Abstract

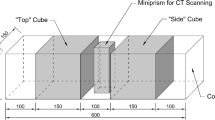

Wedge splitting test gained popularity as a stable and simple method to predict the fracture mechanism properties of concrete specimens. The present research focuses on understanding the behavior of self-compacting concrete specimens made with and without steel fibers tested using wedge splitting test, later scanned under high resolution computed tomography. The contribution of hooked end steel fiber and coarse aggregates in fiber reinforced specimens was compared without steel fiber reinforced concrete specimens using high resolution computed tomography. As fracture takes place across the plane perpendicular to the splitting force, i.e. along the depth of specimens. High resolution computed tomography technique was adopted in visualizing the changes taking place across the matrix, coarse aggregate and steel fibers, along with the specimen’s depth. Datasets of the images, obtained from computed tomography, after images analysis and volume reconstruction, revealed a higher coarse aggregate and steel fiber participation in the failure region of without and with fibers specimens. Computed tomography investigation indicated a total of 23 coarse aggregate and 64 steel fibers participated in resisting the failure, during wedge splitting test of without and with fibers specimens. Therefore, high resolution computed tomography can be used in understanding, quantifying the participation of coarse aggregate and steel fiber in the failure plane, under fracture loads.

Similar content being viewed by others

References

Okamura H, Ouchi M. Self-compacting concrete. J Adv Concr Technol. 2003;1(1):5–15.

Tavakoli H, Fallahtabar M, Parvin M. Mechanical behavior of self-compacting reinforced concrete including synthetics and steel fibers. Civil Eng Infrastruct J. 2016;49(2):197–213.

Atewi YR, Hasan MF, Güneyisi E. Fracture and permeability properties of glass fiber reinforced self-compacting concrete with and without nanosilica. Constr Build Mater. 2019;226:993–1005.

Aslani F, Sun J, Huang G. Mechanical behavior of fiber-reinforced self-compacting rubberized concrete exposed to elevated temperatures. J Mater Civil Eng. 2019;31(12):04019302.

Alyhya WS, Dhaheer MA, Al-Rubaye MM, Karihaloo BL. Influence of mix composition and strength on the fracture properties of self-compacting concrete. Constr Build Mater. 2016;110:312–22.

Sahmaran, M. Self-compacting concrete with high volumes of fly ash. Doctoral dissertation, PhD. Thesis, Department of Civil Engineering, METU, Ankara, Turkey. 2006.

Nikbin IM, Beygi MHA, Kazemi MT, Amiri JV, Rahmani E, Rabbanifar S, Eslami M. Effect of coarse aggregate volume on fracture behavior of self compacting concrete. Constr Build Mater. 2014;52:137–45.

Beygi MH, Kazemi MT, Amiri JV, Nikbin IM, Rabbanifar S, Rahmani E. Evaluation of the effect of maximum aggregate size on fracture behavior of self compacting concrete. Constr Build Mater. 2014;55:202–11.

Tavakoli HR, Jalali P, Mahmoudi S. Experimental evaluation of the effects of adding steel fiber on the post-cyclic behavior of reinforced self-compacting concrete beams. J Build Eng. 2019;25:100771.

Aslani F, Nejadi S. Mechanical characteristics of self-compacting concrete with and without fibres. Mag Concr Res. 2013;65(10):608–22.

Giaccio G, Zerbino R. Combined effects of coarse aggregates and strength level. Adv Cem Based Mater. 1998;7(2):41–8.

Amparano FE, Xi Y, Roh YS. Experimental study on the effect of aggregate content on fracture behavior of concrete. Eng Fract Mech. 2000;67(1):65–84.

Löfgren I. Fibre-reinforced concrete for industrial construction—a fracture mechanics approach to material testing and structural analysis. Gothenburg: Chalmers University of Technology; 2005.

Yang ZJ, Qsymah A, Peng YZ, Margetts L, Sharma R. 4D characterisation of damage and fracture mechanisms of ultra high performance fibre reinforced concrete by in-situ micro X-ray computed tomography tests. Cement Concr Compos. 2020;106:103473.

