Abstract

Blended cements, where Portland cement clinker is partially replaced by supplementary cementitious materials (SCMs), provide the most feasible route for reducing carbon dioxide emissions associated with concrete production. However, lowering the clinker content can lead to an increasing risk of neutralisation of the concrete pore solution and potential reinforcement corrosion due to carbonation. carbonation of concrete with SCMs differs from carbonation of concrete solely based on Portland cement (PC). This is a consequence of the differences in the hydrate phase assemblage and pore solution chemistry, as well as the pore structure and transport properties, when varying the binder composition, age and curing conditions of the concretes. The carbonation mechanism and kinetics also depend on the saturation degree of the concrete and CO2 partial pressure which in turn depends on exposure conditions (e.g. relative humidity, volume, and duration of water in contact with the concrete surface and temperature conditions). This in turn influence the microstructural changes identified upon carbonation. This literature review, prepared by members of RILEM technical committee 281-CCC carbonation of concrete with supplementary cementitious materials, working groups 1 and 2, elucidates the effect of numerous SCM characteristics, exposure environments and curing conditions on the carbonation mechanism, kinetics and structural alterations in cementitious systems containing SCMs.

Similar content being viewed by others

1 Mechanisms of carbonation in cementitious hydrates, and CO2 sequestration

This section summarises the chemical reactions occurring during carbonation of cementitious hydrate phases, and the effects of these reactions on hydrated reaction products and pore solution chemistry. In Portland cement-based systems, the term carbonation describes the reaction of dissolved carbonates with cementitious products, mainly through interaction with calcium ions that are extracted from hydrate phases. Once CO2 enters the material, at pH > 10, gaseous CO2 rapidly dissolves into the alkaline pore solution and subsequently hydrolyses to bicarbonate (HCO3−) and carbonate ions (CO32−) via a multi-step reaction sequence that can be summarised as: CO2 + OH− → HCO3− → CO32− + H+ [1, 2]. At pH < 8, direct hydration of CO2 occurs and results in carbonic acid H2CO3 (via CO2 + H2O → H2CO3), which can then dissociate into HCO3− and CO32− ions [3] at higher pH. At pH 8-10, both mechanisms are important. In the pore solution the carbonate ions react with calcium ions that are re-solubilised from the solid products, and precipitate as calcium carbonate. Carbonation is a reactive transport process. The presence of water lowers the diffusion of gaseous CO2. At the same time, the presence of water is essential for calcium and carbon dioxide to dissolve and react.

The main carbonation reaction product is calcium carbonate, which can precipitate in three crystalline polymorphs: calcite, aragonite and vaterite, depending on the internal concrete conditions (e.g. pH, temperature and supersaturation) [4], and the presence of impurities or additives [5,6,7]. Calcite is the most stable polymorph under ambient conditions, while metastable phases including amorphous calcium carbonate, monohydrocalcite, vaterite and aragonite can form prior to or along with calcite precipitation (Ostwald’s rule of stages) [8, 9]. Amorphous calcium carbonate and vaterite form in the early stages of atmospheric carbonation and also during carbonation in a CO2-rich atmosphere [10, 11]. Calcite and vaterite are the most common forms of CaCO3 found in carbonated cement paste [12, 13] at ambient or close to ambient conditions.

The formation of calcium carbonate through carbonation leads to the release of some of the water that was bound in portlandite and other hydrates, and results in changes in the total solid volume as illustrated in Fig. 1. These changes might be positive or negative dependent on the cement chemistry and can have a major impact on porosity and hence on the transport properties of the carbonated cement paste. Thermodynamic modelling of the carbonation of hydrated cement can be used to understand the pH changes and the destabilisation sequence of the different Portland cement hydrated products. The thermodynamic model depicted in Fig. 1 shows the phase assemblage of a white Portland cement as a function of the amount of CO2 that has reacted with the cement paste, and the corresponding decrease of pH and of the Ca/Si ratio of the calcium silicate hydrate (C–S–H). Carbonation proceeds according to the following steps:

Thermodynamic modelling of the phase assemblage during carbonation of a white PC w/b = 0.5 and degree of hydration 90% (a), and changes of pH and Ca/Si of the C–S–H during carbonation (b). In both graphics, the undamaged cement paste is shown on the right-hand side, moving to the left as more CO2 reacts with the hydrates. Adapted from [16]

-

Initially any monosulfate- and hemicarbonate-AFm phases, if present, will destabilise to monocarbonate-AFm [14], leading to small changes of the solid volume (molar volume of monosulphate: 332 cm3/mol; hemicarbonate: 285 cm3/mol and monocarbonate-AFm: 262 cm3/mol) (not shown in Fig. 1).

-

Portlandite is the first major hydrate that decomposes to calcium carbonate during carbonation, leading to a moderate volume increase (ΔV = 12% of portlandite) as the molar volume of calcite (36.9 cm3/mol) is greater than that of portlandite (33.0 cm3/mol). The pH remains stable at around ~ 12.5 [12].

-

After all accessible portlandite is consumed, C–S–H starts to decalcify down to a Ca/Si ratio of ~ 1.3. The pH decreases only marginally during this step. This decalcification is not accompanied by significant volume change.

-

Monocarbonate decomposes to strätlingite, which accommodates the released aluminium and silicon from the C–S–H; C–S–H continues to be consumed without change of its Ca/Si ratio. This reaction also leads to some changes of the solid volume. The molar volume of monocarbonte (262 cm3/mol) is greater than that of strätlingite (216 cm3/mol), which is compensated by the formation of calcium carbonate and consumption of C–S–H.

-

After monocarbonate is consumed, the decalcification and decomposition of the C–S–H continues down to Ca/Si of ~ 0.75 and pH of ~ 11. This step is accompanied by the largest drop in pH.

-

Upon further carbonation strätlingite decomposes, followed by ettringite at pH around 10. The released aluminium and sulphur are bound in aluminium hydroxide or zeolites [15] and gypsum, respectively. In parallel, the C–S–H decalcifies to Ca/Si of around 0.67 while the pH is lowered to 10.

-

Upon further carbonation, C–S–H decomposed into calcite and hydrated amorphous silica and the pH drops rapidly below 10 to 8.5.

-

At the final stage, hydrotalcite decomposes at pH around 8.5.

-

The total CO2 bound is around 40 to 50 g CO2/100 g Portland cement.

The same sequence of destabilisation is also observed in PC blended with fly ash [15], metakaolin [16] and in calcium sulfoaluminate cements [14]. The consumption of calcium during the carbonation reaction lowers the pH in pore solution from initially 13.5 to 14 (in the absence of carbonation) to below 8, when the cement hydrates have completely carbonated. This decrease happens stepwise, as the pH is buffered by different hydrate assemblages, which are destabilised [17,18,19,20]. This buffering capacity, i.e. the amount of calcium oxide available, as well as the buffered pH depend on the type of the hydrates [14, 21].

It is worth noting, however, that under real carbonation exposure conditions different steps might occur simultaneously, and/or may halt before completion for kinetic or microstructural reasons, although the general sequence will be the same as indicated by thermodynamic modelling. For example, it has often been observed that not all portlandite and C–S–H are carbonated, particularly at low RH [13, 22, 23]. From a thermodynamic point of view initially no C–S–H should decalcify, which does not agree with what has been reported in real carbonated pastes [24, 25].

Portlandite carbonation occurs as a consequence of a dissolution–precipitation reaction and the reaction kinetic is initially more rapid than the carbonation of C–S–H [13]. Calcium carbonate grows on the portlandite surfaces as illustrated in Fig. 2, which slows down the further carbonation by limiting the transport of water and CO2 [22, 23]. CH carbonation releases water, while C–S–H loses water mainly upon complete carbonation [27].

