Abstract

The brazed plate heat exchanger (BPHE) has some advantages over the plate-fin heat exchanger (PFHE) when used in natural gas liquefaction processes, such as the convenient installation and transportation, as well as the high tolerance of carbon dioxide (CO2) impurities. However, the BPHEs with only two channels cannot be applied directly in the conventional liquefaction processes which are designed for multi-stream heat exchangers. Therefore, the liquefaction processes using BPHEs are different from the conventional PFHE processes. In this paper, four different liquefaction processes using BPHEs are optimized and comprehensively compared under respective optimal conditions. The processes are compared with respect to energy consumption, economic performance, and robustness. The genetic algorithm (GA) is applied as the optimization method and the total revenue requirement (TRR) method is adopted in the economic analysis. The results show that the modified single mixed refrigerant (MSMR) process with part of the refrigerant flowing back to the compressor at low temperatures has the lowest specific energy consumption but the worst robustness of the four processes. The MSMR with fully utilization of cold capacity of the refrigerant shows a satisfying robustness and the best economic performance. The research in this paper is helpful for the application of BPHEs in natural gas liquefaction processes.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer area/m2

- C e :

-

Constant cost of electricity consumption/($·(kW·h)−1)

- h :

-

Mass enthalpy/(kJ·kg−1)

- m :

-

Flowrate/(N·m3·d−1)

- P :

-

Pressure/kPa

- T :

-

Temperature/K

- U :

-

Total heat transfer coefficient/(kW·(K·m2)−1)

- W :

-

Power/kW

- τ :

-

Annual time of operation/h

- BL:

-

Book life

- BOG:

-

Boil-off gas

- BPHE:

-

Brazed plate heat exchanger

- CFD:

-

Computational fluid dynamics

- CH4 :

-

Methane

- C2H4 :

-

Ethylene

- C2H6 :

-

Ethane

- C3H6 :

-

Propylene

- C3H8 :

-

Propane

- CO2 :

-

Carbon dioxide

- COP:

-

Coefficient of performance

- CRF:

-

Capital recovery factor

- DMR:

-

Dual mixed refrigerant

- FC:

-

Fuel cost

- FEM:

-

Finite element method

- GA:

-

Genetic algorithm

- i-C4H10 :

-

Iso-butane

- LNG:

-

Liquefied natural gas

- MR:

-

Mixed refrigerant

- MRC:

-

Mixed refrigerant cycle

- MSMR:

-

Modified single mixed refrigerant

- N2 :

-

Nitrogen

- NGL:

-

Natural gas liquid

- OMC:

-

Operation and maintenance costs

- PEC:

-

Purchased equipment cost

- PFHE:

-

Plate-fin heat exchanger

- PNEC:

-

Parallel nitrogen expansion cycle

- PRICO:

-

Poly refrigerant integrated cycle operations

- ROI:

-

Return on investment

- SEC:

-

Specific energy consumption

- SMR:

-

Single mixed refrigerant

- TCR:

-

Total capital recovery

- TRR:

-

Total revenue requirement

References

He T, Karimi I A, Ju Y. Review on the design and optimization of natural gas liquefaction processes for onshore and offshore applications. Chemical Engineering Research & Design, 2018, 132: 89–114

He T, Chong Z R, Zheng J, Ju Y, Linga P. LNG cold energy utilization: prospects and challenges. Energy, 2019, 170: 557–568

Kim D, Hwang C, Gundersen T, Lim Y. Process design and economic optimization of boil-off-gas re-liquefaction systems for LNG carriers. Energy, 2019, 173: 1119–1129

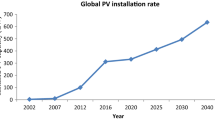

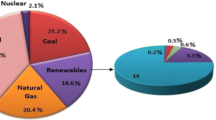

Waldrup S P. 2018 Outlook for energy: a view to 2040. ExxonMobil, 2018

Nguyen T V, Rothuizen E D, Markussen W B, Elmegaard B. Thermodynamic comparison of three small-scale gas liquefaction systems. Applied Thermal Engineering, 2018, 128: 712–724

Khan M S, Lee M. Design optimization of single mixed refrigerant natural gas liquefaction process using the particle swarm paradigm with nonlinear constraints. Energy, 2013, 49: 146–155

He T B, Liu Z M, Ju Y L, Parvez A M. A comprehensive optimization and comparison of modified single mixed refrigerant and parallel nitrogen expansion liquefaction process for small-scale mobile LNG plant. Energy, 2019, 167: 1–12

Mehrpooya M, Ansarinasab H. Exergoeconomic evaluation of single mixed refrigerant natural gas liquefaction processes. Energy Conversion and Management, 2015, 99: 400–413

Qyyum M A, Ali W, Long N V D, Khan M S, Lee M. Energy efficiency enhancement of a single mixed refrigerant LNG process using a novel hydraulic turbine. Energy, 2018, 144: 968–976

Tan H B, Shan S Y, Nie Y, Zhao Q X. A new boil-off gas re-liquefaction system for LNG carriers based on dual mixed refrigerant cycle. Cryogenics, 2018, 92: 84–92

Cao L, Liu J P, Xu X W. Robustness analysis of the mixed refrigerant composition employed in the single mixed refrigerant (SMR) liquefied natural gas (LNG) process. Applied Thermal Engineering, 2016, 93: 1155–1163

