Abstract

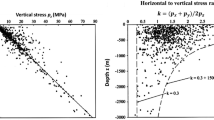

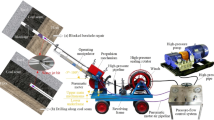

The presence of hard roof poses a significant threat to the safety of underground coal mining. In this study, a mechanical model is established for underground stopes to analyze the overburden structure with the advancing of the mining face. It is indicated that the load-bearing arch structure (LBAS) is formed above the stope for roofs with regular hardness, whereas the reversed-basin bearing structure (RBBS) is formed for hard roofs. Compared with the LBAS, the RBBS can induce an additional pressure at the foot of the bearing structure, and this effect becomes less as the distance between the hard roof and stope increases. The ultra-deep borehole hydro-fracturing technique (UHT) is proposed to weaken the hard roof for pressure release, and the associated equipment and procedures are also presented. The UHT is based on horizontal drilling along the axial direction of the roadway in the roof, and then the receding segmented hydraulic fracturing technique is used to achieve the purpose of fracturing (weakening) of the surrounding rocks. Field tests are carried out in 3022 roadway of Daliangwan coal mine in Yulin to assess the developed technique, equipment, and fracturing procedures. To evaluate the fracturing effect, deep borehole stress-meters are installed at different depths of the fractured and un-fractured zones of the roadway, along with hydraulic support pressure sensors placed at the mining face. The results show that compared with the un-fractured zone, the pressure on the wall and pillar sides is lower than that in the fractured zone, and the associated weighting duration and weighting area ratio of the fractured are reduced by 53.23% and 33.59%, respectively. This indicates that the presented UHT can provide a new solution for the prevention and control of mining disasters induced by hard roof failures in underground coal mining.

Similar content being viewed by others

References

Kang H (2014) Support technologies for deep and complex roadways in underground coal mines: a review. Int J Coal Sci Technol 3(1):261–277

Xia B, Zhang X, Yu B, Jia J (2018) Weakening effects of hydraulic fracture in hard roof under the influence of stress arch. Int J Min Sci Technol 28(6):951–958

Lu C, Liu Y, Wang H, Liu P (2016) Microseismic signals of double-layer hard and thick igneous strata separation and fracturing. Int J Coal Geol 160-161:28–41

He H, Dou L, Fan J, Du T, Sun X (2012) Deep-hole directional fracturing of thick hard roof for rockburst prevention. Tunn Undergr Space Technol 32:34–43

Huang B, Cheng Q, Zhao X, Xue W, Scoble M (2018) Using hydraulic fracturing to control caving of the hanging roof during the initial mining stages in a longwall coal mine: a case study. Arab J Geosci 11:603

Yiouta-Mitra P, Sofianos AI (2018) Μulti-jointed stratified hard rock roof analysis and design. Int J Rock Mech Min Sci 106:96–108

Zhang Z, Zhang N, Shimada H, Sasaoka T, Wahyudi S (2017) Optimization of hard roof structure over retained goaf-side gateroad by pre-split blasting technology. Int J Rock Mech Min Sci 100:330–337

He J, Dou L, Mu Z, Cao A, Gong S (2016) Numerical simulation study on hard-thick roof inducing rock burst in coal mine. J Cent South Univ 23:2314–2320

Zhang Z et al (2018) An Innovative Approach for Gob-Side Entry Retaining With Thick and Hard Roof: A Case Study. Tech Gazette 25(4):1028–1036

Zhao T, Zhang S, Liu C, Yetilmezsoy K, Zhang B (2017) Fractural structure of thick hard roof stratum using long beam theory and numerical modeling. Environ Earth Sci 76:751

Cong L, Jianqiang D, Yaoru L, Qiang Y, Hongfei D (2016) Experiment simulation of hydraulic fracture in colliery hard roof control. J Pet Sci Eng 138:265–271

Cui F, Dong S, Lai X, Chen J, Cao J, Shan P (2019) Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof. Energies 12:4780

Ding Z, Jia J, Li X, Li J, Li Y, Liao J (2020) Experimental study and application of medium-length hole blasting technique in coal-rock roadway. Energy Sci Eng 00:1–13

Liu Q, Chai J, Chen S, Zhang D, Yuan Q, Wang S (2020) Monitoring and correction of the stress in an anchor bolt based on Pulse Pre‐Pumped Brillouin Optical Time Domain Analysis. Energy Sci Eng 1–13

Ju W, Zheng J, Wei D, Sun L, Li W (2019) Study on the causes and control technology about the coal bump in multi-layered mining roadway in steep-thick coal seams. J Mining Saf Eng 36(2):280–289

Wojtecki Ł, Konicek P, Mendecki MJ, Gołda I, Zuberek WM (2019) Geophysical Evaluation of Effectiveness of Blasting for Roof Caving During Longwall Mining of Coal Seam. Pure Appl Geophys 177(2):905–917

