Abstract

In recent years, the topic of catalysis by carbon materials (carbocatalysis) has experienced rapid growth. Every year the scope of application of carbocatalysts is expanding swiftly, spreading to areas in which metal catalysts seemed to have no alternative until recently. Due to their structural diversity and functionalization possibilities, carbon materials offer almost limitless possibilities for creating various catalytically active sites. It is of crucial importance to understand the mechanisms of action of chemically active sites of carbocatalysts for the development of this field. The latest discoveries have unveiled the complexity of this topic and the need to take into account the effects associated with the simultaneous presence of various active sites on the surface of carbon materials. Despite the significant advances in modern research in the field of carbocatalysis, it is important to remember the origins of the use of carbon materials in catalysis. New methods of studying old and almost forgotten reactions often lead to very interesting discoveries. This review focuses on the historical development of ideas about the catalytic activity of carbon materials, modern concepts of the mechanisms of carbocatalytic reactions, and recent studies of the role of carbene centers of graphene materials in catalytic processes.

Similar content being viewed by others

I. INTRODUCTION

The use of carbon as a catalyst in organic synthesis has deep historical roots that can be traced back almost to the very beginnings of organic chemistry. But the term “carbocatalysis” was first proposed only in 2010 by Bielawski [1], who showed that graphene oxide (GO) can act as an inexpensive and affordable carbon catalyst for the production of aldehydes and ketones from various alcohols, alkenes, and alkynes.

Since that moment, the topic of carbocatalysis has been actively developed. According to the Internet search platform Web of Science, the number of papers on this topic has grown more than 10 times since 2013 (from about 250 in 2013 to almost 2600 in 2019). In recent years, many reviews have also been devoted to the topic of carbon catalysts, unveiling various aspects of carbocatalysis [2–13]. The topic of carbocatalysis has become so relevant that since 2004 the International Symposium on Carbon for Catalysis, CarboCat, has been held. Interest in carbocatalysis is the result of a “synergistic effect” from the discovery of new forms of carbon and the desire to reduce the use of metals in organic synthesis for economic and environmental reasons. Carbon materials are cheap, nontoxic, and easier to dispose of after use. Within the framework of the concept of sustainable development, researchers are trying to create catalysts from renewable sources, such as biomass [14]. This would make many of the chemical processes completely “green.”

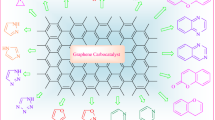

A wide variety of new carbon forms and their modifications have significantly expanded the scope and catalytic capabilities of carbon materials as catalysts. At the moment, the scope of application of carbocatalysts in organic synthesis includes the oxidation [15], reduction [16], addition [17], substitution [18], condensation [19], dehydration [20], hydrolysis [21], polymerization [22], hydrogenation [23], dehydrogenation [24], C–C bond formation [25], C–H bond activation [26], electrochemical reactions [27], and many others. However, in order for carbocatalysis in the hands of organic chemists to become a truly efficient tool that can compete with catalysts containing various metals, it is necessary to understand how carbon catalysts work.

Carbocatalysis has become a real challenge for many researchers trying to understand the mechanistic basis of this phenomenon. The chemistry and structure of carbon materials are quite complex and diverse. The surface of carbon materials can contain a large number of various functional groups, heteroatomic inclusions, defects, and radical and carbene centers. The catalytic capabilities of the starting carbon materials can also be extended by introducing heteroatoms and adding functional groups, which helps to controllably create additional active sites. The extensive conjugated π-system of a graphene sheet can play a special role. A set of different active sites creates a huge number of possible combinations and can produce a synergistic effect. On the one hand, this makes carbon materials a potential platform for creating catalytic systems for almost any synthetic purpose. On the other hand, this complexity makes it difficult to understand how carbon materials work as catalysts.

The first evidence of carbocatalysis is associated with studies of the polymerization of acetylene and the oxidation of hydrocarbons and alcohols back in the mid-19th century. But only now are we coming to an understanding of the mechanisms of the catalytic activity of carbon materials. It is mechanistic studies that should become a reliable basis for the widespread introduction of carbocatalysis into modern organic synthesis.

In this review, we have focused our attention on three aspects of carbocatalysis: (1) the historical origins of the concept of carbocatalysis and the first evidence of the influence of carbon on organic reactions; (2) the state-of-the-art of the field in the context of mechanistic ideas about the catalytic activity of carbon materials and their functionalized derivatives; and (3) recent studies of the role of carbene centers of graphene materials in carbocatalytic transformations.

II. ACETYLENE TRIMERIZATION AND HYDROCARBON OXIDATION AT THE ORIGIN OF CARBOCATALYSIS

The historical use of carbon materials dates back to prehistoric times. However, the scientific interest of chemists in carbon materials as chemically active substances arose at the dawn of chemistry as a science at the turn of the 18th–19th centuries. At that time, the ability of charcoal to absorb various substances began to be actively studied (Fig. 1). In particular, in 1777, Scheele and Fontana independently reported the observation of the absorption of various gases by charcoal [28–30]. In 1785, T. Lowitz described the phenomenon of absorption of substances by charcoal in a liquid medium and proposed to use it for the purification of aqueous and alcoholic solutions and organic substances [31]. Since the 19th century, activated carbon has been widely used in industry for sugar decolorization and in a number of other processes. This is how scientific studies of the chemical activity of carbon materials began.

Fragment of the title page of Carl Scheele’s book “Chemische Abhandlung von der Luft und dem Feuer” (Chemical Treatise on the Air and the Fire) first published in 1777. In this book, Scheele mentions that charcoal can absorb gases, which indicates the preparation of activated carbon by him. Reprinted with permission from Springer Nature: [32], Copyright ©2017.

I.1. Berthelot–Zelinsky Reaction

In 1866, the French chemist Berthelot published the work “The Effect of Heating on Certain Hydrocarbons” [33]. In this work, Berthelot showed that acetylene, when passed through a red-hot porcelain tube, decomposes into elements (hydrogen and carbon), and liquid hydrocarbons are also formed. Berthelot has noticed that the presence of various foreign bodies affects the course of the reaction. In particular, the presence of coke led to a change in the composition of the products. In a subsequent work, Berthelot reported on the composition of liquid products formed during the pyrolysis of acetylene: benzene, styrene, naphthalene, anthracene, and fluoranthene (“fluorescent hydrocarbons”) [34]. In addition, Berthelot has suggested that the almost complete decomposition of acetylene into elements is determined by the presence of carbon, which was deposited on the walls of the tube during gas pyrolysis. Thus, this is probably the first mention of the catalytic activity of carbon.

By the beginning of the 20th century, despite many attempts at pyrolysis of acetylene in the presence of various metals as a catalyst, researchers failed to achieve satisfactory yields of the desired condensate. In 1924, the Russian chemist Nikolai Dmitrievich Zelinsky improved Berthelot’s approach by proposing condensation of acetylene in the presence of activated charcoal [35]. Zelinsky suggested that an increase in pressure in the system could lead to an increase in the yield of target hydrocarbons. However, the immediate increase in pressure was associated with the risk of acetylene detonation. Therefore, Zelinsky decided that the presence of a porous material in the reaction could have a similar effect on the course of the acetylene condensation reaction. As such a porous material, Zelinsky used activated wood charcoal. This helped to achieve a good benzene yield (35 wt %). In addition, the presence of activated carbon allowed the reaction to proceed safely without dilution with an inert gas to prevent acetylene ignition. Zelinsky determined that the optimum temperature for the acetylene conversion to benzene is 600–650°C. Zelinsky’s method made it possible to radically reduce the amount of formed carbon and hydrogen, as well as the formation of solid hydrocarbons during the decomposition of acetylene, thus ensuring the formation of benzene as the major product. Later, this reaction was called the Berthelot–Zelinsky reaction. In the conclusion of his work, Zelinsky suggested that in the future the production of aromatic hydrocarbons would be based on the conversion of acetylene obtained from calcium carbide, which, in turn, could be directly produced from coal [35].

Despite Zelinsky’s assumption that activated carbon works due to the pressure in the pores, subsequent research by Zelinsky’s contemporaries has questioned this assumption [36]. It turned out that the porosity of carbon is not the only important parameter. Less porous materials, such as pumice, coke, kaolin, and porcelain, showed similar results. Fischer [37] and Lozovoy [38] have suggested that the real catalyst for acetylene trimerization is carbon films formed during the decomposition of acetylene. It has been noted that when a dense, shiny carbon layer is formed, acetylene trimerization proceeds intensively [39, 40]. At the same time, when carbon was formed in the form of soot and there was an insignificant release of condensate, acetylene decomposed into elements.

In the 1930s, Clemo and coworkers [41, 42] used the Berthelot–Zelinsky reaction to obtain hexadeuterated benzene (Fig. 2). They also noted that a large amount of acetylene had to be passed preliminarily in order for the carbon to become active. This confirmed the idea that thin carbon layers deposited from the decomposition of acetylene served as a real catalyst.

In the 1950s, in the USSR, the process of obtaining benzene from acetylene was considered a potential method for the production of antiknock additives for aviation fuel [43]. However, more efficient catalysts based on metal complexes were soon proposed, such as the Reppe catalyst based on nickel, which allowed the reaction to be carried out at 60°C [44]. As a result, the Berthelot–Zelinsky reaction remained for a long time only the subject of theoretical consideration from chemistry textbooks. The understanding of how thin carbon layers work in acetylene trimerization was lacking until recently.

