Abstract

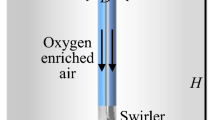

In this research, the proposal to use a nonconsumable lance or heat pipe to decrease the mixing times in a secondary refining ladle is evaluated. The main idea is to minimize the stirring times to get the complete mixing of liquid steel, mainly due to the fact that a consumable lance once its melted changes the operation conditions. Use of a nonconsumable lance is well known because of its excellent self-protective characteristics; in general, this kind of nonconsumable lance is used in almost any gas injection operation process. Hence, a set of experiments in a physical model demonstrated the viability and competitiveness of the nonconsumable lance in a secondary refining ladle. The results obtained in the physical modeling revealed that the vibration signals, acquired by the accelerometer, are proportional to the amount of agitation energy induced by the injected gas (kinetic and potential energy). Regarding the increment in the vibrations, the inclination angle of the lance showed that the mixing times have a significant effect on the mixing time of the liquid.

Similar content being viewed by others

Notes

LABVIEW is a trademark of National Instruments, Austin, TX.

HIQ is a trademark of National Instruments, Austin, TX.

MINITAB is a trademark of Minitab, LLC, State College, PA.

SYSTAT is a trademark of Systat Software, San Jose, CA.

NEUROSHELL 2 is a trademark of Ward Systems Group, Inc., Frederick, MD.

Abbreviations

- A :

-

Lance transversal area

- D :

-

Lance diameter

- E c :

-

Kinetic energy

- E p :

-

Potential energy

- E T :

-

Agitation energy

- F :

-

Injected airflow

- G :

-

Tilt angle

- G 1 :

-

Oscillation movement

- Int:

-

Integral absolute value of the vibration signal

- Int1 :

-

Integral value of the signal

- P :

-

Lance radial position

- P a :

-

Atmospheric pressure

- P mg :

-

Molecular weight of the gas injected

- Q g :

-

Surface flow of the injected air

- R :

-

Gas constant

- T g :

-

Gas temperature at the exit of the nozzle

- T m :

-

Metal temperature

- V :

-

Water volume to agitate

- V 1 :

-

Agitation volume

- W m :

-

Metal weight

- Z 1 :

-

Lance depth

- g :

-

Acceleration due to gravity

- r :

-

lance radio

- ρ m :

-

Metal density

References

R.K. Singh, K.K. Keshari, S. Devi, S. Mukhopadhayay, T.K. Pratihar, and A.K. Ray: Mater. Manuf. Processes, 2010, vol. 25, pp. 92–98.

V.P. Piptyuk, V.F. Polyakov, S.E. Samokhvalov, O.B. Isaev, S.N. Pavlov, and A.A. Travinchev: Metallurgist, 2011, vol. 55, pp. 483–88.

W. Lou and M. Zhu: ISIJ Int., 2015, vol. 55, pp. 961–69.

H. Lee and K. Yi: Met. Mater. Int., 2015, vol. 21, pp. 511–20.

Y. Wang, S. Yang, J. Li, F. Wang, and Y. Gu: J. Sustain. Metall., 2017, vol. 3, pp. 274–79.

D. Felice, I.L.A. Daoud, B. Dussoubs, A. Jardy, and J.P. Bellot: ISIJ Int., 2012, vol. 52, pp. 1273–80.

D.Q. Geng, H. Lei, and J.C. He: ISIJ Int., 2010, vol. 50, pp. 1597–1605.

S. Li, X. Gao, T. Chai, and X. Wang: IFAC Proc. Volumes, IFAC, Seoul, 1997, pp. 165–68.

W. Lou and M. Zhu: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 3196–212.

Q. Cao, A. Pitts, and L. Nastac: Ironmak. Steelmak., 2018, vol. 45, pp. 280–87.

W. Lou and M. Zhu: ISIJ Int., 2014, vol. 54, pp. 9–18.

K. Krishnapisharody and G.A. Irons: ISIJ Int., 2010, vol. 50, pp. 1413–21.

Y.I. Shishkin, O.A. Grigorova, A.A. Dobromilov, V.V. Gorbunov, and G.V. Kuznetsov: Russ. Metall., 2008, vol. 2008, pp. 674–76, 10.1134/S0036029508080065

P.S. Srinivas, A.K. Kothari, and A. Agrawal: ISIJ Int., 2016, vol. 56, pp. 977–85.

D. Mazumdar, P. Dhandapani, and R. Sarvanakumar: ISIJ Int., 2017, vol. 57, pp. 286–95.

L. Zhongqiu, L. Linmin, and L. Baokuan: ISIJ Int., 2017, vol. 55, pp. 1971–79.

A. Alexiadis: Appl. Math. Model., 2007, vol. 31, pp. 1534–47.

S.W.P. Cloete, J.J. Eksteen, and S.M. Bradshaw: Miner. Eng., 2013, vols. 46–47, pp. 16–24.

S. Yu, Z.S. Zou, L. Shao, and S. Louhenkilpi: ISIJ Int., 2016, vol. 56, pp. 1303–05.

S.P.T. Piva and P.C. Pistorius: Advances in Molten Slags, Fluxes, and Salts: Proceedings of the 10th International Conference on Molten Slags, Fluxes, and Salts, Seattle, WA, 2016, pp. 117–25.

H. Tian, Z. Mao, and A. Wang: J. Iron Steel Res. Int., 2009, vol. 16, pp. 1–6.

K. Mandal and D. Mazumdar: ISIJ Int., 1998, vol. 38, pp. 1150–52.

V.P. Piptyuk, V.F. Polyakov, S.E. Samokhvalov, A.B. Kovura, A.A. Travinchev, and S.N. Pavlov: Metallurgist, 2009, vol. 53, pp. 679–84.

X. Wang, M. You, Z. Mao, and P. Yuan: Adv. Eng. Inform., 2016, vol. 30, pp. 368–75.

F. Liu, R. Zhu, Q. Wang, and R. Bai: ISIJ Int., 2015, vol. 55, pp. 1633–41.

A. Zimmer, Á.N.C. Lima, R.M. Trommer, S.R. Bragança, and C.P. Bergmann: J. Iron Steel Res. Int., 2008, vol. 15, pp. 11–14.

M.M. Erofeev and E.B. Agapitov: Russ. Metall., 2009, vol. 2009, pp. 571–75, Doi 10.1134/S0036029509070040.

Acknowledgment

Two of the authors (IEG and HAG) gratefully acknowledge the support from the Cátedras–CONACYT program through Project No. 674.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 16, 2019; accepted September 25, 2020.

Rights and permissions

About this article

Cite this article

Arcos-Gutiérrez, H., Aparicio-Fernández, R., Barrera-Cardiel, G. et al. Physical Simulation of a Nonconsumable Lance for Secondary Refining Operations. Metall Mater Trans B 52, 190–198 (2021). https://doi.org/10.1007/s11663-020-01992-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01992-9