Konicek P, Soucek K, Stas L, Singh R (2013) Long-hole destress blasting for rockburst control during deep underground coal mining. Int J Rock Mech Min Sci 61:141–153

Gao Y, Wang Y, Yang J, Zhang X, He M (2019) Meso- and macroeffects of roof split blasting on the stability of gateroad surroundings in an innovative nonpillar mining method. Tunn Undergr Space Technol 90:99–118

Saharan MR, Mitri H (2011) Destress blasting as a mines safety tool: some fundamental challenges for successful applications. Procedia Eng 26:37–47

Petr Konicek MRS (2011) Hani Mitri, "Destress blasting in coal mining – state-of-the-art review,". Procedia Eng Cp 6

He M, Zhang X, Zhao S (2017) Directional destress with tension blasting in coal mines. Procedia Eng 191:89–97

Lai X, Shan P, Cao J, Sun H, Suo Z, Cui F (2014) Hybrid assessment of pre-blasting weakening to horizontal section top coal caving (HSTCC) in steep and thick seams. Int J Min Sci Technol 24:31–37

Shan P, Lai X (2019) Mesoscopic structure PFC∼2D model of soil rock mixture based on digital image. J Vis Commun Image Represent 58:407–415

Shan P and Lai X (2020) "An associated evaluation methodology of initial stress level of coal-rock masses in steeply inclined coal seams, Urumchi coal field, China," Engineering Computations, vol. ahead-of-print, no. ahead-of-print

Yang J, Liu C, Yu B (2017) Application of confined blasting in water-filled deep holes to control strong rock pressure in hard rock mines. Energies 10:1874

Zhu WC , Gai D, Wei CH et al (2016) High-pressure air blasting experiments on concrete and implications for enhanced coal gas drainage[J]. J Nat Gas ence Eng 2016:1253-1263

Gao J, Wang H, Qin W, Ma Q, Yang G (2019) Experimental study on high-pressure air blasting fracture for coal and rock mass. Adv Civil Eng 2019:9613563

Huang B, Liu J, Zhang Q (2018) The reasonable breaking location of overhanging hard roof for directional hydraulic fracturing to control strong strata behaviors of gob-side entry. Int J Rock Mech Min Sci 103:1–11

Adachi J, Siebrits E, Peirce A, Desroches J (2007) Computer simulation of hydraulic fractures. Int J Rock Mech Min Sci 44(5):739–757

Lei Q, Latham J-P, Tsang C-F (2017) The use of discrete fracture networks for modelling coupled geomechanical and hydrological behaviour of fractured rocks. Comput Geotech 85:151–176

Yu B, Gao R, Kuang T, Huo B, Meng X (2019) Engineering study on fracturing high-level hard rock strata by ground hydraulic action. Tunn Undergr Space Technol 86:156–164

Osiptsov AA (2017) Fluid mechanics of hydraulic fracturing: a review. J Pet Sci Eng 156:513–535

Detournay E (2016) Mechanics of hydraulic fractures. Annu Rev Fluid Mech 48:311–339

Brady BHG, Brown ET (2007) Rock Mechanics for underground mining. Kluwer Academic Publishers, Rotterdam

Jiang Y, Zhao Y, Wang H, Zhu J (2017) A review of mechanism and prevention technologies of coal bumps in China. J Rock Mech Geotech Eng 9(1):180–194

Golik VI, Efremenkov AB (2017) Control of rock mechanics in underground ore mining. IOP Conf Series: Mater Sci Eng 221:012013

Wang SR, Wu XG, Zhao YH, Hagan P, Cao C (2019) Evolution characteristics of composite pressure-arch in thin bedrock of overlying strata during shallow coal mining. Int J Appl Mech 2019(03):1950030

Wang F, Xu J, Xie J (2019) Effects of arch structure in unconsolidated layers on fracture and failure of overlying strata. Int J Rock Mech Min Sci 114:141–152

Zhao Y, Wang S, Hagan P, Guo W (2018) Evolution characteristics of pressure-arch and elastic energy during shallow horizontal coal mining. Tehnicki vjesnik - Tech Gazette 25(3)

Wang S, Wu X, Zhao Y, Hagan P (2018) Mechanical performances of pressure arch in thick bedrock during shallow coal mining. Geofluids 2018:1–13

Zhao Y, Wang S, Hagan P, Ren L, Zou Z (2018) Pressure-arching characteristics in roof blocks during shallow coal mining. Adv Civil Eng 2018:1–12

Poulsen BA (2010) Coal pillar load calculation by pressure arch theory and near field extraction ratio. Int J Rock Mech Min Sci 47:1158–1165

