Abstract

While raw earth can be used as a structural material, its water sensitivity limits its use in modern construction. Earth has a strong affinity with water. Both water imbibition and water vapour transfer have to be taken into consideration. This affinity can be a positive point to regulate indoor ambience, but it can also negatively affect earth’s mechanical properties. To avoid this possible detrimental effect, bio-based additions are used all around the world to stabilize, protect from water and enhance the mechanical properties of earth-based building materials. Bio-based stabilizers have to limit liquid water absorption and maintain mechanical properties without acting as a water vapour barrier that can lead to durability issues. In this article, capillary water absorption and water vapour permeability measurements are performed for combinations of various earths and bio-based additions (linseed oil, xanthan gum, casein, alginate and tannins). Linseed oil and xanthan gum help to protect the earth-based samples from absorbing liquid water without affecting the water vapour transfer in these materials.

Similar content being viewed by others

References

Azeredo G, Morel J-C, Lamarque C-H (2008) Applicability of rheometers to characterizing earth mortar behavior. Part I: experimental device and validation. Mater Struct 41:1465–1472. https://doi.org/10.1617/s11527-007-9343-9

Aubert JE, Maillard P, Morel JC, Al Rafii M (2016) Towards a simple compressive strength test for earth bricks? Mater Struct 49:1641–1654. https://doi.org/10.1617/s11527-015-0601-y

Bui Q-B, Morel J-C, Hans S, Meunier N (2009) Compression behaviour of non-industrial materials in civil engineering by three scale experiments: the case of rammed earth. Mater Struct 42:1101–1116. https://doi.org/10.1617/s11527-008-9446-y

Moevus M, Jorand Y, Olagnon C, Maximilien S, Anger R, Fontaine L, Arnaud L (2016) Earthen construction: an increase of the mechanical strength by optimizing the dispersion of the binder phase. Mater Struct 49:1555–1568. https://doi.org/10.1617/s11527-015-0595-5

Pacheco-Torgal F, Jalali S (2012) Earth construction: lessons from the past for future eco-efficient construction. Constr Build Mater 29:512–519. https://doi.org/10.1016/j.conbuildmat.2011.10.054

Arrigoni A, Beckett C, Ciancio D, Dotelli G (2017) Life cycle analysis of environmental impact vs. durability of stabilised rammed earth. Constr Build Mater 142:128–136. https://doi.org/10.1016/j.conbuildmat.2017.03.066

Morel JC, Mesbah A, Oggero M, Walker P (2001) Building houses with local materials: means to drastically reduce the environmental impact of construction. Build Environ 36:1119–1126. https://doi.org/10.1016/S0360-1323(00)00054-8

Houben H, Guillaud H, CRAterre (2006) Traité de construction en terre. Parenthèses

Minke G (2006) Building with earth: design and technology of a sustainable architecture. Birkhäuser-Publishers for Architecture, Basel

Jaquin PA, Augarde CE, Gallipoli D, Toll DG (2009) The strength of unstabilised rammed earth materials. Géotechnique 59:487–490. https://doi.org/10.1680/geot.2007.00129

Bui Q-B, Morel J-C, Hans S, Walker P (2014) Effect of moisture content on the mechanical characteristics of rammed earth. Constr Build Mater 54:163–169. https://doi.org/10.1016/j.conbuildmat.2013.12.067

Morel J-C, Pkla A, Walker P (2007) Compressive strength testing of compressed earth blocks. Constr Build Mater 21:303–309. https://doi.org/10.1016/j.conbuildmat.2005.08.021

Guihéneuf S, Rangeard D (2019a) Perrot A (2019) Addition of bio based reinforcement to improve workability, mechanical properties and water resistance of earth-based materials. Acad J Civil Eng 37(2):184-192. Special Issue—ICBBM 2019

Guihéneuf S, Rangeard D (2019b) Perrot A (2019) Cast, compaction, vibro-compaction or extrusion: processing methods for optimizing the mechanical strength of raw earth-based materials. Acad J Civil Eng 37(2):156–163. Special Issue—ICBBM 2019

Champiré F, Fabbri A, Morel J-C, Wong H, McGregor F (2016) Impact of relative humidity on the mechanical behavior of compacted earth as a building material. Constr Build Mater 110:70–78. https://doi.org/10.1016/j.conbuildmat.2016.01.027

Hall M, Allinson D (2009) Analysis of the hygrothermal functional properties of stabilised rammed earth materials. Build Environ 44:1935–1942. https://doi.org/10.1016/j.buildenv.2009.01.007

Allinson D, Hall M (2010) Hygrothermal analysis of a stabilised rammed earth test building in the UK. Energy Build 42:845–852. https://doi.org/10.1016/j.enbuild.2009.12.005