The most abundant calcium-bearing phase in hydrated cement paste is C–S–H, and this is also the phase that displays the most complex carbonation behaviour. The carbonation process of C–S–H depends on its original Ca/Si ratio, CO2 concentration, and on the presence of portlandite [28]. The C–S–H carbonation proceeds in steps; first CaO is removed from the interlayer space. The initially short silicate chains present in high-Ca C–S–H become longer until a C–S–H with a very low Ca/Si ratio of around 0.7 and a pH value of 10 is reached. Only then is the main CaO in C–S–H also consumed, leading to the formation of amorphous silica [11, 29] and further reduction of pH to around 8.5. The destabilisation of C–S–H to silica gel, however, often remains incomplete, particularly at lower relative humidity [27, 30].

The extent of C–S–H carbonation also depends on the CO2 concentration [31]. Above 3% of CO2 in the gas phase, C–S–H can fully decompose into calcium-modified silica gel, while below this concentration, partially decalcified C–S–H was found after the “completion” of carbonation [29,30,31,32]. The behaviour of C–S–H gels also varies depending on Ca/Si, due to the composition dependence of the thermodynamic stability of C–S–H [33].

Initial C–S–H decalcification, involving interlayer calcium, is not accompanied by significant volume changes (see Fig. 1), and C–S–H carbonation can thus contribute significantly to the densification of cement paste microstructure by calcite precipitation. However, below a Ca/Si ratio of ~ 1.3, significant decalcification shrinkage has been observed [34]. The fine-textured initial microstructure of C–S–H is preserved after the initial decalcification [35], and both inner and outer C–S–H undergo a comparable decalcification although only outer C–S–H shows morphological changes upon decalcification [35]. These morphological changes involve coarsening of the porosity and precipitation of calcium carbonate at the tips of the C–S–H fibrils. Carbonation shrinkage has been observed to increase with CO2 concentration and with decreasing Ca/Si ratio, and shows a maximum at high to moderate relative humidity [36], mainly attributed to the polymerisation of C–S–H.

The total amount of CO2 that can be bound (binding or buffering capacity of a cement) depends directly on the amount of CaO available to form CaCO3 [9, 12, 23, 37], i.e., all CaO in the hydrates minus calcium bound in calcium carbonate or calcium sulfates. Thus, the CO2 binding capacity of blended cements and calcium sulfoaluminate cements is generally lower than that of plain PC, since the available CaO content is lower [14, 16,17,18,19,20,21]. Additionally, a lower degree of carbonation of portlandite and calcium silicate hydrate in specific conditions alters the buffering capacity. These differences mean that a direct application of the understanding of the carbonation mechanism and CO2 binding capacity for plain PC cannot be used to infer how concretes with SCMs will perform when exposed to different environments.

2 Carbonation kinetics and carbonation coefficient

The dependence of carbonation resistance on CO2 diffusion and the amount of carbonatable matter is also clear from the well-known square-root-time relation (Eq. 1) for carbonation rate, mentioned in various literature including [38,39,40], which is essentially a solution to Fick’s first law of diffusion.

Here xc is the carbonation depth (m), Dc is the diffusion coefficient of CO2 (m2/s), cs is the CO2 concentration at the concrete surface (kg/m3), ac is the amount of carbonatable material per unit volume (kg/m3), t is the time (s), Rcarb (= ac/Dc) is the carbonation resistance ((kg/m3)/(m2/s)), and k (= √(2·s/Rcarb) is the carbonation coefficient (m/√s). Equation (1) assumes a linear decline of CO2 concentration across the surface layer, from the CO2 concentration at the concrete surface (cs), down to the concentration at the carbonation front, which has a negligible value. The carbonation progress is accelerated with increasing CO2 concentration (cs) and increasing CO2 diffusion coefficient (Dc) but slows down with increasing amount of carbonatable material (ac).

The formula containing the carbonation coefficient k in Eq. (1) is commonly used in experimental studies. When plotting carbonation depths as a function of the square-root of the exposure time, a more or less linear relationship is obtained, the slope of which is taken as the carbonation coefficient.

It should be noted, though, that Eq. 1 assumes a steady-state condition (i.e. constant carbonation coefficient). However, since carbonation reaction products tend to block the pores in concrete and cause a reduction in gas diffusivity, and because cementitious materials continue to hydrate and refine the pores inside the material, the carbonation coefficient should decrease with time (or depth). When carbonation coefficient becomes time dependent, Eq. 2 can be applied as used in [41, 42].

Here the exponent n should be negative, to account for pore blockage by reaction products, wetting events, increased moisture content and ageing effects; a value of zero would define pure diffusion control and an unchanging material, neither with depth nor time. A positive value indicates that the material dries out and/or cracks due to carbonation shrinkage. The empirical exponent n was found to be between 0.0 and − 0.2 in [42]. They observed that n depends on curing duration and binder type. Hunkeler and Greve-Dierfeld [43] showed for three days water cured samples a decrease in n with decreasing w/b ratio and increasing relative humidity.

The carbonation resistance of a cement paste or a concrete—which is usually expressed in terms of the depth to which atmospheric CO2 has penetrated the material at a given time, or as a coefficient describing this rate of ingress—depends not only on its CO2 binding capacity, but also on its porosity and pore size distribution [16, 21, 44]. Changes in the effective permeability due to hydrate/carbonate volume changes and microcracking can be a significant consequence of carbonation [45]. In concretes with conventional SCMs, an increase in porosity upon carbonation is typically reported, in contrast to plain PC systems where carbonation decreases their permeability due to pore blocking as discussed above [46]. However, the correlation between the hydrate products in blended PCs and the associated volume and permeability changes is not yet clear. Of more concern, it is not clear what mechanism is leading to microcracking, and to what extent these microcracks might modify the transport properties of the carbonated layer, reducing the resistance to ingress of CO2. Due to the large variety of SCMs used in the production of modern concretes and the broad range of properties exhibited by concretes produced with them, in the following sections the main effects of the type and amount of SCM added are discussed, as well as the influence of concrete mix design parameters and other factors on the carbonation process of SCM-containing materials.

3 Concrete mix design and its effect on carbonation

3.1 Effect of SCM type

When PC is blended with SCMs, the phase assemblages and chemistry of the pore solution change significantly. In PC blended with siliceous SCMs, a reduced content of portlandite is present, as consequence of pozzolanic or latent-hydraulic reactions. The main reaction product observed is an Al-substituted C–S–H type phase, with lower Ca/Si than in plain PC systems [47]. Formation of different secondary reaction products such as layered double hydroxides (e.g. AFm phases and Mg–Al hydroxides) is also reported when using Al-rich SCMs [48].

The effect of SCMs on the chemistry and properties of cementitious materials has been extensively evaluated, including by recent RILEM technical committees, and the reader can find more detailed information in [49,50,51]. In this review a brief description of the chemistry of SCM-blended cements is presented to explain potential correlations between material properties and carbonation performance.

