Abstract

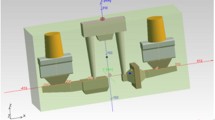

The efficiency of removal of solid alumina inclusions by filtration and the distribution of inclusions captured through the thickness of the filter was investigated for an aluminum killed 316 stainless steel casting. A mold design was developed using modeling software to produce two castings that fill simultaneously, one with a filter and the other without a filter. The design was optimized to produce the filtered casting and unfiltered casting from a single ladle pour, while also matching the fill rates and avoiding turbulence and reoxidation during pouring. Samples from the filters and the castings were analyzed using an SEM with EDS and automated feature analysis to measure the efficiency of inclusion removal for a 10 ppi zirconia foam filter. Results showed that inclusion removal efficiency depends strongly on the initial inclusion concentration and that the alumina inclusions are captured within the filter at the filter web-steel interface. This study also documented that inclusion floatation inside the mold cavity plays a role in reducing the inclusion concentration in the casting. The distribution of alumina inclusions captured through the filter thickness was quantified using elemental mapping and the inclusion distribution was found to decrease exponentially, following first-order capture kinetics.

Similar content being viewed by others

References

W. Simmons, Influence of metal filtration on the production of high integrity cast products, Foundry Trade J, p. 24 (1985)

D. Apelian, R. Mutharasan, S. Ali, Removal of inclusions from steel melts by filtration. J. Mater. Sci. 20, 3501 (1985)

K. Janiszewski, Z. Kudlinski, The influence of non-metallic inclusions physical state on effectiveness of the steel filtration process. Steel Res. Int. 77(3), 169 (2006)

K. Raiber, P. Hammerschmid, D. Janke, Experimental studies on Al2O3 inclusions removal from steel melts using ceramic filters. ISIJ Int. 35(4), 380 (1995)

L. Aubrey, J. Brockmeyer, P. Wieser, I. Dutta, A. Ilhan, Cast steel quality improvement by filtration with ceramic foam filters. AFS Trans. 93, 177 (1985)

L. Aubrey, J. Schmahl, M. Cummings, Application of advanced reticulated ceramic foam filter technology to produce clean steel castings. AFS Trans. 101, 59 (1993)

J. Stamper, Filtration of steel castings with ceramic foam filters. AFS Trans. 93, 867 (1985)

W. Su, T. Johnson, J. Day, J. Wallace, F. Li, The development and characterization of extruded cellular-ceramic filters for steel foundry applications. AFS Trans. 96, 161 (1988)

T. Johnson, H. Kind, J. Wallace, C. Nieh, H. Kim, Laboratory and foundry performance characterization of extruded cellular ceramic filters for steel foundry applications. AFS Trans. 97, 879 (1989)

S. Ali, R. Mutharasan, D. Apelian, Physical refining of steel melts by filtration. Metall. Trans. B 16B, 725 (1985)

C. Tian, On the removal of non-metallic inclusions from molten steel through filtration, PhD Thesis, McGill University (1990)

K. Janiszewski, Influence of slenderness ratios of a multi-hole ceramic filters at the effectiveness of process of filtration of non-metallic inclusions from liquid steel. Arch. Metall. Mater. 57(1), 135 (2012)

D. Apelian, R. Mutharasan, Filtration: a melt refining method. J. Metals, p. 14 (1980)

MAGMASOFT® 5.3.1: https://www.magmasoft.com/en/

S. Chakraborty, R. O’Malley, L. Bartlett, M. Xu, Efficiency of solid inclusion removal from the steel melt by ceramic foam filter: design and experimental validation. AFS Trans. 126, 325 (2018)

S. Chakraborty, R. O’Malley, L. Bartlett, L. Huddleston, Effect of physical state of non-metallic inclusions on the accumulation within magnesia stabilized zirconia foam filters, in Proceedings of the Iron & Steel Technology Conference, (Pittsburgh, PA, USA, 2019), p. 1029

J. Campbell, Complete Casting Handbook (Elsevier Ltd., Oxford, 2011)

S. Majidi, C. Beckermann, Effect of pouring conditions and gating system design on air entrainment during mold filling. Int. J. Metalcast. 13, 255–272 (2019). https://doi.org/10.1007/s40962-018-0272-x

K. Metzloff, K. Mageza, D. Sekotlong, Velocity measurement and verification with modeling of naturally pressurized gating systems. Int. J. Metalcast. 14, 610–621 (2020). https://doi.org/10.1007/s40962-020-00471-w

FactSage™ 7.2: www.factsage.com

M. Heidarzadeh, H. Keshmiri, Influence of mould and insulation design on soundness of tool steel ingot by numerical simulation. J. Iron. Steel Res. Int. 20(7), 78 (2013)

K. Carlson, C. Beckermann, Use of the niyama criterion to predict shrinkage-related leaks in high-nickel steel and nickel-based alloy castings, in Proceedings of the 62nd SFSA Technical and Operating Conference, Chicago, IL, USA (2008)

M. Kang, H. Gao, J. Wang, L. Ling, B. Sun, Prediction of microporosity in complex thin-wall castings with the dimensionless niyama criterion. Materials 6, 1789 (2013)

K. Carlson, S. Ou, R. Hardin, C. Beckermann, Development of a methodology to predict and prevent leaks caused by microporosity in steel castings, in Proceedings of the 55th SFSA Technical and Operating Conference, Chicago, IL, USA (2001)

E. Underwood, Quantitative Stereology (Addison-Wesley Publ. Co., Massachusetts, 1970)

Acknowledgements

The authors wish to gratefully acknowledge the support and guidance from the industry mentoring committee of Peaslee Steel Manufacturing Research Center. Special thanks go to MetalTek International and Foseco for their donation of materials to carry out these experiments. The authors would also like to greatly acknowledge Dr. Von Richards, Dr. Jeffrey Smith and Dr. Simon Lekakh for their technical support, and Logan Huddleston for helping with sample preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chakraborty, S., O’Malley, R.J., Bartlett, L. et al. Removal of Alumina Inclusions from Molten Steel by Ceramic Foam Filtration. Inter Metalcast 15, 1006–1020 (2021). https://doi.org/10.1007/s40962-020-00537-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00537-9