Almost 100 years later, when a request arose to minimize the use of metals in catalysis and to develop carbocatalysis, researchers have again turned their attention to this reaction (see Section IV of this review). In 2020, studies using quantum-chemical modeling have shown that the key role is played by carbene centers of graphene sheets, which catalyze the trimerization process [45]. Thus, the Berthelot–Zelinsky reaction can be regarded as the first example of a carbocatalytic transformation.

I.2. Other Early Examples of Carbon-Catalyzed Reactions

Parallel to the studies of Berthelot and Zelinsky, the catalytic activity of charcoal was observed in oxidation reactions. In particular, Calvert [46] as early as 1867 drew attention to the oxidation of gaseous hydrocarbons and ethanol vapors to acetic acid in the presence of charcoal. In doing so, Calvert relied on the earlier work of Stenhouse [10, 47], who in 1854 noticed that activated carbon can oxidize a mixture of organic gases coming from decaying biomass.

At the beginning of the 20th century, a lot of studies have appeared focusing on the catalytic activity of charcoal in the catalysis of aerobic oxidation reactions. In 1907, the oxidation of ethanol to acetaldehyde by passing over charcoal was investigated by Lemoine [48]. He has shown that charcoal is an effective catalyst in this reaction. Matsui [49] in 1908 demonstrated that hydroquinone in the presence of animal charcoal was rapidly oxidized to quinhydrone. Moreover, this happened both in solution and when hydroquinone was ground with charcoal in a mortar. Warburg and his colleagues [50] discovered in 1914 that, in the presence of charcoal, catalytic oxidation of oxalic acid could take place. In 1921, the same authors demonstrated the oxidation of cysteine and other α-amino acids under similar conditions [51]. Later, Warburg [52] has shown that sugar charcoal owes its catalytic properties not to iron, although iron in certain forms is a very efficient promoter.

In addition to oxidation reactions, the catalytic activity of charcoal has been found in other reactions. In particular, Senderens [53] has stated in 1907 that amorphous carbon can act as a catalytic agent in the conversion of alcohols into aliphatic hydrocarbons. He demonstrated that when ethanol vapor was passed over animal charcoal heated to 350°C, it was converted to ethylene, methane, hydrogen, carbon monoxide, and carbon dioxide. Isopropanol under these conditions gave propylene, ethane, and, to a lesser extent, hydrogen and carbon monoxide. At the same time, Senderens explained the increased catalytic effect of animal charcoal in comparison with ordinary charcoal by the presence of silicate components. Later, Senderens [54] also has studied the catalytic action of charcoal on aliphatic acids. Acetic, propionic, butyric, isobutanoic, and isovaleric acids are completely stable at temperatures up to 460°C. When vapor of these acids were passed through a tube containing powdered industrial charcoal, they began to decompose already at temperatures 330–340°C. At 360–380°C, a mixture was formed, consisting of aliphatic hydrocarbons, CO2, CO, and H2.

In 1878 Paternò [55] reported that phosgene could be obtained by passing a mixture of CO and Cl2 over animal charcoal. In 1920, Pope and coworkers [56] investigated the Paternò method and reported testing various types of commercial animal and vegetable charcoals. It turned out that most of them showed no catalytic activity. Bone charcoal made from fresh ox bones has proven to be an efficient catalyst. In the presence of this charcoal, COCl2 readily formed at temperatures from 40 to 50°C. At the same time, Pope noted that the activity of the catalyst did not decrease even after production of a significant amount of phosgene. In addition, Pope showed that activated charcoal from an army box respirator was an even more efficient catalyst and produced phosgene at 14°C. Interestingly, this method for producing phosgene is still used in industry. In the 1990s, DuPont improved the existing technology, using the Russian carbon material Sibunit [57, 58], which made it possible to increase selectivity by reducing the amount of carbon tetrachloride formed by an order of magnitude [59]. This is an example of how modern science is helping to create new carbon catalysts for long-running industrial processes, solving important environmental problems.

Another example of the long-term use of carbon catalysts in industrial production is the production of such an important organic synthesis product as cyanuric chloride, which is a precursor for the production of herbicides, dyes, and optical brighteners [60]. The technology for producing cyanuric chloride by trimerization of cyanogen chloride over activated carbon was developed as early as 1945 [61].

Thus, researchers of the first half of the 20th century already had a rich understanding of the catalytic activity of carbon materials and even used them in chemical production. Already at that time, the first mechanistic ideas about the operation of such catalysts appeared. In particular, Rideal and Wright [62–64] have suggested that the acid surface formed during thermal activation of carbon improves the adsorption of gaseous oxygen, thereby promoting the oxidation reaction. Garner’s studies [65] demonstrate that some bonds on the carbon surface are destroyed after activation, and as a result, atoms less saturated than the atoms of the graphite system are formed, which suggests their greater chemical reactivity.

Later in the 1970s, it has been discovered that charcoal can act as a catalyst in the oxidative dehydrogenation of ethylbenzene to styrene [66]. This process was also associated with oxygen adsorbed on the surface of the charcoal. Despite the enormous practical significance of the reaction, the commercialization of carbon catalysts turned out to be difficult due to their low resistance to oxidation [67]. Another early example of a carbocatalytic reaction is the reduction of various substituted nitrobenzenes to the corresponding anilines using hydrazine and graphite as a catalyst, which was described by Sung Yun Cho [68] in 1985.

Table 1 shows carbocatalytic transformations in the synthesis of organic molecules; it should be noted that carbon materials were also actively used in the reactions of inorganic chemistry. For example, oxidation of various inorganic ions, such as Fe2+, \({\text{Hg}}_{2}^{{2 + }}\), I–, \({\text{SO}}_{3}^{{2 - }}\), and S2– [69–71], decomposition of H2O2 [72, 73], and others can be mentioned as interesting reactions. However, despite the many organic and inorganic transformations that manifested the chemical activity of carbon materials in the 20th century, the real surge in the study of carbon as catalysts began with the discovery of new carbon forms, such as carbon nanotubes and graphene.

III. CARBOCATALYSIS IN MODERN ORGANIC SYNTHESIS. MECHANISTIC ASPECTS

Despite the long history of the development of carbocatalysis, the mechanisms of carbocatalytic reactions remained a mystery for many years. A new stage in the development of carbocatalysis is primarily characterized by focusing on a deep mechanistic understanding of the nature of carbocatalysis. Only in recent decades, under the influence of the avalanche-like growth of research on the chemistry of carbon materials, it has been possible to study the real variety of chemically active sites on the surface of carbon materials and their distribution. This, in turn, became the basis for a mechanistic understanding of carbocatalysis. It is the understanding of the mechanisms of operation of carbocatalytic centers in different types of reactions that should ensure the further development and success of carbocatalysis in modern organic synthesis.

Many carbon materials used in catalysis are structures containing thin sheets one atom thick (graphene sheets). In turn, these sheets are composed of sp2-hybridized carbon atoms arranged in a hexagonal lattice. Among these carbon materials exhibiting catalytic properties, the most important are activated carbons (AC), carbon black (CB), graphite, carbon nanotubes (CNT), graphene, and their derivatives [74]. However, the structure of these carbon materials is usually far from ideal and can contain many different defects and functional groups. Different sp2-carbon materials can have their own structural features responsible for their unique properties.

It is worth distinguishing key functional centers of sp2-carbon materials located at the edges of the sheet or on the basal surface. The chemistry of the edges is different from that of the basal surface of carbon materials. In addition, two types of edges (zigzag and armchair) can also have their own characteristics [75]. Various oxygen-containing groups (carboxyl, hydroxyl, lactone, quinone-like, pyrone-like), as well as radical and carbene centers, can be located at the edges. The basal surface can contain a large number of oxygen groups, primarily carboxyl, carbonyl, epoxy, and hydroxyl, as well as various defects, pores, and inclusions of heteroatoms [74]. Different functional groups have different properties and show different chemical activities. Hydroxyl and epoxy moieties, which are distributed on the basal surface of graphene sheets, preferably react with electrophiles; carbonyl and carboxyl groups located at the edges of graphene sheets react with nucleophiles [76].

After the discovery of graphene, one of the carbon materials that gained popularity and became widespread in laboratory practice was graphene oxide prepared by the Hummers method [77] or by its various modifications [78]. Graphene oxide initially attracted attention as a precursor for the chemical production of graphene on a large scale. But soon, thanks to the diverse surface chemistry, the presence of numerous oxygen-containing groups and acid sites (Fig. 3), as well as the hydrophilic nature and good solubility in water and alcohols, graphene oxide found its application in many areas of chemistry [79, 80]. Whereas in the 20th century most of the described reactions catalyzed by carbon materials were associated with the activity of activated carbons, it is graphene oxide that has become one of the most popular carbocatalysts since 2010.

III.1. Sulfur-Containing Active Sites

The key methods for producing graphene oxide involve the use of an excess of sulfuric acid, which leads to the enrichment of the resulting graphene oxide in sulfate groups. Partial oxidation of carbon sheets leads to the formation of other acidic centers, in particular, carboxylic groups. These functional groups introduced during the preparation of graphene oxide become excellent acidic catalytic sites. Acid sites can have a catalytic effect in many important organic reactions such as dehydration, condensation, esterification, hydrolysis, and polymerization.