Addition of SCMs can increase the early reactivity of PC clinker due to its (physical) filler effect promoting nucleation and growth of the hydrates, and the higher effective water/cement (w/c) ratio [52, 53]. In the pozzolanic reaction SiO2 and Al2O3 react with water and CH to form additional C–S–H with a reduced Ca/Si ratio, an increased silicate mean chain length, and some incorporation of Al [54,55,56]. Thermodynamic calculations indicate that for complete consumption of portlandite, the required ratio of SCM to total binder content is approximately 75 wt% for blast furnace slag (BFS) [44, 53], 35 wt% for Class F/siliceous fly ash (FA), 18 wt% for silica fume (SF) [47, 57, 58] and 6–18 wt% for metakaolin (MK) [59], although microstructural (kinetic) constraints can lead to the persistence of portlandite at higher SCM contents than would be indicated from thermodynamics alone [60]. The consumption of portlandite leads to a reduced pH value in the pore solution, which is in the range of pHPC,LS ≈ 12.7–13.8, pHBFS,FA,MK ≈ 12–13, pHSF ≈ 11.0–12.5 at high clinker replacement levels, according to [57, 61, 62] and is accompanied by reduced K+ and Na+ concentration [15, 57]. Furthermore, a reduction of coarse porosity and an improvement in quality of the interfacial transition zone are generally noticed [61, 63].

Limestone (LS) provides CaO mainly in form of CaCO3. The replacement of a small amount of PC by limestone is beneficial as it promotes nucleation and increases the effective w/c ratio for hydration [64]. In addition, CaCO3 can react with C3A to form monocarboaluminate, which indirectly stabilises ettringite by increasing sulfate availability, leading to an increase of the total volume of hydrate phases [16, 64,65,66]. According to [67], 15 wt% LS addition with a similar size distribution to PC, and used as an addition instead of interground, increases porosity of the hydrated binder, while a smaller size distribution and intergrinding decreases porosity.

Figure 3a shows a Ca–Si–Al ternary diagram, highlighting the regions corresponding to the major SCM groups and Portland cement [68]. Figure 3b shows cement hydrate phases that commonly form from Portland cement—SCM blends in the H2O-CaO-Al2O3-SiO2 system [47]. The precise extent of the C–S–H and C–A–S–H domains is the subject of ongoing research, but these graphics do highlight the broad range of compositions of the main binding phases forming in SCM blended cementitious systems, as a function of the type of SCM used.

The significant difference in Al2O3 contained in SCMs influences the composition and structure of the C-A-S–H phases and secondary reaction products forming in these materials [44]. Therefore, the role of Al in defining the carbonation rates and mechanisms of C(-A)-S–H has received some attention in the recent literature. Irbe [69] found faster carbonation of C–A–S–H than a comparable C–S–H gel when testing synthetic gels of molar ratio Ca/(Al + Si) = 0.96-0.97, under 0.04%, 2% and 4% CO2 conditions. The thermogravimetry data of [70] show a significant increase in CaCO3 formation after 28 days of carbonation of synthetic gels of molar ratio Ca/(Al + Si) ~ 1 when moving from zero Al content to Al/Si = 0.02, but no notable trend when increasing Al content further up to Al/Si = 0.14. In this study and other publications [29, 71] the formation of an additional Al-enriched silicate gel as a carbonation product is described when C-A-S–H gels are decalcified. This phase (and/or the formation of additional potential Al-containing reaction products) deserves further attention in characterisation, as its formation may alter the energetics of the carbonation process sufficiently to induce changes in its rate or mechanism.

According to several studies [42, 72,73,74], PC carbonation under moderate environmental conditions is governed by the reaction of portlandite to mainly form calcite, yielding a denser microstructure due to the positive difference of molar volume of calcite compared to CH (+4 cm3/mol as mentioned in Sect. 1), which more than compensates the shrinkage induced by C–S–H decomposition and subsequent microcracking e.g. [74, 75].

In the case of BFS-blended cements, with increasing C-A-S–H carbonation the percentage of the CaCO3 that is present as calcite is found to be reduced, while the metastable aragonite and vaterite tend to increase [21, 75,76,77]. The microstructural changes identified in these materials lead to higher permeability [75] and diffusivity [78] after carbonation, compared to PC with the same water to binder (w/b) ratio. The reduced calcium and alkali contents lead to a lower buffering capacity in BFS blended cements, and polymerisation shrinkage may lead to increased porosity. Experimental results from [79, 80] indicate that at a replacement level ≥ 25%, the carbonation resistance is decreased compared to plain PC. Several researchers have determined that, under moderately accelerated carbonation conditions (3-5 vol% CO2), not all portlandite and C–A–S–H were consumed during carbonation of BFS-blended cements [21, 26]. However, especially at high BFS replacement levels, the degree of portlandite and C-A-S–H carbonation is higher compared to plain Portland cement systems [21, 74]. This may compensate for the lowered buffering capacity to some extent, because if the degree of portlandite and C–A–S–H carbonation is increased, the actual available Ca is increased. However, if the maximum possible degree of portlandite carbonation is reduced, for example because portlandite is covered by calcium carbonate crystals and therefore the release of Ca from portlandite into the pore solution is hindered, the available Ca to buffer carbonation is reduced.

Compared to BFS, low calcium fly ash (FA) provides less initial CaO to blended systems. At the same FA replacement level (30 wt%), portlandite reduction compared to PC is higher for FA than for BFS [15, 64, 65, 76, 81]. A higher degree of C-A-S–H carbonation (full polymerisation) was identified at > 20 wt% FA replacement levels [73]. A less pronounced decrease in mercury and water intruded porosity upon carbonation has been found in FA blended systems compared to plain PC and BFS-containing concretes [24, 27, 77, 82, 83] and an increase in pore size threshold upon carbonation [82]. The slow pozzolanic reaction of FA compared with slag hydration, and the higher degree of C-A-S–H carbonation accompanied by a release of physical water [73] may be a reason for the deviation from Fick´s first law that has been observed in these systems [42, 84, 85]. There is an increase in the partly carbonated zone with increasing FA replacement, determined through depth dependent pH measurements by the ex situ leaching method [86], indicating divergence from the assumption of pure diffusion-controlled kinetics required for Fickian diffusion (and formation of a sharp carbonation front). In several studies [87,88,89,90], a significant increase in carbonation progress compared to PC was found with increasing FA replacement levels between 30 and 50 wt% for the same w/b ratio. The difference was more pronounced for longer water curing durations (> 7 days) and high relative humidity during carbonation exposure. Thomas and Matthews [91] found that concretes with the same strength grade containing 15–30 wt% FA in the cementitious fraction carbonated to only a slightly greater extent than plain PC. However, concretes containing 50 wt% FA carbonated at a significantly higher rate than PC concrete.

From a thermodynamic point of view, less CO2 can be bound if less calcium is available in the liquid and solid phases (except CaO already bound in CaCO3 or CaSO4) and if less Na+ or K+ are available in the pore solution. When using highly siliceous SCMs such as SF, where Al2O3 and CaO are solely provided by the Portland clinker, the carbonation reaction process is comparable to that identified in plain Portland cement systems, as the main reaction product forming is C–S–H. For synthetic C–S–H it has been reported [33, 92] that with an increasing molar ratio of C–S–H versus portlandite, i.e. with increasing C–S–H carbonation, decalcification shrinkage may be dominant, leading to a coarsening of the pore structure. The carbonation (decalcification) shrinkage seems to increase with the degree of C–S–H polymerisation, and with a decrease in Ca/Si molar ratio. Carbonation shrinkage may reverse the beneficial, experimentally determined, porosity reduction that is related to portlandite carbonation to CaCO3 [27].

