Abstract

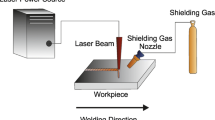

Advanced welding processes for structural materials are gaining increasing importance for strategic applications in nuclear, aerospace, automobile, and defence sectors. These processes have been designed keeping in view the criterion of minimal stress generation, microstructure retentivity, and process reproducibility. Narrow gap laser welding (NGLW) is one such advanced welding technique that has been developed in the past decade owing to its fabricate-ability of thick-section steels at high welding speeds. Of the many advantages, several characteristics of the process outperform the traditional arc welding processes as well as single-pass autogenous laser welding, including process flexibility, increased welding productivity, excellent weld properties, and the potential for automation. This paper provides a state-of-the-art technological review on the NGLW process primarily for structural steels covering several topics including the effect of process parameters, structure-property relationship, and induced defects and residual stresses of NGLWed joints. A list of future research recommendations based on several research gaps is also reported in this article.

Similar content being viewed by others

Abbreviations

- NGLW:

-

Narrow gap laser welding

- GMAW:

-

Gas metal arc welding

- GTAW:

-

Gas tungsten arc welding

- NGSAW:

-

Narrow gap submerged arc welding

- NGGMAW:

-

Narrow gap GMAW

- NGGTAW:

-

Narrow gap GTAW

- FZ:

-

Fusion zone

- HAZ:

-

Heat-affected zone

- ICHAZ:

-

Inter-critical HAZ

- FGHAZ:

-

Fine-grained HAZ

- CGHAZ:

-

Coarse-grained HAZ

- PWHT:

-

Post-weld heat treatment

- Ar:

-

Argon inert gas

- BPP:

-

Beam parameter product

- rad:

-

Radians (units)

- UTS:

-

Ultimate tensile strength

- RPV:

-

Reactor pressure vessel

- HSLA:

-

High-strength low alloy

- SS:

-

Stainless steel

- UHSS:

-

Ultra-high-strength steel

- HSS:

-

High-strength steel

- M s :

-

Martensite formation start temperature

References

Tsuchiya K, Kawamura H, Kalinin G (2000) Re-weldability tests of irradiated austenitic stainless steel by a TIG welding method. J Nucl Mater 283-287(PART II):1210–1214. https://doi.org/10.1016/S0022-3115(00)00153-7

Zhang X, Ashida E, Tarasawa S (2010) Properties of welded joint for narrow gap laser welding of austenitic stainless steels. In: 29th International Congress on Applications of Lasers and Electro-Optics. ICALEO 2010, Anaheim, pp 632–637

Zhang X, Ashida E, Tarasawa S, Anma Y, Okada M, Katayama S, Mizutani M (2011) Welding of thick stainless steel plates up to 50 mm with high brightness lasers. J Laser Appl 23(2):022002. https://doi.org/10.2351/1.3567961

Feng JC, Rathod DW, Roy MJ, Francis JA, Guo W, Irvine NM, Vasileiou AN, Sun YL, Smith MC, Li L (2017) An evaluation of multipass narrow gap laser welding as a candidate process for the manufacture of nuclear pressure vessels. Int J Press Vessel Pip 157:43–50. https://doi.org/10.1016/j.ijpvp.2017.08.004

Yu YC, Yang SL, Yin Y, Wang CM, Hu XY, Meng XX, Yu SF (2013) Multi-pass laser welding of thick plate with filler wire by using a narrow gap joint configuration. J Mech Sci Technol 27(7):2125–2131. https://doi.org/10.1007/s12206-013-0525-9

Zeng Z, Yang M, Oliveira JP, Song D, Peng B (2016) Laser welding of NiTi shape memory alloy wires and tubes for multi-functional design applications. Smart Mater Struct 25(8):085001. https://doi.org/10.1088/0964-1726/25/8/085001

Oliveira JP, Schell N, Zhou N, Wood L, Benafan O (2019) Laser welding of precipitation strengthened Ni-rich NiTiHf high temperature shape memory alloys: Microstructure and mechanical properties. Mater Des 162:229–234. https://doi.org/10.1016/j.matdes.2018.11.053

Oliveira JP, Zeng Z, Berveiller S, Bouscaud D, Braz Fernandes FM, Miranda RM, Zhou N (2018) Laser welding of Cu-Al-Be shape memory alloys: microstructure and mechanical properties. Mater Des 148:145–152. https://doi.org/10.1016/j.matdes.2018.03.066