Florence F (2013) A new direction in drilling. IEEE Instrum Meas Mag 43–46

Yan X, Ariaratnam ST, Dong S, Zeng C (2018) Horizontal directional drilling: State-of-the-art review of theory and applications. Tunn Undergr Space Technol 72(2018):162–173

Ge Z et al (2019) Directional distance prediction model of slotting–directional hydraulic fracturing (SDHF) for coalbed methane (CBM) extraction. J Pet Sci Eng 183:106429

Inyang IJ, Whidborne JF (2019) Bilinear modelling, control and stability of directional drilling. Control Eng Pract 82:161–172

Zhou F, Xia T, Wang X, Zhang Y, Sun Y, Liu J (2016) Recent developments in coal mine methane extraction and utilization in China: A review. J Nat Gas Sci Eng 31:437–458

Shi Z, Dong S, Yao N, and Tian D (2011) "The Underground directional drilling technology and equipments for kilometer deep borehole with MWD in coalmine," in 2011 Xi'an International Conference on Fine Geological Exploration and Groundwater & Gas Hazards Control in Coal Mines, xi'an China, 3, 17 – 22: Procedia Earth and Planetary Science.

Dong G, Chen P (2016) A review of the evaluation, control, and application technologies for drill string vibrations and shocks in oil and gas well. Shock Vib 2016:7418635

Saruev AL, Saruev LA, Vasenin SS (2016) Development of small diameter pilot hole directional drilling for trenchless utility installation. IOP Conf Series: Earth Environ Sci 43:012075

Haimson BC, Cornet FH (2003) ISRM Suggested methods for rock stress estimation—part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF). Int J Rock Mech Min Sci 40:1011–1020

Zhang D, Ranjith PG, Perera MSA (2016) The brittleness indices used in rock mechanics and their application in shale hydraulic fracturing: a review. J Pet Sci Eng 143:158–170

Barbati AC, Desroches J, Robisson A, McKinley GH (2016) Complex fluids and hydraulic fracturing. Annu Rev Chem Biomol Eng 7:415–453

Zhu H, Deng J, Jin X, Hu L, Luo B (2014) Hydraulic fracture initiation and propagation from wellbore with oriented perforation. Rock Mech Rock Eng 48(2):585–601

Davies RJ, Mathias SA, Moss J, Hustoft S, Newport L (2012) Hydraulic fractures: How far can they go? Mar Pet Geol 37:1–6

Yang TH, Tham LG, Tang CA, Liang ZZ, Tsui Y (2004) Influence of heterogeneity of mechanical properties on hydraulic fracturing in permeable rocks Rock Mech. Rock Engng 37(4): 251-275

Murdoch LC (2002) "Mechanical analysis of idealized shallow hydraulic fracture."J Geotech Geoenviron Eng 128(6): 488-495

Barati R, Liang J-T (2014) A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J Appl Polym Sci ID:40735

Bunger AP, Detournay E, Garagash DI (2005) Toughness-dominated Hydraulic Fracture with Leak-off. Int J Fract 134(2):175–190

Hyman JD et al (2016) Understanding hydraulic fracturing: a multi-scale problem. Philos Trans A Math Phys Eng Sci A 374:20150426

Wang Z, Xu C, Dowd P (2018) A modified cubic law for single-phase saturated laminar flow in rough rock fractures. Int J Rock Mech Min Sci 103:107–115

Xu C, Lin J, Wang Y, Shi Y, Yang J (2019) Influence of pump flow to fracture gauche of hydraulic fracturing with cutting along bore direction. Coal Mining Technol 24(1):11–15

Li H, Liu S, Cheng G, Guo C (2019) Numerical investigation on rock fracturing mechanism by using splitter under hole assistance. Shock Vib 2019:4395729

Lin J, Xu C, and Yang J (2020) Study on the influence of pump flow rate on the deflection of hydraulic fracturing cracks in longitudinal flume cutting."J China Coal Soc 45(8):2804-2812

Acknowledgments

The authors are grateful to Daliangwan coal mine for providing field testing.

Funding

This study was supported by the Tiandi Science and Technology Co., Ltd. Science and Technology Innovation Venture Capital Special Project, grant numbers “2019-TD-ZD008, KJ-2018-TDKCZL-05 and 2019-TD-ZD006”; State Key Program of National Natural Science of China “Grant No. 2017YFC0603003”; National Science Foundation for Distinguished Young Scholars of China “Grant No. 51704160 and 51704156.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, J., Ju, W., Sun, X. et al. Analysis of Hydro-fracturing Technique Using Ultra-deep Boreholes for Coal Mining with Hard Roofs: a Case Study. Mining, Metallurgy & Exploration 38, 471–484 (2021). https://doi.org/10.1007/s42461-020-00334-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00334-2