The C–S–H amount in SF blended paste is high and the amounts of ettringite and AFm are reduced compared to PC or blends containing FA or BFS. However, the higher extents of self-desiccation and autogenous shrinkage leading to high internal stresses and micro-cracking, a pronounced reduction of pH, challenges of early-age workability, and high increase in strength provided by small amounts of SF addition usually lead to its application at low replacement levels. The number of published research papers on carbonation of SF-blended binary [78, 93, 96] and ternary [74] cement pastes is limited compared to BFS or FA blends. According to Leemann et al. [96], the reduction in total porosity of SF blended cement paste is less pronounced and coarse porosity is increased compared to PC upon carbonation. Consequently, higher oxygen diffusion coefficients are expected for carbonated SF blended cementitious materials than for PC and BFS blended cements for similar replacement levels. A decreasing carbonation resistance compared to PC was found for constant w/b [96] and for constant strength grade [93].

MK provides less CaO than FA but makes available more Al2O3 into the cementitious system than other SCMs. Carbonation when using MK or other calcined clays as SCMs has been investigated in an increasing number of studies [16, 25, 83, 93, 94]. At moderate replacement levels, a negligible amount of portlandite was found prior to carbonation due to pozzolanic reaction, and the C-A-S–H carbonation degree was higher than for PC (polymerised C-A-S–H for MK, decalcified C–S–H for PC) [16]. Consequently, the accessible porosity was on a similar level [16, 83] and the threshold pore radius was increased compared to PC upon carbonation [16]. Higher carbonation rates were found for MK blended cementitious materials either for a constant strength grade [93] or for constant w/b [16] upon carbonation compared to PC, but lower than for SF blends [93] or for LS blends [16] at the same replacement level.

Initial portlandite contents in LS blended cement pastes are slightly lower than in PC pastes [16, 64, 66]. The LS-containing pastes were found to carbonate to a higher degree [16, 95]. Both the initial porosity and the porosity upon carbonation were increased compared to PC. A similar reduction in accessible porosity compared to plain PC was found after carbonation [16, 96], leading to a reduced diffusivity.

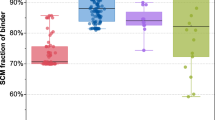

Figure 4 shows some effects of clinker replacement levels on the change in carbonation coefficient relative to PC mixes as reported by different authors—all samples have been cured for 28 days. According to these analyses, at the same replacement level the reduction in carbonation resistance is more pronounced for FA and SF blended concretes and mortars, than for LS or BFS blended concretes and mortars. It should be stated that differences in w/b, aggregate type and grading, execution and carbonation conditions can affect these results.

In order to assess the carbonation resistance of a specific cementitious material from its composition three main approaches have been developed:

-

(a)

estimating carbonation resistance based on the clinker content and water to binder ratio (w/b) [41, 97].

-

(b)

k-value concept (EN 206), using the type of SCM and water/(cement + k·addition) (w/ceq) [99].

-

(c)

assessing buffering capacity based on the ratio of mixing water to reactive calcium oxide (w/CaOreactive), see Sect. 1 [44, 96, 100].

Figure 5 a, b, c illustrate the approaches (a), (b) and (c), respectively.

approach a carbonation resistance in dependency of w/b and clinker content for 7-day water cured concretes (20 °C/ 65% RH/ 0.04 vol%CO2) [41, 97]. Error bars indicate ± standard deviation; b) approach b carbonation resistance in dependency of w/ceq of concretes [99] c) approach c carbonation resistance in dependency of w/CaOreactive of samples tested according to SIA262-1 [44] and samples cured for 91-day [100] and 28-day [96] carbonated at 1% CO2 and related to 0.04% CO2

The approach (a), which uses the clinker content and w/b [41, 97], shows carbonation rates of concretes water cured for 7-day and carbonated at 65% RH, 20 °C under natural CO2 concentration. The lines show the potential regression curves to the mean carbonation rates of groups of concretes summarized in dependency of the ranges of clinker content according to EN197-1, including CEM I (95-100% clinker), CEM II/A (80–94% clinker), CEM II/B (65–79% clinker), CEM III/A (35-64% clinker) and CEM III/B (20–34% clinker). In addition the effect of maximum grain size (4 - 32 mm), admixtures (retarder, water reducers, air-entrainment agent), binder content, cement strength grade and clinker replacement level by specific types of SCM has been evaluated for mixes with the same w/b ratio. No systematic effect has been found for the maximum grain size, binder content and the admixture except for the air-entrainment admixture. With air-entrainment admixture the carbonation rate increased at fresh concrete air content > 8%. A small decrease in carbonation rate has been found with increasing cement strength grade in this curing protocol. The increase in carbonation rate with increasing replacement level was higher for LS than for BFS.

The k-value concept, approach (b) according to [99], shows carbonation rates of concretes water cured for 7-day and carbonated at 65% RH, 20 °C under natural CO2 concentration. Based on the equivalent performance concept for type II additions in CEN/TR 16639 the efficiency factor kc has been determined for the concrete property carbonation rate. The efficiency factor is used to reduce the creditable amount of mineral addition when calculating the w/ceq with ceq = clinker + kc · addition. Using the w/ceq the same performance shall be reached as if pure Portland cement would have been used with the same w/c = w/ceq ratio. Hence, plain PC concrete has the efficiency factor kc = 1.0, which is named category 0. For BFS and FA blended cements 3 and 2 categories have been built, respectively. Increasing category represents increasing amount of type II addition. For example, CEM III/B concretes are allocated to category 3 BFS. Efficiency factors were in the range of 0.8-0.6 for BFS blended cement concretes and 0.3–0.35 for FA blended cement concretes. For BFS blends the efficiency factors where in the range of those determined in [101] with 0.65–0.81 and higher than determined in [98] with 0.2–0.4. For FA blends the efficiency factor was similar with those determined in [101] with 0.25–0.58 and [98] with 0.05–0.3.

Approach (c) [44, 96, 100] replaces the clinker content in approach (a) by the amount of all CaO available to react with CO2 -, i.e. w/CaOreactive (w/CaOreactive). In order to determine the CaOreactive Papadakis et al. [38] suggested a simplified mass balance equation to calculate CaO: [Ca(OH)2] + 3[C–S–H] + 3[C3S] + 2[C2S], this expression however, neglects CaO present in aluminate or ferrite phases. For modern cements, which can contain significant amounts of calcium carbonate as an SCM or minor additional constituent, the fraction of CaO already bound by CaCO3 has also to be considered as well as the amount of SO3, as SO3 will be present as CaSO4 in completely carbonated cements [14, 21]. Also, the amount of CaO present in unreacted cement clinker and supplementary cementitious material must be accounted for [14, 21, 44]. Thus, the CaO available for carbonation can be calculated according to: \({\text{CaO}}_{\mathrm{reactive}} = \, {\text{CaO}}_{\mathrm{total}} - {\text{CaO}}_{CaCO3\_init} - {\text{CaO}}_{CaSO4} - {\text{CaO}}_{\mathrm{unreacted clinker}} - {\text{CaO}}_{\mathrm{unreacted SCM}}\) where each term can be determined using thermodynamic modelling (see Fig. 1) or mass balance calculations.

The simplified approaches (a-c) used to describe the carbonation resistance in dependency of parameters of the mix design have their benefits and drawbacks. Approach (a), clinker content and w/b, is simple to apply, but it neglects the buffering capacity of the specific type of SCM and their differences regarding alteration in pore size distribution upon carbonation. The K-value concept, approach (b) is less simple to apply because it requires the allocation of the specific concretes to efficiency factor required for each type of SCM. Approach (c), is the most scientific approach. It also accounts for the contribution of SCM on CO2 binding capacity. But for its application, the reactive CaO content has to be known or assessed and the effect of specific types of SCM on pore size distribution are little accounted for. Approach (a) and (b) are restrictive regarding the implementation of new materials, while in approach (c) new materials can be simply included. All three approaches are highly dependent on degree of hydration. In all three approaches, the mixing water w accounts for the diffusivity i.e. the volume of capillary pores. Alteration of porosity prior and upon carbonation due to the use of alternative materials and SCM`s is little accounted for.

