Abstract

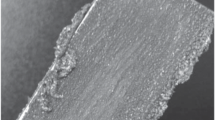

Gold cementation kinetic features from cyanide solutions using zinc powders of various origins were studied. The first powder was obtained by distillation and is currently used in the vast majority of industries (traditional powder). The second powder was obtained by electrochemical reduction from alkaline solution (electrolytic powder). The main distinguishing feature of these powders is specific surface area. This indicator for the electrolytic powder is 2.6 times higher than for the traditional one (3.02 and 1.16 m2/g, respectively), which is associated with dendritic form of electrolytic powder. For cementation studies, a solution with a gold content of 50.8 μmol/dm3 and 0.04 mol/dm3 sodium cyanide (NaCN) was taken. Studies have shown the presence of a depassivation period associated with oxide film dissolution on the powder surface and overcoming diffusion difficulties. The depassivation period of a traditional powder (10–15 seconds) exceeds the depassivation period of an electrolytic powder (5–8 seconds). Values of cementation reaction experimental rate constants are determined for the process using traditional and electrolytic powders at different ratios of zinc and gold masses in solution. Experimental reaction rate constants for electrolytic powder under the studied conditions are 1.3–1.6 times higher than the experimental rate constants for traditional powder. Zinc oxidation rates are compared under these conditions for various ratios m(Zn)/m(Au). Powder dissolution rates referred to specific surface area (taken in initial period) practically do not differ. The electrolytic powder’s absolute dissolution rate at the initial time is almost two times greater. As powder reacts with an alkaline solution, absolute dissolution rates of electrolytic and traditional powders are equalized.

Similar content being viewed by others

REFERENCES

Jiachao, J., Jianli, M., Xiaofu, S., Yuan, T., Ping, L., and Youcai, Z., Particle size refinement of Zn electrodeposits in alkaline zincate solutions with polyethylene glycol and Tween 80, Int. J. Electrochem. Sci., 2017, vol. 12, pp. 917–927.

Abbar, A.H., Rushdi, S.A., and Al-Tameemi, H.M., Electrochemical preparation of ultrafine zinc powder, Int. J. Electrochem. Sci., 2017, vol. 12, no. 8, pp. 7075–7088.

Kim, H.I. and Shin, H.C., SnO additive for dendritic growth suppression of electrolytic zinc, J. Alloys Compd., 2015, vol. 645, pp. 7–10.

St-Pierre, J. and Piron, D.L., Electrowinning of zinc from alkaline solutions at high current densities, J. Appl. Electrochem., 1990, vol. 20, no. 1, pp. 163–165.

Gürmen, S. and Emre, M., A laboratory-scale investigation of alkaline zinc electrowinning, Miner. Eng., 2003, vol. 16, no. 6, pp. 559–562.

Palimakaa, P., Pietrzyk, S., Stępień, M., Ciećko, K., and Nejman, I., Zinc recovery from steelmaking dust by hydrometallurgical methods, Metals, 2018, vol. 8, no. 7, p. 547.

Kamran Haghighi, H., Moradkhani, D., Sardari, M.H., and Sedaghat, B., Production of zinc powder from Co-Zn plant residue using selective alkaline leaching followed by electrowinning, Physicochem. Probl. Miner. Process., 2015, vol. 51, no. 2, pp. 411–425.

Alkatsev, M.I., Protsessy tsementatsii v tsvetnoi metallurgii (Cementation Processes for Non-Ferrous Metallurgy), Moscow: Metallurgiya, 1981.

Yap, C.Y. and Mohamed, N., An electrogenerative process for the recovery of gold from cyanide solutions, Chemosphere, 2007, vol. 67, no. 8, pp. 1502–1510.

Fabian, M., Balaz, P., and Briancin, J., Study of the silver ions cementation after mechanical activation of cementator, Hydrometallurgy, 2009, vol. 97, pp. 15–20.

Naumov, K.D. and Lobanov, V.G., Features of gold cementation in percolation mode by electrolytic zinc powders, Izv. Vyssh. Uchebn. Zaved.,Tsvetn. Metall., 2020, vol. 1, pp. 19–26.

Buinovskii, A.S., Kontsentrirovanie zolota i metallov platinovoi gruppy na uglerodnykh sorbentakh (Concentration of Gold and Platinum Group Metals on Carbon Sorbents), Seversk: Seversk State Technological Institute, 2005.

Oo, M.T. and Tran, T., The effect of lead on the cementation of gold by zinc, Hydrometallurgy, 1991, vol. 26, pp. 61–74.

Nguyen, H.H., Tran, T., and Wong, P.L.M., A kinetic study of the cementation of gold from cyanide solutions onto copper, Hydrometallurgy, 1997, vol. 46, pp. 55–69.

Lee, H.Y., Kim, S.G., and Oh, J.K., Cementation behavior of gold and silver onto Zn, Al and Fe powders from acid thiourea solutions, Can. Metall. Q., 1997, vol. 36, pp. 149–155.

Mpinga, C.N., Evaluation of the Merrill-Crowe process for the simultaneous removal of platinum, palladium and gold from cyanide leach solutions, Hydrometallurgy, 2014, vol. 142, pp. 36–46.

Gal-Or, L. and Calmanovici, B., Gold recovery from cyanide solutions. Part I. Electrochemical deposition, Met. Finish., 1983, vol. 15, pp. 15–21.

Martinez, G.V.F., Torres, J.R.P., Garcia, J.L.V., Munive, G.C.T., and Zamarripa, G.G., Kinetic aspects of gold and silver recovery in cementation with zinc power and electrocoagulation iron process, Adv. Chem. Eng. Sci., 2012, vol. 2, pp. 342–349.

Karavasteva, M., Kinetics and deposit morphology of gold cemented on magnesium, aluminum, zinc, iron and copper from ammonium thiosulfate-ammonia solutions, Hydrometallurgy, 2010, vol. 104, pp. 119–122.

Gamboa, G.V., Noyola, M.M., and Valdivieso, A.L., The effect of cyanide and lead ions on the cementation rate, stoichiometry and morphology of silver in cementation from cyanide solutions with zinc powder, Hydrometallurgy, 2005, vol. 76, pp. 193–205.

Hsu, Y.J. and Tran, T., Selective removal of gold from copper-gold cyanide liquors by cementation using zinc, Miner. Eng., 1996, vol. 9, pp. 1–13.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Muravev

About this article

Cite this article

Naumov, K.D., Lobanov, V.G. & Kolmachikhina, E.B. Gold Cementation Kinetic Features Using Dendritic Zinc Powders. Russ. J. Non-ferrous Metals 61, 494–499 (2020). https://doi.org/10.3103/S1067821220050107

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220050107