Abstract

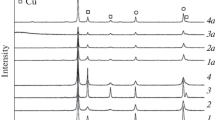

To fabricate Cu–Ti composite particles, the method of copper deposition from its sulfate solution on titanium powder particles with the simultaneous mechanical activation (MA) of the mixture in an AGO‑2 planetary ball mill for 5 min is used. The CuSO4 ⋅ 5H2O concentration in solutions is 10 and 16%, which provides molar ratio Cu/Ti = 0.85 and 1.36, respectively, with the complete reduction of copper. The rapid reduction of copper in the form of highly dispersed partially amorphized powder occurs during MA, and composite particles with a thin laminate structure and high reaction ability are formed. Prepared composites are rinsed and stored in argon because reduced copper possesses high activity and rapidly oxidizes in air to oxide Cu2O. After drying, the additional MA of the mixture is performed for 5 min. Pellets 3 mm in diameter and up to 1.5 mm in height are compacted from prepared powders and heated in argon to 700–1200°C. An intense reaction with heat liberation (heat explosion) and the formation of TiCu, Ti2Cu3, and Ti2Cu intermetallic compounds starts upon sample heating. The critical inflammation temperature for composite powders formed by MA with simultaneous copper deposition from the solution is 480°C, which is 400°C below the inflammation temperature of the usual powder mixture of titanium and copper. The alloy has a dendritic structure at a heating temperature close to the melting point, while, if it is exceeded by more than 100°C, the phase distribution in the alloys becomes more uniform and their size decreases.

Similar content being viewed by others

REFERENCES

Alshammari, Y., Yang, F., and Bolzoni, L., Low-cost powder metallurgy Ti-Cu alloys as a potential antibacterial material, J. Mech. Behav. Biomed. Mater., 2019, vol. 95, pp. 232–239. https://doi.org/10.1016/j.jmbbm.2019.04.004

Zhou Kun, Liu Ying, Pang Shujie, and Zhang Tao, Formation and properties of centimeter-size Zr–Ti–Cu–Al–Y bulk metallic glasses as potential biomaterials, J. Alloys Compd., 2016, vol. 656, pp. 389–394. https://doi.org/10.1016/j.jallcom.2015.09.254

Liu Ying, Pang Shujie, Li Haifei, Hu Qiao, Chen Bin, and Zhang Tao, Formation and properties of Ti-based Ti–Zr–Cu–Fe–Sn–Si bulk glasses with different (Ti + Zr)/Cu ratios for biomedical application, Intermetallics, 2016, vol. 72, pp. 36–43. https://doi.org/10.1016/j.intermet.2016.01.007

Semboshi, S., Yamauchi, S., and Numakura, H., Formation of titanium hydride in dilute CuTi alloy by aging in hydrogen atmosphere and its effects on electrical and mechanical properties, Mater. Trans., 2013, vol. 54, no. 4, pp. 520–527. https://doi.org/10.2320/matertrans.M2012423

Kalin, B.A., Fedotov, V.T., Sevryukov, O.N., Mamedova, T.T., Rybkin, B.V., Ivanov, A.V., and Timoshin, S.N., Development and application of quick-hardened solders for precision brazing of dissimilar materials for nuclear technology, Vopr. At. Nauki Tekh., 2005, no. 5, pp. 150–155.

Brunelli, K., Dabalà, M., and Magrini, M., Cu-based amorphous alloy electrodes for fuel cells, J. Appl. Electrochem., 2002, vol. 32, no. 2, pp. 145–148. https://doi.org/10.1023/A:1014733910695

Maeland, A.J., Rapidly Quenched Metals, Amsterdam: Elsevier, 1985, p. 1507.

Shmorgun, V.G., Slautin, O.V., Evstropov, D.A., and Taube, A.O., Diffusion processes on interlayer boundary of explosive-welded-ply composite of system of Cu–Ti, Izv. Vyssh. Uchebn. Zaved., Poroshk. Metall. Funkts. Pokrytiya, 2014, no. 4, pp. 36–39. https://doi.org/10.17073/1997-308X-2014-4-36-39

Tomolya, K., Ti-Cu-based amorphous powders produced by ball-milling, Mater. Sci. Forum, 2017, vol. 879, pp. 1974–1979. https://doi.org/10.4028/www.scientific.net/MSF.879.1974

Delogu, F. and Cocco, G., Compositional effects on the mechanochemical synthesis of Fe–Ti and Cu–Ti amorphous alloys by mechanical alloying, J. Alloys Compd., 2003, vol. 352, no. 1, pp. 92–98. https://doi.org/10.1016/S0925-8388(02)01109-X

Molnar, A., Domokos, L., Katona, T., Martinek, T., Mulas, G., Cocco, G., Bertoti, I., and Szepvolgyi, J., Activation of amorphous Cu–M (M—Ti, Zr, or Hf) alloy powders made by mechanical alloying, Mater. Sci. Eng., 1997, nos. 226–228, pp. 1074–1078.

