Abstract

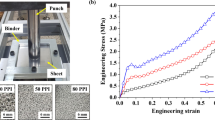

Electrohydraulic forming (EHF) is one of the high-velocity metal forming processes that can significantly increase the formability of metals compared with quasi-static forming processes. On the other way, multi-point forming (MPF) is one of the flexible forming methods that provides different sheet metal geometries by varying the height of the pins. The purpose of this study is to take the advantages of both the EHF and MPF processes by presenting a design for flexible dies to be used in the electrohydraulic forming process. As the first step, electrohydraulic free-forming was performed to investigate the reproducibility and to obtain some of the parameters needed for simulations. Then, the ABAQUS finite element software and Coupled Eulerian-Lagrangian method were used to simulate this process. Afterward, the experimental tests were undergone to determine the defects of the forming process using a flexible pin die. Various geometries were produced by conducting experiments and inserting the proper elastic layer to eliminate the dimpling. The reproducibility and validity of the flexible pin die forming simulation was investigated by analyzing the dome height and final profile of the specimens. After ensuring the accuracy of the simulation, a thicker elastic layer was used to remove the dimpling defect completely. The results of the experiments and simulations illustrated that the use of flexible pin die is possible in the process of EHF and the proper final forms can be obtained by applying the appropriate thickness of the polyurethane layer.

Similar content being viewed by others

Data availability

Not applicable.

References

Cheah L, Heywood J (2011) Meeting US passenger vehicle fuel economy standards in 2016 and beyond. Energy Policy 39(1):454–466. https://doi.org/10.1016/j.enpol.2010.10.027

Rohatgi A, Stephens EV, Soulami A, Davies RW, Smith MT (2011) Experimental characterization of sheet metal deformation during electro-hydraulic forming. J Mater Process Technol 211(11):1824–1833. https://doi.org/10.1016/j.jmatprotec.2011.06.005

Balanethiram V, Hu X, Altynova M, Daehn GS (1994) Hyperplasticity: enhanced formability at high rates. J Mater Process Technol 45(1-4):595–600. https://doi.org/10.1016/0924-0136(94)90404-9

Fenton GK, Daehn GS (1998) Modeling of electromagnetically formed sheet metal. J Mater Process Technol 75(1-3):6–16. https://doi.org/10.1016/S0924-0136(97)00287-2

Golovashchenko SF, Mamutov VS, Dmitriev VV, Sherman AM (2003) Formability of sheet metal with pulsed electromagnetic and electrohydraulic technologies. In: ALUMINUM 2003, pp 99–110 Conference held during the TMS Annual Meeting

Golovashchenko SF, Gillard AJ, Mamutov AV (2013) Formability of dual phase steels in electrohydraulic forming. J Mater Process Technol 213(7):1191–1212. https://doi.org/10.1016/j.jmatprotec.2013.01.026

Zohoor M, Mousavi SM (2018) Evaluation and optimization of effective parameters in electrohydraulic forming process. J Braz Soc Mech Sci Eng 40(11):524. https://doi.org/10.1007/s40430-018-1449-1

Yutkin LA (1955) Electrohydraulic effect. Mashgiz, Moscow, p 5–22

Oyane M, Masaki S (1964) Fundamental study on electrohydraulic forming. Bull JSME 7(26):474–480. https://doi.org/10.1299/jsme1958.7.474

Oyane M, Masaki S (1965) Fundamental study on electrohydraulic forming: II. The effect of kinds of fuse wires and circuit inductance on pressure pulse. Bull JSME 8(30):251–258. https://doi.org/10.1299/jsme1958.8.251

Oyane M, Masaki S (1965) Fundamental study on electrohydraulic forming: III. The effect of diameter of fuse wire and circuit inductance on pressure pulse. Bull JSME 8(30):259–263. https://doi.org/10.1299/jsme1958.8.259

Rohatgi A, Stephens EV, Davies RW, Smith MT, Soulami A, Ahzi S (2012) Electro-hydraulic forming of sheet metals: Free-forming vs. conical-die forming. J Mater Process Technol 212(5):1070–1079. https://doi.org/10.1016/j.jmatprotec.2011.12.014

Samei J, Green DE, Golovashchenko S, Hassannejadasl A (2013) Quantitative microstructural analysis of formability enhancement in dual phase steels subject to electrohydraulic forming. J Mater Eng Perform 22(7):2080–2088. https://doi.org/10.1007/s11665-012-0438-2

Gillard AJ, Golovashchenko SF, Mamutov AV (2013) Effect of quasi-static prestrain on the formability of dual phase steels in electrohydraulic forming. J Manuf Process 15(2):201–218. https://doi.org/10.1016/j.jmapro.2012.12.005

Ahmed M, Kumar DR, Nabi M (2017) Enhancement of formability of AA5052 alloy sheets by electrohydraulic forming process. J Mater Eng Perform 26(1):439–452. https://doi.org/10.1007/s11665-016-2446-0

Woetzel M, Löffler M, Spahn E, Ritter H (2006) Preliminary examination of high-velocity metal-shaping with electrical wire explosion. In: Proceeding of 1st Euro-Asian Pulsed Power Conference, pp 18–22

Bonnen JJ, Golovashchenko SF, Dawson SA, Mamutov AV (2013) Electrode erosion observed in electrohydraulic discharges used in pulsed sheet metal forming. J Mater Eng Perform 22(12):3946–3958. https://doi.org/10.1007/s11665-013-0690-0