Elmesalamy AS, Li L, Francis JA, Sezer HK (2013) Understanding the process parameter interactions in multiple-pass ultra-narrow-gap laser welding of thick-section stainless steels. Int J Adv Manuf Technol 68(1-4):1–17. https://doi.org/10.1007/s00170-013-4739-x

Katayama S, Abe Y, Ido R, Mizutani M, Kawahito Y (2011) Deep penetration welding with high power disk lasers in low vacuum. ICALEO 2011(1):669–678. https://doi.org/10.2351/1.5062308

Yang W, Xin J, Fang C, Dai W, Wei J, Wu J, Song Y (2019) Microstructure and mechanical properties of ultra-narrow gap laser weld joint of 100 mm-thick SUS304 steel plates. J Mater Process Technol 265:130–137. https://doi.org/10.1016/j.jmatprotec.2018.10.017

Malin V (1983) The state-of-the-art of narrow gap welding. Weld J 62(6):37–46

Scandella F, Jubin L (2013) State-of-the-art of narrow gap welding technologies. Etat de l’art des technologies de soudage en chanfrein etroit. SFEN, France

Elmesalamy A, Francis JA, Li L (2014) A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel. Int J Press Vessel Pip 113:49–59. https://doi.org/10.1016/j.ijpvp.2013.11.002

Shi H, Zhang K, Xu Z, Huang T, Fan L, Bao W (2014) Applying statistical models optimize the process of multi-pass narrow-gap laser welding with filler wire. Int J Adv Manuf Technol 75(1-4):279–291. https://doi.org/10.1007/s00170-014-6159-y

Ning J, Zhang LJ, Yang JN, Yin XQ, Wang XW, Wu J (2019) Characteristics of multi-pass narrow-gap laser welding of D406A ultra-high strength steel. J Mater Process Technol 270:168–181. https://doi.org/10.1016/j.jmatprotec.2019.02.026

Guo W, Li L, Dong S, Crowther D, Thompson A (2017) Comparison of microstructure and mechanical properties of ultra-narrow gap laser and gas-metal-arc welded S960 high strength steel. Opt Lasers Eng 91:1–15. https://doi.org/10.1016/j.optlaseng.2016.11.011

Jones LP, Aubert P, Avilov V, Coste F, Daenner W, Jokinen T, Nightingale KR, Wykes M (2003) Towards advanced welding methods for the ITER vacuum vessel sectors. Fusion Eng Des 69(1-4 SPEC):215–220. https://doi.org/10.1016/S0920-3796(03)00341-7

Huang Z, Cai Y, Mu W, Li Y, Hua X (2018) Effects of laser energy allocation on weld formation of 9%Ni steel made by narrow gap laser welding filled with nickel based alloy. J Laser Appl 30(3):032013. https://doi.org/10.2351/1.5010072

Wu S, Zou J, Xiao R, Zhang G (2016) Ultra-narrow-groove laser welding for heavy sections in ITER. Weld J 95:300S–308S

Zhao Y, Ma S, Huang J, Wu Y (2017) Narrow-gap laser welding using filler wire of thick steel plates. Int J Adv Manuf Technol 93(5):2955–2962. https://doi.org/10.1007/s00170-017-0470-3

Zhao Y, Su F, Huang J, Zou JS, Wu YX (2018) Microstructure and mechanical properties of a 10CrNi3MoV thick plate welded joint using narrow gap laser welding with filler wire. Lasers Eng 41(1-3):57–72

Dittrich D, Schedewy R, Brenner B, Standfuß J Laser-multi-pass-narrow-gap-welding of hot crack sensitive thick aluminum plates. In: 7th International WLT Conference on Lasers in Manufacturing, LiM 2013, Munich, 2013. Elsevier B.V, pp 225–233. https://doi.org/10.1016/j.phpro.2013.03.073

Zhang ZH, Dong SY, Wang YJ, Xu BS, Fang JX, He P (2016) Study on microstructures and mechanical properties of super narrow gap joints of thick and high strength aluminum alloy plates welded by fiber laser. Int J Adv Manuf Technol 82(1-4):99–109. https://doi.org/10.1007/s00170-015-7334-5

Keßler B, Brenner B, Dittrich D, Standfuß J, Beyer E, Leyens C (2019) Laser-multi-pass-narrow-gap-welding of nickel superalloy - alloy 617OCC. J Laser Appl 31(2):022412. https://doi.org/10.2351/1.5096132

Sun J, Ren W, Nie P, Huang J, Zhang K, Li Z (2019) Study on the weldability, microstructure and mechanical properties of thick Inconel 617 plate using narrow gap laser welding method. Mater Des 175:107823. https://doi.org/10.1016/j.matdes.2019.107823

