Plasma arc coatings produced from powder-cored wires developed at the Paton Electric Welding Institute that were deposited onto a low-carbon steel substrate were characterized. Interaction between the steel sheath (constituting at least 80 wt.% of the wire) and powder cores, such as B4C, B4C + ZrO2(nano), B4C + (Cr, Fe)7C3, and B4C + (Cr, Fe)7C3 + Al, in the arc plasma spraying process was analyzed. The resultant coatings were free of defects and had low porosity (to 2.5%) and lamellar structure. The core carbide components were found to dope the coating ferritic matrix and strengthen it with carbide, carboboride, and boride precipitates. An addition of 0.5% ZrO2 nanopowder refined the coating structure and participated in the formation of Fe2B and Fe3B precipitates. An aluminum addition within 10 wt.% did not led to iron aluminides but, being easily melted, activated the interaction between components, reduced porosity, and improved adhesion strength of the coatings. The coatings reached a microhardness of 6.25–8.59 GPa, being 4 to 5.5 times higher than the microhardness of the steel wire sheath. The development and use of such powder-cored wires expanded the application of plasma arc spraying, particularly for the protection of equipment against abrasive gas wear in chemical engineering, in the production of parts for pumps, compressors, and other components, and for the recovery of worn parts.

Similar content being viewed by others

References

B. Wielage, C. Rupprecht, and A. Pokhmurska, “Features of thermal spray deposition of powder-cored wire coatings (Overview),” Avtomat. Svarka, No. 10, 26–30 (2011).

M.Yu. Kharlamov, I.V. Krivtsun, V.N. Korzhyk, S.V. Petrov, and A.I. Demianov, “Mathematical model of arc plasma generated by a plasma spray gun with a wire anode,” Avtomat. Svarka, No. 12, 15–20 (2007).

M.Yu. Kharlamov, I.V. Krivtsun, V.N. Korzhyk, and S.V. Petrov, “Heating and melting of an anode wire in plasma arc spraying,” Avtomat. Svarka, No. 5, 5–11 (2011).

B. Wielage, C. Rupprecht, and M. Bruhl, “Thermal spraying—potentials, developments, markets,” Thermal Spray Bulletin 1, DVS Verlag (2008), pp. 30–36.

S.V. Petrov and I.N. Karp, Plasma Gas Air Spraying [in Russian], Naukova Dumka, Kyiv (1993).

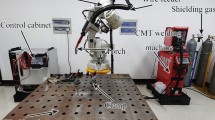

V.N. Korzhyk and M.F. Korob, “Automated PLAZER 30PL-W line for plasma arc wire spraying of coatings,” Svarshchyk, No. 4(86), 13–16 (2012).

M.Yu. Kharlamov, I.V. Krivtsun, V.N. Korzhyk, and S.V. Petrov, “Generation of a liquid metal film at the top of a wire anode in plasma arc spraying,” Avtomat. Svarka, No. 2, 3–8 (2011).

Yu.S. Borisov, I.A. Koziakov, and V.N. Korzhyk, “Structure and properties of thermal spraying coatings deposited with powder-cored wires in the Fe–Cr–B and Fe–Cr–B–C systems,” Avtomat. Svarka, No. 5, 21–24 (1996).

V.I. Pokhmurski, M.M. Student, V.M. Gvozdetski, and A.V. Pokhmurska, “Powder-cored FMI wires for electric arc spraying of coatings (Overview),” Avtomat. Svarka, No. 9, 52–57 (2011).

A.D. Korotaev, V.Yu. Moshkov, S.V. Ovchinnikov, Yu.P. Pinzhin, V.M. Savostikov, and A.N. Tyumentsev, “Nanostructured and nanocomposite superhard coatings,” Fiz. Mezomech., 8, No. 5, 103–116 (2005).

L.N. Belyanchikov, “Current nanomaterials and nanotechnology—key to technical progress,” Izv. Vyssh. Uczeb. Zav. Chern. Metall., No. 11, 39–47 (2002).

G.M. Grigorenko, V.N. Korzhyk, A.A. Chaika, L.I. Adeeva, and A.Yu. Tunik, “Structural features and properties of supersonic plasma arc coatings reinforced by hardening particles produced from wires with WC and WC + NbC powder cores,” Tekhnol. Syst., No. 2, 26–36 (2016).

G.M. Grigorenko, L.O. Adeeva, and A.Yu. Tunik, “Features of metallurgical processes in plasma arc spraying of coatings produced from a steel wire with WC and WC–Co powder cores,” Sovr. Elektrometall., No. 4, 14–24 (2015).

G.M. Grigorenko, L.I. Adeeva, and A.Yu. Tunik, “Structural features of plasma arc coatings produced from powder-cored wires with steel sheaths and refractory precipitates,” Avtomat. Svarka, No. 9, 27–32 (2017).

G.M. Grigorenko, L.I. Adeeva, A.Yu. Tunik, V.N. Korzhyk, L.K. Doroshenko, Ye.P. Titkov, and A.A. Chaika, “Structurization of coatings in the plasma arc spraying process using B4C + (Cr, Fe)7C3-cored wires,” Powder Metall. Met. Ceram., 58, No. 5–6, 312–322 (2019).

A.D. Panasyuk, V.S. Fomenko, and G.G. Glebova, Stability of Nonmetallic Materials in Melts: Handbook [in Russian], Naukova Dumka, Kyiv (1986), p. 352.

V.I. Trefilov (ed.), T.I. Serebriakova, V.A. Neronov, and P.D. Peshev, High-Temperature Borides [in Russian], Metallurgiya, Moscow (1991), p. 367.

G.M. Grigorenko, A.L. Borisova, Yu.S. Borisov, L.I. Adeeva, L.K. Doroshenko, and V.L. Rupchev, “Study of phase interaction between ferrotitanium and boron carbide in powder mixtures for thermal spray coatings,” Sovr. Elektrometall., No. 1, 28–31 (2003).

V.G. Samsonov and I.M. Vinnitski, Refractory Compounds: Handbook [in Russian], Metallurgiya, Moscow (1976), p. 560.

E. Gudremon, Special Steels [in Russian], Metallurgiya, Moscow (1966), p. 1274.

A.L. Borisova, L.I. Adeeva, A.Yu. Tunik, A.P. Gryshchenko, T.V. Tsymbalistaya, and M.V. Kolomytsev, “Multilayer thermal barrier plasma spray ZrO2–NiCrAlY coatings,” Avtomat. Svarka, No. 10, 29–36 (2010).

A.L. Borisova, L.I. Adeeva, A.Yu. Tunik, T.V. Tsymbalistaya, and A.P. Gryshchenko, “Plasma spray ZrO2 coatings produced using the Al–Cu–Fe alloy as a metallic sublayer,” Avtomat. Svarka, No. 4, 32–36 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

G.M. Grigorenko is deceased

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 5–6 (533), pp. 107–121, 2020.

Rights and permissions

About this article

Cite this article

Grigorenko, G., Adeeva, L., Tunik, A. et al. Plasma Arc Coatings Produced from Powder-Cored Wires with Steel Sheaths. Powder Metall Met Ceram 59, 318–329 (2020). https://doi.org/10.1007/s11106-020-00165-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00165-2