Abstract

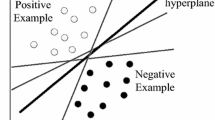

Rotatingmachinery is the main component of mechanical equipment. Nevertheless, due to variation of operating condition results in important detection performance deterioration. Therefore, fault detection and diagnosis of rotating machines is very critical for the reliable operation. In this paper, a novel classification technique is employed for fault detection of rotating machines based on kernelled support tensor machine (KSTM) and multilinear principal component analysis (MPCA). The vibration signal is firstly formulated as a 3-way tensor using trial, condition and channel. In order to process the rotating machines faults and identify the information classes in tensor space, the KSTM is then introduced from sets of binary support tensor machine classifiers by the one-against-one parallel strategy. The MPCA is utilized for reduction dimensionality of the high-dimensional signature space and reservation the tensorial structure information. The performance of the developed technique in classification faults of rotating machinery has been thoroughly evaluated through collecting signals on bearing and gear test-rigs. Experimental results showed that the proposed method can achieve the highest classification results among the six classification techniques investigated in this study.

Similar content being viewed by others

References

Attoui I., Fergani N., Boutasseta N., Oudjani B., Deliou A. (2017) A new time? frequency method for identification and classification of ball bearing faults. Journal of Sound and Vibration 397:241. https://doi.org/10.1016/j.jsv.2017.02.041

Sobie C., Freitas C., Nicolai M. (2018) Simulation-driven machine learning: Bearing fault classification. Mechanical Systems and Signal Processing 99:403. https://doi.org/10.1016/j.ymssp.2017.06.025

Kumar A., Gandhi C. P., Zhou Y., Kumar R., Xiang J. (2020) Latest developments in gear defect diagnosis and prognosis: A review. Measurement 158:107735

Yang Y., Zheng H., Li Y., Xu M., Chen Y. (2019) A fault diagnosis scheme for rotating machinery using hierarchical symbolic analysis and convolutional neural network. ISA transactions 91:235–252

Jiao J., Zhao M., Lin J., Zhao J. (2018) A multivariate encoder information based convolutional neural network for intelligent fault diagnosis of planetary gearboxes. Knowledge-Based Systems 160:237

Funa Z.A.B., Yang S., Fujita C.H, Chen D.D, Wen C.E (2003) Deep learning fault diagnosis method based on global optimization GAN for unbalanced data. Knowledge-Based Systems 187:104–387

Chen P., Zhao X., Zhu Q. (2020) A novel classification method based on ICGOA-KELM for fault diagnosis of rolling bearing. Applied Intelligence 6:1–15

Gao Q. W., Liu W. Y., Tang B. P., Li G. J., Gao Q. W., Liu W. Y., Tang B. P., Li G. J. (2018) A novel wind turbine fault diagnosis method based on intergral extension load mean decomposition multiscale entropy and least squares support vector machine. Renewable Energy 116:S0960148117309242

Liu X., Huang H., Xiang J. (2020) A Personalized Diagnosis Method to Detect Faults in a Bearing Based on Acceleration Sensors and an FEM Simulation Driving Support Vector Machine. Sensors 20(2):420

Wang S., Xiang J., Zhong Y., Zhou Y. (2018) Convolutional neural network-based hidden Markov models for rolling element bearing fault identification. Knowledge-Based Systems 144:65. https://doi.org/10.1016/j.knosys.2017.12.027

Li W., Zhang S., Rakheja S. (2016) Feature Denoising and Nearest? Farthest Distance Preserving Projection for Machine Fault Diagnosis. IEEE Transactions on Industrial Informatics 12(1):393. https://doi.org/10.1109/tii.2015.2475219

Wang S., Xiang J., Zhong Y., Tang H. (2018) A data indicator-based deep belief networks to detect multiple faults in axial piston pumps. Mechanical Systems and Signal Processing 112:154

Liu Z., Zhang Z., Liu Y., Dezert J., Pan Q. (2019) A new pattern classification improvement method with local quality matrix based on K-NN. Knowledge-Based Systems 164:336. https://doi.org/10.1016/j.knosys.2018.11.001

