Abstract

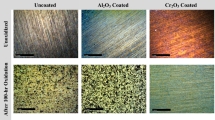

NiCoCrAlYSiHf coating was prepared for the surface of the 3039 Ni-based superalloy. The coating was prepared via arc ion plating, and it was modified using a high-current pulsed electron beam (HCPEB) technique. The effects that HCPEB irradiation had on the hot corrosion properties of the NiCoCrAlYSiHf bonding layer at 900 °C with mixed salt (75 wt% Na2SO4 + 25 wt% K2SO4) were studied. The results showed that after HCPEB irradiation, the defects on the surface of the original coating disappeared, and then the surface remelted. Y-enriched Al2O3 particles formed on the surface after 30 irradiation treatments. The results of the hot corrosion test showed that the original coating had poor hot corrosion resistance and severe spalling of corrosion products and that internal oxidation occurred. A continuous and dense Al2O3 film was expected in the molten salt of the irradiated coating, and this effectively blocked further corrosion of the coating. The results showed that HCPEB irradiation promoted rapid formation of a protective oxide film on the surface of the coating and significantly improved the hot corrosion resistance of the NiCoCrAlYSiHf coating.

Graphic Abstract

Similar content being viewed by others

References

N. P. Padture, M. Gell1, and E. H. Jordan, Science 296, 280 (2002). https://doi.org/10.1126/science.1068609

K. Yuan, R. L. Peng, X. H. Li, A. Talus et al., Surface and Coatings Technology 261, 41 (2015). https://doi.org/10.1016/j.surfcoat.2014.11.065

Y. Zhang, B. Bates, J. Steward, et al, Oxidation of Metals 91, 95 (2019). https://doi.org/10.1007/s11085-018-9868-z

K. Yuan, R. Eriksson, P. Lin, et al. Surface and Coatings Technology 232, 204 (2013). https://doi.org/10.1016/j.surfcoat.2013.05.008

K. Yuan, R. Eriksson, R. L. Peng, et al, Surface and Coatings Technology 254, 79 (2014). https://doi.org/10.1016/j.surfcoat.2014.05.067

M. Hatami, F. Naeimi, M. Shamanian, et al, Oxidation of Metals 90, 153 (2018). https://doi.org/10.1007/s11085-017-9829-y

S. M. Jiang, C. Z. Xu, H. Q. Li, et al. Corrosion Science 52, 1746 (2010). https://doi.org/10.1016/j.corsci.2010.01.025

D. Kim, S. Shang, Z. Li, et al. Oxidation of Metals 92, 303 (2019). https://doi.org/10.1007/s11085-019-09928-8

Y. Q. Wang, and M. Suneson Surface and Coatings Technology 215, 7 (2013). https://doi.org/10.1016/j.surfcoat.2012.07.091

Feng C., Li M., Xin L. et al, Oxidation of Metals 65, 307 (2006). https://doi.org/10.1007/s11085-006-9015-0

M. L. Shen, P. P. Zhao, Y. Gu et al. Corrosion Science 94, 294 (2015). https://doi.org/10.1016/j.corsci.2015.02.032

S. Xie, M. J. Dai, S. S. Lin et al. Corrosion Science 147, 330 (2019). https://doi.org/10.1016/j.corsci.2018.11.030

P. P. Zhao, M. L. Shen, Y. Gu et al. Corrosion Science 126, 317 (2017). https://doi.org/10.1016/j.corsci.2017.07.014

L. Shi, L. Xin, X. Wang, et al. Journal of Alloys and Compounds 649, 515 (2015). https://doi.org/10.1016/j.jallcom.2015.07.095

J. L. Wang, M. H. Chen, Y. X. Cheng, et al. Corrosion Science 123, 27 (2017). https://doi.org/10.1016/j.corsci.2017.04.004

M. Daroonparvar, M. A. M. Yajid, N. M. Yusof, et al, Journal of Alloys and Compounds 571, 205 (2013). https://doi.org/10.1016/j.jallcom.2013.03.168

