Abstract

The use of iron ore–coal composite pellet as a raw material for iron making is an ongoing area of research. Investigations on composite pellet reduction have reported some interesting phenomena, and experimental and modeling results, in which consistent and inconsistent conclusions have been presented in the literature. The aim of this review is to summarize the fundamentals of reduction kinetics of iron ore–coal composite pellet and the effect of various process parameters such as compositions, particle size, pellet geometry, ambient atmosphere and its partial pressure, heating conditions, and compaction pressure, etc., on it. The industrial application of composite pellet is also discussed. This article will be useful for the researchers carrying out experimental as well as modeling work related to the iron oxide–carbon composite pellet reduction.

Graphical Abstract

Similar content being viewed by others

References

Biswas AK (1981) Principles of blast furnace ironmaking. SBA Publications, Calcutta

Sahoo S, Sarkar S et al (2019) Role of scrap recycling for CO2 emission reduction in steel plant: a model based approach. Steel Res Int 90:1–11

Halder S, Fruehan RJ (2008) Reduction of iron-oxide-carbon composites: part II. Rates of reduction of composite pellets in a rotary hearth furnace simulator. Metall Mater Trans 39B:796–808

Dutta SK, Ghosh A (1994) Study of non-isothermal reduction of iron ore-coal/char composite pellet. Metall Mater Trans 25B:15–26

Kasai A, Matsui Y (2004) Lowering thermal reserve zone temperature in blast furnace by adjoining carbonaceous material and iron ore. ISIJ Int 44(12):2073–2078

Donskoi E, Mcelwain DLS, Wibberley LJ (2003) Estimation and modeling parameters for direct reduction in iron ore/coal composites: part II. Kinetic parameters. Metall Mater Trans 34B:255–266

Pal S, Lahiri AK (2003) Mathematical model of COREX melter gasifier: part I. steady-state model. Metall Mater Trans 34B:103–114

Michishita H, Tanaka H (2010) Prospects for coal-based direct reduction process. Kobelco Technol Rev 29:69–76

Otsuka K, Kunii D (1967) Reduction of powdery ferric oxide mixed with graphite particles. J Chem Eng Jpn 2:46–50

Rao YK (1971) The kinetics of reduction of hematite by carbon. Metall Trans B 2:1439–1447

Fruehan RJ (1977) The rate of reduction of iron oxides by carbon. Metall Trans 8B:279–289

Srinivasan NS, Lahiri AK (1977) Studies on the reduction of hematite by carbon. Metall Trans 8B:175–178

Ajersch F (1987) Chemical and physical characteristics affecting the reduction kinetics of iron oxide pellets with solid carbon. Can Metall Q 26:137–144

Basu P, Sarkar SB, Ray HS (1989) Isothermal reduction of coal mixed iron oxide pellets. Trans Ind Inst Met 42(2):165–172

Reddy GV, Sharma T, Chakravorty S (1991) Kinetic rate equation for direct reduction of iron ore by non-coking coal. Ironmak Steelmak 18(3):211–213

Haque R, Ray HS, Mukherjee A (1993) Reduction of iron ore fines by coal fines in a packed bed and fluidised bed apparatus-a comparative study. Metall Trans 24B:511–520

Narcin N, Aydin S, Sesen K, Dikec F (1995) Reduction of iron ore pellets with domestic lignite coal in a rotary tube furnace. Int J Miner Process 43:49–59

Sah R, Dutta SK (2011) Kinetic studies of iron ore-coal composite pellet reduction by TG-DTA. Trans Ind Inst Met 64(6):583–591

Jung SM (2014) Effects of the content and particle size of char in the composite on the carbothermic reduction of titanomagnetite at 1100°C. ISIJ Int 54(12):2933–2935

Dey SK, Jana B, Basumallick A (1993) Kinetics and reduction characteristics of hematite-noncoking coal mixed pellets under nitrogen gas atmosphere. ISIJ Int 33(7):735–739

Sharma T (1993) Reduction of iron ore fines with coal fines. Ironmak Steelmak 20(5):362–366

Bryk C, Lu WK (1986) Reduction phenomena in composites of iron ore concentrates and coals. Ironmak Steelmak 13(2):70–75

Kasai E, Kitajima T, Kawaguchi T (2000) Carbothermic reduction in the combustion bed packed with composite pellets of iron oxide and coal. ISIJ Int 40(9):842–849

