Abstract

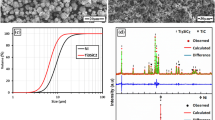

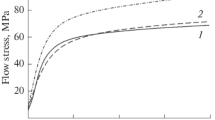

In this study, TiC-reinforced NiCrBSi matrix composite materials were produced using the hot pressing powder metallurgy (PM) technique. The effect of the addition of titanium carbide to NiCrBSi powder in different proportions (5, 10, and 20 wt %) on the microstructure, hardness, relative density, and wear properties of composites was investigated experimentally. NiCrBSi–TiC composites were produced for 10 min at 1000°C with an applied pressure of 45 MPa using a vacuum-assisted automatic hot-pressing machine. The wear behaviors of the composites were compared through dry sliding wear tests. Wear rates and coefficient of friction (COF) values were observed of composites. In addition, the main wear mechanisms are investigated by using SEM and EDS analyses of the worn surfaces. The wear rates of the composites were decreased by increasing the TiC content.

Similar content being viewed by others

REFERENCES

Neville, A., Reza, F., Chiovelli, S., and Revega, T., Assessing metal matrix composites for corrosion and erosion-corrosion applications in the oil sands industry, Corrosion, 2006, vol. 62, no. 8, pp. 657–675. https://doi.org/10.5006/1.3278293

Tjong, S.C. and Ma, Z.Y., Microstructural and mechanical characteristics of in situ metal matrix composites, Mater. Sci. Eng., R, 2000, vol. 29, nos. 3–4, pp. 49–113. https://doi.org/10.1016/S0927-796X(00)00024-3

Wang, J. and Fu, S., Production of in situ vanadium carbide particulate reinforced iron matrix composite, Mater. Sci., 2014, vol. 20, no. 4, pp. 409–413. https://doi.org/10.5755/j01.ms.20.4.6445

Serres, N., Hlawka, F., Costil, S., Langlade, C., and Machi, F., Microstructures and mechanical properties of metallic NiCrBSi and composite NiCrBSi-WC layers manufactured via hybrid plasma/laser process, Appl. Surf. Sci., 2011, vol. 257, no. 12, pp. 5132–5137. https://doi.org/10.1016/j.apsusc.2010.11.062

Bin, C.A.I., Tan, Y.F., Long, H.E., Hua, T.A.N., and Li, G.A.O., Tribological properties of TiC particles reinforced Ni-based alloy composite coatings, Trans. Nonferrous Met. Soc. China, 2013, vol. 23, no. 6, pp. 1681–1688. https://doi.org/10.1016/S1003-6326(13)62648-5

Buytoz, S., Ulutan, M., Islak, S., Kurt, B., and Çelik, O.N., Microstructural and wear characteristics of high velocity oxygen fuel (HVOF) sprayed NiCrBSi-SiC composite coating on SAE 1030 steel, Arabian J. Sci. Eng., 2013, vol. 38, no. 6, pp. 1481–1491. https://doi.org/10.1007/s13369-013-0536-y

Zikin, A., Antonov, M., Hussainova, I., Katona, L., and Gavrilović, A., High temperature wear of cermet particle reinforced NiCrBSi hardfacings, Tribol. Int., 2013, vol. 68, pp. 45–55. https://doi.org/10.1016/j.triboint.2012.08.013

Ma, J., Yang, J., Bi, Q., and Liu, W., Dry-sliding tribological behavior of Fe–28Al–5Cr/TiC composites, Wear, 2011, vol. 271, nos. 5–6, pp. 881–888. https://doi.org/10.1016/j.wear.2011.03.020

Zhang, X., Ma, J., Fu, L., Zhu, S., Li, F., Yang, J., and Liu, W., High temperature wear resistance of Fe–28Al–5Cr alloy and its composites reinforced by TiC, Tribol. Int., 2013, vol. 61, pp. 48–55. https://doi.org/10.1016/j.triboint.2012.12.005

Gómez-del Rio, T., Garrido, M.A., Fernández, J.E., Cadenas, M., and Rodriguez, J., Influence of the deposition techniques on the mechanical properties and microstructure of NiCrBSi coatings, J. Mater. Process. Technol., 2008, vol. 204, nos. 1–3, pp. 304–312. https://doi.org/10.1016/j.jmatprotec.2007.11.042