McGregor F, Heath A, Fodde E, Shea A (2014) Conditions affecting the moisture buffering measurement performed on compressed earth blocks. Build Environ 75:11–18. https://doi.org/10.1016/j.buildenv.2014.01.009

McGregor F, Heath A, Maskell D, Fabbri A, Morel J-C (2016) A review on the buffering capacity of earth building materials. Proc Inst Civil Eng Constr Mater 169:241–251. https://doi.org/10.1680/jcoma.15.00035

Walker P, Stace T (1997) Properties of some cement stabilised compressed earth blocks and mortars. Mat Struct 30:545–551. https://doi.org/10.1007/BF02486398

Venkatarama Reddy BV, Prasanna Kumar P (2011a) Cement stabilised rammed earth. Part A: Compaction characteristics and physical properties of compacted cement stabilised soils. Mater Struct 44:681–693. https://doi.org/10.1617/s11527-010-9658-9

Venkatarama Reddy BV, Prasanna Kumar P (2011b) Cement stabilised rammed earth. Part B: Compressive strength and stress–strain characteristics. Mater Struct 44:695–707. https://doi.org/10.1617/s11527-010-9659-8

Khelifi H, Perrot A, Lecompte T, Ausias G (2013) Design of clay/cement mixtures for extruded building products. Mater Struct 46:999–1010. https://doi.org/10.1617/s11527-012-9949-4

Tripura DD, Singh KD (2014) Behavior of cement-stabilized rammed earth circular column under axial loading. Mater Struct 49:371–382. https://doi.org/10.1617/s11527-014-0503-4

Landrou G, Ouellet-Plamondon C, Brumaud C, Habert G (2014) Development of a self-compacted clay based concrete, rheological, mechanical and environmental investigations. Acad J Civil Eng. https://doi.org/10.13140/2.1.1054.2401

Khelifi H, Lecompte T, Perrot A, Ausias G (2015) Mechanical enhancement of cement-stabilized soil by flax fibre reinforcement and extrusion processing. Mater Struct 49:1143–1156. https://doi.org/10.1617/s11527-015-0564-z

Van Damme H, Houben H (2018) Earth concrete stabilization revisited. Cem Concr Res 114:90–102. https://doi.org/10.1016/j.cemconres.2017.02.035

Marsh ATM, Heath A, Walker P, Reddy BVV, Habert G (2020) Discussion of “Earth concrete: Stabilization revisited.” Cem Concr Res 130:105991. https://doi.org/10.1016/j.cemconres.2020.105991

Van Damme H, Houben H (2020) Reply to the discussion of the paper “Earth Concrete. Stabilization Revisited” by A. T. M. Marsh, A. Heath, P. Walker, B. V. Venkatarama Reddy, and G. Habert. Cem Concr Res 130:105992. https://doi.org/10.1016/j.cemconres.2020.105992

Ouedraogo KAJ, Aubert J-E, Tribout C, Escadeillas G (2020) Is stabilization of earth bricks using low cement or lime contents relevant? Constr Build Mater 236:117578. https://doi.org/10.1016/j.conbuildmat.2019.117578

Perrot A, Lecompte T, Khelifi H, Brumaud C, Hot J, Roussel N (2012) Yield stress and bleeding of fresh cement pastes. Cem Concr Res 42:937–944. https://doi.org/10.1016/j.cemconres.2012.03.015

Perrot A, Rangeard D, Levigneur A (2016) Linking rheological and geotechnical properties of kaolinite materials for earthen construction. Mater Struct 49:4647–4655. https://doi.org/10.1617/s11527-016-0813-9

Landrou G, Brumaud C, Plötze ML, Winnefeld F, Habert G (2018) A fresh look at dense clay paste: deflocculation and thixotropy mechanisms. Colloids Surf A 539:252–260. https://doi.org/10.1016/j.colsurfa.2017.12.029

Bruno AW, Gallipoli D, Perlot C, Mendès J, Salmon N (2015) Briques de terre crue: procédure de compactage haute pression et influence sur les propriétés mécaniques. 10

Bruno AW (2016) Étude du comportement hygro- mécanique de la terre crue hyper-compactée pour la construction durable. Thèse de doctorat, Pau

Bruno AW, Gallipoli D, Perlot C, Mendes J (2017) Mechanical behaviour of hypercompacted earth for building construction. Mater Struct 50:160. https://doi.org/10.1617/s11527-017-1027-5

Bruno AW, Gallipoli D, Perlot C, Mendes J (2019) Optimization of bricks production by earth hypercompaction prior to firing. J Cleaner Prod 214:475–482. https://doi.org/10.1016/j.jclepro.2018.12.302

Anger R, Fontaine L, Vissac A, Couvreur L, Moevus M, Bourgès A, Gandreau D, Joffroy T (2013) PaTerre+: Interactions argiles/biopolymères. Patrimoine Architectural en terre et stabilisants naturels d’origine animale et végétale, CRAterre ENSAG

