Abstract

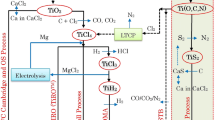

TiC was examined as a starting material for Ti metal production by sulfidation and electrochemical reduction in molten salt. The sulfur evaporation temperature, sulfidation temperature, and time were optimized in a dual-zone furnace for the efficient and sustainable formation of TiS2 as well as carbon removal from TiC by S2 gas sulfidation. A mixture of TiS2 and Ti2.45S4 powders was synthesized from TiC at 1200 °C, and a perfect carbon removal was achieved to a very clean level as low as 0.025 mass pct C. The sulfides derived from TiC were then electrochemically reduced in molten CaCl2-0.5 mol pct CaS salt. The spherical shape Ti powder consisting of high-purity Ti sheets was obtained from TiS2 without the carbon contamination. This method might be applied for sustainable recycling of waste carbides and for production of low-cost Ti powders via TiC or TiOxCyNz from the titanium ore.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

LECO is a trademark of LECO Corporation, St. Joseph, MI.

REFERENCES

A. Chaturvedi, P. Hu, Y. Long, C. Kloc, S. Madhavi, and V. Aravindan: Scripta Mater., 2019, vol. 161, pp. 54–57.

E. Long, S.O. Brien, E.A. Lewis, E. Prestat, C. Downing, C.S. Cucinotta, S. Sanvito, S.J. Haigh, and V. Nicolosi: NPJ 2D Mater. Appl., 2017, vol. 1, p. 22.

A. Chaturvedi, P. Hu, V. Aravindan, C. Kloc, and S. Madhavi: J. Mater. Chem. A, 2017, vol. 5, pp. 9177–81.

V. Vega-Mayoral, R. Tian, A.G. Kelly, A. Griffin, A. Harvey, M. Borrelli, K. Nisi, C. Backes, and J.N. Coleman: Nanoscale, 2019, vol. 11, pp. 6206–16.

E.A. Suslov, O.V. Bushkova, E.A. Sherstobitova, O.G. Reznitskikh, and A.N. Titov: Ionics, 2016, vol. 22, pp. 503–14.

A. Garsuch, S. Herzog, L. Montag, A. Krebs, and K. Leitner: ECS Electrochem. Lett., 2012, vol. 1, pp. A24–A26.

Q.H. Wang, K. Kalantar-Zadeh, A. Kis, J.N. Coleman, and M.S. Strano: Nat. Nanotechnol., 2012, vol. 7, pp. 699–712.

A.L. Let, D.E. Mainwaring, C. Rix, and P. Murugaraj: J. Non-Cryst. Solids, 2008, vol. 354, pp. 1801–07.

J. Ma, H. Jin, X. Liu, M.E. Fleet, J. Li, X. Cao, and S. Feng: Cryst. Growth Des., 2008, vol. 8, pp. 4460–64.

H. Jing, Q. Cheng, J.M. Weller, X.S. Chu, Q.H. Wang, and C.K. Chan: J. Mater. Res., 2018, vol. 33, pp. 3540–48.

T.Y.T. Umebayashi, H. Itoh, and K. Asai: Appl. Phys. Lett., 2002, vol. 81, pp. 454–56.

H.Y. He: Res. Chem. Intermediat., 2010, vol. 36, pp. 155–61.

M. Ohta, S. Satoh, T. Kuzuya, S. Hirai, M. Kunii, and A. Yamamoto: Acta Mater., 2012, vol. 60, pp. 7232–40.

D. Li, X.Y. Qin, J. Zhang, L. Wang, and H.J. Li: Solid State Commun., 2005, vol. 135, pp. 237–40.

D. Li, X.Y. Qin, J. Zhang, and H.J. Li: Phy. Lett. A., 2006, vol. 348, pp. 379–85.

D. Li, X.Y. Qin, and J. Zhang: J. Mater. Res., 2006, vol. 21, pp. 480–83.

N. Suzuki, M. Tanaka, H. Noguchi, S. Natsui, T. Kikuchi, and R.O. Suzuki: Mater. Trans., 2017, vol. 58, pp. 367–70.

E. Ahmadi and R.O. Suzuki: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 140–48.

R.O. Suzuki, Y. Yashima, E. Ahmadi, S. Nobuyoshi, S. Natsui, and T. Kikuchi: 11th Int. Symp. on Molten Salts Chemistry and Technology (MS11), Orleans, France, May 19–23, 2019.

R.O. Suzuki, N. Suzuki, Y. Yashima, S. Natsui, and T. Kikuchi: Extraction 2018, Springer International Publishing, Cham, 2018, pp. 763–71.

M.S. Whittingham: Chem. Rev., 2004, vol. 104, pp. 4271–4302.

R.M.A. Lieth and J.C.J.M. Terhell: Transition Metal Dichalcogenides, R.M.A. Lieth, ed., Preparation and Crystal Growth of Materials with Layered Structures, Springer Netherlands, Dordrecht, 1977, pp. 141–223.

