Abstract

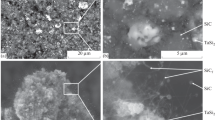

A new method is proposed for the engineering of SiC-based ceramic-matrix composite materials strengthened by discrete carbon fibers and single-crystal silicon carbide nanowires. Depending on the macrokinetic characteristics of the combustion process, either diffusion layers, particles of silicon carbide, or silicon carbide nanowires with a diameter of 10–50 nm and a length of 15–20 μm can be formed on the surface of carbon fibers. The sequence of chemical transformations and structure formation in the combustion wave of Si–C–C2F4 and Si–C–C2F4–Ta mixtures was studied. Silicon carbide nanowires formed in the combustion wave had high crystallinity and a defect-free TaSi2/SiC interface. The misorientation of the lattices at the interface is about 6%. Nanowires are able to relax the mechanical stresses during growth via the rotation along the growth direction. The optimal combustion temperature for the growth of silicon carbide nanofibers is 1700 K at a ratio of C2F4 : C = 2. The lower temperature threshold for the growth of silicon carbide nanowires is caused by a decrease in the yield of reactive fluorides, while the upper-temperature threshold is caused by a failure of the adsorption blocking mechanism on the surface of the nanofibers and the destabilization of the TaSi2 + Si eutectic droplet. Composites with a SiC–TaSi2 ceramic matrix and a relative density of 98%, a hardness of 19 GPa, a flexural strength of 420 MPa, and fracture toughness of 12.5 MP m1/2 were obtained by hot pressing. An increase in the strength of the carbon fiber-matrix interface has manifested in the suppression of carbon fiber pull-out from the matrix.

Similar content being viewed by others

REFERENCES

Yang, W., Araki, H., Tang, C., Thaveethavorn, S., Kohyama, A., Suzuki, H., and Noda, T., Single-crystal SiC nanowires with a thin carbon coating for stronger and tougher ceramic composites, Adv. Mater., 2005, vol. 17, no. 12, pp. 1519–1523.

Marshall, D.B. and Evans, A.G., Failure mechanisms in ceramic-fiber/ceramic-matrix composites, J. Am. Ceram. Soc., 1985, vol. 68, no. 5, pp. 225–231.

Infed, F., Handrick, K., Lange, H., Steinacher, A., Weiland, S., and Wegmann, C., Development of thermal protective seal for hot structure control surface actuator rod, Acta Astron., 2012, vol. 70, pp. 122–138.

Christin, F., CMC materials for space and aeronautical applications, in Ceramic Matrix Composites, Krenkel, W., Ed., Weinheim: Wiley-VCH, 2008, pp. 327–351.

Evans, A.G. and Marshall, D.B., Overview no. 85. The mechanical behavior of ceramic matrix composites, Acta Metall., 1989, vol. 37, no. 10, pp. 2567–2583.

Becher, P.F., Hsueh, C.-H., Angelini, P., and Tiegs, T.N., Toughening behavior in whisker-reinforced ceramic matrix composites, J. Am. Ceram. Soc., 1988, vol. 71, no. 12, pp. 1050–1061.

Vedrtnam, A. and Sharma, S.P., Study on the performance of different nano-species used for surface modification of carbon fiber for interface strengthening, Composites, Part A, 2019, vol. 125, p. 105509. https://doi.org/10.1016/j.compositesa.2019.105509

Schneck, T.K., Brück, B., Schulz, M., Spörl, J.M., Hermanutz, F., Clauß, B., Mueller, W.M., Heidenreich, B., Koch, D., Horn, S., and Buchmeiser, M.R., Carbon fiber surface modification for tailored fiber-matrix adhesion in the manufacture of C/C–SiC composites, Composites, Part A, 2019, vol. 120, pp. 64–72.

Tiwari, S. and Bijwe, J., Surface treatment of carbon fibers: A review, Procedia Technol., 2014, vol. 14, pp. 505–512.

Wang, Z., Huang, X., Xian, G., and Li, H., Effects of surface treatment of carbon fiber: Tensile property, surface characteristics, and bonding to epoxy, Polym. Compos., 2016, vol. 37, no. 10, pp. 2921–2932.

