Abstract

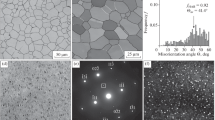

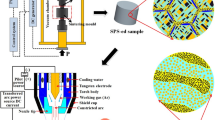

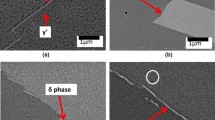

The influence of hydroextrusion on structural changes in Invar high-carbon alloy 1N31 with a graphite component has been studied by metallography, microhardness measurements, and transmission electron microscopy. This process is accompanied by an almost twofold increase in microhardness up to a depth of 270–300 μm measured along scratches applied across the longitudinal section of the sample in the last cycle of the second hydrodynamic extrusion pass. It has been proved by means of transmission electron microscopy that the achieved strengthening of the near-surface layers is connected not only with additional solid-solution strengthening of austenite owing to a complete dissolution of the graphite component in it, but also with the extreme dispersion level of structural elements that form twin orientations in two mutually normal directions. The results are discussed in the scope of the model proposed earlier for the formation and features of the hydrodynamic state of the sample material in the course of hydrodynamic extrusion.

Similar content being viewed by others

REFERENCES

Gavrilyuk, V.G., Raspredelenie ugleroda v stali (Carbon Distribution in Steel), Kiev: Naukova Dumka, 1987.

Belous, M.V. and Cherepnin, V.T., Changes in the carbide phase of steel under cold plastic deformation, Fiz. Met. Metalloved., 1961, vol. 12, no. 5, pp. 685–692.

Volosevich, P.Yu., Gavrilyuk, V.G., Petrov, Yu.N., and Polushkin, V.G., Electron microscopic analysis of structural changes during heating of cold-deformed steel, Metallofizika, 1977, no. 69, pp. 71–77.

Volosevich, P.Yu. and Gavrilyuk, V.G., Electron microscopic analysis of structural changes during plastic deformation and subsequent heating of steel, Metallofizika, 1980, vol. 2, no. 2, pp. 75–82.

Bakharev, O.G., Gavrilyuk, V.G., Nadutov, V.M., Schastlivtsev, V.M., et al., Structural changes during heating of cold-deformed carbon steel with pearlitic structure, Phys. Met. Metallogr., 1989, vol. 67, no. 2, pp. 125–130.

Belous, M.V., Molchanovskaya, G.M., Novozhilov, V.B., and Cherepnin, V.T., Carbon in cold-deformed steel, Metallofiz. Nov. Tekhnol., 1994, vol. 16, no. 2, pp. 52–60.

Volosevich, P.Yu., Mechanics of plastic deformation and fracture in terms of modern physical concepts, Materiali 4-a Mizhnarodna konferentsiya “Mekhanika ruinuvannya materialiv i mitsnist’ konstruktsii” (Proc. Fourth Int. Conf. “Mechanics of Destruction of Materials and Strength of Constructions”), Lviv, 2009, pp. 93–106.

Volosevich, P.Yu., Stress concentrators and their role in the mechanical properties of polycrystals with structural nanoelements, Usp. Fiz. Met., 2011, vol. 12, pp. 367–382.

Gruzin, P.L., Kornev, Yu.V., and Kurdyumov, G.V., Effect of carbon on self-diffusion of iron, Dokl. Akad. Nauk SSSR, 1951, vol. 80, no. 1, pp. 49–51.

Nadutov, V., Vashchuk, D., Karbovsky, V., and Volosevich, P., Allotropic forms of carbon in the Invar Fe–Ni–C alloy before and after plastic deformation by upsetting, Philos. Mag., 2018, vol. 98, no. 12, pp. 1087–1098.

Volosevich, P.Yu., Stress concentrators in metallic materials under multidimensional compression, Usp. Fiz. Met., 2018, vol. 19, no. 2, pp. 223–250.

Nadutov, V.M., Vashchuk, D.L., Volosevich, P.Yu., et al., Structure and properties of invar fcc alloy Fe–35% Ni after hydroextrusion, Metallofiz. Nov. Tekhnol., 2012, no. 3, pp. 395–414.

Nadutov, V.M., Vashchuk, D.L., Volosevich, P.Yu., et al., Structure and properties of invar fcc alloy Fe–35% Ni after combined plastic deformation by hydroextrusion and drawing, Fiz. Tekh. Vys. Davlenii, 2013, no. 2, pp. 125–137.

Kosevich, O.M., Tokii, V.V., and Strel’tsov, V.A., Dislocations and point defects in a hydrostatically compressed crystal, Fiz. Met. Metalloved., 1978, vol. 45, no. 6, pp. 1135–1144.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

About this article

Cite this article

Volosevich, P.Y., Vashchuk, D.L. Hydrodynamic Extrusion and Its Effect on Graphite Behavior and Structure Formation in Invar 1N31 Alloy. Steel Transl. 50, 420–425 (2020). https://doi.org/10.3103/S096709122006011X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709122006011X