In addition to those three approaches, which describe the carbonation resistance based on the mix design, other approaches have been developed, which describe carbonation resistance based on compressive strength [101, 102] or permeability [103]. For a 7 day compressive strength between 20 and 25 MPa the carbonation rate was found to be in the range between 4 to 7 mm/year0.5 in [102] for concrete samples water cured for 7 day and carbonated at 65% RH, 20 °C and natural CO2. The concretes where prepared with CEM I, CEM III/A, CEM II/B-M and CEM IV as well as CEM II/C-M cements and the carbonation rate was the highest for concretes with high clinker replacement levels within the same strength grade. Similar were the results from [101] for samples carbonated in 2% CO2 converted to 0.04 vol%with k(0.04% CO2) = k(2% CO2)·√(0.04/2). Imamoto et al. [103] used the correlation between air permeability and carbonation rate determined from existing structures, and thus under variable environmental conditions (moisture, temperature, CO2 concentration) in Japan, Switzerland and Portugal to rate the quality of the placed concrete. For example, for a coefficient of air permeability between 0.1 and 1 10-16 m2 the concrete was classified moderate and the carbonation rate was found in the broad range between > 0 and 5 mm/year0.5. Compressive strength as well as the air permeability are indicators for the air tightness of a concrete and hence also its resistance against CO2 diffusion; however compressive strength does not account for the CO2 binding capacity of the specific type of binder and the differences in alteration of pore size distribution upon carbonation. This may explain to some extend the high scatter observed for this correlation. The benefit of both approaches is that the compressive strength is usually available and the air permeability [103] may be determined non-destructively.

To summarize, the carbonation resistance is depending on more factors than just the clinker replacement level, FA or BFS, the calcium oxide content, compressive strength or air permeability. In addition, the binder specific alteration of porosity, the reaction products formed, the composition dependent reaction kinetics, the degree of hydration, the water retention and hence the testing conditions are important parameters, which leads to a limited precision in all the correlations discussed above.

3.2 Aggregate volume and grading: paste-mortar-concrete

The carbonation coefficients reported in [38, 39] for plain Portland cement concrete samples carbonated at 50 vol% CO2, 30 °C and 65% RH increased by a factor of 1.1 and 1.5 when the aggregate to cement ratio (a/c) increased by a factor of 1.7 and 2.3, respectively. Similar results have been reported at 5 vol% CO2 [104]. If a coarser aggregate was used (unchanged total volume of aggregate), the measured carbonation depth was similar or slightly higher [38, 39]. In contrast, Jung et al. [105] found no significant differences in the effective CO2 diffusion coefficients between concrete and mortar, but a significant increase in diffusivity was observed for cement paste systems upon carbonation (i.e. if the a/c ratio decreases). The increase of gas diffusion coefficient for paste systems was explained by the larger porosity per unit of volume hydrated paste compared to hydrated concrete. This is in line with investigations of plain Portland cement pastes and mortars from [27, 105, 106].

Carbonation rates of cement paste, mortar and concrete systems have been compared in [107]. Figure 6 plots the carbonation coefficients obtained after 7 weeks in 2 and 10 vol%CO2 for cement paste, mortar and concrete, manufactured with either 30 wt% PC replacement by FA (70PC30FA), or 70 wt% PC replacement by BFS (30PC70S). Carbonation coefficients of mortar and cement paste (w/b = 0.5) were higher by a factor of 1.2–1.3 and 1.6–2.3, respectively (depending on binder type and CO2 concentration), compared to the carbonation coefficients of concrete. The increase in carbonation coefficient for cement paste compared to concrete is more pronounced for FA than for slag systems, and more pronounced at higher CO2 concentration. A better correlation has been observed between mortar and concrete (R2 = 0.96) than between cement paste and concrete (R2 = 0.82 for w/b ratio of 0.50).

The increase in carbonation coefficient with increasing a/c for PC concretes reported in [38, 39, 104] may be attributed to the increasing fraction of more porous portlandite-rich interfacial transition zone (ITZ) providing paths for fast CO2 diffusion [77]. In contrast, the faster carbonation in the presence of less aggregate reported in [107] could be related to more autogenous and drying shrinkage in case of cement paste system and subsequent increase of porosity [106,107,108,109].

The majority of studies evaluating carbonation resistance when using SCMs are conducted in paste and mortars, with the assumption that the observations for these systems can be directly translated into concrete. However, this is not the case for the data shown here due to the differences in CO2 diffusivity, consistent with variations in pore structure based on the different paste contents and ITZ zones; differences in the degree of water saturation in materials with diverse permeability; and the different type and amount of carbonation products expected to be forming at a given time. The porosity of carbonated and partly carbonated regions as well as the amount of cement phases buffering the reactions involving CO2, will modify the carbonation reaction kinetics. This has important implications for the development of modelling tools for prediction of the long-term performance of concretes with SCMs, and for the determination of the real carbonation resistance of these materials.

3.3 Effect of recycled and lightweight aggregate

Independent of the SCM used, concretes produced with recycled and lightweight aggregate show to some extent different carbonation performance from those produced with conventional dense aggregates. Recycled aggregate (RA) may contain mortar, unbound aggregate, ceramics, floating particles and bituminous matter. Its different physical (e.g. water absorption, porosity) and mechanical properties (e.g. Los Angeles coefficient) compared with natural aggregate may impact concrete performance. In recent reviews on the durability of concretes with recycled aggregates, Guo et al. [110] and Silva et al. [111] reported that concrete carbonation resistance is affected adversely by the aggregate replacement ratio, w/c ratio, adhered mortar, aggregate size, and exposure time, particularly in concretes with SCMs. Carbonation resistance improves with addition of superplasticisers, consistent with a reduced water content in the concrete, and can also be improved by RA pre-treatment.

Even in the absence of major RA contaminants, due to the heterogeneity and wide variability in the properties of recycled concrete aggregate (RCA), which depend on its source and service history, it is impossible to draw general conclusions about its potential effect on carbonation performance of concretes with SCMs. However, numerous authors [112,113,114,115,116,117,118,119,120,121,122,123,124] studying the effect of the RCA replacement ratio on carbonation resistance of concretes with and without SCMs found that in the case of coarse aggregate replacement the carbonation depth, relative to normal concrete, increased 1.06 to 2.00-fold. However, some studies report higher carbonation resistance in RCA concrete [119, 125, 126], which can be explained by two mutually opposing effects, as the adverse effect of larger porosity counteracts the benefits of greater amounts of (alkaline) carbonatable matter (uncarbonated mortar). Using recycled aggregate as fine rather than as coarse aggregates seems to increase the carbonation depth, so that concrete with RCA showed carbonation depths up to 3.75 to 12.25 times greater than for concrete with natural aggregate [127,128,129,130].

The use of porous and gas-permeable lightweight aggregate (LWA) requires a concrete cover at least 5 mm thicker than the maximum particle size [131]. LWA nonetheless lowers concrete gas permeability, as it absorbs the water in fresh concrete which can form an adhesive water layer on a `dense` aggregate surface. The water adsorption may reduce the water/binder ratio around the LWA in the aggregate-matrix interface, and thus eliminates the interfacial transition zone (ITZ) typically identified when using natural aggregates (Fig. 7). As cement hydration reactions proceed, the absorbed water migrates from the LWA to the hydrating cement paste, favouring internal curing. The outcome is a larger high-quality paste-aggregate transition zone (larger grey zone in Fig. 7 bottom left), less permeable in lightweight than in normal concrete [132, 133]. Research on existing structures confirms the beneficial impact of LWA on the carbonation coefficient [134,135,136].