Park, S.-J. and Meng, L.-Y., Surface treatment and sizing of carbon fibers, in Carbon Fibers, vol. 210 of Springer Series in Materials Science, Dordrecht: Springer, 2014, pp. 101–133.

Zhang, X., Li, S., Pan, D., Pan, B., and Kondoh, K., Microstructure and synergistic-strengthening efficiency of CNTs–SiCp dual-nano reinforcements in aluminum matrix composites, Composites, Part A, 2018, vol. 105, pp. 87–96.

He, F., Liu, Y., Tian, Z., Zhang, C., Ye, F., Cheng, L., and Zhang, L., Carbon fiber/SiC composites modified SiC nanowires with improved strength and toughness, Mater. Sci. Eng., A, 2018, vol. 734, pp. 374–384.

Wang, H.-f., Bi, Y.-b., Zhou, N.-s., and Zhang, H.-j., Preparation and strength of SiC refractories with in situ β-SiC whiskers as bonding phase, Ceram. Int., 2016, vol. 42, no. 1, pp. 727–733.

Li, J., Sha, J., Dai, J., Lv, Z., Shao, J., Wang, S., and Zhang, Z., Fabrication and characterization of carbon-bonded carbon fiber composites with in-situ grown SiC nanowires, Carbon, 2017, vol. 118, pp. 148–155.

Fu, Q., Wang, L., Tian, X., and Shen, Q., Effects of thermal shock on the microstructures, mechanical and thermophysical properties of SiCnfs–C/C composites, Composites, Part B, 2019, vol. 164, pp. 620–628.

He, F., Liu, Y., Tian, Z., Zhang, C., Ye, F., Cheng, L., and Zhang, L., Improvement of the strength and toughness of carbon fiber/SiC composites via chemical vapor infiltration-grown SiC nanowire interphases, Ceram. Int., 2018, vol. 44, no. 2, pp. 2311–2319.

Kolasinski, K.W., Catalytic growth of nanowires: Vapor–liquid–solid, vapor–solid–solid, solution–liquid–solid and solid–liquid–solid growth, Curr. Opin. Solid State Mater. Sci., 2006, vol. 10, nos. 3–4, pp. 182–191.

Nersisyan, G.A., Nikogosov, V.N., Kharatyan, S.L., and Merzhanov, A.G., Chemical transformation mechanism and combustion regimes in the system silicon–carbon–fluoroplastic, Combust., Explos., Shock Waves, 1991, vol. 27, no. 6, pp. 720–724.

Duus, H.C., Thermochemical studies on fluorocarbons. Heat of formation of CF4, C2F4, C3F6, C2F4 dimer, and C2F4 polymer, Ind. Eng. Chem., 1955, vol. 47, no. 7, pp. 1445–1449.

Levashov, E.A., Mukasyan, A.S., Rogachev, A.S., and Shtansky, D.V., Self-propagating high-temperature synthesis of advanced materials and coatings, Int. Mater. Rev., 2017, vol. 62, no. 4, pp. 203–239.

Concise Encyclopedia of Combustion Synthesis: History, Theory, Technology, and Products, Borovinskaya, I., Gromov, A., Levashov, E., Maksimov, Yu., Mukasyan, A., and Rogachev, A., Eds., Amsterdam: Elsevier, 2017.

Sciti, D., Silvestroni, L., Celotti, G., Melandri, C., and Guicciardi, S., Sintering and mechanical properties of ZrB2–TaSi2 and HfB2–TaSi2 ceramic composites, J. Am. Ceram. Soc., 2008, vol. 91, no. 10, pp. 3285–3291.

Talmy, I.G., Zaykoski, J.A., and Opeka, M.M., High-temperature chemistry and oxidation of ZrB2 ceramics containing SiC, Si3N4, Ta5Si3, and TaSi2, J. Am. Ceram. Soc., 2008, vol. 91, no. 7, pp. 2250–2257.