Vissac A, Bourgès A, Gandreau D, Anger R, Fontaine L (2017) Argiles & biopolymères, les stabilisants naturels pour la construction en terre. CRAterre éditions, Villefontaine

Achenza M, Fenu L (2007) On earth stabilization with natural polymers for earth masonry construction. Mater Struct 39:21–27. https://doi.org/10.1617/s11527-005-9000-0

Galán-Marín C, Rivera-Gómez C, Petric J (2010) Clay-based composite stabilized with natural polymer and fibre. Constr Build Mater 24:1462–1468. https://doi.org/10.1016/j.conbuildmat.2010.01.008

Anger R (2011) Approche granulaire et colloïdale du matériau terre pour la construction. Thèse de doctorat, Institut national des sciences appliquées de Lyon

Dove CA, Bradley FF, Patwardhan SV (2016) Seaweed biopolymers as additives for unfired clay bricks. Mater Struct 49:4463–4482. https://doi.org/10.1617/s11527-016-0801-0

Hafshejani KS, Moslemizadeh A, Shahbazi K (2016) A novel bio-based deflocculant for bentonite drilling mud. Appl Clay Sci 127–128:23–34. https://doi.org/10.1016/j.clay.2016.03.037

Banakinao S, Tiem S, Lolo K, Koutsawa Y, Bedja K-S (2016) Dataset of the use of tannin of néré (parkia-biglobosa) as a solution for the sustainability of the soil constructions in West Africa. Data Brief 8:474–483. https://doi.org/10.1016/j.dib.2016.05.072

Menasria F, Perrot A, Rangeard D, Rennes I (2017) Using alginate biopolymer to enhance the mechanical properties of earth-based materials. France, Clermont-Ferrand, p 6

Perrot A, Rangeard D, Menasria F, Guihéneuf S (2018) Strategies for optimizing the mechanical strengths of raw earth-based mortars. Constr Build Mater 167:496–504. https://doi.org/10.1016/j.conbuildmat.2018.02.055

Ouedraogo KAJ (2019) Stabilisation de matériaux de construction durables et écologiques à base de terre crue par des liants organiques et/ou minéraux à faibles impacts environnementaux. Université Toulouse 3 - Paul Sabatier

Chang I, Jeon M, Cho G-C (2015) Application of microbial biopolymers as an alternative construction binder for earth buildings in underdeveloped countries. Int J Polym Sci 2015:1–9. https://doi.org/10.1155/2015/326745

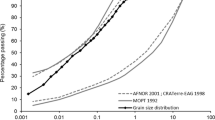

Nouveau guide du béton et de ses constituants - Georges Dreux, Jean... - Librairie Eyrolles. https://www.eyrolles.com/BTP/Livre/nouveau-guide-du-beton-et-de-ses-constituants-9782212102314/

Funami T, Fang Y, Noda S, Ishihara S, Nakauma M, Draget KI, Nishinari K, Phillips GO (2009) Rheological properties of sodium alginate in an aqueous system during gelation in relation to supermolecular structures and Ca2+ binding. Food Hydrocolloids 23:1746–1755. https://doi.org/10.1016/j.foodhyd.2009.02.014

Cadmus MC, Jackson LK, Burton KA, Plattner RD, Slodki ME (1982) Biodegradation of xanthan gum by Bacillus sp. Appl Environ Microbiol 44:5–11. https://doi.org/10.1128/AEM.44.1.5-11.1982

Becker A, Katzen F, Pühler A, Ielpi L (1998) Xanthan gum biosynthesis and application: a biochemical /genetic perspective. Appl Microbiol Biotechnol 50:145–152. https://doi.org/10.1007/s002530051269

Chang I, Im J, Prasidhi AK, Cho G-C (2015) Effects of Xanthan gum biopolymer on soil strengthening. Constr Build Mater 74:65–72. https://doi.org/10.1016/j.conbuildmat.2014.10.026

Schaich KM (2005) Lipid oxidation: theoretical aspects. In: Bailey’s industrial oil and fat products. Wiley, American Cancer Society, Chicago

Schaich KM (2020) Lipid oxidation: new perspectives on an old reaction. In: Bailey’s industrial oil and fat products. Wiley, American Cancer Society, Chicago, pp 1–72

Dridi W (2016) Influence de la formulation sur l’oxydation des huiles végétales en émulsion eau-dans-huile. 205

AFNOR (2002) NF EN 13057—Produits et systèmes pour la protection et la réparation des structures en béton—Méthodes d’essai—Détermination de l’absorption capillaire. AFNOR

AFNOR (2017) XP P 13-901—Blocs de terre comprimée pour murs et cloisons. AFNOR

Hall C (1989) Water sorptivity of mortars and concretes: a review. Mag Concr Res 41:51–61. https://doi.org/10.1680/macr.1989.41.147.51