4 Effect of curing on carbonation resistance

Curing has an important effect on the carbonation resistance of concrete as it influences the pore structure and the degree of hydration of the cement, and consequently the amount of carbonatable material. The effect is less pronounced for plain PC concrete than for concrete with SCMs due to their slower reaction. Nevertheless, if adequate precautions are taken, e.g. sufficiently long curing and reduced w/c ratio, the depth of carbonation of concrete with binders containing SCMs may be the same as for concrete with PC [138]. Thus, the type of curing, its duration and temperature as well as other environmental and geometrical conditions like wind speed, size of structural element, and type of formwork need to be considered when estimating the impact on the carbonation resistance.

Typical curing methods in practice are in air, moist, sealed, heat or steam curing, or the use of a chemical curing compound. The type of curing drastically affects the carbonation rate as shown by [139], who reported that the carbonation rate of water-cured samples was only 17% of the carbonation rate of air-cured samples (28 days), in a chamber filled continuously with 100% CO2 (carbonation measurements between 1 and 28 days).

In the laboratory, curing at > 95% RH is common practice but is not representative for on-site hydration circumstances. The duration of curing on construction sites is typically a few days. For varying replacement levels by FA and BFS, researchers have reported that the carbonation coefficient increases dramatically when shortening the curing periods from 7 to 1 day [140,141,142]. In [143], it is shown for concretes (grades C16/20 to C30/37) with blended cements (CEM II A-M and CEM IV A-M) based on natural carbonation tests for 1 year, how the period of wet curing, and the type of curing (wet curing vs. use of a membrane), affect the carbonation rate and therefore the service life of reinforced concrete structures. In that study, an extension of the wet curing period from 1 to 3 days increased the predicted service life by a factor of more than 2, and a factor of 4 improvement is gained by increasing from 1 to 7 days of wet curing. It was found that 3 days of curing should be enough for replacement levels of less than 30 wt% for FA or 50 wt% for BFS [141, 142]. For higher replacement levels, longer curing periods are desirable.

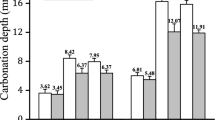

For accelerated carbonation testing in the laboratory, longer curing periods are in most cases recommended to obtain a more realistic and representative microstructure before subjecting the concrete to high CO2 levels. Continuous curing over periods longer than 1 month can significantly increase the durability of BFS concrete (50–85 wt% cement replacement), but periods longer than 3 months were found not to considerably affect the resistance to carbonation anymore [52]. In contrast, Sailio [144] showed that the carbonation depth of systems containing slag cement, or 30 wt% FA, seems to decrease progressively and continuously also with curing times exceeding 3 months. However, no significant effect of wet curing beyond 3 months was observed for Portland cement systems containing 10 wt% or 25 wt% MK [143,144,145]. Atis [146] reported for concrete with FA (50 wt% and 70 wt% cement replacement) the importance of a longer initial curing before testing at 5 vol% CO2 (testing from 3 days up to 3 months of moist curing), which resulted in lower carbonation depths. Burdon [87] found that the carbonation rate significantly increases with increasing FA replacement between 30 and 50 wt% for the same w/b ratio, but that the relative difference to PC concrete decreases with moist curing time. Parrott [79] examined the effect of 15–25 wt% LS replacement (at the samew/b = 0.59) on carbonation rate on samples water cured for 1, 3 and 28 days prior to natural carbonation exposure. Compared to plain cement, the carbonation rate increased with increasing LS replacement; the difference was smallest for 1-day curing for both exposure times under temporal variable outdoor conditions, see Fig. 8. With increasing exposure time and therefore decreasing moisture and temperature variations at the carbonation front, the differences decrease compared to plain PC after 1.5 years of exposure.

Effect of sealed curing duration on carbonation rate for different limestone replacement levels, compared to PC [79] concretes for the same w/b ratio

Also, the temperature during curing has an impact on the carbonation resistance. Borges et al. [75] concluded that, for a curing period of 90 days, raising temperature from 20 °C to 60 °C reduced the carbonation rate by 10–30% for cement pastes with high replacement levels by BFS. Li et al. [148] investigated the effect of high temperature curing (water curing at 20 °C, 40 °C, 60 °C, 80 °C until equal strength grade) of concrete made of PC and with FA, FA and BFS, and SF. The minimal carbonation depth was found for samples cured at 60 °C, pronounced for blended cements and less pronounced for PC.

In different models e.g. fib MC 2006 bulletin 34 [149] an execution transfer parameter is introduced to take into account the influence of curing on the effective carbonation resistance. It should be noted that all actions preventing premature desiccation of the concrete close to the surface are here considered as curing measures, and that no distinction is made for the type of curing and type of binder. However, Van den Heede et al. [85] emphasise the importance of a binder-dependent curing parameter. The effect of curing on carbonation rate as obtained from [42, 79, 91, 147, 150,151,152] has been evaluated in Fig. 9. It can be seen that for slag and LS blended cements, increasing curing time from 7 to 28 days is less effective with regard to improving carbonation resistance, despite the expected further reaction processes involving LS and slag with time [66]. In contrast, the FA blended samples showed a pronounced reduction of carbonation rate when increasing curing from 7 to 28 days, especially for the samples exposed outside under sheltered conditions with variable RH and temperature (exposed samples). It should be mentioned that moisture conditions in sheltered small samples differ from large structural elements; i.e., more homogeneous micro- and macro-climates in small samples than in structural elements may lead to different moisture transport processes.

Increase in carbonation resistance in dependency of moist curing time relative to 7 days curing for a PC, b PC with LS addition c PC with BFS addition d PC with FA addition. Data from [42, 79, 91, 147, 150,151,152]; i.e. 20/65/3 indicates T [°C]/ RH [%]/ CO2 [vol. %] where the climate conditions are given in the original literature source

5 Effect of relative humidity, temperature and CO2 concentration on carbonation

5.1 Relative humidity and temperature

Carbonation of cementitious materials occurs when CO2 diffuses through the material and dissolves in the pore solution where it reacts with the solid phases. At very low RH, there is not enough water in the pores to dissolve CO2 for the chemical reaction to happen. At very high RH, the pores become saturated and consequently the diffusion of CO2 is slowed down significantly. For Portland cement-based materials, the carbonation rate at 20 °C reaches maximum values at RH between 40% and 80% [38, 39, 153,154,155]. This RH range is quite large because the literature results relate to different CO2 concentrations with various preconditioning conditions (temperature and relative humidity, duration) and different curing times, as well as different material compositions (paste vs. mortar, water-to-cement ratio). In recent studies, the fastest carbonation has been observed at approximately 50–55% RH for plain cementitious materials; the carbonation coefficient of plain cementitious material is reduced by a factor of 0.6 ± 0.4, 0.5 ± 0.4 and 0.4 ± 0.4 if the relative humidity increases to 70%, 80% and 90% respectively [43, 44, 72]. The carbonation coefficient has been observed to be reduced to zero in the range 10 to 30% RH [72]. These broad ranges and various conditions involve varying degrees of saturation of the test specimens. For example, in the accelerated carbonation tests for both French standard XP P 18-458 [156] and European standard EN 12390-12 [157], the RH during carbonation is fixed at 57 ± 3%, while conditions specified for sample preconditioning are different.