Keßler B, Brenner B, Dittrich D, Standfuß J, Beyer E, Leyens C, Maier G (2019) Laser multi-pass narrow-gap welding–a promising technology for joining thick-walled components of future power plants. In: MATEC Web of Conferences. EDP Sciences, p 02011. https://doi.org/10.1051/matecconf/201926902011

Ning J, Zhang LJ, Jiang GC, Xie MX, Yin XQ, Zhang JX (2017) Narrow gap multi-pass laser butt welding of explosion welded CP-Ti/Q235B bimetallic sheet by using a copper interlayer. J Alloys Compd 701:587–602. https://doi.org/10.1016/j.jallcom.2017.01.129

Guo W, Crowther D, Francis JA, Thompson A, Li L (2016) Process-parameter interactions in ultra-narrow gap laser welding of high strength steels. Int J Adv Manuf Technol 84(9-12):2547–2566. https://doi.org/10.1007/s00170-015-7881-9

Li R, Wang T, Wang C, Yan F, Shao X, Hu X, Li J (2014) A study of narrow gap laser welding for thick plates using the multi-layer and multi-pass method. Opt Laser Technol 64:172–183. https://doi.org/10.1016/j.optlastec.2014.04.015

Shelyagin V, Khaskin V, Bernatskyi A, Siora A, Sydorets V, Chinakhov DA (2018) Multi-pass laser and hybrid laser-arc narrow-gap welding of steel butt joints. Mater Sci Forum 927:64–71. https://doi.org/10.4028/www.scientific.net/MSF.927.64

Feng J, Guo W, Francis J, Irvine N, Li L (2016) Narrow gap laser welding for potential nuclear pressure vessel manufacture. J Laser Appl 28(2):022421. https://doi.org/10.2351/1.4943905

Näsström I, Frostevarg J, Kaplan AFH (2018) Arc formation in narrow gap hot wire laser welding. Weld J 97(6):171s–178s. https://doi.org/10.29391/2018.97.015

Elmesalamy AS, Abdolvand H, Walsh JN, Francis JA, Suder W, Williams S, Li L (2016) Measurement and modelling of the residual stresses in autogenous and narrow gap laser welded AISI grade 316L stainless steel plates. Int J Press Vessel Pip 147:64–78. https://doi.org/10.1016/j.ijpvp.2016.09.007

Wu S, Zhang J, Yang J, Lu J, Liao H, Wang X (2018) Investigation on microstructure and properties of narrow-gap laser welding on reduced activation ferritic/martensitic steel CLF-1 with a thickness of 35 mm. J Nucl Mater 503:66–74. https://doi.org/10.1016/j.jnucmat.2018.02.038

Näsström J, Brueckner F, Kaplan AFH (2020) A near-vertical approach to laser narrow gap multi-layer welding. Opt Laser Technol 121:105798. https://doi.org/10.1016/j.optlastec.2019.105798

Kaplan AFH, Kim KH, Bang HS, Bang HS, Näsström J, Frostevarg J (2016) Narrow gap laser welding by multilayer hot wire addition. J Laser Appl 28(2):022410. https://doi.org/10.2351/1.4943904

Tsukamoto T, Kawanaka H, Maeda Y (2011) Laser narrow gap welding of thick carbon steels using high brightness laser with beam oscillation. In: 30th International Congress on Applications of Lasers and Electro-Optics. ICALEO 2011, Orlando, pp 141–146

Li J, Sun Q, Kang K, Zhen Z, Liu Y, Feng J (2020) Process stability and parameters optimization of narrow-gap laser vertical welding with hot wire for thick stainless steel in nuclear power plant. Opt Laser Technol 123:105921. https://doi.org/10.1016/j.optlastec.2019.105921

Feng J, Guo W, Irvine N, Li L (2017) Understanding and elimination of process defects in narrow gap multi-pass fiber laser welding of ferritic steel sheets of 30 mm thickness. Int J Adv Manuf Technol 88(5-8):1821–1830. https://doi.org/10.1007/s00170-016-8929-1

Li R, Yue J, Shao X, Wang C, Yan F, Hu X (2015) A study of thick plate ultra-narrow-gap multi-pass multi-layer laser welding technology combined with laser cleaning. Int J Adv Manuf Technol 81(1):113–127. https://doi.org/10.1007/s00170-015-7193-0

Kaplan A (1994) A model of deep penetration laser welding based on calculation of the keyhole profile. J Phys D 27(9):1805–1814. https://doi.org/10.1088/0022-3727/27/9/002

