Abstract

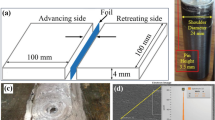

The present study demonstrates the friction stir welding (FSW) process can be used as a mechanical alloying tool to fabricate a solid solution. An attempt has been taken for alloying the AM20 Mg base matrix using Zn at the weld zone during friction stir welding. Successful joints with sound mechanical properties and enhanced quality attributes are observed in the welds. Use of Zn alloying element at the nugget zone, the joint efficiency reached 90% to that of the base material and also which is about 25% more than the strength obtained in the case of without alloying element set of experiments. The addition of Zn alloy to Mg substrate forms Mg–Zn binary solid solution reinforcing intermetallic compounds, namely MgZn and Mg7Zn3 resulting in improved joint properties. This research work also reports the investigative outcomes, namely flow in the joint area, metallurgical deviation, microstructural modification, and diffusion of the constituent alloying element during the welding process. The targeted objective was effectively accomplished and the Zn alloyed stir area can fulfil the required application. The findings from the selective alloying process may be relevant for the implementation of industrial users over Mg alloys using a FSW process with better weldability and improved strength.

Similar content being viewed by others

References

Schneider C, Weinberger T, Inoue J, et al. Characterisation of interface of steel/magnesium FSW. Sci Technol Weld Join. 2011;16:100–6.

Cam G, Ipekoglu G, Serindag HT. Effects of use of higher strength interlayer and external cooling on properties of friction stir welded AA6061-T6 joints. Sci Technol Weld Join. 2014;19:715–20.

Xu RZ, Ni DR, Yang Q, et al. Influence of Zn coating on friction stir spot welded magnesium-aluminium joint. Sci Technol Weld Join. 2016;22:512–9.

Peng L, Yajiang L, Haoran G, Juan W. A study of phase constitution near the interface of Mg/Al vacuum diffusion bonding. Mater Lett. 2005;59:2001–5.

Sahu PK, Pal S. Multi-response optimization of process parameters in friction stir welded AM20 magnesium alloy by Taguchi grey relational analysis. J Magnes Alloys. 2015;3:36–46.

Shiri SG, Sarani A, Hosseini SRE, et al. Diffusion in FSW joints by inserting the metallic foils. J Mater Sci Technol. 2013;29(11):1091–5.

Mishra RS, Ma ZY. Friction stir welding and processing. Mater Sci Eng R. 2005;50:1–78.

Afrin N, Chen DL, Cao X, et al. Microstructure and tensile properties of friction stir welded AZ31B magnesium alloy. Mater Sci Eng A. 2008;472:179–86.

Lim S, Kim S, Lee C, et al. Tensile behavior of friction stir-welded AZ31-H24 Mg alloy. Metall Mater Trans A. 2005;36:1609–12.

Karthik GM, Janaki Ram GD, Kottada RS. Friction stir selective alloying. Mater Sci Eng A. 2017;684:186–90.

Sirong Y, Xianjun C, Zhiqiu H, et al. Microstructure and mechanical properties of friction stir welding of AZ31B magnesium alloy added with cerium. J Rare Earths. 2010;28(2):316–20.

Chang WS, Rajesh SR, Chun CK, et al. Microstructure and mechanical properties of hybrid laser-friction stir welding between AA6061-T6 Al alloy and AZ31 Mg alloy. J Mater Sci Technol. 2011;27(3):199–204.

Ratanathavorn W, Melander A. Influence of zinc on intermetallic compounds formed in friction stir welding of AA5754 aluminium alloy to galvanised ultra-high strength steel. Sci Technol Weld Join. 2017;22:673–80.

Niu S, Ji S, Yan D, Meng X, Xiong X. AZ31B/7075-T6 alloys friction stir lap welding with a zinc interlayer. J Mater Process Tech. 2019;263:82–90.