Sulfate groups account only for a small percentage of the functional groups of graphene oxide [80]. However, many studies point precisely to sulfate groups as catalytic sites. Thus, Garcia and coworkers [81] reported that graphene oxide promotes acetalization of aldehydes in methanol and acetonitrile (Fig. 4). At the same time, the authors, based on spectroscopic and analytical data, assume that it is the sulfate groups spontaneously introduced during the oxidation of graphite by the Hummers method that are responsible for the catalytic activity.

The same authors have shown that graphene oxide is an acid catalyst in the reaction of epoxide ring opening in the presence of alcohols [82]. The heterogeneous nature of catalysis has been proved by demonstrating that the reaction in solution terminates when graphene oxide is removed by filtration. In addition, it has been found that it is the sulfur-containing groups that are responsible for the catalytic activity, and their removal from graphene oxide decreases the catalytic activity.

In recent years, sulfonated carbons have become a separate class of carbocatalysts [11]. Such materials can be considered as solid substitutes to sulfuric acid in catalysis. Sulfonate and sulfone groups are purposefully linked to carbon materials to improve catalytic properties (Fig. 5).

Loh and coworkers [83] have demonstrated the high efficiency of graphene oxide as a catalyst in the multicomponent Strecker reaction. To improve the catalytic activity, the authors have intentionally introduced sulfonate groups into graphene oxide. Comparison with other solid catalysts has shown a significant superiority in the activity of graphene oxide and its derivatives (Fig. 6).

Reduced graphene oxide (rGO) with “grafted” sulfone groups can be used in a similar way as a catalyst. This catalyst exhibits excellent activity in the reactions of acetic acid esterification with cyclohexanol (EAC), acetic acid esterification with butanol (EAB), the Peckmann reaction of resorcinol with ethyl acetoacetate (PRE), and propylene oxide hydration (HPO) (Fig. 7) [84].

Sulfated graphene-catalyzed esterification of acetic acid with cyclohexanol (EAC), esterification of acetic acid with 1-butanol (EAB), reaction of resorcinol with ethyl acetoacetate (PRE), and hydration of propylene oxide (HPO). Reprinted with permission from [84]. Copyright ©2012 Royal Society of Chemistry.

The sulfur-containing groups are not only responsible for the catalytic activity of graphene materials, but can also be used to improve the catalytic performance of other carbon materials. It has recently been shown that sulfonation improves the catalytic activity of activated carbons in the esterification of oleic acids [85]. New “green” methods of sulfonation of various carbon materials, such as carbon nanotubes, reduced graphene oxide, and activated carbon, have been developed to create carbocatalysts for biomass conversion. The active species generated by gas–liquid interfacial plasma on the surface of the solution can be “grafted” directly to the defects and edges of the carbon material without causing severe damage to the carbon structure [86]. In addition, carbonaceous materials can be functionalized with sulfonic acid using diazonium derivatives of benzyl sulfonic acids. The authors showed that sulfonic functions provided high selectivity in the hydrolysis of cellobiose to glucose in a neutral aqueous medium (Fig. 8) [87].

III.2. Other Oxygen-Containing Functional Groups

The importance of oxygen-containing functional groups on the surface of carbon materials for the catalytic activity of carbocatalysts has also been noted. A possible synergistic effect of oxygen-containing and sulfonic groups [88], as well as a synergistic effect of oxygen-containing groups and unpaired electrons at the edges of carbon sheets in the oxidation reaction [89], has been reported.

In particular, it has been shown that graphene oxide can be used as a “green” and efficient catalyst for the dehydration of fructose into 5-hydroxymethylfurfural (HMF). Comparison of the catalytic performance of graphene oxide with that of the catalyst Amberlyst-15, which contains only sulfonic groups, allowed the authors to deduce that other oxygen-containing functional groups on the graphene oxide surface also play an important role in the dehydration of fructose into HMF. Thus, the combination of a small amount of sulfonic groups and a diverse array of oxygen-containing groups (hydroxy, epoxy, carboxyl) produces a synergistic effect, providing a high efficiency of graphene oxide [88].

Khatri and coworkers [90] compared the performance of various graphene oxide fractions differing in the composition of functional groups as carbocatalysts. As a result, the authors attributed the high activity of the catalyst in the esterification reaction to the presence of both sulfonic and carboxylic and phenolic groups. The authors also noted that acidic functional groups are located over the entire surface of nanosheets (including the basal plane, edges, and pores), so that the reagent molecules can easily approach the active catalytic sites (Fig. 9).

In 2016, Ma and coworkers [91] reported on the catalytic activity of oxygen functional groups of graphene oxide in another important type of reaction: C–H activation in benzene arylation. Reactions with various model compounds and DFT calculations have confirmed that negatively charged oxygen atoms promote the stabilization and activation of K+ ions, which, in turn, facilitates the activation of the C–I bond. The authors believe that the type of oxygen group is not the only factor influencing the catalytic activity. Also important is the type of carbon skeleton grafted to such groups, which also has a significant impact. Moreover, the carbon π-system greatly facilitates the reaction due to the adsorption of aromatic substrates (Fig. 10).

Heterogeneous acid–base catalysts are very important in modern organic synthesis. Solid catalysts are much more convenient, safer, and more environmentally friendly than traditional liquid acids. Acid–base catalysis using carbon materials could make significant improvements in many organic chemistry processes.

III.3. Oxygen-Containing Functional Groups in Catalysis of Redox Reactions

Carboxyl and carbonyl groups at the edges of graphene sheets can also play a significant role in redox reactions, as shown in many studies.

Investigation of the oxidation of HMF to 2,5-diformylfuran (DFF) in the presence of graphene oxide and 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) as a cocatalyst showed that the oxygen functional groups of the carbon material had a decisive effect on the catalytic oxidation of HMF [89]. Carboxyl groups at the edges of defects, along with localized unpaired electrons, worked synergistically to provide improved kinetics for the capture and activation of molecular oxygen and TEMPO through sequential electron transfer from TEMPO to molecular oxygen (Fig. 11). In addition, graphene oxide could function as an anaerobic oxidant of HMF; during this reaction, the amount of carboxyl groups in graphene oxide decreased.

Recent studies [92] have shown the key role of the carboxyl groups of graphene oxide in the catalysis of highly efficient and chemoselective aerobic oxidation of primary alcohols to aldehydes or carboxylic acids in the presence of nitric acid (Fig. 12). Carboxyl groups were responsible for both reactivity and reaction selectivity.

Quinone-like structures of carbon materials represent an interesting type of oxygen-containing catalytic site. Such centers can play a key role in various reduction and oxidation reactions. Back in 1999, Figueiredo [93, 94] showed that the activity of carbon catalysts in the oxidative dehydrogenation of ethylbenzene depends on the amount of carbonyl and quinone/hydroquinone groups on the surface. It is these groups that have been identified as active reaction sites. Other studies [95] have shown that hydroquinone/quinone-like redox pairs in reduced graphene oxide can act as catalysts for the Fenton reaction, possessing the correct potential to reduce H2O2.

In order to elucidate the catalytic role of various functional groups on the surface of carbon materials in the reduction of nitrobenzene with hydrazine, Su and coworkers [96] used model catalysts with different functional groups to simulate carbocatalysis. As a result, it was determined that carbonyl and hydroxyl groups played an important role in the catalysis of nitrobenzene reduction. This has been explained by the ability of these groups to activate hydrazine. In the proposed mechanism for 9,10-anthraquinone as a model compound, the carbonyl oxygen, which has unpaired electrons, interacts with a hydrogen atom of the hydrazine molecule. This leads to the formation of a hydrogen bond, while the N–H bond is weakened. When nitrobenzene is bound to the benzene ring of the catalyst through π–π interaction, two oxygen atoms of the nitro group split off two activated hydrogen atoms. Then, the nitro group is reduced to the nitroso group. Nitrosobenzene is converted to aniline directly through a noncatalytic process (Fig. 13). In comparison, the ester, ether, and lactone groups were found to be inactive, while the carboxyl group had a negative effect in this reaction.

III.4. Basic Sites, Nitrogen Inclusions and Functional Groups

The surface of carbon materials can contain various types of basic sites (Fig. 14) [97]. The most significant and studied basic centers of the carbon surface are pyrone-like groups. Pyrone-like structures are a combination of nonadjacent carbonyl and ether groups at the edges of a graphene sheet. Pyrones may be the most important Brønsted basic sites located at the edges of the carbon sheets. It is assumed that such groups are formed when thermally treated carbon materials are exposed to air. The basicity of pyrone-like structures can be explained by the stabilization of the protonated form by means of electron π-conjugation over the entire sp2-surface.

In addition, there is experimental evidence that protons can be adsorbed on the basal plane of carbon due to electrostatic interaction with the π-electron system of the graphene sheet [98]. Theoretical calculations have shown that H3O+ cations and the basal plane of a carbon sheet can form close contact structures through π–π interactions [99]. Aromatic rings act as efficient hydrogen bond acceptors, while counterions can be held at distances by solvent molecules, which provides electroneutrality. However, other computational studies have shown that the basic strength of the basal planes is probably much lower than that of pyrone-like groups [100]. Nevertheless, the catalytic activity of such basic sites of the carbon material has not yet been described in the literature [97].