For materials containing SCMs, the RH range at which carbonation proceeds the fastest may differ from the values determined for Portland cement systems (Fig. 10). Drouet et al. [72] found the most rapid carbonation RH around 33% for CEM V/A paste (containing slag and fly ash) carbonated at a CO2 concentration of 50% at 20 °C, which is a much lower RH value than was obtained for plain Portland cement paste (CEM I) in the same study, which was around 50%. Leemann and Moro [44] studied mixtures with different SCMs: BFS, SF, FA and LS. They found that increasing RH from 57 to 70% or 80%, at a CO2 concentration of 4% not only decreases the carbonation coefficient but also changes the ranking of the different concrete mixtures. The authors explained these differences via the effect of pore size effect on capillary condensation. For cementitious materials with a higher amount of fine pores, such as those containing blast furnace slag and pozzolans, the pore volume filled with water due to condensation is higher at a fixed value of RH [72, 158, 159]. De Ceukelaire et al. [160] found a maximum carbonation progress at 50% RH for concretes containing BFS, at different CO2 concentrations. A decrease of carbonation coefficient with increasing RH (40% to 60% to 80%) for different binders containing SCMs was also reported in [25].

7-day carbonation depth as a function of RH, for CEM I and CEM V/A pastes with w/b = 0.40, at a CO2 concentration of 50% [72]

It should be noted that apart from the externally imposed humidity conditions, the applied CO2 concentration during carbonation testing could also affect the internal humidity and saturation degree of cementitious binders. According to [161], excessive water production during carbonation at high CO2 levels could have a pore blocking effect. Hence, the humidity range at which carbonation is most rapid is most probably dependent on CO2 concentration for any concentrations above the natural atmospheric levels.

In addition to RH, temperature is a main external parameter that affects carbonation of cementitious materials. Higher temperature accelerates carbonation as chemical reactions and diffusion are faster. However, higher temperature also decreases the solubility of portlandite and CO2 in water [2, 162, 163].

The carbonation coefficient increases by a factor of approximately 1.1 from 20 to 30 °C and from 30 to 40 °C for plain and for blended cements (e.g. limestone and low calcium FA). For calcined clay blended cements, a higher increase of the carbonation coefficient was determined (by approximately a factor of 1.3) [25]. The decrease in carbonation coefficient when the temperature decreases from 20 to 10 °C is less pronounced (multiplicative factor of 0.95) [25, 38, 164].

Temperature also affects the stability of the calcium carbonate polymorphs that precipitate during carbonation. Tai and Chen [165] have shown that the formation of these polymorphs by precipitation from a CaCl2/Na2CO3 solution is a function of pH and temperature (Fig. 11). At high pH, calcite is the main polymorph regardless of temperature (24 °C and 58 °C). At lower pH, the dominant polymorph changes as a function of temperature; for high temperature (58 °C), aragonite will be the main polymorph to precipitate while for ambient temperature (24 °C) vaterite has been observed. Drouet et al. [72] have studied the effect of both temperature and RH on the stability of calcium carbonate polymorphs. They found that the two metastable forms of calcium carbonate (aragonite and vaterite) were observed in varying amounts for both Portland cement and CEM V pastes. The amount of aragonite and vaterite increased when the RH decreased. This increase is more significant at higher temperature.

Polymorphs of calcium carbonate observed to precipitate from a 1:1 molar mix of CaCl2 and Na2CO3 at a supersaturation of 5.5, according to pH (controlled by NaOH or HCl addition) and temperature [165]

One key aspect is that if the temperature increases without maintaining a fixed RH, a part of the water from the specimen evaporates and the carbonation could be lower in spite of the increased temperature. The literature results reflect these contradictory effects. Drouet et al. [72] observed that the carbonation depth of Portland cement paste increased continuously with temperature at a fixed RH, whereas the carbonation depth of CEM V/A reached a maximum at around 50 °C.

These findings are particularly important considering that when evaluating carbonation resistance of concretes according to accelerated carbonation standardised testing methodologies, the exposure temperature is generally set to be between 20 and 25 °C, which is not representative of all climates, and can yield carbonation results that can be far from being a realistic representation of what can be expected of concretes with SCMs under natural carbonation conditions in the field.

5.2 CO2 concentration

Increasing the CO2 concentration is a common approach to accelerate carbonation for testing purposes, and the results of accelerated tests are often used as performance criteria for validation of new concrete mixes and service life prediction models. Different factors and equations have been proposed to transform the results from accelerated carbonation testing to predict natural carbonation [151, 166, 167]. However, there is still need for research to define relations applicable for different concrete compositions [142].

From a thermodynamic viewpoint, increasing the CO2 concentration should not change the expected phase formation in plain Portland cement [28, 168]. Nonetheless, experiments have shown that:

-

The C–S–H carbonation rate increases with the applied CO2 concentration [32]. The proportion of CaCO3 originating from portlandite and C–S–H carbonation changes significantly from 1% CO2 onwards, in favor of C–S–H carbonation [169].

-

A CO2 concentration above 3% favours formation of aragonite and vaterite [26, 170] due to pH reduction because of increased amounts of dissolved CO2, [171], (Fig. 11).

-

A CO2 concentration above 10% leads to incomplete reaction of portlandite, e.g. due to a fast surface reaction causing an overgrowth of portlandite with calcite, which permanently prevents further portlandite carbonation [28, 170, 172]. A high CO2 concentration also lowers the pH and thus the solubility of CO2 in water or in solutions containing alkali hydroxides (such as cement pore fluids), leading to the formation of more HCO -3 and less CO 2-3 [2, 171].

-

However, in cementitious materials with limestone fillers only calcite is formed [168, 172, 173]. In high-volume fly ash binder systems, the preferred precipitation of aragonite and vaterite over calcite could not be confirmed for 1% and 10% CO2, but was evident at 0.03–0.04% CO2 [169].

-

For a high CO2 level, the amount of water produced during carbonation could be more than the porous matrix is capable of expelling in the same time interval. The time needed to establish a condition of equilibrium again is believed to slow down further carbonation [161, 174].

-

The correlation between accelerated and natural carbonation coefficients decreased from laboratory to sheltered (R2 = 0.69) and finally to unsheltered exposure (R2 = 0.15). Key parameters to consider for natural carbonation are temperature, relative humidity and amount of precipitation [44, 96]. The correlation strongly depends on the microclimatic conditions (i.e. RH, orientation, wind, precipitation).

Rozière et al. [175] found correlation coefficients of only 0.45-0.67 when correlating natural to accelerated carbonation at 50% CO2, although the ranking of the concrete types considered remained similar. This is in line with other studies [38, 39, 176]. On the other hand, several researchers [175,176,177] noticed small changes in ranking between mixes when carbonated at 1%, 4% or 10% CO2. Increasing the RH at 4% CO2 from 57% to 70-80% RH also affected the ranking for carbonation resistance, probably as the result of a different w/c and pore size distributions of the concrete types tested [44].

As the pore structure and the ratio w/CaOreactive are cement-specific, the correlation between accelerated and natural carbonation depends strongly on the binder [150, 179]. Hainer 150 points out that clinker-reduced concrete shows relatively higher carbonation rates under field than under accelerated conditions. In contrast, Leemann et al. [96] and Bernal et al. [171] noted that accelerated carbonation is more aggressive than natural carbonation for concrete with SCMs. A detailed comparison of literature data is challenging due to the many different storage and exposure conditions assessed by different authors, and is beyond the scope of this review.

