Abstract

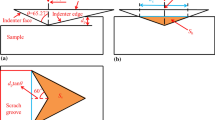

The plastic deformation zone sizes in various metallic materials (steel, copper, armco-iron) are studied during tests by scratching with a tetrahedral Vickers pyramid under the scratch formation conditions at a constant depth. The ratio of the plastic deformation zone depth under a scratch to the scratch depth is found to weakly depend on the scratch depth and to be 6.3–8.5 for the materials under study. Based on these results, we concluded that, when the mechanical properties of a metallic material are determined by scratching, the ratio of the material thickness to the scratch depth should be at least 8.5.

Similar content being viewed by others

REFERENCES

K. K. Selivanov, A. M. Smyslov, and A. N. Petukhov, “Sclerometry study of the properties of vacuum-plasma coatings on a CSM Scratch Test device,” Vestn. UGATU 15 (4), 230–236 (2011).

S. M. Ignatovich and I. M. Zakiev, “Universal Micron-gamma micronanoindentometer,” Zavod. Lab., No. 1, 61–67 (2011).

B. Ya. Mokritskii, A. D. Verkhoturov, D. A. Pustovalov, A. A. Vereshchaka, A. I. Evstigneev, and E. G. Kravchenko, “Choice of an effective tool material from the parameters of a scribing trace,” Zavod. Lab., No. 9, 45–49 (2015).

V. M. Matyunin, Indentation in the Diagnostics of the Mechanical Properties of Materials (Izd. Dom MEI, Moscow, 2015).

M. B. Bakirov, M. A. Zaitsev, and I. V. Frolov, “Mathematical modeling of indenting a sphere into an elastic plastic half-space,” Zavod. Lab., No. 1, 37–47 (2001).

N. Ogasawara, Y. Shimizu, T. Kami, and H. Yamada, “Influence of strain rate on strain field for sharp indentation,” J. Japan Soc. Mater. Sci. 64 (10), 783–789 (2015).

Z. Wang, T. G. Murthy, and C. Saldana, “Deformation field interaction in sequential circular indentation of a strain hardening material,” Philos. Mag. 99 (10), 1259–1276 (2019).

Y. I. Oka, M. Matsumura, and H. Funaki, “Measurements of plastic strain below an indentation and piling-up between two adjacent indentations,” Wear 186–187, 50–55 (1995).

M. M. Chaudhri, “Subsurface strain distribution around Vickers hardness indentations in annealed polycrystalline copper,” Scr. Materialia 46 (9), 3047–3056 (1998).

D. Allen, J. Wittge, A. Zlotos, et al., “Observation of nano-indent induced strain fields and dislocation generation in silicon wafers using micro-Raman spectroscopy and white beam X-ray topography,” Nucl. Instrum. Methods Phys. Res., Sect. B 268, 383–387 (2010).

T. G. Murthy, C. Huang, and S. Chandrasekar, “Characterization of deformation field in plane-strain indentation of metals,” J. Physics D: Appl. Phys. 41 (7), article no. 074206 (2008).

V. M. Matyunin, A. Yu. Marchenkov, E. V. Terent’ev, and A. N. Demidov, “Justification of the ratio of the thickness of a controlled object to the indentation depth in determining the hardness of materials,” Tekhn. Met., No. 8, 30–34 (2016).

V. M. Matyunin, N. Abusaif, and A. Y. Marchenkov, “Characteristics of the deformed zone around Vickers indentations in metals,” Mater. Sci. Eng. 537 (3), article no. 032004 (2019).

B. Feng, “Effects of surface roughness on scratch resistance and stress–strain fields during scratch tests,” AIP Advances 7 (3), article no. 035217 (2017).

G. D. Del, “Determination of Stresses in the Plastic Region from a Hardness Distribution (Mashinostroenie, Moscow, 1971).

A. V. Udalov, S. V. Parshin, and A. A. Udalov, “Indentation determination of the strain resistance of metals and alloys,” Deform. Razrushenie Mater., No. 4, 40–44 (2019).

N. Abusaif, “Scratching study of the deformed volume during tests,” in Proceedings of Conference on Physicochemistry and Technology of Inorganic Materials (IMET RAN, Moscow, 2018), pp. 155–157.

Funding

This work was supported by a grant of the President of the Russian Federation for supporting Russian scientists (Candidates of Sciences), project no. 075-15-2019-333, MK-2162.2019.8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Marchenkov, A.Y., Chernov, D.V., Zhgut, D.A. et al. Plastic Deformation Zone Size during Indenter Scratch Tests of Materials. Russ. Metall. 2020, 1218–1221 (2020). https://doi.org/10.1134/S0036029520100171

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520100171