McAdam GD, O’Brien DJ, Marshall T (1977) Rapid reduction of New Zealand ironsands. Ironmak Steelmak 1:1–9

Halder S, Fruehan RJ (2008) Reduction of iron-oxide-carbon composites: part I. estimation of the rate constants. Metall Mater Trans 39B:784–795

Mishra S, Roy GG (2016) Effect of amount of carbon on the reduction efficiency of iron ore-coal composite pellets in multi-layer bed rotary hearth furnace. Metall Trans 47B:2347–2356

Han H, Duan D, Chen S, Yuan P (2015) Mechanism and influencing factors of iron nugget forming in rotary hearth furnace process at lower temperature. Metall Trans 46B:2208–2217

Borra CR, Dwarapudi S, Kapure G, Tathavadkar V, Denys MB (2013) Effects of alumina on slag-metal separation during iron nugget formation from high alumina Indian iron ore fines. Ironmak Steelmak 40(6):443–451

Sah R, Dutta SK (2010) Effects of binder on the properties of iron ore-coal composite pellets. Miner Process Extract Metall Rev 31:73–85

Agrawal BB, Prasad KK, Sarkar BB, Ray HS (2000) Cold bonded ore-coal composite pellets for sponge ironmaking part 1 laboratory scale development. Ironmak Steelmak 27(6):421–425

Li J, Wei R, Long H, Wang P, Cang D (2014) Sticking behavior of iron ore-coal pellets and its inhibition. Powder Technol 262:30–35

Prakash S, Goswami MC, Mahapatra AKS et al (2000) Morphology and reduction kinetics of fluxed iron ore pellets. Ironmak Steelmak 27(3):194–201

Seaton CE, Foster JS, Velasco JV (1983) Reduction kinetics of hematite and magnetite pellets containing coal char. Trans ISIJ 23:490–496

Basumallick A (1995) Influence of CaO and Na2CO3 as additive on thr reduction of hematite-lignite mixed pellets. ISIJ Int 35(9):1050–1053

Jung SM (2015) Effects of CaO/CaCO3 on the carbothermic reduction of titanomagnetite ores. Metall Mater Trans 46B:1162–1174

Zhou LL, Zeng FH (2010) Statistical analysis of the effect of Na2CO3 as additive on the reduction of vanadic-titanomagnetite-coal mixed pellet. Adv Mater Res 97:465–471

Sohn I, Jung SM (2011) Effect of metal additions to the reduction of iron oxide composite pellets with hydrogen at moderate temperatures. Steel Res Int 82(12):1345–1354

Park H, Sahajwalla V (2013) Influence of CaO-SiO2-Al2O3 ternary oxide system on the reduction behavior of carbon composite pellet: part I. reaction kinetics. Metall Mater Trans 44B:1379–1389

Vastola FJ, Walker PL (1961) The reaction of graphite wear dust with carbon dioxide and oxygen at low pressures. J Chim Phys 58:20–24

Turkdogan ET, Vinters JV (1972) Catalytic oxidation of carbon. Carbon 10:97–111

Rao YK, Jalan BP (1972) A study of the rates of carbon-carbon dioxide reaction in the temperature range 839 to 1050 C. Metall Trans 3:2465–2477

Haque R, Ray HS, Mukherjee A (1992) Reduction of iron ore fines by coal char fines—development of a mathematical model. Scand J Metall 21:78–85

Sun S, Lu WK (1999) Building a mathematical model for the reduction of iron ore in ore/coal composites. ISIJ Int 39(2):130–138

Coetsee T, Pistorius PC, de Villiers EE (2002) Rate-determining steps for reduction in magnetite-coal pellets. Miner Eng 15:919–929

Fortini OM, Fruehan RJ (2005) Rate of reduction of ore-carbon composites: part I. Determination of intrinsic rate constants. Metall Mater Trans 36B:865–872

Sharma T (1993) Non-coking coal quality and composite pre-reduced pellets. Int J Miner Process 39:299–311

Yang J, Mori T, Kuwabara M (2007) Mechanism of carbothermic reduction of hematite in hematite-carbon composite pellets. ISIJ Int 47(10):1394–1400

Konishi H, Ichikawa K, Usui T (2010) Effect of residual volatile matter on reduction of iron oxide in semi-charcoal composite pellets. ISIJ Int 50(3):386–389

Man Y, Zeng F, Qi G, Li F (2014) Effect of particle size on reduction behavior in iron ore-coal composite pellets. J Chem Pharm Res 6(7):2484–2490