Xiaohong, S., Xierong, Z., Hejun, L., Qiangang, F., and Jizhao, Z., TaSi2 oxidation protective coating for SiC coated carbon/carbon composites, Rare Met. Mater. Eng., 2011, vol. 40, no. 3, pp. 403–406.

Peng, F. and Speyer, R.F., Oxidation resistance of fully dense ZrB2 with SiC, TaB2, and TaSi2 additives, J. Am. Ceram. Soc., 2008, vol. 91, no. 5, pp. 1489–1494.

Du, B., Hong, C., Qu, Q., Zhou, S., Liu, C., and Zhang, X., Oxidative protection of a carbon-bonded carbon fiber composite with double-layer coating of MoSi2–SiC whisker and TaSi2–MoSi2–SiC whisker by slurry method, Ceram. Int., 2017, vol. 43, no. 12, pp. 9531–9537.

Wang, S., Xu, C., Ding, Y., and Zhang, X., Thermal shock behavior of ZrB2–SiC composite ceramics with added TaSi2, Int. J. Refract. Met. Hard Mater., 2013, vol. 41, pp. 507–516.

Xia, M. and Ge, C., Morphological control of tungsten-assisted β-Si3N4 nanowhiskers: Synthesis, mechanical and photoluminescence properties, Chem. Phys. Lett., 2012, vols. 525–526, pp. 92–96.

Wagner, R.S. and Ellis, W.C., Vapor-liquid-solid mechanism of single crystal growth, Appl. Phys. Lett., 1964, vol. 4, no. 5, pp. 89–90.

Ishiyama, T., Nakagawa, S., and Wakamatsu, T., Growth of epitaxial silicon nanowires on a Si substrate by a metal-catalyst-free process, Sci. Rep., 2016, vol. 6, p. 30608.

Hannon, J.B., Kodambaka, S., Ross, F.M., and Tromp, R.M., The influence of the surface migration of gold on the growth of silicon nanowires, Nature, 2006, vol. 440, pp. 69–71.

Hofmann, S., Sharma, R., Wirth, C.T., Cervantes-Sodi, F., Ducati, C., Kasama, T., Dunin-Borkowski, R.E., Drucker, J., Bennett, P., and Robertson, J., Ledge-flow-controlled catalyst interface dynamics during Si nanowire growth, Nature, 2008, vol. 7, pp. 372–375.

Zhang, Y., Wang, N., Gao, S., He, R., Miao, S., Liu, J., Zhu, J., and Zhang, X., A simple method to synthesize nanowires, Chem. Mater., 2002, vol. 14, no. 8, pp. 3564–3568.

Hu, P., Dong, S., Zhang, X., Gui, K., Chen, G., and Hu, Z., Synthesis and characterization of ultralong SiC nanowires with unique optical properties, excellent thermal stability and flexible nanomechanical properties, Sci. Rep., 2017, vol. 7, no. 1, p. 3011.

Pujar, V.V. and Cawley, J.D., Effect of stacking faults on the X-ray diffraction profiles of β-SiC powders, J. Am. Ceram. Soc., 1995, vol. 78, no. 3, pp. 774–782.

Liu, Z., Kong, Q.-Q., Chen, C.-M., Zhang, Q., Hu, L., Li, X.-M., Han, P.-D., and Cai, R., From two-dimensional to one-dimensional structures: SiC nano-whiskers derived from graphene via a catalyst-free carbothermal reaction, RSC Adv., 2015, vol. 5, no. 8, pp. 5946–5950.

Dai, J., Sha, J., Shao, J., Zu, Y., Lei, M., Flauder, S., Langhof, N., and Krenkel, W., In-situ growth of SiC nanostructures and their influence on anti-oxidation capability of C/SiC composites, Corros. Sci., 2017, vol. 124, pp. 71–79.

Wu, R., Yang, Z., Fu, M., and Zhou, K., In-situ growth of SiC nanowire arrays on carbon fibers and their microwave absorption properties, J. Alloys Compd., 2016, vol. 687, pp. 833–838.