However, in one of the works [101], graphene oxide was used as a heterogeneous basic catalyst in the condensation reaction of various substituted benzaldehydes with acetophenone (aldol condensation) and with an active methylene compound of malononitrile (Knoevenagel reaction) at room temperature in the absence of a solvent. The authors have not reported which active sites could be responsible for the catalytic activity of graphene oxide in these transformations.

Another cause of the basicity of carbon materials can be nitrogen inclusions in the structure of carbon sheets. The pyridine group is the strongest basic site, while graphite nitrogen has the lowest basicity and does not introduce any changes in comparison with the undoped carbon material [102].

In 2006, Bitter and his colleagues [103] showed that nitrogen-doped carbon nanotubes are an efficient heterogeneous catalyst in Knoevenagel condensation. In this case, the catalytic performance was comparable to that of conventional base catalysts. The pyridine nitrogen atoms incorporated into the structure of carbon nanotubes provided a high basicity, which made it possible to use such a carbon material as a highly active and recyclable catalyst. Since then, various nitrogen-doped carbon materials have been repeatedly investigated as the basic catalysts in the Knoevenagel condensation reaction [104, 105].

In addition, nitrogen-doped reduced graphene oxide showed high activity in the reduction reactions of polyaromatic hydrocarbons [106]. The authors showed a synergistic effect from graphite nitrogen and sp2-carbon structures, which could activate anthracene molecules (model compound) through π–π interaction. At the same time, pyridine nitrogen included in the carbon structure can facilitate dissociative hydrogen adsorption.

Recent studies have shown the activity of nitrogen-doped graphene in Michael and Henry addition reactions [107]. According to DFT calculations, the most active basic sites present in N-doped graphene are pyridine nitrogen atoms, especially those located at zigzag edges, as well as carbon sites at doped and undoped zigzag edges and carbon atoms adjacent to protonated nitrogen at armchair edges. These protonated pyridine nitrogen sites activate neighboring carbon centers, which makes them capable of cleavage of the α-C–H bond.

It is also worth mentioning that nitrogen-doped carbon materials are high-performance catalysts for electrochemical processes, such as the oxygen reduction reaction [13, 27, 108]. In such reactions, carbon bonded to nitrogen atoms is an active site for oxygen reduction [109].

The traditional advantage of carbon materials is the ability to easily attach the required functional groups to the carbon surface. As a rule, the creation of catalytically active basic sites is carried out by introducing nitrogen-containing functional groups into carbon materials. Among the basic nitrogen-containing functional groups attached to carbon materials, various amino groups are most often encountered. In particular, carbon nanotubes functionalized with triethylamine groups were used as an efficient catalyst for transesterification of triglycerides [110]. In another work, triethylamine groups were “grafted” to graphene to create a highly efficient solid basic catalyst for the hydrolysis of ethyl acetate [111]. Excellent catalytic activity was demonstrated by graphene oxide bifunctionalized with primary and tertiary amines in the reaction of obtaining trans-β-nitrostyrene from benzaldehyde and nitromethane [112].

Cyclic amines can also be used as basic functional groups. For example, a heterogeneous basic catalyst was prepared from reduced graphene oxide grafted with piperazine molecules. This basic catalyst has demonstrated high efficiency in many classical reactions, such as the Michael and Knoevenagel reactions and aldol condensation [113]. By varying amino groups of different structures, it is possible to control not only the basicity, but also the polarity of the carbon material. Tessonnier and his colleagues [114] have demonstrated how aliphatic amines with hydroxyl groups can be used to improve the conversion of glucose isomerization to fructose. The authors have suggested that hydroxyl groups facilitate the solvation of the carbon catalyst and enhance the intermolecular hydrogen bond with sugars.

Thus, the basicity of various carbon materials can be efficiently controlled both by incorporating nitrogen heteroatoms into the carbon lattice and by adding basic functional groups. Such solid bases, as well as acid catalysts based on carbon materials, are highly adjustable and easy to handle for synthetic chemistry applications.

III.5. Frustrated Lewis Acid–Base Pairs

Catalysis of hydrogenation reactions has long been considered an area in which transition metals seemed indispensable. Hydrogenation in the presence of metal-containing catalysts is one of the most important processes in industrial chemistry. However, in the last couple of decades, significant progress has been made in the development of metal-free hydrogenation catalysts. The literature describes various organic molecules containing Lewis acid–base pairs, rigidly separated at short distances. Such structures are called frustrated Lewis acid–base pairs (FLPs). Similar molecules can activate molecular hydrogen and act as catalysts for hydrogenation [115–117]. Various carbocatalysts can also contain FLPs and are capable of catalyzing hydrogenation reactions.

In 2014, Garcia and coworkers [118] reported on the selective hydrogenation of acetylene and alkenes in the presence of graphene. Based on the known activity of FLPs in organic molecules acting as metal-free catalysts for hydrogenation, the authors assumed the existence of similar FLPs on graphene sheets, consisting of independent pairs of acids and bases located at a sufficient distance to facilitate the cleavage of H2 molecules. In this case, the activation of H2 on graphene will occur through the polarization of H2 molecules with the simultaneous formation of H+- and H–-like centers. Later, Garcia and coauthors [119] have demonstrated the activity of a similar graphene catalyst in the hydrogenation of nitro compounds.

Theoretical studies have shown that nitrogen- and boron-doped bilayer graphene and graphene nanoribbons in which nitrogen and boron are located in different layers, can be efficient FLP catalysts for hydrogen dissociation [120]. Interestingly, carbon atoms around doped boron and nitrogen atoms in graphene turned out to be the active sites demonstrating the strongest hydrogen bonding.

Recently Li and coworkers [121] have reported that carbon quantum dots (CQDs) can be used to substitute Pd nanoparticles in hydrogenation reactions. Due to the presence of FLPs, such carbon particles can be efficient catalysts for the hydrogenation of imines.

Replacing metal catalysts in hydrogenation reactions with carbocatalysts could radically change many important chemical industries, making them more environmentally and economically attractive.

III.6. Radical Sites at Edges and Defects

No less important active sites in carbon materials are radical centers at the edges and defects of carbon sheets. Due to their electronic structure, many carbon materials can function as solid radical initiators [122]. The radicals are well stabilized by the extensive aromatic sp2-carbon structure. This allows them to easily react with oxygen without any significant decomposition of the material [123, 124]. Mostly unpaired electrons catalyze redox reactions. The fact that where graphene oxide promotes the oxidation reactions of alcohols and alkynes has been reported in the classic work by Bielawski and coworkers [1]. However, they used a weight excess of graphene oxide with respect to the reagents, which casts doubt on the possibility of calling graphene oxide a catalyst in these transformations. Nevertheless, they have shown that graphene oxide itself is not an oxidizing agent in this transformation, but promotes the activation of air oxygen molecules.

However, shortly after Bielawski’s work, other reports appeared on the activity of catalytic amounts of carbon materials in oxidation reactions. The presence of defects and doping with heteroatoms led to a change in the electronic structure of neighboring carbon atoms and contributed to the appearance of a sufficient number of active sites. In particular, it has been shown that nitrogen- and boron-doped graphene is a highly efficient catalyst for the self-oxidation of benzyl hydrocarbons. Using the model compound tetralin as an example, Garcia and coworkers [125] proposed a catalytic oxidation mechanism in which these carbon atoms react with oxygen to give peroxide-like species. Such formation of peroxide derivatives, H2O2, and HO\(_{2}^{ - }\) upon contact of carbon materials with oxygen in aqueous solutions has been known for a long time [62, 126, 127]. In this case, the resulting peroxo groups eliminated a hydrogen atom from tetraline, generating a benzyl radical that reacts with oxygen to give tetraline hydroperoxide. Subsequent decomposition of this intermediate gives tetralone and tetralol (Fig. 15). The authors also managed to reduce the quantitative catalyst-to-substrate ratio to 1 : 100.

In 2012, Loh and coworkers [128] have proposed a simple chemical treatment method that increased the number of defects in graphene oxide and thereby ensured a high catalytic activity of the obtained carbon material in the oxidative coupling of amines with imines. The authors managed to achieve a yield of 98% with a carbon catalyst loading of only 5 wt %. Modified graphene oxide was obtained by sequential treatment of a carbon material with a base and an acid, which made it possible to remove metal impurities and oxidation products. According to the proposed mechanism, the edges with unpaired electrons form active catalytic sites and provide improved kinetics for the capture and activation of molecular oxygen via the electron transfer followed by reduction to the superoxide radical. It is also assumed that carboxyl groups at the edges of defects, along with localized unpaired electrons, work synergistically, trapping oxygen and amine molecules, thereby facilitating intermolecular interactions. One of the possible mechanisms involving both an unpaired electron and carboxyl groups suggests the following steps: benzylamine binds to acidic carboxylic groups through a hydrogen bond and forms an electron-donor complex. The unpaired electrons of porous graphene oxide reduce molecular oxygen to form \({\text{O}}_{2}^{{ \bullet - }}\), which remains bound to the graphene oxide surface to stabilize the positive charge of the pore. At the same time, the fixed amine is oxidized by the positive charge of the pore to form a radical cation complex. The superoxide radical \({\text{O}}_{2}^{{ \bullet - }}\) can remove a hydrogen atom from the amine radial cation to form intermediate compounds of the imine and H2O2. Meanwhile, the active site is released, which brings the catalyst to its original state, and the catalytic cycle can be repeated. Imine intermediates can react with free amines to form coupling products or with water to form benzaldehydes, which are then converted to coupling products via a condensation reaction (Fig. 16).