Guwer, A., Nowosielski, R., Borowski, A., and Babilas, R., Fabrication of copper-titanium powders prepared by mechanical alloying, Indian J. Eng. Mater. Sci., 2014, vol. 21, pp. 261–271. http://hdl.handle.net/ 123456789/28985.

Grigor'eva, T.F., Šepelák, V., Letsko, A.I., Talako, T.L., Kuznetsova, T.A., Tsybulya, S.V., Ilyushchenko, A.F., and Lyakhov, N.Z., Mechanochemical synthesis of nanocomposites for interacting metals Cu–Zr, Cu–Ti, Powder Metall. Prog., 2011, vol. 11, nos. 3–4, pp. 277–283.

Bateni, M.R., Mirdamadi, S., Ashrafizadeh, F., Szpunar, J.A., and Drew, R.A.L., Formation of Ti‒Cu intermetallic coating on copper substrate, Mater. Manuf. Processes, 2001, vol. 16, no. 2b, pp. 219–228. https://doi.org/10.1081/AMP-100104302

Meilakh, A.G., Production and properties of steels from nickel plated iron powders, Stal, 2014, no. 2, pp. 71–74.

Kontsevoi, Yu.V., Dolmatov, A.V., Pastukhov, E.A., and Grigor’eva, T.F., Mechanical plating the Fe–Al and Fe–Cu dispersed systems under dynamic loads, Izv. Vyssh. Uchebn. Zaved., Poroshk. Metall. Funkts. Pokrytiya, 2015, no. 1, pp. 8–11. https://doi.org/10.17073/1997-308X-2015-1-8-11

Vadchenko, S.G., Boyarchenko, O.D., Shkodich, N.F., and Rogachev, A.S., Thermal explosion in various Ni‒Al systems: Effect of mechanical activation, Int. J. Self-Propag. High-Temp. Synth., 2013, vol. 22, no. 1, pp. 60–64. https://doi.org/10.3103/S1061386213010123

Naoya Shirasawa, Yorinobu Takigawa, Tokuteru Uesugi, and Kenji Higashi, Calculation of alloying effect on formation enthalpy of TiCu intermetallics from first-principles calculations for designing Ti–Cu-system metallic glasses, Philos. Mag. Lett., 2016, vol. 96, no. 1, pp. 1–8. https://doi.org/10.1080/09500839.2015.1134833

Eremenko, V.N., Buyanov, Y.I., and Prima, S.B., Phase diagram of the system titanium-copper, Sov. Powder Metall. Met. Ceram., 1966, vol. 5, pp. 494–502. https://doi.org/10.1007/BF00775543

Shanker Rao, T.L., Lad, K.N., and Pratap, A., Study of non-isothermal crystallization of amorphous Cu50Ti50 alloy, J. Therm. Anal. Calorim., 2004, vol. 78, no. 3, pp. 769–774. https://doi.org/10.1007/s10973-005-0444-0

Rogachev, A.S., Vadchenko, S.G., Aronin, A.S., Shchkin, A.S., Kovalev, D.Yu., Nepapushev, A.A., Rouvimov, S., and Mukasyan, A.S., Self-sustained exothermal waves in amorphous and nanocrystalline films: A comparative study, J. Alloys Compd., 2018, vol. 749, pp. 44–51. https://doi.org/10.1016/j.jallcom.2018.03.255

Shkodich, N.F., Rogachev, A.S., Vadchenko, S.G., Kovalev, I.D., Nepapushev, A.A., Rouvimov, S.S., and Mukasyan, A.S., Formation of amorphous structures and their crystallization in the Cu–Ti system by high-energy ball milling, Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 5, pp. 543–549. https://doi.org/10.3103/S1067821218050176

Kovalev, D.Yu., Vadchenko, S.G., Rogachev, A.S., Alymov, M.I., and Aronin, A.S., Time-resolved X-ray diffraction study of the transition of an amorphous TiCu alloy to the crystalline state, Dokl. Phys., 2017, vol. 62, no. 3, pp. 111–114. https://doi.org/10.1134/S1028335817030028

ACKNOWLEDGMENTS

These investigations were performed using equipment from the Distributed Joint Use Center at the Institute of Structural Macrokinetics, Russian Academy of Sciences.

Funding

This study was supported by the Russian Foundation for Basic Research, project no. 18-03-00438

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Korovin

About this article

Cite this article

Vadchenko, S.G., Suvorova, E.V., Mukhina, N.I. et al. Copper Deposition from Its Sulfate Solution onto Titanium Powder with the Simultaneous Mechanical Activation of the Mixture. Russ. J. Non-ferrous Metals 61, 534–539 (2020). https://doi.org/10.3103/S1067821220050144

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220050144