Vorotilo, S., Levashov, E.A., Kurbatkina, V.V., Kovalev, D.Yu., and Kochetov, N.A., Self-propagating high-temperature synthesis of nanocomposite ceramics TaSi2–SiC with hierarchical structure and superior properties, J. Eur. Ceram. Soc., 2018, vol. 38, no. 2, pp. 433–443.

Bondarev, A.V., Vorotilo, S., Shchetinin, I.V., Levashov, E.A., and Shtansky, D.V., Fabrication of Ta–Si–C targets and their utilization for deposition of low friction wear resistant nanocomposite Si–Ta–C–(N) coatings intended for wide temperature range tribological applications, Surf. Coat. Technol., 2019, vol. 359, pp. 342–353.

Laurila, T., Zeng, K., Kivilahti, J.K., Molarius, J., and Suni, I., TaC as a diffusion barrier between Si and Cu, J. Appl. Phys., 2002, vol. 91, no. 8, pp. 5391–5399.

Zhu, Y., Xu, F., Qin, Q.Q., Fung, W.Y., and Lu, W., Mechanical properties of vapor-liquid-solid synthesized silicon nanowires, Nano Lett., 2009, vol. 9, no. 11, pp. 3934–3939.

Zhu, Y., Qin, Q.Q., Xu, F., Fan, F.R., Ding, Y., Zhang, T., Wiley, B.J., and Wang, Z.L., Size effects on elasticity, yielding, and fracture of silver nanowires: In situ experiments, Phys. Rev. B, 2012, vol. 85, no. 4, p. 045443.

Richter, G., Hillerich, K., Gianola, D.S., Mönig, R., Kraft, O., and Volkert, C.A., Ultrahigh strength single crystalline nano-whiskers grown by physical vapor deposition, Nano Lett., 2009, vol. 9, no. 8, pp. 3048–3052.

Agrawal, R., Peng, B., and Espinosa, H.D., Experimental-computational investigation of ZnO nanowires strength and fracture, Nano Lett., 2009, vol. 9, no. 12, pp. 4177–4183.

He, M.-R. and Zhu, J., Defect-dominated diameter dependence of fracture strength in single-crystalline ZnO nanowires: In situ experiments, Phys. Rev. B: Condens. Matter Mater. Phys., 2011, vol. 83, no. 16, p. 161302.

Mehan, R.L. and Herzog, J.A., in Whisker Technology, Levitt, A.P., Ed., New York: Wiley-Interscience, 1970.

Cheng, G., Chang, T.-H., Qin, Q., Huang, H., and Zhu, Y., Mechanical properties of silicon carbide nanowires: effect of size-dependent defect density, Nano Lett., 2014, vol. 14, no. 2, pp. 754–758.

Gusev, A.I., Phase equilibria in M–X–X' and M–Al–X ternary systems (M = transition metal; X, X' = B, C, N, Si) and the crystal chemistry of ternary compounds, Russ. Chem. Rev., 1996, vol. 65, no. 5, pp. 407–451.

Gudiksen, M.S. and Lieber, C.M., Diameter-selective synthesis of semiconductor nanowires, J. Am. Chem. Soc., 2000, vol. 122, no. 36, pp. 8801–8802.

Grosse, Y., Loomis, D., Guyton, K.Z., Lauby-Secretan, B., El Ghissassi, F., Bouvard, V., Benbrahim-Tallaa, L., Guha, N., Scoccianti, C., Mattock, H., and Straif, K., Carcinogenicity of fluoro-edenite, silicon carbide fibres and whiskers, and carbon nanotubes, Lancet Oncol., 2014, vol. 15, no. 13, pp. 1427–1428.

Rodil, S.E., Olivares, R., Arzate, H., and Muhl, S., Biocompatibility, cytotoxicity and bioactivity of amorphous carbon films, Top. Appl. Phys., 2006, vol. 100, pp. 55–75.

Huang, Y., Duan, X., Wei, Q., and Lieber, C.M., Directed assembly of one-dimensional nanostructures into functional networks, Science, 2001, vol. 291, no. 5504, pp. 630–633.

Whang, D., Jin, S., Wu, Y., and Lieber, C.M., Large-scale hierarchical organization of nanowire arrays for integrated nanosystems, Nano Lett., 2003, vol. 3, no. 9, pp. 1255–1259.