Corbari R, Fruehan R (2010) Reduction of iron oxide fines to wustite with CO/CO2 gas of low reducing potential. Metall Mater Trans 41B:318–329

Teplov OA (2012) Kinetics of the low temperature hydrogen reduction of magnetite concentrate. Russ Metall 2012:14–30

Wang H, Sohn HY (2013) Hydrogen reduction kinetics of magnetite concentrate particles relevant to a novel flash ironmaking process. Metall Mater Trans 44B:133–145

Chowdhury GM, Murmu CS, Roy SK, Roy GG (2010) Some studies to establish the reaction mechanism for the reduction of iron ore-graphite composite pellets in a packed bed reactor. Steel Res Int 81(11):925–931

Sun K, Lu WK (2009) Mathematical modeling of the kinetics of carbothermic reduction of iron oxides in ore-coal composite pellets. Metall Mater Trans 40B:91–103

Donoskoi E, Mcelwain DLS (2001) Mathematical modeling of non-isothermal reduction in highly swelling iron ore-coal char composite pellet. Ironmak Steelmak 28(5):384–389

Sharma MK, Sholanki V, Roy GG, Sen PK (2013) Study of reduction behavior of prefabricated iron ore-graphite/coal composite pellet in rotary hearth furnace. Ironmak Steelmak 40(8):590–597

Mishra S, Roy GG (2017) Reduction behaviour of iron ore-coal composite pellets in rotary hearth furnace-effect of pellet size, shape and bed packing materials. Trans Ind Inst Met 70(4):967–978

Ghosh A, Mungole MN, Gupta G, Tiwari S (1999) A premilinary study of influence of atmosphere on reduction behavior of iron ore-coal composite pellets. ISIJ Int 39(8):829–831

Chowdhury GM, Roy GG, Roy SK (2008) Reduction kinetics of iron ore-graphite composite pellets in a packed-bed reactor under inert and reactive atmosphere. Metall Mater Trans 39B:160–178

Carvalho RJD, Netto PGQ, D’Abreu JC (1994) Kinetics of reduction of composite pellets containing iron ore and carbon. Can Metall Q 33(3):217–225

Iguchi Y, Yokomoto S (2004) Kinetics of the reactions in carbon composite iron ore pellets under various pressures from vacuum to 0.1 MPa. ISIJ Int 44(12):2008–2017

Yang XM, Xie YS, Wang DG et al (2000) Reduction behavior of iron ore pellets containing carbon under non-isothermal condition. Acta Met Sin (Eng Letters) 13(5):1059–1067

Takegoshi E, Hirasawa Y, Imura S, Shimazaki T (1984) Measurement of thermal properties of iron oxide pellets. Int J Thermophys 5(2):219–228

Cypres R, Soudan-Moinet C (1980) Pyrolysis of coal and iron oxide mixtures. 1. Influence of iron oxides on the pyrolysis of coal. Fuel 59:48–54

Takyu Y, Murakami T, Son SH, Kasai E (2015) Reduction mechanism of composite consisted of coal and hematite ore by volatile matter at 700–1100 K. ISIJ Int 55(6):1188–1196

Wang Q, Yang Z, Tian J, Li W, Sun J (1998) Reduction kinetics of iron ore-coal pellet during fast heating. Ironmak Steelmak 25(6):443–447

Coetsee T, Pistorius PC (2009) Reduction in packed bed of iron ore and coal under one-dimensional heating: experimental results and modeling. Ironmak Steelmak 36(5):363–370

Sohn I, Fruehan RJ (2006) The reduction of iron oxides by volatiles in a rotary hearth furnace process: part III. The simulation of volatile reduction in a multi-layer rotary hearth furnace process. Metall Mater Trans 37B:231–238

Huang TY, Liu SH, Shiau GH (2014) Effect of volatile matter content of coal on carbothermic reduction of ore/coal composite pellets packed in a tall bed. China Steel Tech Rep 27:11–19

Solomon PR, Colket MB (1978) Coal devolatilisation. In: 17th Symposium (International) on Combustion, The Combustion Institute, Pittsburg, PA, pp 131–143

Nascimento RC, Mourao MB, Capocchi JDT (1999) Kinetics and catastrophic swelling during reduction of iron ore in carbon bearing pellets. Ironmak Steelmak 26(3):182–186

