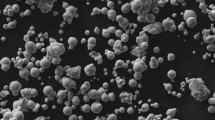

The hand forging of cylindrical powder pellets of small weight (8.0–8.5 g), pressed at 700 MPa from mixtures of iron and graphite powders, was studied. The pre-sintered pellets were heated in charcoal at 1100°C and subjected to double-ended face forging on a heated flat anvil with a hammer with a flat striker and naturally cooled on a steel plate. The vertical setting of the forged pellets was 70-80%. The pellets were cut into samples for analysis. The influence of the graphite content on the compaction process and the mechanical properties of powder materials during hot free face forging have been established. The improvement in the properties of materials with a high graphite content (4 and 12%) was shown to be due to an increase in the number of sections for hot welding of iron grains. It is associated with shear deformation of the pellet material during free forging, contributing to the emergence of new iron–iron contacts. The high characteristics of materials containing 1.7% graphite are due to the action of several mechanisms in parallel: the dissolution of carbon in iron, decrease in total porosity, elimination of interparticle gaps, and grain refinement under shear deformation. The use of a steel shell makes it possible to significantly expand the range of powders and powder composites without rupture of the pellets in hot forging. The combination of experimental results and analytical data allowed us to conclude that hand forging was promising for a quick and cheap screening of formulations for dense powder materials.

Similar content being viewed by others

References

Forging and Stamping: Handbook, in 4 Vols., E.I. Semenov, O.A. Ganago, and L.I. Zhyvov (Eds.), Vol. 1: Materials and Heating. Equipment. Forging [in Russian], Mashynostroenie, Moscow (1985), p. 568.

Z.I. Yusipov and N.I. Lyapunov, Hand Forging [in Russian], Vysh. shk., Moscow (1990), p. 304.

K. Agte and I. Vacek, Wolfram and Molybdenum [in Russian], Energia, Moscow–Leningrad (1964), p. 456.

Manufacture of Refractory Metal Products, N.I. Korneev and B.G. Arabeya (Eds.) [Russian translation], Mir, Moscow (1968), p. 434.

A.P. Kolikov, A.V. Krupin, P.I. Polukhin, I.N. Potapov, M.A. Bondarev, and V.M. Izotov, Technology and Equipment for Processing Refractory Powders and Composite Materials [in Russian], Metallurgiya, Moscow (1989), p. 384.

G.H. Gessinger, Powder Metallurgy of Superalloys, Elsevier (1984), p. 362; https://doi.org/10.1016/C2013-0-06291-3.

L.A. Sosnovsky, G.A. Baglyuk, and O.V. Vlasova, “Sintering in incompletely sealed containers without gas flows,” Powder Metall. Met. Ceram., 52, No. 1–2, 102–108 (2013).

L.G. Voroshnin, L.S. Lyakhovich, F.G. Lovshenko, and G.F. Protasevich, Chemical-Thermal Processing of Metal-Ceramic Materials [in Russian], Nauka i Tekhnika, Moscow (1977), p. 272.

I.M. Fedorchenko, I.N. Frantsevich, I.D. Radomyselsky, M.S. Kovalchenko, P.S. Kisly, T.Ya. Kosolapova, V.K. Mai, and N.I. Shcherban, Powder Metallurgy. Materials, Technology, Properties, Fields of Application: Handbook [in Russian], Naukova Dumka, Kyiv (1985), p. 624.

A.T. Mamedov and V.A. Mamedov, “Properties of Highly-Dense Iron-Base Powder Metallurgy Materials Pressed without Zinc Stearate,” Powder Metal. Met. Ceram., 42, 5–6, 245–248 (2003).

A.V. Minitsky, L.A. Sosnovsky, and P.I. Loboda, “Recompacting of pellets from iron powder based mixtures,” Naukovi Notatky (Lutsk), Issue 54, 220–225 (2016).

Yu.N. Podrezov, D.G. Verbilo, and Ya.I. Yevich, “Role of Shear Deformations in Consolidation of Powder Materials,” Phys. Tekhn. Vysokikh Davlenii, 24, Issue 1, 98−109 (2014).

S.R. Ignatovich and I.M. Zakiev, “Universal Micron-gamma micro-indentometer,” Zavod. Lab. Diagnost. Mater., 77, Issue 1, 61–67 (2011).

Acknowledgements

The authors would like to thank L.A. Sosnovsky for his help in conducting the research and discussing the results.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 5–6 (533), pp. 68–75, 2020.

Rights and permissions

About this article

Cite this article

Minitsky, A.V., Loboda, P.I., Yevych, Y.I. et al. Hot Free Forging of Iron-Based Powder Pellets. Powder Metall Met Ceram 59, 290–295 (2020). https://doi.org/10.1007/s11106-020-00161-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00161-6