A. Rabiei, and A. G. Evans, Acta Materialia 48, 3963 (2000). https://doi.org/10.1016/s1359-6454(00)00171-3

Y. Li, C. J. Li, Q. Zhang, G. J. Yang, et al, Journal of Thermal Spray Technology 19, 168 (2010). https://doi.org/10.1007/s11666-009-9372-8

J. N. Lv, X. L. Fan, Q. Li, Surface and Coatings Technology 309, 1033 (2017). https://doi.org/10.1016/j.surfcoat.2016.10.039

T. Gheno, and B. Gleeson, Oxidation of Metals 87, 527 (2017). https://doi.org/10.1007/s11085-016-9686-0

E. K. Hao, X. Q. Zhao, Y. L. An, et al., Applied Surface Science 489, 187 (2019). https://doi.org/10.1016/j.apsusc.2019.05.334

J. Cai, P. Lv, Q. F. Guan, et al. ACS Applied Materials & Interfaces 8, 32541 (2016). https://doi.org/10.1021/acsami.6b11129

Z. Q. Zhang, S. Z. Yang , P. Lv, et al, Applied Surface Science 294, 9 (2014). https://doi.org/10.1016/j.apsusc.2013.12.178

Y. R. Liu, K. M. Zhang, J. X. Zou, et al., Journal of Alloys and Compounds 741, 65 (2018). https://doi.org/10.1016/j.jallcom.2017.12.227

T. Grosdidier, J. X. Zou, B. Bolle, et al., Journal of Alloys and Compounds 504, 508 (2010). https://doi.org/10.1016/j.jallcom.2010.04.010

Y. K. Gao, Journal of Alloys and Compounds 572, 180 (2013). https://doi.org/10.1016/j.jallcom.2013.04.002

P. Lyu, Y. N. Chen, Z. J. Liu, et al., Applied Surface Science 504, 144453 (2020). https://doi.org/10.1016/j.apsusc.2019.144453

J. Cai, S. Z. Yang, L. Ji et al, Surface and Coatings Technology 251, 217 (2014). https://doi.org/10.1016/j.surfcoat.2014.04.029

J. Cai, Q. F. Guan, X. Hou, et al, Appl Surf Sci 317, 360 (2014). https://doi.org/10.1016/j.apsusc.2014.08.049

J. Cai, C. Z. Gao, P. Lv et al, Journal of Alloys and Compounds 784, 1221 (2019). https://doi.org/10.1016/j.jallcom.2019.01.071

W. Y. Liu, Y. Hou, C. Liu et al, Surface and Coatings Technology 270, 33 (2015). https://doi.org/10.1016/j.surfcoat.2015.03.022.

A. Gil, D. Naumenko, R. Vassen et al, Surface and Coatings Technology 204, 531 (2009). https://doi.org/10.1016/j.surfcoat.2009.08.034

J. Ma, S. M. Jiang, J. Gong et al, Corrosion Science 58, 251–259 (2012). https://doi.org/10.1016/j.corsci.2012.01.034

J. A. Goebel, F. S. Pettit, G. W. Goward, Metallurgical Transactions 4, 261 (1973). https://doi.org/10.1007/BF02649626

H. Asteman, M. A. Spiegel, Corrosion Science 50, 1734 (2008). https://doi.org/10.1016/j.corsci.2007.12.012

J. Lu, Y. Chen, C. S. Zhao et al, Corrosion Science 153, 178 (2019). https://doi.org/10.1016/j.corsci.2019.03.051

B. A. Pint, Oxidation of Metals, 45, 1 (1996). https://doi.org/10.1007/bf01046818

R. Cueff, H. Buscail, E. Caudron et al, Corrosion Science 45, 1815 (2003). https://doi.org/10.1016/s0010-938x(02)00254-8

Acknowledgements

Financial supports from the National Natural Science Foundation of China (Nos. U1933124 and U1810112) and Youth Talent Development Program of Jiangsu University are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cai, J., Zu, Z., Li, C. et al. Hot Corrosion Behavior of Arc Ion Plating NiCoCrAlYSiHf Coating Via High-Current Pulsed Electron Beam. Oxid Met 94, 569–586 (2020). https://doi.org/10.1007/s11085-020-10007-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-10007-6