Hwang J H, Ku N K, Roh M I, Lee K Y. Optimal design of liquefaction cycles of liquefied natural gas floating, production, storage, and offloading unit considering optimal synthesis. Industrial & Engineering Chemistry Research, 2013, 52(15): 5341–5356

Hwang J H, Roh M I, Lee K Y. Determination of the optimal operating conditions of the dual mixed refrigerant cycle for the LNG FPSO topside liquefaction process. Computers & Chemical Engineering, 2013, 49: 25–36

Xiong X, Lin W, Gu A. Design and optimization of offshore natural gas liquefaction processes adopting PLNG (pressurized liquefied natural gas) technology. Journal of Natural Gas Science and Engineering, 2016, 30: 379–387

de Mello P E B, Villanueva H H S, Scuotto S, Donato G H B, Ortega F D. Heat transfer, pressure drop and structural analysis of a finned plate ceramic heat exchanger. Energy, 2017, 120: 597–607

Wang Z, Li Y Z. A combined method for surface selection and layer pattern optimization of a multistream plate-fin heat exchanger. Applied Energy, 2016, 165: 815–827

Ma H, Hou C, Yang R, Li C, Ma B, Ren J, Liu Y. The influence of structure parameters on stress of plate-fin structures in LNG heat exchanger. Journal of Natural Gas Science and Engineering, 2016, 34: 85–99

Zhan Y, Wang J, Wang W, Wang R S. Dynamic simulation of a single nitrogen expansion cycle for natural gas liquefaction under refrigerant inventory operation. Applied Thermal Engineering, 2018, 128: 747–761

Sun H, Hu H, Ding G, Chen H, Zhang Z, Wu C, Wang L. A general distributed-parameter model for thermal performance of cold box with parallel plate-fin heat exchangers based on graph theory. Applied Thermal Engineering, 2019, 148: 478–490

Berstad D, Nekså P, Anantharaman R. Low-temperature CO2 removal from natural gas. Energy Procedia, 2012, 26: 41–48

Wu J T, He T B, Ju Y L. Experimental study on CO2 frosting and clogging in a brazed plate heat exchanger for natural gas liquefaction process. Cryogenics, 2018, 91: 128–135

Wu J T, Ju Y L. Design and optimization of natural gas liquefaction process using brazed plate heat exchangers based on the modified single mixed refrigerant process. Energy, 2019, 186: 115819

Aslambakhsh A H, Moosavian M A, Amidpour M, Hosseini M, AmirAfshar S. Global cost optimization of a mini-scale liquefied natural gas plant. Energy, 2018, 148: 1191–1200

Lee W, An J, Lee J M, Lim Y. Design of single mixed refrigerant natural gas liquefaction process considering load variation. Chemical Engineering Research & Design, 2018, 139: 89–103

Watson H A J, Vikse M, Gundersen T, Barton P I. Optimization of single mixed-refrigerant natural gas liquefaction processes described by nondifferentiable models. Energy, 2018, 150: 860–876

He T B, Ju Y L. Design and optimization of a novel mixed refrigerant cycle integrated with NGL recovery process for small-scale LNG plant. Industrial & Engineering Chemistry Research, 2014, 53(13): 5545–5553

Pham T N, Khan M S, Minh L Q, Husmil Y A, Bahadori A, Lee S, Lee M. Optimization of modified single mixed refrigerant process of natural gas liquefaction using multivariate Coggin’s algorithm combined with process knowledge. Journal of Natural Gas Science and Engineering, 2016, 33: 731–741

Nekså P, Brendeng E, Drescher M, Norberg B. Development and analysis of a natural gas reliquefaction plant for small gas carriers. Journal of Natural Gas Science and Engineering, 2010, 2(2–3): 143–149

Holland J H. Adaptation in Natural and Artificial Systems: an Introductory Analysis with Applications to Biology, Control and Artificial Intelligence. Cambridge: MIT Press, 1992

Technical Assessment Guide (TAGTM). TR-100281 Revision 6 Palo Alto Electric Power Research Institute. CA (Edinburgh), 1993

Bejan A TG, Moran M. Thermal Design and Optimization. New York: Wiley, 1996

Ghorbani B, Mehrpooya M, Hamedi M H, Amidpour M. Exergoeconomic analysis of integrated natural gas liquids (NGL) and liquefied natural gas (LNG) processes. Applied Thermal Engineering, 2017, 113: 1483–1495

Couper J R, Penney W R, Fair J R. Chemical Process Equipment: Selection and Design. Oxford: Butterworth-Heinemann, 2010

Towler Gavin R K S. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design. London: Elsevier, 2012

Khan T S, Khan M S, Chyu M C, Ayub Z H. Experimental investigation of single phase convective heat transfer coefficient in a corrugated plate heat exchanger for multiple plate configurations. Applied Thermal Engineering, 2010, 30(8–9): 1058–1065

Khan T S, Khan M S, Chyu M C, Ayub Z H. Experimental investigation of evaporation heat transfer and pressure drop of ammonia in a 60° Chevron plate heat exchanger. International Journal of Refrigeration, 2012, 35(2): 336–348

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, J., Ju, Y. Comprehensive comparison of small-scale natural gas liquefaction processes using brazed plate heat exchangers. Front. Energy 14, 683–698 (2020). https://doi.org/10.1007/s11708-020-0705-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-020-0705-0