Linsbauer HN, Tschegg EK. Fracture energy determination of concrete with cube shaped specimens. Zement und Beton. 1986;31(1):38–40.

Brühwiler E, Wittmann FH. The wedge splitting test, a new method of performing stable fracture mechanics tests. Eng Fract Mech. 1990;35(1–3):117–25.

Jin S, Gruber D, Harmuth H. Determination of Young’s modulus, fracture energy and tensile strength of refractories by inverse estimation of a wedge splitting procedure. Eng Fract Mech. 2014;116:228–36.

Löfgren I, Stang H, Olesen JF. Fracture properties of FRC determined through inverse analysis of wedge splitting and three-point bending tests. J Adv Concr Technol. 2005;3(3):423–34.

Jansson A, Gylltoft K, Löfgren I. A fracture mechanics approach to material testing and structural analysis of FRC beams. In: conference proceedings for FRAMCOS-6, Catania, Italy June 2007, 1491–6.

Löfgren I. The wedge splitting test a test method for assessment of fracture parameters of FRC?. In: Fracture mechanics of concrete structures, vol 2. Proceedings of the fifth international conference on fracture mechanics of concrete and concrete structures. 2004, In Vail, Colorado/USA/12–16 April 2004;2: 1155–1162).

Haach VG, Ramirez FC. Qualitative assessment of concrete by ultrasound tomography. Constr Build Mater. 2016;119:61–70.

Vicente MA, González DC, Mínguez J. Recent advances in the use of computed tomography in concrete technology and other engineering fields. Micron. 2019;118:22–34.

Liu Z, Wang J, Zhang Y, Lv H, Fu P, Li A. In situ characterisation of the depth and mass of water intrusion in unsaturated cement pastes via X-ray computed tomography. Adv Cem Res. 2016;29(3):91–100.

Pavani HP, Tadepalli TP, Agrawal AK. Characterization of micro-and mesoporosity in Portland cement at elevated temperatures. Mag Concr Res. 2019;72:1–10.

Han J, Sun W, Pan G, Wang C, Rong H. Application of X-ray computed tomography in characterization microstructure changes of cement pastes in carbonation process. J Wuhan Univ Technol Mater Sci Ed. 2012;27(2):358–63.

Ren W, Yang Z, Sharma R, Zhang CH, Withers PJ. Two-dimensional X-ray CT image based meso-scale fracture modelling of concrete. Eng Fract Mech. 2015;133:24–7.

Rios JD, Leiva C, Ariza MP, Seitl S, Cifuentes H. Analysis of the tensile fracture properties of ultra-high-strength fiber-reinforced concrete with different types of steel fibers by X-ray tomography. Mater Des. 2019;165:107582.

Zhang M, Jivkov AP. Micromechanical modelling of deformation and fracture of hydrating cement paste using X-ray computed tomography characterisation. Compos B Eng. 2016;88:64–72.

Yang ZJ, Li BB, Wu JY. X-ray computed tomography images based phase-field modeling of mesoscopic failure in concrete. Eng Fract Mech. 2019;208:151–70.

Yang Z, Ren W, Sharma R, McDonald S, Mostafavi M, Vertyagina Y, Marrow TJ. In-situ X-ray computed tomography characterisation of 3D fracture evolution and image-based numerical homogenisation of concrete. Cem Concr Compos. 2017;75:74–83.

Yang S, Cui H, Poon CS. Assessment of in-situ alkali-silica reaction (ASR) development of glass aggregate concrete prepared with dry-mix and conventional wet-mix methods by X-ray computed micro-tomography. Cem Concr Compos. 2018;90:266–76.

Yu Q, Liu H, Yang T, Liu H. 3D numerical study on fracture process of concrete with different ITZ properties using X-ray computerized tomography. Int J Solids Struct. 2018;147:204–22.