A similar mechanism for the aerobic oxidative dehydrogenation of hydrazo compounds catalyzed by reduced graphene oxide has been proposed by Ma and coworkers [129]. They have suggested that the reduction of graphene oxide produces a large number of unpaired electrons as compared to the original carbon material. This leads to that reduced graphene oxide is more active and can be used as a recyclable and efficient carbocatalyst under mild conditions. According to the authors, the structure of reduced graphene oxide is similar to the structure of modified graphene oxide presented by Loh and coworkers [128], except for the carboxyl groups at the edges of the carbon sheet. Therefore, the active sites of reduced graphene oxide can activate O2 in a similar way to form a superoxide radical \({\text{O}}_{2}^{{ \bullet - }}\). Then, the hydrazo compound is oxidized to form the corresponding azo compound and H2O2. Meanwhile, an electron is released and transferred back to the carbocatalyst. Thus, the structure of the carbocatalyst with an unpaired electron returns to its initial state (Fig. 17).

In another work, Ma and coworkers [130] have suggested the same mechanism for the synthesis of bis(aminothiocarbonyl) disulfides from secondary amines and carbon disulfide, also catalyzed by reduced graphene oxide (Fig. 18). The superoxide radical \({\text{O}}_{2}^{{ \bullet - }}\) abstracts a hydrogen atom from the addition product of carbon disulfide to secondary amine I with the formation of HOO– and the corresponding radical II. At the same time, HOO– reacts with compound I to form H2O2 and dithiocarbamate ion III. The rGO cation accepts an electron from compound III, generating a second radical II and reduced graphene oxide with an unpaired electron. Then, two radicals II are combined to give thiuram disulfide IV.

Structural defects in graphene oxide can play an important role in the formation of surface-bound superoxide particles. It has been shown [131] that an increase in the content of structural defects of graphene oxide increases its activity as a catalyst. In another recent work, it was shown that it is possible to controllably create pores in graphene sheets by forming zigzag edges while simultaneously removing other defects [132]. The catalytic activity of localized π-edge states has been demonstrated experimentally in this work due to the absence of other defects on the basal surface of modified holey graphene.

Another way to increase the activity of the carbocatalyst and generate radical species on the surface of the carbon material can be the use of special additives. For example, graphene oxide in the presence of BF3 ‧ OEt2 showed good catalytic activity in the oxidative C–H coupling reactions [133], in the presence of p-TsOH in cross-coupling reactions of xanthenes with arenes [134], and in the presence of tBuOK in the C–H bond activation reactions [91].

It has been recently shown that nitrogen-doped reduced graphene oxide (NrGO) can work as a selective catalyst for the hydrogenation of nitro compounds in the presence of tBuOK [135]. In such a catalytic system, the nitro group could be selectively reduced in the presence of multiple bonds and a carbonyl group. The addition of tBuOK to NrGO promotes the neutralization of acidic functional groups and accelerates the localization of radicals at the basic sites. Molecular hydrogen reacts with radicals to form hydrogen radicals (Fig. 19). The formation of such radicals was confirmed by a spin trap reaction using 5,5-dimethyl-1-pyrroline N-oxide. The ionic site on the NrGO surface interacts much better with polarized nitro groups than with less polarized alkynes, alkenes, and carbonyls, which explains the selectivity of the reaction.

It is evident that radicals concentrated at the edges and defects of carbon sheets play an important role in redox reactions. Other active sites also assist in the course of reactions, working in conjunction with radical sites. It is important to take into account this cooperative action of several types of active sites at once, as well as the influence of the extensive aromatic π-system. Available research deals at best with the operation of two types of active sites. However, it cannot be ruled out that a multitude of active sites simultaneously present on the surface of the carbon material contribute to a greater or lesser extent to the reaction mechanism.

One of the most important advantages of carbon materials is the ability to tune their electronic properties. By functionalization and doping, a wide variety of active sites can be created in a controlled manner. An interesting approach to functionalization and changes in the electronic properties of carbon materials is the process of fluorination/defluorination of carbon compounds [136, 137], which can provide interesting materials for carbocatalytic applications.

In this section, only the key active sites were considered, while many other structural features, defects, and electronic effects can be essential for the catalytic activity of carbon materials. Among such features of carbon materials, which are just beginning to be actively investigated in the context of carbocatalysis, are Stone–Wales defects [138], inclusions of sulfur [139] and phosphorus [140] atoms, heterojunction effects [141], and many others.

IV. THE ROLE OF CARBENE CENTERS IN THE CATALYTIC ACTIVITY OF CARBON MATERIALS

IV.1. Carbene Centers in Carbon Materials

In 2005, Radovic and Bockrath presented [142] models of the chemical composition of graphene edges. They concluded that under ambient conditions, a significant portion of the oxygen-free edge sites are neither H-terminated nor unadulterated free radicals, as universally assumed. The zigzag sites are carbene-like, with the triplet ground state being most common. The armchair edges are carbyne-like, with the singlet ground state being most common.

In a recent review, Primo and coworkers [10] have noted that it is highly likely that the presence of carbene-like defects in highly doped carbon materials may be the reason for their catalytic activity. The catalytic activity of N-heterocyclic carbenes (NHCs) may also indicate an important role of carbene sites in the catalytic activity. Despite the fact that the most widespread use of NHCs is their use as electron-rich ligands for the formation of catalytically active metal complexes, NHCs can also exhibit catalytic activity in the absence of transition metals [143, 144]. Nevertheless, the role of carbene sites in carbocatalysis remains poorly understood.

Recently, the study of the mechanisms of carbocatalytic reactions with the participation of active centers of carbene nature has become especially urgent, since methods of targeted and controlled generation of defects on the surface of carbon materials have appeared [132, 145, 146]. Carbene derivatives of polyaromatic hydrocarbons can also be considered promising carbocatalysts, since in this case active sites of the same type can be generated, and the use of low-molecular-weight polyaromatic compounds makes it possible to carry out the reaction under homogeneous catalysis conditions.

IV.2. The Role of Carbene Centers in the Mechanism of Carbocatalytic Acetylene Trimerization

In 2020, for molecular polyaromatic carbocatalysts with one carbene active center, the mechanism of acetylene trimerization, leading to the formation of benzene, has been proposed and substantiated by quantum-chemical methods [45]. Similar models of carbon materials with carbene active centers obtained by removing a hydrogen atom from one of the carbon atoms at the zigzag edge have been used, for example, to study the formation of a CO2 molecule as a result of the reaction of oxygen with graphene [147].

The trimerization process has been considered for various carbon structures, which can be divided into Kekulé (C6H6, C14H10, C19H10, C37H14) and non-Kekulé (C25H12, C29H14, C33H16) structures (Fig. 20). Compounds from the first group can be described by the formal Kekulé structure, while the molecules from the second group are polycyclic compounds with a system of conjugated bonds, for which the formal Kekulé structure cannot be matched, and two electrons in non-Kekulé carbocatalysts remain unpaired. It should be noted that all the considered molecules of polyaromatic carbenes are in the triplet electronic state, regardless of the group of structures to which they belong.

Molecular structures of possible carbocatalysts for acetylene trimerization to give benzene. Unpaired electrons are denoted by asterisks. For each of the non-Kekulé structures, one of the possible resonance structures is shown. Adapted with permission from [45]. Copyright ©2020 American Chemical Society.

For a detailed study of the acetylene trimerization mechanism, a medium-sized carbocatalyst C37H14 has been chosen. This size of the molecule, on the one hand, allows one to study all the stages of the process at a sufficiently high level of theory, and on the other hand, it can be considered as a model of a graphene sheet (Fig. 21).

Free energy profiles for the acetylene cyclotrimerization involving the C37H14 molecule as the carbocatalyst, the structure of which is shown in the box. For each stationary point on the profile, the optimized molecular structure is shown and the free energy values are given relative to the initial reference point, which is taken to be the free energy of the initial carbene molecule. The associative pathway of the carbocatalyst regeneration is shown in red, and the dissociative pathway of the carbocatalyst regeneration is shown in blue. Adapted with permission from [45]. Copyright ©2020 American Chemical Society.

The acetylene trimerization process begins with the attachment of the first acetylene molecule to the carbene center of graphene 1 to form species 3. The activation energy of such a process is low and amounts to 11.3 kcal/mol. The next acetylene molecule is added to the resulting intermediate 3 to form intermediate 5. Further addition of the third acetylene molecule leads to the formation of compound 7, the linear fragment of which cyclizes through transition state 8-TS to form intermediate 9. In intermediate 9, the resulting six-membered ring of the benzene molecule is connected to the carbene center of the carbocatalyst, forming a σ-complex. At the final stage of the process, the benzene molecule is released and the catalyst is regenerated, which can proceed in two ways: associative and dissociative. In the associative mechanism of regeneration, the benzene molecule is released from the active center synchronously with the binding of the acetylene molecule to the same carbene center, that is, benzene is replaced by acetylene. In the course of this substitution, at an intermediate stage, compound 11 is formed, in which alkyne and benzene moieties are simultaneously linked to the active center. The dissociative mechanism includes the stage of elimination of the benzene molecule through the transition state 13-TS without the participation of the acetylene molecule, which leads to the regeneration of carbene 1 in one stage [45]. As can be seen from the free energy profile, for the carbocatalyst C37H14, the dissociative pathway for benzene elimination has a significantly lower activation energy (26.2 kcal/mol) as compared to the associative pathway (49.0 kcal/mol).