Janssen H, Vereecken E, Holúbek M (2015) A confrontation of two concepts for the description of the over-capillary moisture range: air entrapment versus low capillarity. Energy Proced 78:1490–1494. https://doi.org/10.1016/j.egypro.2015.11.175

Wilson MA, Carter MA, Hoff WD (1999) British standard and RILEM water absorption tests: a critical evaluation. Mat Struct 32:571–578. https://doi.org/10.1007/BF02480491

Philip JR (1969) Theory of Infiltration. In: Advances in Hydroscience. Elsevier, pp 215–296

Feng C, Janssen H (2018) Hygric properties of porous building materials (III): impact factors and data processing methods of the capillary absorption test. Build Environ 134:21–34. https://doi.org/10.1016/j.buildenv.2018.02.038

Collet F, Chamoin J, Pretot S, Lanos C (2013) Comparison of the hygric behaviour of three hemp concretes. Energy Build 62:294–303. https://doi.org/10.1016/j.enbuild.2013.03.010

Collet F (2004) CARACTERISATION HYDRIQUE ET THERMIQUE DE MATERIAUX DE GENIE CIVIL A FAIBLES IMPACTS ENVIRONNEMENTAUX. Rennes 1

Mazhoud B, Collet F, Pretot S, Chamoin J (2016) Hygric and thermal properties of hemp-lime plasters. Build Environ 96:206–216. https://doi.org/10.1016/j.buildenv.2015.11.013

(2016) NF EN ISO 12572:2016 Performance hygrothermique des matériaux et produits pour le bâtiment—Détermination des propriétés de transmission de la vapeur d’eau—Méthode de la coupelle. AFNOR

Huggett JM (2015) Clay minerals. In: Reference module in earth systems and environmental sciences. Elsevier, New York, p B9780124095489096000

Fabbri A, Soudani L, McGregor F, Morel J-C (2019) Analysis of the water absorption test to assess the intrinsic permeability of earthen materials. Constr Build Mater 199:154–162. https://doi.org/10.1016/j.conbuildmat.2018.12.014

Salager S (2007) Etude de la rétention d’eau et de la consolidation des sols dans un cadre thermo-hydro-mécanique. Université Montpellier 2, sciences et techniques du Languedoc

Miller CJ, Yesiller N, Yaldo K, Merayyan S (2002) Impact of soil type and compaction conditions on soil water characteristic. J Geotech Geoenviron Eng 128:733–742. https://doi.org/10.1061/(ASCE)1090-0241(2002)128:9(733)

Simons A, Bertron A, Roux C, Laborel-Préneron A, Aubert J-E, Roques C (2018) Susceptibility of earth-based construction materials to fungal proliferation laboratory and in situ assessment. RILEM Tech Lett 3:140–149

Venkatarama Reddy BV (2012) Stabilised soil blocks for structural masonry in earth construction. In: Hall M, Lindsay R, Krayenhoff M (eds) Modern Earth Buildings. Elsevier, Newyork, pp 324–363

Chen C, Wu L, Perdjon M, Huang X, Peng Y (2019) The drying effect on xanthan gum biopolymer treated sandy soil shear strength. Constr Build Mater 197:271–279. https://doi.org/10.1016/j.conbuildmat.2018.11.120

NF EN ISO 10456 (2008) Building materials and products—hygrothermal properties—tabulated design values and procedures for determining declared and design thermal values. AFNOR, Paris

Rode C, Peuhkuri R.H, Hansen K.K, Time B, Svennberg K, Arfvidsson J, Ojanen T (2005) NORDTEST project on moisture buffer value of materials. In: AIVC Conf. ‘Energy Perform. Regul. Vent. Relat. Energy Perform. Build., Bruxelles, Belgique, pp 47–52.

Acknowledgements

The authors would like to thank Patrice Estellé, Associate professor at LGCGM, for his support and advice for the contact angles measurements.

Funding

The authors would like to thank ECOMATERRE who funded a part of this study, and for its work in structuring the regional research program on earth construction.

Author information

Authors and Affiliations

Contributions

Conceptualization, S.G., D.R., A.P.; Validation, S.G., D.R., A.P., T.C., F.C., S.P.; Investigation T.C., S.G., D.R., A.P., F.C., S.P.; Writing-original draft, S.G.; Writing-review and editing D.R., A.P., F.C., S.P., T.C.

Availability of data and material

The data that support the findings of this study are available from the corresponding author, S. G., upon reasonable request.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guihéneuf, S., Rangeard, D., Perrot, A. et al. Effect of bio-stabilizers on capillary absorption and water vapour transfer into raw earth. Mater Struct 53, 138 (2020). https://doi.org/10.1617/s11527-020-01571-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01571-z