 239:83–91

Barati E, Esfahani JA (2011) A new solution spprosch for simulation heat and mass transfer during convective drying of mango. J Food Eng 102:302–309

Beigi M, Torki-Harchegani M, Tohidi M (2017) Experimental and ANN modeling investigation of energy traits for rough rice drying. Energy 141:2196–2205

Tohidi M, Sadeghi M, Mousavi SR, Mireei SA (2012) Artificial neural network modeling of process and product indices in deep bed drying of rough rice. Turk J Agric For 36:738–748

Aghbashlo M, Hosseinpour S, Mujumdar AS (2015) Application of artificial neural networks (ANNs) in drying technology–a comprehensive review. Dry Technol 33:1397–1462

Azadbakht M, Aghili H, Ziaratban A, Vahedi Torshizi M (2017) Application of artificial neural network method to exergy and energy analyses of fluidized bed dryer for potato cubes. Energy 120:947–958

Ergün A, Ceylan İ, Acar B, Erkaymaz O (2017) Energy–exergy–ANN analyses of solar-assisted fluidized bed dryer. Dry Technol 35:1711–1720

Liu Z-L, Bai J-W, Wang S-X, Meng J-S, Wang H, Yu X-L, Gao Z-J, Xiao H-W (2019) Prediction of energy and exergy of mushroom slices drying in hot air impingement dryer by artificial neural network. Dry Technol. https://doi.org/10.1080/07373937.2019.1607873

Zare D, Naderi H, Ranjbaran M (2015) Energy and quality attributes of combined hot air/infrared drying of paddy. Dry Technol 33:570–582

Aghbashlo M, Mobli H, Rafiee S, Madadlou A (2013) An artificial neural network for predicting the physicochemical properties of fish oil microcapsules obtained by spray drying. Food Sci Biotechnol 22:677–685

Çakmak G, Yildiz C (2011) The prediction of seedy grape drying rate using a neural network method. Comput Electron Agric 75:132–138

Omari A, Behroozi-Khazaei N, Sharifian F (2018) Drying kinetic and artificial neural network modeling of mushroom drying process in microwave-hot air dryer. J Food Process Eng 41. https://doi.org/10.1111/jfpe.12849

Jahedi Rad S, Kaveh M, Rasooli Sharabiani V, Taghinezhad E (2018) Fuzzy logic, artificial neural network and mathematical model for prediction of white mulberry drying kinetics. Heat Mass Transf 54:3361–3374

Darvishi H, Mohammadi P, Azadbakht M, Farhudi Z (2018) Effect of different drying conditions on the mass transfer characteristics of kiwi slices. J Agric Sci Technol 20:249–264

Darvishi H, Zarein M, Farhudi Z (2016) Energetic and exergetic performance analysis and modeling of drying kinetics of kiwi slices. J Food Sci Technol 53:2317–2333

Arsalan D, Özcan MM (2010) Study the effect of sun, oven and microwave drying on quality of onion slice. LWT Food Sci Technol 43:1121–1127

Cuccurullo G, Giordano L, Metallo A, Cinquanta L (2017) Influence of mode stirrer and air renewal om controlled microwave drying of slices zucchini. Biosyst Eng 158:95–101

Wang J, Xi YS (2005) Drying characteristics and drying quality of carrot using a two-stage microwave process. J Food Eng 68:505–511

Yan WQ, Zhang M, Huang LL, Tang J, Mujumdar AS, Sun JC (2010) Studies on different combined microwave drying of carrot pieces. Int J Food Sci Technol 45:2141–2148

Dadali G, Apar DK, Özbek B (2007) Microwave drying kinetics of okra. Dry Technol 25:917–924

Yan WQ, Zhang M, Huang LL, Mujumdar AS, Tang J (2013) Influence of microwave drying method on the characteristics of the sweet potato dices. J Food Process Preserv 37:662–669

Beigi M (2017) Thin layer drying of wormwood (Artemisia absinthium L.) leaves: dehydration characteristics, rehydration capacity and energy consumption. Heat Mass Transf 53:2711–2718

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Azimi-Nejadian H, Hoseini SS (2019) Study the effect of microwave power and slices thickness on drying characteristics of potato. Heat Mass Transf 55:2921–2930

Nazghelichi T, Aghbashlo M, Kianmehr MH, Omid M (2011) Prediction of energy and exergy of carrot cubes in a fluidized bed dryer by artificial neural networks. Dry Technol 29:295–307

Süfer Ö, Sezar S, Demir H (2017) Thin layer mathematical modeling of convective, vacuum and microwave drying of intact and brined onion slices. J food process Preserv 41. https://doi.org/10.1111/jfpp.13239

Sadin R, Chegini GR, Sadin H (2014) The effect of temperature and slice thickness on drying kinetics tomato in the infrared dryer. Heat Mass Transf 50:501–507

Sadeghi M, Mirzabeigi Kesbi O, Mireei SA (2013) Mass transfer characteristics during convective, microwave and combined microwave-convective drying of lemon slices. J Sci Food Agric 93:471–478

Azadbakht M, Tajari N (2015) The effect of thickness and power on Hayward variety in drying process f kiwifruit using microwave. Agric Eng Int CIGR J 17:300–305

Ghanbarian D, Baraani Dastjerdi M, Torki-Harchegani M (2016) Mass transfer characteristics of bisporus mushroom (Agaricus bisporus) slices during convective hot air drying. Heat Mass Transf 52:1081–1088

Nguyen MH, Price WE (2007) Air-drying of banana: influence of experimental parameters, slab thickness, banana maturity and harvesting season. J Food Eng 79:200–207

Darvishi H (2012) Energy consumption and mathematical modeling of microwave drying of potato slices. Agric Eng Int CIGR J 14:94–102

Beigi M (2018) Effect of infrared drying power on dehydration characteristics, energy consumption, and quality attributes of common wormwood (Artemisia absinthium L.) leaves. J Agric Sci Technol 20:709–718

Barzegar M, Zare D, Stroshine RL (2015) An integrated energy and quality approach to optimization of green peas drying in a hot air infrared-assisted vibratory bed dryer. J Food Eng 166:302–315

Khoshtaghaza MH, Darvishi H, Minaei S (2015) Effects of microwave-fluidized bed drying on quality, energy consumption and drying kinetics of soybean kernels. J Food Sci Technol 52:4749–4760

Martynenko A, Zheng W (2016) Electrohydrodynamic drying of apple slices: energy and quality aspects. J Food Eng 168:215–222

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beigi, M., Torki, M. Experimental and ANN modeling study on microwave dried onion slices. Heat Mass Transfer 57, 787–796 (2021). https://doi.org/10.1007/s00231-020-02997-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02997-5