It should be noted that acetylene molecules can be further added to intermediate 7 and the chain can continue its linear growth. However, a comparison of the stages of trimer cyclization and the formation of a linear tetramer demonstrates that the cyclization process is characterized by a lower free activation energy (5.5 kcal/mol) than the linear tetramerization (11.4 kcal/mol), since intramolecular cyclization almost does not change the entropy of the system, whereas the addition of the fourth acetylene molecule leads to a decrease in entropy. In addition, the thermodynamic driving force for the cyclization of the trimer is greater (–47.1 kcal/mol) than the driving force for the formation of a linear tetramer (–34.7 kcal/mol), which is also associated with different changes in entropy in these processes.

For comparison, the mechanism of acetylene trimerization was studied using monoradical polyaromatic compounds as carbocatalysts: C37H15 and C19H11 (olympicenyl radical) [45]. It has been shown that, in the case of monoradicals, the stage of addition of the first acetylene molecule has a significantly higher activation energy (33.3 kcal/mol for C37H15) as compared to carbene carbocatalysts (11.3 kcal/mol for C37H14). In the case of a phenyl monoradical, intermediate 9 is characterized by a very low energy; therefore, the stage of product elimination becomes kinetically hindered: the free activation energy is 78.5 kcal/mol for the associative elimination mechanism and 44.5 kcal/mol for the dissociative one.

It has been shown that the mechanism of benzene elimination and catalyst regeneration depends on the molecular structure of the carbocatalyst. For example, for C37H14, C25H12, C19H10, and C33H16, the dissociative regeneration pathway of the carbocatalyst is more preferable, while for C14H10 and C6H6, the associative regeneration pathway is more likely [45].

An interesting feature in the spatial distribution of unpaired electrons has been found when comparing the Kekulé and non-Kekulé carbocatalysts at the stage of active site regeneration by the associative mechanism (Fig. 22). In particular, it has been demonstrated that for Kekulé structures, for example, C37H14, unpaired electrons are delocalized over the entire plane of the polyaromatic system, with the exception of intermediate 11, in which such delocalization is disturbed, and both unpaired electrons of the triplet species are localized mainly in the region of the active site. Upon transition to the state following intermediate 11, the delocalization of electrons over the plane of the carbocatalyst molecule is restored again. For non-Kekulé structures, such spin density oscillations are not observed, and in intermediate 11, delocalization of unpaired electrons is retained over the entire plane of the carbocatalyst molecule. In this case, it is precisely for non-Kekulé structures that a higher energy of intermediate 11 and transition state 12-TS is observed, which reduces the probability of catalyst regeneration by the associative pathway for such systems, while for Kekulé structures, especially of small size, the carbocatalyst regeneration by the associative pathway is quite probable.

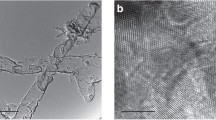

The feasibility of carbocatalytic acetylene cyclotrimerization has been studied experimentally [45]. During the experiment, acetylene with a volume of 7.3 L was passed through the channel of a quartz tube filled with glass wool at 650°C for 20 min (Figs. 23a, 23b). Upon heating, carbonization of acetylene occurred to form carbon flakes on the glass fiber surface (Figs. 23c–23f). These carbon particles later became carriers of catalytically active centers, on which acetylene trimerization occurred. The use of acetylene as a carbocatalyst precursor eliminated the influence of metal impurities commonly encountered in commercial carbon. As a result of this process, a liquid condensate was obtained, mainly consisting of benzene (55%) and naphthalene (12%) with minor impurities of other polyaromatic compounds. This experiment independently demonstrated the possibility of the catalytic action of carbon in the acetylene cyclotrimerization reaction.

Experimental setup for carbocatalytic acetylene cyclotrimerization: (a) a photograph of the glass wool-filled quartz tube reactor placed in a tube furnace; (b) schematic representation of the experimental setup for carrying out carbocyclic acetylene cyclotrimerization; (c) the glass wool filling before and after the experiment; (d, e) SEM images of glass fibers after the reaction; (f) TEM image of carbon flakes formed on the glass fibers during the experiment. Adapted with permission from [45]. Copyright ©2020 American Chemical Society.

In conclusion, it should be noted that fabrication of new types of carbon materials and scaling up their production is one of the key factors in the development of this area. As a striking example, we can note the studies by Likholobov and his colleagues dealing with the carbon material Sibunit and various areas of its application [58, 148–150].

V. CONCLUSIONS

In this review, we briefly reviewed the historical development of carbocatalysis from the first reactions with the participation of activated carbons to the modern mechanistic concepts of carbocatalysis and the structure of carbocatalysts. Due to their great structural diversity and vast possibilities for the functionalization and doping of carbon materials, carbocatalysts have enormous potential in a wide variety of areas of organic synthesis, from oxidation reactions to biomass processing. The variety of catalytic sites on the carbon surface allows carbocatalysts to participate in redox processes, acid–base catalysis, and radical processes. Carbocatalysts have shown high performance even in those reactions in which metal catalysts were considered uncontested: Fenton’s reaction, hydrogenation, and C–C coupling. Thus, carbon materials are remarkable for their versatility and ability to act as catalysts in a wide variety of types of catalytic reactions.

Many issues related to the operation of carbocatalysts have yet to be resolved. For the development of this area and the development of new carbocatalysts for the needs of organic chemistry, as well as expanding the scope of application of carbocatalysts, it is very important to understand the mechanisms of the carbocatalytic reactions. At this stage, most studies consider the operation of active catalytic centers separately. However, it is obvious that the performance of the carbocatalyst will be determined by the superposition of the chemical activity of various structures in the carbon material. Many studies have revealed synergistic effects from the joint operation of several active sites or the participation of a π-conjugated catalytic system in the operation of catalytic sites. But the models of mechanisms that take into account the role of a whole heterogeneous cocktail of active sites may turn out to be even more complex. For their study, the use of traditional methods may not be sufficient.

The development of methods of quantum-chemical calculations provides great opportunities for studying polyatomic carbon systems. This allows one to explore more and more complex and multicomponent systems. Experimental methods currently do not allow the detection of short-lived intermediates and transition states under conditions of high-temperature chemical processes, and a detailed analysis of the electronic structure of such species is possible only by quantum-chemical methods. Modern methods of molecular modeling greatly facilitate the task of studying reaction mechanisms, especially in such a complex type of reaction as reactions involving radical and carbene centers.

The efforts made in this area will undoubtedly pay off. There is every reason to believe that potentially cheap and environmentally friendly carbocatalysts can in the future supplement or replace metal catalysts in fundamental areas of the chemical industry, such as fine organic synthesis, biomass processing, and petrochemistry.

VI. ABBREVIATIONS

AC—activated carbon;

CB—carbon black;

CNT—carbon nanotubes;

CQD—carbon quantum dots;

DFF—2,5-diformylfuran;

DFT—density functional theory;

FLP—frustrated Lewis acid–base pairs;

GO—graphene oxide;

rGO—reduced graphene oxide;

HMF—5-hydroxymethylfurfural;

NrGO—N-doped reduced graphene oxide;

TEMPO—2,2,6,6-tetramethylpiperidine 1-oxyl.

REFERENCES

Dreyer, D.R., Jia, H.P., and Bielawski, C.W., Angew. Chem. Int. Ed. Engl., 2010, vol. 49, no. 38, pp. 6813–6816. https://doi.org/10.1002/anie.201002160

Figueiredo, J.L. and Pereira, M.F.R., in: Carbon Materials for Catalysis, Serp, P. and Figueiredo, J.L., Eds., Hoboken, New Jersey: Wiley, 2008, ch. 6, pp. 177–217. https://doi.org/10.1002/9780470403709.ch6

Su, C. and Loh, K.P., Acc. Chem. Res., 2013, vol. 46, no. 10, pp. 2275–2285. https://doi.org/10.1021/ar300118v

Navalon, S., Dhakshinamoorthy, A., Alvaro, M., et al., Chem. Rev., 2014, vol. 114, no 12, pp. 6179–6212. https://doi.org/10.1021/cr4007347

Serp, P. and Machado, B., in: Nanostructured Carbon Materials for Catalysis, Cambridge: Royal Society of Chemistry, 2015. https://doi.org/10.1039/9781782622567-00223

Chua, C.K. and Pumera, M., Chem.-Eur. J., 2015, vol. 21, no. 36, pp. 12550–12562. https://doi.org/10.1002/chem.201501383

Tang, P., Hu, G., Li, M., et al., ACS Catal., 2016, vol. 6, no. 10, pp. 6948–6958. https://doi.org/10.1021/acscatal.6b01668

Su, D.S., Wen, G., Wu, S., et al., Angew. Chem. Int. Ed. Engl., 2017, vol. 56, no. 4, pp. 936–964. https://doi.org/10.1002/anie.201600906

Navalon, S., Dhakshinamoorthy, A., Alvaro, M., et al., Chem. Soc. Rev., 2017, vol. 46, no. 15, pp. 4501–4529. https://doi.org/10.1039/C7CS00156H

Antonietti, M., Lopez-Salas, N., and Primo, A., Adv. Mater., 2019, vol. 31, no. 13, 1805719. https://doi.org/10.1002/adma.201805719