Javey, A., Nam, S., Friedman, R.S., Yan, H., and Lieber, C.M., Layer-by-layer assembly of nanowires for three-dimensional, multifunctional electronics, Nano Lett., 2007, vol. 7, no. 3, pp. 773–777.

Coltrin, M.E., Kee, R.J., and Evans, G.H., A mathematical model of the fluid mechanics and gas-phase chemistry in a rotating disk chemical vapor deposition reactor, J. Electrochem. Soc., 1989, vol. 136, no. 3, pp. 819–829.

Givargizov, E.I., Fundamental aspects of VLS growth, J. Cryst. Growth, 1975, vol. 31, pp. 20–30.

Kim, B.J., Tersoff, J., Kodambaka, S., Reuter, M.C., Stach, E.A., and Ross, F.M., Kinetics of individual nucleation events observed in nanoscale vapor-liquid-solid growth, Science, 2008, vol. 322, no. 5904, pp. 1070–1073.

Kodambaka, S., Tersoff, J., Reuter, M.C., and Ross, F.M., Diameter-independent kinetics in the vapor–liquid–solid growth of Si nanowires, Phys. Rev. Lett., 2006, vol. 96, no. 9, p. 096105.

Kempers, L.J.T.M., A comprehensive thermodynamic theory of the Soret effect in a multicomponent gas, liquid, or solid, J. Chem. Phys., 2001, vol. 115, no. 14, pp. 6330–6341.

Ross, F.M., Tersoff, J., and Reuter, M.C., Sawtooth faceting in silicon nanowires, Phys. Rev. Lett., 2005, vol. 95, no. 14, p. 146104.

Wu, Y., Cui, Y., Huynh, L., Barrelet, C.J., Bell, D.C., and Lieber, C.M., Controlled growth and structures of molecular-scale silicon nanowires, Nano Lett., 2004, vol. 4, no. 3, pp. 433–436.

Schmidt, V., Senz, S., and Gösele, U., Diameter-dependent growth direction of epitaxial silicon nanowires, Nano Lett., 2005, vol. 5, no. 5, pp. 931–935.

Lee, G., Woo, Y.S., Yang, J.-E., Lee, D., Kim, C.-J., and Jo, M.-H., Directionally integrated VLS nanowire growth in a local temperature gradient, Angew. Chem., 2009, vol. 48, no. 40, pp. 7366–7370.

Johansson, J. and Dick, K.A., Recent advances in semiconductor nanowire heterostructures, CrystEngComm, 2011, vol. 13, no. 24, pp. 7175–7184.

Chuang, L.C., Moewe, M., Chase, C., Kobayashi, N.P., Chang-Hasnain, C., and Crankshaw, S., Critical diameter or III–V nanowires grown on lattice-mismatched substrates, Appl. Phys. Lett., 2007, vol. 90, no. 4, p. 043115.

Cirlin, G.E., Dubrovskii, V.G., Soshnikov, I.P., Sibirev, N.V., Samsonenko, Y.B., Bouravleuv, A.D., Harmand, J.C., and Glas, F., Critical diameters and temperature domains for MBE growth of III–V nanowires on lattice mismatched substrates, Phys. Status Solidi RRL, 2009, vol. 3, no. 4, pp. 112–114.

Yunlong, Z., Ming, H., Xiangge, Q., and Xiaogang, S., The influence of additive content on microstructure and mechanical properties on the Csf/SiC composites after annealed treatment, Appl. Surf. Sci., 2013, vol. 279, pp. 71–75.

Funding

This work was financially supported by the Russian Foundation Research (project no. 19-19-00117).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Saetova

About this article

Cite this article

Vorotilo, S., Levashov, E.A., Potanin, A.Y. et al. Features of Synthesizing Ceramic Composites Discretely Reinforced by Carbon Fibers and SiC Nanowires Formed in situ in the Combustion Wave. Russ. J. Non-ferrous Metals 61, 559–570 (2020). https://doi.org/10.3103/S1067821220050168

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220050168