C. Wu, M. Tan, G. Ye, D.J. Fray, and X. Jin: ACS Sustain. Chem. Eng., 2019, vol. 7, pp. 8340–46.

E. Ahmadi, Y. Yashima, R.O. Suzuki, and S.A. Rezan: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1808–21.

K. Ono and R.O. Suzuki: JOM, 2002, vol. 54, pp. 59–61.

G.Z. Chen, D.J. Fray, and T.W. Farthing: Nature, 2000, vol. 407, pp. 361–64.

E. Ahmadi, S.A. Rezan, N. Baharun, S. Ramakrishnan, A. Fauzi, and G. Zhang: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2354–66.

N. Suzuki, M. Tanaka, H. Noguchi, S. Natsui, T. Kikuchi, and R.O. Suzuki: ECS Trans., 2016, vol. 75, pp. 507–15.

29. Fang ZZ, Froes FH, Zhang Y (2019) Extractive Metallurgy of Titanium: Conventional and Recent Advances in Extraction and Production of Titanium Metal, 1st ed. Elsevier, New York

R.O. Suzuki: J. Phy. Chem. Solids, 2005, vol. 66, pp. 461–65.

R.O. Suzuki, K. Teranuma, and K. Ono: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 287–95.

C. Schwandt, G.R. Doughty, and D.J. Fray: Key Eng. Mater., 2010, vol. 436, pp. 13–25.

R.O. Suzuki and S. Inoue: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 277–85.

H. Noguchi, S. Natsui, T. Kikuchi, and R.O. Suzuki: Electrochemistry, 2018, vol. 86, pp. 82–87.

J.L. Murray and H.A. Wriedt: J. Phase Equilibria, 1987, vol. 8, pp. 148–65.

P. Masset and R.A. Guidotti: J. Power Sources, 2007, vol. 164, pp. 397–414.

H. Xie, H. Zhao, J. Qu, Q. Song, Z. Ning, and H. Yin: J. Solid State Electrochem., 2019, vol. 23, pp. 903–09.

T. Matsuzaki, R.O. Suzuki, S. Natsui, T. Kikuchi, and M. Ueda: Mater. Trans., 2019, vol. 60, pp. 411–15.

T. Matsuzaki, R.O. Suzuki, S. Natsui, T. Kikuchi, and M. Ueda: Mater. Trans., 2019, vol. 60, pp. 386–90.

E. Ahmadi, A. Fauzi, H. Hussin, N. Baharun, K.S. Ariffin, and S.A. Rezan: Int. J. Miner. Metall. Mater., 2017, vol. 24, pp. 444–54.

E. Ahmadi, S.A.R.B.S.A. Hamid, H.B. Hussin, N.B. Baharun, S. Ramakrishnan, K.S.B. Ariffin, and M.N.A. Fauzi: INROADS Int. J. Jaipur Nat. Univ., 2016, vol. 5, pp. 11–16.

W.-Y. Li, and F.L. Riley: J. Eur. Ceram. Soc., 1991, vol. 8, pp. 345–54.

Z.S. Rak and J. Czechowski: J. Eur. Ceram. Soc., 1998, vol. 18, pp. 373–80.

Y.-C. Lin, A.C. Wang, D.-A. Wang, and C.-C. Chen: Mater. Manuf. Process, 2009, vol. 24, pp. 667–74.

Y.H. Fei, C.Z. Huang, H.L. Liu, and B. Zou: Ceram. Int., 2014, vol. 40, pp. 10205–10209.

M. Kitiwan and D. Atong: J. Solid Mech. Mater. Eng., 2007, vol. 1, pp. 938–46.

W.J. Liu and J.J. Jonas: Metall. Trans. A, 1989, vol. 20A, pp. 1361–74.

Y. Ishiguro, T. Murayama, T. Fujita, and K. Kuroda: Mater. Trans., 2009, vol. 50, pp. 1380–89.

W.J. Liu, S. Yue, and J.J. Jonas: Metall. Trans. A,1989, vol. 20A, pp. 1907–15.

L.-J. Norrby and H.F. Franzen: J. Solid State Chem., 1970, vol. 2, pp. 36–41.

W. Wang, G. Wang, G. Chen, S. Chen, and Z. Huang: Sol. Energy, 2017, vol. 148, pp. 12–16.

A. Roine: “Outokumpu HSC Chemistry for Windows, Chemical Reaction and Equilibrium Software with Extensive Thermochemical Database.” HSC Ver. 8.08, Outokumpu Research Oy, Pori, 2014.

S.K. Basu and M. Taniguchi: Thermochim. Acta, 1986, vol. 109, pp. 253–65.

ACKNOWLEDGMENTS

This work was supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI (Grant Nos. 18F18054 and 17H03434), MEXT Nanotechnology Platform Program (A-19-HK-0034), and Japan Mining Industry Association. The kind support from JSPS and the International Affairs Office of the Faculty of Engineering, Hokkaido University, are also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 30, 2020; accepted September 23, 2020.

Rights and permissions

About this article

Cite this article

Ahmadi, E., Suzuki, R.o., Kaneko, T. et al. A Sustainable Approach for Producing Ti and TiS2 from TiC. Metall Mater Trans B 52, 77–87 (2021). https://doi.org/10.1007/s11663-020-01988-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01988-5