Wang Y., Wei Z., Yang J. (2019) Feature Trend Extraction and Adaptive Density Peaks Search for Intelligent Fault Diagnosis of Machines. IEEE Transactions on Industrial Informatics 15(1):105. https://doi.org/10.1109/tii.2018.2810226

Liu X., Huang H., Xiang J. (2020) A personalized diagnosis method to detect faults in gears using numerical simulation and extreme learning machine, Knowledge Based Systems, p 105653

Gao Y., Liu X., Xiang J. (2020) FEM simulation- based generative adversarial networks to detect bearing faults. IEEE Transactions on Industrial Informatics 7:1–1

Wang S., Xiang J. (2020) A minimum entropy deconvolution-enhanced convolutional neural networks for fault diagnosis of axial piston pumps. Soft Computing 24(4):2983

He Z., Shao H., Cheng J., Zhao X., Yang Y. (2019) Support tensor machine with dynamic penalty factors and its application to the fault diagnosis of rotating machinery with unbalanced data. Mechanical System sand Signal Processing 141:106–441

He Z., Shao H., Wang P., Lin J., Yang Y. (2019) Deep transfer multi-wavelet auto-encoder for intelligent fault diagnosis of gearbox with few target training samples, vol 191

Guo X., Huang X., Zhang L., Zhang L., Plaza A. (2016) J.A. Benediktsson, IEEE Transactions on Geoscience and Remote Sensing 54(6):3248. https://doi.org/10.1109/tgrs.2016.2514404

Tao D., Li X., Hu W., Maybank S., Wu X. (2007) Supervised Tensor Learning. Knowledge and Information Systems 13(1 ):1

Li S., Yang N., Li B., Zhou Z., Hao H., Folkert M.R., Iyengar P., Westover K., Choy H., Timmerman R., Jiang S., Wang J. (2018) A pilot study using kernelled support tensor machine for distant failure prediction in lung SBRT. Med Image Anal 50:106. https://doi.org/10.1016/j.media.2018.09.004

Xing Y., Wang M., Yang S., Zhang K. (2018) Pansharpening With Multiscale Geometric Support Tensor Machine. IEEE Transactions on Geoscience and Remote Sensing 56(5):2503. https://doi.org/10.1109/tgrs.2017.2742002

Lu H., Plataniotis K.N., Venetsanopoulos A.N. (2008) MPCA: Multilinear Principal Component Analysis of Tensor Objects. IEEE Trans Neural Netw 19:18. https://www.ncbi.nlm.nih.gov/pubmed/18269936

Han L., Wu Z., Zeng K., Yang X. (2018) Online multilinear principal component analysis. Neurocomputing 275:888. https://doi.org/10.1016/j.neucom.2017.08.070

Hu C., Wang Y. (2019) Multidimensional denoising of rotating machine based on tensor factorization. Mechanical Systems and Signal Processing 122 :273. https://doi.org/10.1016/j.ymssp.2018.12.012

Hu C., Wang Y., Bai T. (2019) A tensor-based approach for identification of multi-channel bearing compound faults. IEEE Access 7:1–1. https://doi.org/10.1109/access.2019.2906784

Hu C., Wang Y. (2019) Research on Multi-channel Signal Denoising Method for Multiple Faults Diagnosis of Rolling Element Bearings Based on Tensor Factorization. Journal of Mechanical Engineering 12 :7

Chen Y., Sun W., Xi M., Yuan J. (2019) A seminorm regularized alternating least squares algorithm for canonical tensor decomposition. Journal of Computational and Applied Mathematics 347 :296. https://doi.org/10.1016/j.cam.2018.05.046

CORTES C., VAPNIK V. (1995) Support-Vector Networks. Machine Learning 20(3):273

Smith W. A., Randall R.B. (2015) Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mechanical Systems and Signal Processing 64-65:100. https://doi.org/10.1016/j.ymssp.2015.04.021

Acknowledgments

The financial sponsorship from the project of National Natural Science Foundation of China (51875032, 51965013) and Doctoral Research Foundation (UF20027Y).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, C., He, S. & Wang, Y. A classification method to detect faults in a rotating machinery based on kernelled support tensor machine and multilinear principal component analysis. Appl Intell 51, 2609–2621 (2021). https://doi.org/10.1007/s10489-020-02011-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10489-020-02011-9