Konwar, L.J., Mäki-Arvela, P., and Mikkola, J.-P., Chem. Rev., 2019, vol. 119, no. 22, pp. 11576–11630. https://doi.org/10.1021/acs.chemrev.9b00199

Ahmad, M.S. and Nishina, Y., Nanoscale, 2020, vol. 12, no. 23, pp. 12210–12227. https://doi.org/10.1039/D0NR02984J

Li, Y., Tong, Y., and Peng, F., J. Energy Chem., 2020, vol. 48, pp. 308–321. https://doi.org/10.1016/j.jechem.2020.02.027

Konwar, L.J., Boro, J., and Deka, D., Renew. Sust. Energ. Rev., 2014, vol. 29, pp. 546–564. https://doi.org/10.1016/j.rser.2013.09.003

Yang, Q., Chen, Y., Duan, X., et al., Appl. Catal. B, 2020, vol. 276, p. 119146. https://doi.org/10.1016/j.apcatb.2020.119146

Wang, G., Wang, P., Zhang, X., et al., Nanoscale, 2020, vol. 12, no. 14, pp. 7797–7803. https://doi.org/10.1039/d0nr00516a

Verma, S., Mungse, H.P., Kumar, N., et al., Chem. Commun., 2011, vol. 47, no. 47, pp. 12673–12675. https://doi.org/10.1039/c1cc15230k

Vijay Kumar A. and Rama Rao K., Tetrahedron Lett., 2011, vol. 52, no. 40, pp. 5188–5191. https://doi.org/10.1016/j.tetlet.2011.08.002

Singh Chauhan, S.M. and Mishra, S., Molecules, 2011, vol. 16, no. 9, pp. 7256–7266. https://doi.org/10.3390/molecules16097256

Shaikh, M., Singh, S.K., Khilari S., et al., Catal. Commun., 2018, vol. 106, pp. 64–67. https://doi.org/10.1016/j.catcom.2017.12.018

Ji, J., Zhang, G., Chen, H., et al., Chem. Sci., 2011, vol. 2, no. 3, pp. 484–487. https://doi.org/10.1039/c0sc00484g

Dreyer, D.R., Bielawski, C.W., Adv. Funct. Mater., 2012, vol. 22, no. 15, pp. 3247–3253. https://doi.org/10.1002/adfm.201103152

Chen, X., Shen, Q., Li, Z., et al., ACS Appl. Mater. Interfaces, 2020, vol. 12, no. 1, pp. 654–666. https://doi.org/10.1021/acsami.9b17582

Jia, H.-P., Dreyer, D.R., and Bielawski, C.W., Tetrahedron, 2011, vol. 67, no. 24, pp. 4431–4434. https://doi.org/10.1016/j.tet.2011.02.065

Morimoto, N., Morioku, K., Suzuki, H., et al., Chem. Commun., 2017, vol. 53, no. 53, pp. 7226–7229. https://doi.org/10.1039/C7CC02337E

Modak, A., Mondal, J., and Bhaumik, A., ChemCatChem, 2013, vol. 5, no. 7, pp. 1749–1753. https://doi.org/10.1002/cctc.201300009

Honda, K., Waki, Y., Matsumoto, A., et al., Diamond Relat. Mater., 2020, vol. 107, p. 107900. https://doi.org/10.1016/j.diamond.2020.107900

Deitz, V. R., Bibliography of Solid Adsorbents: An Annotative Bibliographical Survey of the Scientific Literature on Bone Char, Activated Carbons, and Other Technical Solid Adsorbents, for the Years 1900 to 1942 Inclusive, Washington D.C.: National Bureau of Standards, 1944, p. 877.

Scheele, C.W., Chemische Abhandlung von der Luft und dem Feuer, Nebst einem Vorbericht von Torbern Bergman (Chemical Treatise on the Air and the Fire, with a preface by Torbern Bergman), Upsala, Leipzig: Magn. Swederus, 1777. https://books.google.ru/books?id=zLk5AAAAcAAJ&redir_esc=y. Cited August 24, 2020

Fontana, F., in: Memorie di matematica e fisica della Societ, scritta il dì 20. d’Ottobre 1781, 1782, no. 1 (2), pp. 655–659. https://bibdig.museogalileo.it/Teca/Viewer?an=000000985848.

Lowitz, T., Ann. Chim. Paris, 1792, vol. 14, pp. 327–329.

Lennartson, A., The Chemical Works of Carl Wilhelm Scheele, Springer Briefs in History of Chemistry, Cham: Springer, 2017. https://doi.org/10.1007/978-3-319-58181-1

Berthelot, M., Ann. Chim. Phys., 1866, vol. 9, p. 445.

Berthelot, M., Ann. Chim. Phys., 1867, vol.12, p. 52.

Zelinsky, N., Ber. Dtsch. Chem. Ges. B, 1924, vol. 57, pp. 264–276. https://doi.org/10.1002/cber.19240570219

Iki, S. and Ogawa, M., J. Soc. Chem. Ind. Jpn., 1927, vol. 30, p. 435.

Fischer, F., Bangert, F., and Pichler, H.,Brennstoff-Chem., 1929, vol. 10, pp. 279–282.

Lozovoy, A.V., Zh. Obshch. Khim., 1931, vol. 1, p. 717.

Berl, E. and Hoffman, K.W., Z. Anorg. Chem., 1931, vol. 44, no. 14, pp. 259–261. https://doi.org/10.1002/ange.19310441404

Schläpfer, P., and Brunner, M., Helv. Chim. Acta, 1930, vol. 13, no. 5, pp. 1125–1151. https://doi.org/10.1002/hlca.19300130539

Clemo, G.R. and McQuillen, A., J. Chem. Soc., 1935, pp. 851–855. https://doi.org/10.1039/JR9350000851

Clemo, G. R. and Robson, A.C., J. Chem. Soc., 1939, pp. 429–430. https://doi.org/10.1039/JR9390000429

Dobryanskii, A.F. and Drabkin, A.Ya., Zh. Obsch. Khim., 1950, vol. 20, no. 12, pp. 2255–2260.

Reppe, V.W. and Schweckenddick, W.J., Justus Liebigs Ann. Chem., 1948, vol. 560, no. 1, pp. 104–116. https://doi.org/10.1002/jlac.19485600104

Gordeev, E.G., Pentsak, E.O., and Ananikov, V.P., J. Am. Chem. Soc., 2020, vol. 142, no. 8, pp. 3784–3796. https://doi.org/10.1021/jacs.9b10887

Calvert, F.C., J. Chem. Soc., 1867, vol. 20, pp. 293–296. https://doi.org/10.1039/JS8672000293

Stenhouse, J., Ann. Chem. Pharm., 1854, vol. 90, no. 2, pp. 186–190.https://doi.org/10.1002/jlac.18540900211

Lemoine, G., C. R. Acad. Sci., 1907, vol. 144, pp. 357–358. https://www.biodiversitylibrary.org/it-em/31394#page/363/mode/1up.

Matsui, M., Mem. Coll. Sci. Kyoto Imp. Univ., 1908, vol. 1, pp. 386–390.

Warburg, O., Arch. Ges. Physiol., 1914, vol 155, pp. 547–560. https://doi.org/10.1007/BF01682054

Warburg, O. and Negelein, E., Biochem. Z., 1921, vol. 113, pp. 257–284.

Warburg, O. and Brefeld, W., Biochem. Z., 1924, vol. 145, p. 461–480.

Senderens, J.-B., C. R. Acad. Sci., 1907, vol. 144, pp. 381–383. https://www.biodiversitylibrary.org/item/31394#page/387/mode/1up.

Senderens, J.-B. and Aboulenc, J., C. R. Acad. Sci., 1920, vol. 170, pp. 1064–1067. https://www.biodiversitylibrary.org/item/111456#pa-ge/1063/mode/1up.

Paternò, E., Gazz. Chim. Ital., 1878, vol. 8, pp. 233–234.

Atkinson, R.H., Heycock, C.T., and Pope, W.J., J. Chem. Soc., Trans., 1920, vol. 117, pp. 1410–1426. https://doi.org/10.1039/CT9201701410

Surovikin, V.F., Plaxin, G.V., Likholobov, V.A., and Tiunova, I.J., US Patent 4978649, 1990.

Likholobov, V.A., Fenelonov, V.B., Okkel, L.G., et al., React. Kinet. Catal. Lett., 1995, vol. 54, pp. 381–411. https://doi.org/10.1007/BF02071033

Abrams, L., Cicha, W.V., Manzer, L.E., et al., Stud. Surf. Sci. Catal., 2000, vol. 130, pp. 455–460. https://doi.org/10.1016/S0167-2991(00)80999-4

Huthmacher, K. and Most, D., in: Ullmann’s Encyclopedia of Industrial Chemistry, Wiley-VCH, 2000. https://doi.org/10.1002/14356007.a08_191

US Patent 2491459, 1945.