Halder S, Fruehan RJ (2008) Reduction of iron oxide-carbon composites: part III. Shrinkage of composite pellet during reduction. Metall Mater Trans 39B:809–817

Seaton CE, Foster JS, Velasco J (1983) Structural changes occurring during reduction of hematite and magnetite pellets containing coal char. Trans ISIJ 23:497–503

Fortini OM, Fruehan RJ (2005) Rate of reduction of ore-carbon composites: part II. Modeling of reduction in extended composites. Metall Mater Trans 36B:709–717

Han H, Duan D, Yuan P, Li D (2015) Biomass reducing agent utilization in rotary hearth furnace process for DRI production. Ironmak Steelmak 42(8):579–584

Chernyshev AM, Karnilova NK, Tarasenko YuV (1977) Calculating degree of reduction of iron-ore materials from data obtained by weight and chemical-analysis. Steel USSR 7:133–135

Dam OG, Jeffes HE (1987) Model for detailed assessment of chemical composition of reduced iron ores from single measurements. lronmak Steelmak 14:217–221

Dutta SK, Ghosh A (1993) A new method for measurement of degree of reduction in composite pellets of iron ore with carbonaceous matter. ISIJ Int 33(10):1104–1106

Prakash S, Ray HS (1987) Reduction of iron ore under rising temperature and fluctuating temperature conditions. Thermochim Acta 111:143–146

Mookherjee S, Ray HS, Mukherjee A (1986) Isothermal reduction of iron ore fines surrounded by coal or char fines. Ironmak Steelmak 13:229–235

Ghosh PC, Tiwari SN (1970) Reduction of pellets of iron ore plus lignite coke. J Iron Steel Inst London 208:255–257

Agrawal BB (1993) Development of ore-coal composite pellets and investigations on their reduction behavior. PhD Thesis, IIT Kharagpur, India

Weiss FJ, Goksel A, Kaiser FT (1986) Production of hot metal from carbon-bearing iron oxide pellets by the pellet tech (PTC) process. Iron Steel Eng 63(2):34–40

Habashi F (1997) Handbook of extractive metallurgy, vol 1. Willey, Weinheim

Agrawal BB, Prasad KK, Sarkar SB, Ray HS (2001) Cold bonded ore-coal composite pellets for sponge ironmaking part 2 plant trials in rotary kiln. Ironmak Steelmak 28(1):23–26

Jiang T, Qiu G, Xu J, Zhu D, Singh R (2007) Direct reduction of composite binder pellets and its use for DRI. Electrotherm press, Ahmedabad, pp 29–41

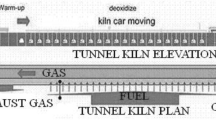

Khattoi SC, Roy GG (2015) Reduction efficiency of iron ore-coal composite pellets in tunnel kiln for sponge iron production. Trans Ind Inst Met 68(5):683–692

Pargeter JK, Hanewald RH, Dombrowski DE (1985) Operating experience at INMETCO and application of the process to the production of DRI. Conserv Recycl 8:363–375

Tsutsumi H, Yoshida S, Tetsumoto M (2010) Features of FASTMET process. Kobelco Technol Rev 29:85–92

Borlee J, Steyls D, Colin R, Munnix R, Economopoulos (1999) COMET: a coal based process for the production of high quality DRI from iron ore fines. Revue de Metallurgie 96(3):331–340

Greene L (2000) Iron making process alternatives screening study, summary report. Energy systems, vol 1. Lockheed Martin, Bethesda, pp 16–26

Kikuchi S, Ito S, Kobayashi I, Tsuge O, Tokuda K (2010) ITmk3 process. Kobelco Technol Rev 29:77–84

Fruehan RJ (2005) New steel making processes: drivers, requirements and potential impact. Ironmak Steelmak 32(1):3–8

Ishikawa H, Kopfle J, Mcclelland J, Ripke J (2008) Rotary hearth furnace technologies for iron ore and recycling applications. Arch Metall Mater 53:541–545

Mishra S, Roy GG (2018) Effect of CaO on the reduction behaviour of iron ore-coal composite pellets in multi-layer bed rotary hearth furnace. Ironmak Steelmak 45(5):426–433

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

Additional information

The contributing editor for this article was Il Sohn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, S. Review on Reduction Kinetics of Iron Ore–Coal Composite Pellet in Alternative and Sustainable Ironmaking. J. Sustain. Metall. 6, 541–556 (2020). https://doi.org/10.1007/s40831-020-00299-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-020-00299-y