Jokinen T, Kujanpää V (2003) High power Nd:YAG laser welding in manufacturing of vacuum vessel of fusion reactor. Fusion Eng Des 69(1):349–353. https://doi.org/10.1016/S0920-3796(03)00071-1

Nivas R, Singh PK, Das G, Das SK, Kumar S, Mahato B, Sivaprasad K, Ghosh M (2017) A comparative study on microstructure and mechanical properties near interface for dissimilar materials during conventional V-groove and narrow gap welding. J Manuf Process 25:274–283. https://doi.org/10.1016/j.jmapro.2016.12.004

Salminen A (2003) Effects of filler wire feed on the efficiency of laser welding, vol 4831. LAMP 2002: International Congress on Laser Advanced Materials Processing. SPIE. https://doi.org/10.1117/12.497889

Cottam R, Palanisamy S, Avdeev M, Jarvis T, Henry C, Cuiuri D, Balogh L, Rashid RAR (2019) Diffraction line profile analysis of 3D wedge samples of Ti-6Al-4 V fabricated using four different additive manufacturing processes. Metals 9(1). https://doi.org/10.3390/met9010060

Gao XL, Zhang LJ, Liu J, Zhang JX (2014) Effects of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. Int J Adv Manuf Technol 72(5-8):895–903. https://doi.org/10.1007/s00170-014-5722-x

Liu S, Mi G, Yan F, Wang C, Li P (2018) Real weld geometry determining mechanical properties of high power laser welded medium plates. Opt Laser Technol 102:100–110. https://doi.org/10.1016/j.optlastec.2017.11.047

Lu GF, Zhang LJ, Pei Y, Ning J, Zhang JX (2018) Study on the size effects of H-shaped fusion zone of fiber laserwelded AZ31 joint. Metals 8(4). https://doi.org/10.3390/met8040198

Rahman Rashid RA, Barr CJ, Palanisamy S, Nazari KA, Orchowski N, Matthews N, Dargusch MS (2019) Effect of clad orientation on the mechanical properties of laser-clad repaired ultra-high strength 300 M steel. Surf Coat Technol 380. https://doi.org/10.1016/j.surfcoat.2019.125090

Rahman Rashid RA, Abaspour S, Palanisamy S, Matthews N, Dargusch MS (2017) Metallurgical and geometrical characterisation of the 316L stainless steel clad deposited on a mild steel substrate. Surf Coat Technol 327:174–184. https://doi.org/10.1016/j.surfcoat.2017.08.013

Deng D (2009) FEM prediction of welding residual stress and distortion in carbon steel considering phase transformation effects. Mater Des 30(2):359–366. https://doi.org/10.1016/j.matdes.2008.04.052

Oliveira JP, Fernandes FMB, Miranda RM, Schell N, Ocaña JL (2016) Residual stress analysis in laser welded NiTi sheets using synchrotron X-ray diffraction. Mater Des 100:180–187. https://doi.org/10.1016/j.matdes.2016.03.137

Francis JA, Bhadeshia HKDH, Withers PJ (2007) Welding residual stresses in ferritic power plant steels. Mater Sci Technol 23(9):1009–1020. https://doi.org/10.1179/174328407X213116

Vollertsen F, Grünenwald S, Rethmeier M, Gumenyuk A, Reisgen U, Olschok S (2010) Welding thick steel plates with fibre lasers and GMAW. Weld World 54(3-4):R62–R70. https://doi.org/10.1007/BF03263489

Tseng KH, Hsu CY (2011) Performance of activated TIG process in austenitic stainless steel welds. J Mater Process Technol 211(3):503–512. https://doi.org/10.1016/j.jmatprotec.2010.11.003

Prasad K, Dwivedi DK (2008) Some investigations on microstructure and mechanical properties of submerged arc welded HSLA steel joints. Int J Adv Manuf Technol 36(5-6):475–483. https://doi.org/10.1007/s00170-006-0855-1

Zhang CZ, Chen H, Yang XY, Zhao X (2020) In situ tensile of ultra-narrow gap laser welded joint of bainitic steel. Mater Sci Technol (United Kingdom) 36(10):1104–1110. https://doi.org/10.1080/02670836.2020.1753934

Ma G, Li L, Chen Y (2017) Effects of beam configurations on wire melting and transfer behaviors in dual beam laser welding with filler wire. Opt Laser Technol 91:138–148. https://doi.org/10.1016/j.optlastec.2016.12.019