Miguel, J.M., Guilemany, J.M., and Vizcaino, S., Tribological study of NiCrBSi coating obtained by different processes, Tribol. Int., 2003, vol. 36, no. 3, pp. 181–187. https://doi.org/10.1016/S0301-679X(02)00144-5

Niranatlumpong, P. and Koiprasert, H., Phase transformation of NiCrBSi-WC and NiBSi-WC arc sprayed coatings, Surf. Coat. Technol., 2011, vol. 206, nos. 2–3, pp. 440–445. https://doi.org/10.1016/j.surfcoat.2011.07.057

Tobar, M.J., Alvarez, C., Amado, J.M., Rodríguez, G., and Yanez, A., Morphology and characterization of laser clad composite NiCrBSi-WC coatings on stainless steel, Surf. Coat. Technol., 2006, vol. 200, nos. 22–23, pp. 6313–6317. https://doi.org/10.1016/j.surfcoat.2005.11.093

Gonzalez, R., Cadenas, M., Fernández, R., Cortizo, J.L., and Rodríguez, E., Wear behavior of flame sprayed NiCrBSi coating remelted by flame or by laser, Wear, 2007, vol. 262, nos. 3–4, pp. 301–307. https://doi.org/10.1016/j.wear.2006.05.009

Jia, J., Lu, J., Zhou, H., and Chen, J., Tribological behavior of Ni-based composite under distilled water lubrication, Mater. Sci. Eng., A, 2004, vol. 381, nos. 1–2, pp. 80–85. https://doi.org/10.1016/j.msea.2004.03.059

Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, vol. 2 of ASM Handbook, Davis, J.R., Ed., Materials Park, OH: ASM Int., 1990.

Onuoha, C.C., Kipouros, G.J., Farhat, Z.N., and Plucknett, K.P., The reciprocating wear behavior of TiC–304L stainless steel composites prepared by melt infiltration, Wear, 2013, vol. 303, nos. 1–2, pp. 321–333. https://doi.org/10.1016/j.wear.2013.03.040

Akhtar, F., Microstructure evolution and wear properties of in situ synthesized TiB2 and TiC reinforced steel matrix composites, J. Alloys Compd., 2008, vol. 459, nos. 1–2, pp. 491–497. https://doi.org/10.1016/j.jallcom.2007.05.018

Karantzalis, A.E., Lekatou, A., and Tsirka, K., Solidification observations and sliding wear behavior of vacuum arc melting processed Ni–Al–TiC composites, Mater. Charact., 2012, vol. 69, pp. 97–107. https://doi.org/10.1016/j.matchar.2012.04.013

Russias, J., Cardinal, S., Aguni, Y., Fantozzi, G., Bienvenu, K., and Fontaine, J., Influence of titanium nitride addition on the microstructure and mechanical properties of TiC-based cermets, Int. J. Refract. Met. Hard Mater., 2005, vol. 23, nos. 4–6, pp. 358–362. https://doi.org/10.1016/j.ijrmhm.2005.05.008

Wang, H., Zhang, R., Hu, X., Wang, C.A., and Huang, Y., Characterization of a powder metallurgy SiC/Cu–Al composite, J. Mater. Process. Technol., 2008, vol. 197, nos. 1–3, pp. 43–48. https://doi.org/10.1016/j.jmatprotec.2007.06.002

Wang, Y., Zhang, X., Zeng, G., and Li, F., In situ production of Fe–VC and Fe–TiC surface composites by cast-sintering, Composites, Part A, 2001, vol. 32, no. 2, pp. 281–286. https://doi.org/10.1016/S1359-835X(00)00118-4

Rahimian, M., Ehsani, N., Parvin, N., and Baharvandi, H.R., The effect of sintering temperature and the amount of reinforcement on the properties of Al–Al2O3 composite, Mater. Des., 2009, vol. 30, no. 8, pp. 3333–3337. https://doi.org/10.1016/j.matdes.2008.11.027

