Abstract

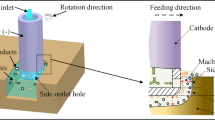

Critical interference error can be mostly resulted from illogical tool-path generations in the penetration and retraction segments of internal cylindrical thread helical milling. Therefore, a less interference tool-path planning method is proposed for the quarter revolution penetration and retraction trajectories in internal cylindrical thread helical milling. Firstly, the parametric expression of the complete tool path of internal cylindrical thread helical milling is established; after that, a definition of eccentricity parameter m is given to adjust the radius of the penetration and retraction trajectories, and Z-axis coordinate of any point on the tool path is defined as a function of the θ; thus, the planned penetration and retraction trajectories in internal cylindrical thread helical milling with the m are derived; finally, the proper eccentricity parameter m is decided to improve the machining accuracy of thread by exploring the influence of the m on the interference error. Taking the experimental of milling, an M20 × 1.5 thread using a φ8 × 1.5 cutter as one of the examples that indicate the maximum interference error of the planning method (m = 0.4) can be reduced by 30.93%, compared with the original trajectory, and can dramatically improve the precision of internal cylindrical thread helical milling.

Similar content being viewed by others

References

Gadelmawla ES (2017) Computer vision algorithms for measurement and inspection of external screw threads. Measurement 100:36–49

Kramer P, Groche P (2018) Defect detection in thread rolling processes–experimental study and numerical investigation of driving parameters. Int J Mach Tools Manuf 129:27–36

Oku Y, Sugino M, Ando Y, Makino T, Komoda R, Takazaki D, Kubota M (2017) Fretting fatigue on thread root of premium threaded connections. Tribol Int 108:111–120

Wan M, Altintas Y (2014) Mechanics and dynamics of thread milling process. Int J Mach Tools Manuf 87:16–26

Smid P (2003) CNC programming handbook: a comprehensive guide to practical CNC programming. Industrial Press Inc, New York

Fromentin G, Poulachon G (2010) Modeling of interferences during thread milling operation. Int J Adv Manuf Technol 49(1-4):41–51

Fromentin G, Dobbeler B, Lung D (2015) Computerized simulation of interference in thread milling of non-symmetric thread profiles. Procedia CIRP 31:496–501

Lee SW, Nestler A (2012) Simulation-aided design of thread milling cutter. Procedia CIRP 1(1):120–125

Fromentin G, Sharma VS, Poulachon G, Paire Y, Brendlen R (2011) Effect of thread milling penetration strategies on the dimensional accuracy. J Manuf Sci Eng 133:041014-1–041014-13

Lee SW, Kasten A, Nestler A (2013) Analytic mechanistic cutting force model for thread milling operations. Procedia CIRP 8(8):546–551

Imani BM, Abdollahzadeh H, El-Mounayri H (2012) Prediction of thread milling instantaneous cutting forces. Int J Adv Manuf Technol 58:849–859

Araujo AC, Fromentin G (2017) Modeling thread milling forces in mini-hole in dental metallic materials. Procedia CIRP 58:623–628

Jun MBG, Araujo AC (2010) Modeling of the thread milling operation in a combined thread/drilling operation: thrilling. J Manuf Sci Eng 132(1):014505-1–014505-6

ISO 68-1 standard (1998) ISO general purpose screw threads—Basic profile—Part 1: Metric screw threads. International Organization for Standardization, Switzerland

VERICUT. V8.0. September 2016. NC Machining Simulation Software. CGTECH, USA

ISO 965-1 standard (1998) ISO general-purpose metric screw threads—Tolerances —Part 1: Principles and basic data. International Organization for Standardization, Switzerland

ISO 965-2 standard (1998) ISO general purpose metric screw threads—Tolerances— Part 2: Limits of sizes for general purpose external and internal screw threads—Medium quality. International Organization for Standardization, Switzerland

Acknowledgments

The authors acknowledge and express their sincere thanks towards Zhuzhou Cemented Carbide Cutting Tools Co. Ltd. of China for providing cutting tool data for the study.

Funding

This work is supported by the key program of Hunan Provincial Department of Science and Technology of China (No.2016GK2014), Hunan Provincial Natural Science Foundation of China (No. 2020JJ6035), program of the Hunan Provincial Department of Education (No.19 K094),key program of Xiangtan Science and Technology Bureau, Hunan, China (No.CG- ZD20201003), and general program of Xiangtan Science and Technology Bureau, Hunan, China (No.CG- YB20201007), which the authors greatly appreciate.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, Z., Tang, Y., Fan, Y. et al. Less interference tool-path planning method for quarter revolution penetration and retraction trajectories in internal cylindrical thread helical milling. Int J Adv Manuf Technol 111, 2687–2703 (2020). https://doi.org/10.1007/s00170-020-06253-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06253-2