Van Steen C, Pahlavan L, Wevers M, Verstrynge E. Localisation and characterisation of corrosion damage in reinforced concrete by means of acoustic emission and X-ray computed tomography. Constr Build Mater. 2019;197:21–9.

Pavani HP, Tadepalli T, Agarwal AK. Estimation of porosity and pore distribution in hydrated Portland cement at elevated temperatures using synchrotron micro tomography. J Adv Concr Technol. 2019;17(1):34–45.

Pavani HP, Tadepalli T, Agrawal AK. Thermal behaviour of PPC and OPC-53 when exposed to extreme temperatures. Adv Cem Res. 2019;32:1–13.

Ponikiewski T, Katzer J, Bugdol M, Rudzki M. X-ray computed tomography harnessed to determine 3D spacing of steel fibres in self compacting concrete (SCC) slabs. Constr Build Mater. 2015;74:102–8.

Vicente MA, Mínguez J, González DC. Computed tomography scanning of the internal microstructure, crack mechanisms, and structural behavior of fiber-reinforced concrete under static and cyclic bending tests. Int J Fatigue. 2019;121:9–19.

Marzec I, Tejchman J. Fracture evolution in concrete compressive fatigue experiments based on X-ray micro-CT images. Int J Fatigue. 2019;122:256–72.

Erdem S. X-ray computed tomography and fractal analysis for the evaluation of segregation resistance, strength response and accelerated corrosion behaviour of self-compacting lightweight concrete. Constr Build Mater. 2014;61:10–7.

Huang Y, Yan D, Yang Z, Liu G. 2D and 3D homogenization and fracture analysis of concrete based on in-situ X-ray computed tomography images and monte Carlo simulations. Eng Fract Mech. 2016;163:37–54.

Obara Y, Tanikura I, Jung J, Shintani R, Watanabe S. Evaluation of micro-damage of concrete specimens under cyclic uniaxial loading by X-ray CT method. J Adv Concr Technol. 2016;14(8):433–43.

Du Plessis A, Boshoff WP. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr Build Mater. 2019;199:637–51.

BIS (Bureau of Indian Standards). IS: 12269:2013 specifications for 53 grade ordinary portland cement. New Delhi: Bureau of Indian Standards; 2013a.

BIS (Bureau of Indian Standards). IS: 383:2016 specification for coarse and fine aggregates from natural sources for concrete. New Delhi: Bureau of Indian Standards; 2016.

BIS (Bureau of Indian Standards). IS: 3812:2013 pulverized fuel ash—specification. New Delhi: Bureau of Indian Standards; 2013b.

ASTM C494. Standard specification for chemical admixtures for concrete. West Conshohocken: ASTM; 2017.

Su N, Hsu KC, Chai HW. A simple mix design method for self-compacting concrete. Cem Concr Res. 2001;31(12):1799–807.

EFNARC. The European guidelines for self-compacting concrete: specification production and use. Flums: EFNARC; 2005.

Otsu N. A threshold selection method from gray-level histograms. IEEE Trans Syst Man Cybern. 1979;9(1):62–6.

Skarżyński Ł, Tejchman J. Experimental investigations of fracture process using DIC in plain and reinforced concrete beams under bending. Strain. 2013;49(6):521–43.

Skarzynski TJ. Experimental investigations of damage evolution in concrete during bending by continuous micro-CT scanning. Mater Charact. 2019;154:40–52.

Acknowledgements

The authors are glad to the Department of Civil Engineering, National Institute of Technology Warangal for providing research amenities to carry out this research work. The authors are thankful to RADAR diagnostic centre, Warangal for providing the scanning facilities apart from there busy medical diagnosis schedule.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rajeshwari, B.R., Sivakumar, M.V.N. & Praneeth, P.H. Visualization and quantification of aggregate and fiber in self-compacting concrete using computed tomography for wedge splitting test. Archiv.Civ.Mech.Eng 20, 139 (2020). https://doi.org/10.1007/s43452-020-00140-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00140-z