Kang, H.K., Microstructure and electrical conductivity of high volume Al2O3-reinforced copper matrix composites produced by plasma spray, Surf. Coat. Technol., 2005, vol. 190, p. 448–552. https://doi.org/10.1016/j.surfcoat.2004.02.002

Islak, S., Çelik, E., Kir, D., and Özorak, C., Characterization of hot pressed CuAl–TiC composites with different TiC grain sizes, Russ. J. Non-Ferrous Met., 2016, vol. 57, no. 4, pp. 374–380. https://doi.org/10.3103/S1067821216040040

da Silva, L.J., Scheuer, C.J., and D’Oliveira, A.S.C., Effect of microstructure on wear performance of NiCrSiBC coatings, Wear, 2019, vols. 428–429, pp. 387–394. https://doi.org/10.1016/j.wear.2019.04.005

Islak, S., Kir, D., and Buytoz, S., Effect of sintering temperature on electrical and microstructure properties of hot-pressed Cu–TiC composites, Sci. Sintering, 2014, vol. 46, no. 1, pp. 15–21. https://doi.org/10.2298/SOS1401015I

Efe, G.C., Ipek, M., Zeytin, S., and Bindal, C., An investigation of the effect of SiC particle size on Cu–SiC composites, Composites, Part B, 2012, vol. 43, no. 4, pp. 1813–1822. https://doi.org/10.1016/j.compositesb.2012.01.006

Ngai, T.L., Zheng, W., and Li, Y., Effect of sintering temperature on the preparation of Cu–Ti3SiC2 metal matrix composite, Prog. Nat. Sci.: Mater. Int., 2013, vol. 23, no. 1, pp. 70–76. https://doi.org/10.1016/j.pnsc.2013.01.011

Shu, K.M. and Tu, G.C., The microstructure and the thermal expansion characteristics of Cu/SiCp composites, Mater. Sci. Eng., A, 2003, vol. 349, nos. 1–2, pp. 236–247. https://doi.org/10.1016/S0921-5093(02)00788-8

Kumar, G.V., Rao, C.S.P., and Selvaraj, N., Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites—a review, J. Miner. Mater. Charact. Eng., 2011, vol. 10, no. 1, pp. 59–91. https://doi.org/10.4236/jmmce.2011.101005

Bin, C.A.I., Tan, Y.F., Hua, T.A.N., Jing, Q.F., and Zhang, Z.W., Tribological behavior and mechanism of NiCrBSi–Y2O3 composite coatings, Trans. Nonferrous Met. Soc. China, 2013, vol. 23, no. 7, pp. 2002–2010. https://doi.org/10.1016/S1003-6326(13)62689-8

Stoica, V., Ahmed, R., Itsukaichi, T., and Tobe, S., Sliding wear evaluation of hot isostatically pressed (HIPed) thermal spray cermet coatings, Wear, 2004, vol. 257, no. 11, pp. 1103–1124. https://doi.org/10.1016/j.wear.2004.07.016

Bailey, R. and Sun, Y., Unlubricated sliding friction and wear characteristics of thermally oxidized commercially pure titanium, Wear, 2013, vol. 308, nos. 1–2, pp. 61–70. https://doi.org/10.1016/j.wear.2013.09.020

Krishna, D.S.R., Brama, Y.L., and Sun, Y., Thick rutile layer on titanium for tribological applications, Tribol. Int., 2007, vol. 40, no. 2, pp. 329–334. https://doi.org/10.1016/j.triboint.2005.08.004

Yetim, A.F., Investigation of wear behavior of titanium oxide films, produced by anodic oxidation, on commercially pure titanium in vacuum conditions, Surf. Coat. Technol., 2010, vol. 205, no. 6, pp. 1757–1763. https://doi.org/10.1016/j.surfcoat.2010.08.079

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Islak, S., Ulutan, M. & Buytoz, S. Microstructure and Wear Properties of Hot-Pressed NiCrBSi/TiC Composite Materials. Russ. J. Non-ferrous Metals 61, 571–582 (2020). https://doi.org/10.3103/S1067821220050053

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220050053