Rideal, E.K. and Wright, W.M., J. Chem. Soc. Trans., 1925, vol. 127, pp. 1347–1357. https://doi.org/10.1039/CT9252701347

Rideal, E.K. and Wright, W.M., J. Chem. Soc., 1926, vol. 129, pp. 1813–1821. https://doi.org/10.1039/JR9262901813

Rideal, E.K. and Wright, W.M., J. Chem. Soc., 1926, vol. 129, pp. 3182–3190. https://doi.org/10.1039/JR9262903182

Blench, E.A. and Garner, W.E., J. Chem. Soc. Trans., 1924, vol. 125, pp. 1288–1295. https://doi.org/10.1039/CT9242501288

Alkhazov, T.G., Lisovskii, A.E., and Gulakhmedova, T.Kh., React. Kinet. Catal. Lett., 1979, vol. 12, no. 2, pp. 189–193. https://doi.org/10.1007/BF02071909

Mestl, G., Maksimova, N.I., Keller, N., et al., Angew. Chem. Int. Ed. Engl., 2001, vol. 40, no. 11, pp. 2066–2068. https://doi.org/10.1002/1521-3773(20010601)40:11<-2066::AID-ANIE2066>3.0.CO;2-I

Byung, H.H., Dae, H.S., and Sung, Y.C., Tetrahedron Lett., 1985, vol. 26, no. 50, pp. 6233–6234. https://doi.org/10.1016/S0040-4039(00)95060-3

Feigl, F., Z. Anorg. Allgem. Chem., 1921, vol. 119, no. 1, pp. 305–309. https://doi.org/10.1002/zaac.19211190122

Kuznetsova, N.I., Likholobov, V.A., Gurrath, M., et al., Appl. Catal. A, 1995, vol. 128, no. 1, pp. 41–52. https://doi.org/10.1016/0926-860X(95)00054-2

Dobrynkin, N.M., Batygina, M.V., and Bal’zhinimaev, B.S., Curr. Top. Catal., 2010, vol. 9, pp. 61–70.

Firth, J.B. and Watson, F.S., J. Chem. Soc., Trans., 1923, vol. 123, pp. 1750–1755. https://doi.org/10.1039/CT9232301750

Skumburdies, K., Kolloid-Z., 1931, vol. 55, pp. 156–164.

Bandosz, T.J., in: Carbon Materials for Catalysis, Serp, P. and Figueiredo, J.L., Eds., Hoboken, New Jersey: Wiley, 2008, ch. 2, pp. 45–92. https://doi.org/10.1002/9780470403709.ch2

Yamada, Y., Kawai, M., Yorimitsu, H., et al., ACS Appl. Mater. Interfaces, 2018, vol. 10, no. 47, pp. 40710–40739. https://doi.org/10.1021/acsami.8b11022

Frank, B., Blume, R., Rinaldi, A., et al., Angew. Chem. Int. Ed. Engl., 2011, vol. 50, no. 43, pp. 10226–10230. https://doi.org/10.1002/anie.201103340

Hummers, W.S. and Offeman, R.E., J. Am. Chem. Soc., 1958, vol. 80, no. 6, pp. 1339–1339. https://doi.org/10.1021/ja01539a017

Marcano, D.C., Kosynkin, D.V., Berlin, J.M., et al., ACS Nano, 2010, vol. 4, no. 8, pp. 4806–4814. https://doi.org/10.1021/nn1006368

Dreyer, D.R., Todd, A.D., and Bielawski, C.W., Chem. Soc. Rev., 2014, vol. 43, no. 15, pp. 5288–5301. https://doi.org/10.1039/C4CS00060A

Brisebois, P.P. and, Siaj, M., J. Mater. Chem., 2020, vol. 8, no. 5, pp. 1517–1547. https://doi.org/10.1039/C9TC03251G

Dhakshinamoorthy, A., Alvaro, M., Puche, M., et al., ChemCatChem, 2012, vol. 4, no. 12, pp. 2026–2030. https://doi.org/10.1002/cctc.201200461

Dhakshinamoorthy, A., Alvaro, M., Concepción, P., et al., Chem. Commun., 2012, vol. 48, no. 44, pp. 5443–5445. https://doi.org/10.1039/C2CC31385E

Sengupta, A., Su, C., Bao, C., et al., ChemCatChem, 2014, vol. 6, no. 9, pp. 2507–2511. https://doi.org/10.1002/cctc.201402254

Liu, F., Sun, J., Zhu, L., et al.,J. Mater. Chem., 2012, vol. 22, no. 12, pp. 5495–5502. https://doi.org/10.1039/C2JM16608A

Ferreira, A.R.O., Silvestre-Albero, J., Maier, M.E., et al., Mol. Catal., 2020, vol. 488, p. 110888. https://doi.org/10.1016/j.mcat.2020.110888

Qin, L., Ishizaki, T., Takeuchi, N., et al., ACS Sust. Chem. Eng., 2020, vol. 8, no. 15, pp. 5837–5846. https://doi.org/10.1021/acssuschemeng.9b07156

Carlier, S. and Hermans, S., Front. Chem., 2020, vol. 8, p. 347. https://doi.org/10.3389/fchem.2020.00347

Wang, H., Kong, Q., Wang, Y., et al., ChemCatChem, 2014, vol. 6, no. 3, pp. 728–732. https://doi.org/10.1002/cctc.201301067

Lv, G., Wang, H., Yang, Y., et al., ACS Catal., 2015, vol. 5, no. 9, pp. 5636–5646. https://doi.org/10.1021/acscatal.5b01446

Mungse, H.P., Bhakuni, N., Tripathi, D., et al., J. Phys. Org. Chem., 2014, vol. 27, no. 12, pp. 944–951. https://doi.org/10.1002/poc.3375

Gao, Y., Tang, P., Zhou, H., et al., Angew. Chem. Int. Ed. Engl., 2016, vol. 55, no. 9, pp. 3124–3128. https://doi.org/10.1002/anie.201510081

Cui, Y., Lee, Y.H., and Yang, J.W., Sci. Rep., 2017, vol. 7, no. 1, p 3146. https://doi.org/10.1038/s41598-017-03468-4

Pereira, M.F.R., Órfão, J.J.M., and Figueiredo, J.L., Appl. Catal. A, 1999, vol. 184, no. 1, pp. 153–160. https://doi.org/10.1016/S0926-860X(99)00124-6

Pereira, M.F.R., Orfão, J.J.M., and Figueiredo, J.L., Appl. Catal. A, 2000, vol. 196, no. 1, pp. 43–54. https://doi.org/10.1016/S0926-860X(99)00447-0

Espinosa, J.C., Navalón, S., Primo, A., et al., Chem.- Eur. J., 2015, vol. 21, no. 34, pp. 11966–11971. https://doi.org/10.1002/chem.201501533

Wu, S., Wen, G., Liu, X., et al., ChemCatChem, 2014, vol. 6, no. 6, pp. 1558–1561. https://doi.org/10.1002/cctc.201402070

Montes-Morán, M.A., Suárez, D., Menéndez, J.A., et al., Carbon, 2004, vol. 42, no. 7, pp. 1219–1225. https://doi.org/10.1016/j.carbon.2004.01.023

Leon y Leon, C.A., Solar, J.M., Calemma, V., et al., Carbon, 1992, vol. 30, no. 5, pp. 797–811. https://doi.org/10.1016/0008-6223(92)90164-R

Montes-Morán, M.A., Menéndez, J.A., Fuente, E., et al., J. Phys. Chem. B, 1998, vol. 102, no. 29, pp. 5595–5601. https://doi.org/10.1021/jp972656t

Menéndez, J.A., Suárez, D., Fuente, E., et al., Carbon,1999, vol 37, no. 6, pp. 1002–1006. https://doi.org/10.1016/S0008-6223(99)00082-2

Islam, S.M., Roy, A.S., Dey, R.C., et al., J. Mol. Catal. A: Chem., 2014, vol. 394, pp. 66–73. https://doi.org/10.1016/j.molcata.2014.06.038

Li, B., Sun, X., and Su, D., Phys. Chem. Chem. Phys., 2015, vol. 17, no. 10, pp. 6691–6694. https://doi.org/10.1039/C4CP05765A

van Dommele, S., de Jong, K.P., and Bitter, J.H., Chem. Commun., 2006, no. 46, pp. 4859–4861. https://doi.org/10.1039/B610208E

Kan-nari, N., Okamura, S., Fujita, S., et al., Adv. Synth. Catal., 2010, vol. 352, no. 9, pp. 1476–1484. https://doi.org/10.1002/adsc.201000029

Wang, L., Wang, L., Jin, H., et al., Catal. Commun., 2011, vol. 15, no. 1, pp. 78–81. https://doi.org/10.1016/j.catcom.2011.08.013

Liu, R., Li, F., Chen, C., et al., Catal. Sci. Technol., 2017, vol. 7, no. 5, pp. 1217–1226. https://doi.org/10.1039/C7CY00058H

Candu, N., Man, I., Simion, A., et al., J. Catal., 2019, vol. 376, pp. 238–247. https://doi.org/10.1016/j.jcat.2019.07.011

Zhuang, S., Nunna, B.B., Mandal, D., et al., Nano-Struct.Nano-Objects, 2018, vol. 15, pp. 140–152. https://doi.org/10.1016/j.nanoso.2017.09.003

Lemes, G., Sebastián, D., Pastor, E., et al., J. Power Sources, 2019, vol. 438, p. 227036. https://doi.org/10.1016/j.jpowsour.2019.227036

Villa, A., Tessonnier, J.-P., Majoulet O., et al., ChemSusChem, 2010, vol. 3. no. 2, pp. 241–245. https://doi.org/10.1002/cssc.200900181

Yuan, C., Chen, W., and Yan, L., J. Mater. Chem., 2012, vol. 22, no. 15, pp. 7456–7460. https://doi.org/10.1039/C2JM30442B