Guo W, Liu Q, Francis JA, Crowther D, Thompson A, Liu Z, Li L (2015) Comparison of laser welds in thick section S700 high-strength steel manufactured in flat (1G) and horizontal (2G) positions. CIRP Ann 64(1):197–200. https://doi.org/10.1016/j.cirp.2015.04.070

Shen X, Li L, Guo W, Teng W, He W (2016) Comparison of processing window and porosity distribution in laser welding of 10 mm thick 30CrMnSiA ultrahigh strength between flat (1G) and horizontal (2G) positions. J Laser Appl 28(2):022418. https://doi.org/10.2351/1.4943992

Rahman Rashid RA, Nazari KA, Barr C, Palanisamy S, Orchowski N, Matthews N, Dargusch MS (2019) Effect of laser reheat post-treatment on the microstructural characteristics of laser-cladded ultra-high strength steel. Surf Coat Technol 372:93–102. https://doi.org/10.1016/j.surfcoat.2019.05.021

Zhang C, Li G, Gao M, Zeng X (2017) Microstructure and mechanical properties of narrow gap laser-arc hybrid welded 40 mm thick mild steel. Mater 10(2). https://doi.org/10.3390/ma10020106

Zhang X, Mi G, Wang C (2018) Study of microstructure and mechanical properties of narrow-gap multi-layer hybrid laser-arc welded 316L austenitic stainless steel. J Laser Appl 30(3):032407. https://doi.org/10.2351/1.5040609

Li R, Yue J, Sun R, Mi G, Wang C, Shao X (2016) A study of droplet transfer behavior in ultra-narrow gap laser arc hybrid welding. Int J Adv Manuf Technol 87(9-12):2997–3008. https://doi.org/10.1007/s00170-016-8699-9

Meng Y, Li G, Gao M, Zhang C, Zeng X (2019) Formation and suppression mechanism of lack of fusion in narrow gap laser-arc hybrid welding. Int J Adv Manuf Technol 100(9-12):2299–2309. https://doi.org/10.1007/s00170-018-2851-7

Meng Y, Li G, Gao M, Zeng X (2018) Effects of groove parameters on space constraint of narrow gap laser-arc hybrid welding. J Manuf Process 33:144–149. https://doi.org/10.1016/j.jmapro.2018.05.006

Cao X, Wanjara P, Huang J, Munro C, Nolting A (2011) Hybrid fiber laser - arc welding of thick section high strength low alloy steel. Mater Des 32(6):3399–3413. https://doi.org/10.1016/j.matdes.2011.02.002

Phaoniam R, Shinozaki K, Yamamoto M, Kadoi K, Tsuchiya S, Nishijima A (2013) Development of a highly efficient hot-wire laser hybrid process for narrow-gap welding - welding phenomena and their adequate conditions. Weld World 57(5):607–613. https://doi.org/10.1007/s40194-013-0055-1

Gu H, Väistö T, Li L (2020) Numerical and experimental study on the molten pool dynamics and fusion zone formation in multi-pass narrow gap laser welding. Opt Laser Technol 126:106081. https://doi.org/10.1016/j.optlastec.2020.106081

Yang T, Liu J, Zhuang Y, Sun K, Chen W (2020) Studies on the formation mechanism of incomplete fusion defects in ultra-narrow gap laser wire filling welding. Opt Laser Technol 129:106275. https://doi.org/10.1016/j.optlastec.2020.106275

Yamazaki Y, Abe Y, Hioki Y, Nakatani M, Kitagawa A, Nakata K (2016) Development of gap sensing system for narrow gap laser welding. Weld Int 30(10):745–754. https://doi.org/10.1080/09507116.2016.1142195

Näsström J, Brueckner F, Kaplan AFH (2020) Imperfections in narrow gap multi-layer welding - potential causes and countermeasures. Opt Lasers Eng 129:106011. https://doi.org/10.1016/j.optlaseng.2020.106011

Davis G, Nagarajah R, Palanisamy S, Rashid RAR, Rajagopal P, Balasubramaniam K (2019) Laser ultrasonic inspection of additive manufactured components. Int J Adv Manuf Technol 102(5-8):2571–2579. https://doi.org/10.1007/s00170-018-3046-y

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramakrishna R, V.S.M., Amrutha, P.H.S.L.R., Rahman Rashid, R.A. et al. Narrow gap laser welding (NGLW) of structural steels—a technological review and future research recommendations. Int J Adv Manuf Technol 111, 2277–2300 (2020). https://doi.org/10.1007/s00170-020-06230-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06230-9