Ji S, Niu S, Liu J, Meng X. Friction stir lap welding of Al to Mg assisted by ultrasound and a Zn interlayer. J Mater Process Tech. 2019;267:141–51.

Sahu PK, Pal S. Effect of FSW parameters on microstructure and mechanical properties of AM20 welds. Mater Manuf Process. 2018;33:288–98.

Zhang G, Su W, Zhang J, Wei Z. Friction stir brazing: a novel process for fabricating Al/steel layered composite and for dissimilar joining of Al to steel. Metall Mater Trans A. 2011;42A:2850–61.

ASM Handbook-Alloy Phase Diagrams, Vol. 3. ASM International. 1992.

Chen GQ, Li H, Wang GQ, Guo ZQ, Zhang S, Dai QL, Wang XB, Zhang G, Shi QY. Effects of pin thread on the in-process material flow behaviour during friction stir welding: a computational fluid dynamics study. Int J Mach Tools Manuf. 2018;124:12–21.

Sahu PK, Pal S, Pal SK, et al. Influence of plate position, tool offset and tool rotational speed on mechanical properties and microstructures of dissimilar Al/Cu friction stir welding joints. J Mater Process Technol. 2016;235:55–67.

Sahu PK, Pal S, Pal SK. Al/Cu dissimilar friction stir welding with Ni, Ti, and Zn foil as the interlayer for flow control, enhancing mechanical and metallurgical properties. Metall Mater Trans A. 2017;48A:3300–17.

Zareian Z, Emamy M, Malekan M, Mirzadeh H, Kim WJ, Bahmani A. Tailoring the mechanical properties of Mg–Zn magnesium alloy by calcium addition and hot extrusion process. Mater Sci Eng A. 2020;774:138929.

Golrang M, Mobasheri M, Mirzadeh H, Emamy M. Effect of Zn addition on the microstructure and mechanical properties of Mg-0.5Ca-0.5RE magnesium alloy. J Alloys Compd. 2020;815:152380.

Xu RZ, Ni DR, Yang Q, Liu CZ, Ma ZY. Pinless friction stir spot welding of Mg-3Al-1Zn alloy with Zn interlayer. J Mater Sci Technol. 2016;32:76–88.

Sahu PK, Vasudevan NP, Das B, Pal S. Assessment of self-reacting bobbin tool friction stir welding for joining AZ31 magnesium alloy at inert gas environment. J Magnes Alloys. 2019;7:661–71.

Md S, Birru AK. Mechanical and metallurgical properties of friction stir welded dissimilar joints of AZ91 magnesium alloy and AA 6082–T6 aluminium alloy. J Magnes Alloys. 2019;7:264–71.

Kurzynowski T, Pawlak A, Smolina I. The potential of SLM technology for processing magnesium alloys in aerospace industry. Arch Civ Mech Eng. 2020;20:23.

Heidarzadeh A, Paidar M, Guleryuz G, Barenji RV. Application of nano-indentation to evaluate the hardness and yield strength of brass joints produced by FSW: microstructural and strengthening mechanisms. Arch Civ Mech Eng. 2020;20:41.

Sun K, Shi QY, Sun YJ, Chen GQ. Microstructure and mechanical property of nano-sicp reinforced high strength Mg bulk composites produced by friction stir processing. Mater Sci Eng A. 2012;547:32–7.

Acknowledgements

This work is done at the Indian Institute of Technology Guwahati, Mechanical Engineering Department as well as Central Instruments Facility, provided experimentation and testing.

Funding

This research article not funded from any sources.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This research work follow all the ethical responsibility instructed from the journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Rights and permissions

About this article

Cite this article

Sahu, P.K., Pal, S., Das, B. et al. Fabrication and effect of Mg–Zn solid solution via Zn foil interlayer alloying in FSW process of magnesium alloy. Archiv.Civ.Mech.Eng 20, 137 (2020). https://doi.org/10.1007/s43452-020-00141-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00141-y