Björkström D (2008) FEM simulatoion of electrohydraulic forming. MSc Thesis, KTH Royal Institute of Technology, Stockholm

Melander A, Delic A, Björkblad A, Juntunen P, Samek L, Vadillo L (2013) Modelling of electro hydraulic free and die forming of sheet steels. Int J Mater Form 6(2):223–231. https://doi.org/10.1007/s12289-011-1080-5

Jenab A, Green DE, Alpas AT, Golovashchenko SF (2018) Experimental and numerical analyses of formability improvement of AA5182-O sheet during electro-hydraulic forming. J Mater Process Technol 255:914–926. https://doi.org/10.1016/j.jmatprotec.2017.12.037

Li M, Nakamura K, Watanabe S, Akutsu Y (1992) Study of the basic principles (1st report: research on multi-point forming for sheet metal). In: Proc. of the Japanese Spring conf. for Technology of Plasticity, pp 519–522

Li M, Liu Y, Su S, Li G (1999) Multi-point forming: a flexible manufacturing method for a 3-d surface sheet. J Mater Process Technol 87(1-3):277–280. https://doi.org/10.1016/S0924-0136(98)00364-1

Li M-Z, Cai Z-Y, Sui Z, Yan Q (2002) Multi-point forming technology for sheet metal. J Mater Process Technol 129(1-3):333–338. https://doi.org/10.1016/S0924-0136(02)00685-4

Quan G-Z, Ku T-W, Kang B-S (2011) Improvement of formability for multi-point bending process of AZ31B sheet material using elastic cushion. Int J Precis Eng Manuf 12(6):1023–1030. https://doi.org/10.1007/s12541-011-0136-2

Wang S, Cai Z, Li M (2010) Numerical investigation of the influence of punch element in multi-point stretch forming process. Int J Adv Manuf Technol 49(5-8):475–483. https://doi.org/10.1007/s00170-009-2420-1

Liu Q, Lu C, Fu W, Tieu K, Li M, Gong X (2012) Optimization of cushion conditions in micro multi-point sheet forming. J Mater Process Technol 212(3):672–677. https://doi.org/10.1016/j.jmatprotec.2011.07.015

Zareh-Desari B, Davoodi B, Vedaei-Sabegh A (2015) Investigation of deep drawing concept of multi-point forming process in terms of prevalent defects. Int J Mater Form 10(2):193–203. https://doi.org/10.1007/s12289-015-1268-1

Paunoiu V, Teodor V, Baraoiu N (2015) The Hydro-Multipoint forming process of complex sheet metal parts. J Mach Eng 15(3):106–116

Liu W, Chen Y-Z, Xu Y-C, Yuan S-J (2016) Evaluation on dimpling and geometrical profile of curved surface shell by hydroforming with reconfigurable multipoint tool. Int J Adv Manuf Technol 86(5-8):2175–2185. https://doi.org/10.1007/s00170-015-8264-y

Nourmohammadi AA, Elyasi M, Mirnia MJ (2019) Flexibility improvement in two-point incremental forming by implementing multi-point die. Int J Adv Manuf Technol 102(9-12):2933–2952. https://doi.org/10.1007/s00170-019-03307-y

Davoodi B, Zareh-Desari B (2014) Assessment of forming parameters influencing spring-back in multi-point forming process: a comprehensive experimental and numerical study. Mater Des 59:103–114. https://doi.org/10.1016/j.matdes.2014.02.043

Abosaf M, Essa K, Alghawail A, Tolipov A, Su S (2017) Optimisation of multi-point forming process parameters. Int J Adv Manuf Technol 92(5-8):1849–1859. https://doi.org/10.1007/s00170-017-0155-y

Halliday D, Resnick R, Walker J (2013) Fundamentals of physics, 10th edn. John Wiley & Sons, New York, p 717–745

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21(1):31–48

Lesuer DR, Kay G, LeBlanc M (2001) Modeling large-strain, high-rate deformation in metals. Lawrence Livermore National Lab

Zhu D, Mobasher B, Rajan S, Peralta P (2011) Characterization of dynamic tensile testing using aluminum alloy 6061-T6 at intermediate strain rates. J Eng Mech 137(10):669–679. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000264

Hajializadeh F, Mashhadi MM (2015) Investigation and numerical analysis of impulsive hydroforming of aluminum 6061-T6 tube. J Manuf Process 20:257–273. https://doi.org/10.1016/j.jmapro.2015.06.027

Ahmadzadeh M, Saranjam B, Fard AH, Binesh A (2014) Numerical simulation of sphere water entry problem using Eulerian–Lagrangian method. Appl Math Model 38(5-6):1673–1684. https://doi.org/10.1016/j.apm.2013.09.005

Dobratz B (1981) LLNL Explosive Handbook, UCRL-52997. Lawrence Livermore National Laboratory, Livermore

Belhassen L, Koubaa S, Wali M, Dammak F (2016) Numerical prediction of springback and ductile damage in rubber-pad forming process of aluminum sheet metal. Int J Mech Sci 117:218–226. https://doi.org/10.1016/j.ijmecsci.2016.08.015

Serway RA, Jewett JW, Beichner RJ (2000) ISBN 0030226570) Physics for scientists and engineers with modern physics, 5th edn. Saunders College

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zavari, S., Bakhshi-Jooybari, M. & Gorji, H. Combined electrohydraulic and flexible pin die forming: a novel high strain rate forming die setup. Int J Adv Manuf Technol 111, 2171–2187 (2020). https://doi.org/10.1007/s00170-020-06242-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06242-5