The increase in carbonation coefficient with increasing CO2 concentration (CO2acc) compared to natural CO2 concentration (CO2nat) is in most experimental investigations lower than what is expected from the theoretical relationship √(CO2acc/CO2nat) [38, 96, 151]. According to these investigations, the deviation from the theoretical relationship is more pronounced for plain cements and cements with LS than for slag blended cementitious materials. It has been indicated [42] that a formula in which the carbonation depth relies on the square-root of the CO2 concentration in play should be reliable up to 3% CO2. Yet, even from 1% CO2, the relationship does not seem to hold [169]. Given that this is the case, the assumption of pure diffusion control of carbonation kinetics appears to break down at higher CO2 concentrations, and this needs more detailed investigation to determine what is the true rate-controlling step if accelerated test results are to be used to predict natural carbonation rates in standards and codes.

6 Effect of carbonation on porosity and transport properties

6.1 Porosity and pore size distribution

Porosity of cementitious mixtures plays an important role in relation to the carbonation resistance, as it is directly linked to the ingress of CO2. When investigating porosity, different aspects need to be considered, for instance pore volume, pore size distribution, tortuosity and interconnectivity. Castellote et al. [31] reported pore clogging and formation of dense, carbonated areas as the main cause for limited accelerated carbonation rates in plain PC pastes. Hyvert et al. [32] and Anstice et al. [180] confirmed a decreasing total porosity with an increasing CO2 concentration, and Knöfel et al. [173] recorded a refinement in pore size distributions using mercury intrusion porosimetry. Mortars with plain PC showed increased amounts of gel pores, while the fraction of capillary pores decreased to around 10%. The decrease in total porosity, and pore clogging, are attributed to the formation of calcium carbonate which takes up a larger volume than the initial hydration product Ca(OH)2. Several studies [24, 25, 181] also identified a decrease in the total porosity of plain cement pastes due to carbonation in combination with a coarsening of the capillary pores. For BFS-containing binders a decrease in gel porosity but an increase in capillary pores (coarsening of the pore structure) has been reported in [26, 83, 182]. Similar are the findings at high FA or SF replacement levels [26, 27, 182, 183]. This coarsening is usually associated with C–S–H/C-A-S–H carbonation. The higher the amount of reactive alumina provided by the SCM, the larger the increase in porosity on carbonation, due to the decomposition of AFm and AFt phases [75].

According to [106] the decrease in micro-pores is attributed to clogging by CaCO3 from C–S–H carbonation, while the reduction of macro-pores is mainly attributed to pore clogging by CaCO3 from portlandite carbonation. However, the increase in meso-pores has been interpreted differently by various authors, and the potential causes are listed in [106] as follows:

-

(i)

porous structure of silica gel formed during carbonation.

-

(ii)

micro-cracks in the CaCO3 layer surrounding portlandite crystals due to the hydric gradient, and.

-

(iii)

micro-cracks induced by carbonation shrinkage.

The more pronounced increase in meso- and macro-pore volumes for FA, SF and slag blended cements upon carbonation can also be attributed to the lower Ca/Si ratio of C–S–H/C-A-S–H formed in these blended cements, by enabling the entrapment of alkalis reducing the amount of hydroxyl ions and also the increased carbonation shrinkage for Ca/Si less than 1.3 [34].

Also Shah et al. [25] reported that because the replacement of PC with Si-rich SCMs results in less portlandite, the decalcification of the C–S–H present leads to an increase of the total porosity in combination with a coarsening of the pore structure. Consequently, the extent of pore coarsening and the increase of total porosity during carbonation depend on both the amount and the type of SCMs.

Prior to carbonation, SCMs can increase the porosity of cementitious materials at early ages but contribute to the development of a more refined pore structure over the time [184]. These two opposing effects will affect the resistance to carbonation of concretes depending on the type of SCM used and its ability to cause pore refinement, the amount of cement replacement, and the reaction degree as a function of time. Upon carbonation it is observed that the total porosity increases with increasing SCM replacement ratios [75, 82]. For example, when SF is used in concrete, Kulakowski et al. [185] found a ‘critical threshold’ related to the amount of replacement and w/b ratio: cement replacement up to 10 wt% by SF will result in an increased carbonation resistance. However, if SF replacement is higher than 10%, this will lead to more carbonation.

The data collected in Table 1, from [82], show an increasing total porosity prior to carbonation when the replacement level by FA is increased from 0 to 30 wt% and 60 wt% substitution. Upon carbonation, the total pore volume decreases in all cases. The decrease of the pore volume in the MIP-accessible range (3 nm to 500 µm) during carbonation seems to be lower at higher replacement levels for the MIP measurements, and similar in the case of GRAM (gamma ray attenuation method) measurements (accessing coarse pores size 200 μm to 1000 μm [186]).

For ternary systems with 50% clinker, 31% calcined clay, 15% limestone and 4% gypsum, a clear increase of the total porosity was observed in Fig. 12a [24], under both natural and accelerated (3%) carbonation conditions. An experimental study on the use of slag in pastes [24] showed that an increase in total porosity is detected when the clinker replacement is 70 wt%. The increase in capillary porosity due to carbonation further accelerates diffusion of detrimental substances and will therefore make concrete with SCMs more vulnerable to deterioration by coupled mechanisms.

Mercury intrusion curve of uncarbonated cylindrical paste samples (solid line) compared with cylindrical paste samples carbonated in natural (dotted line) and accelerated conditions at 3% CO2 (dashed line) cured in lime water for 120 day and preconditioned for 15 day at 60% RH and 27 °C; a) Cumulative intrusion curve of PC, b) Cumulative intrusion curve of 70% PC + 30% FA, c) Cumulative intrusion curve of limestone calcined clay cement (50% clinker, 31% calcined clay, 15% LS, 4% gypsum) from [24]

6.2 Transport properties

The alteration of the pore structure upon carbonation of plain and blended cementitious materials affects the vapour sorption/desorption isotherms, gas and moisture transport. The transport of CO2 through cementitious materials is one of the governing parameters affecting carbonation rate and is strongly affected by moisture conditions as was discussed above. The degree of water saturation under steady-state and isothermal conditions has been determined by means of water vapour sorption/desorption tests [38, 74, 187]. Figure 13 shows sorption isotherms for plain and blended cement pastes. A benefit of adsorption/desorption isotherms is the provision of information about changes in micropores < 10 nm, which are less well reflected by MIP (molecule radius of H2O is 0.1 nm, of nitrogen N2 is 0.215 nm and both are smaller than that of mercury; it avoids also the risk of microcracking in MIP [106]).

Effect of carbonation on degree of pore saturation (adsorption (Ads.)/desorption (Des.) isotherms) of plain PC mortars with w/c = 0.5 from [38, 187] a and desorption isotherms with 22% slag + 22% FA (circle) or 61% slag (rhombus) blended mortars with w/c = 0.4 from [74] b for non-carbonated (NC) and carbonated C samples

Papadakis et al. [38] and Houst et al. [187] observed no alteration in water saturation degree at > 50 vol%CO2 for plain cementitious materials. Borges et al. [75] found a small alteration at low RH when applying 3 vol%CO2 to plain PC, indicating an increase in micro-porosity, compared to a pronounced alteration of pore saturation in FA and BFS blended cementitious materials upon carbonation, indicating an increase in micro-, meso- and macro porosity. Hyvert [188] determined a notable alteration of the water sorption isotherm for plain PC, and an even more evident alteration for blended cementitious materials. The reduced degree of saturation in carbonated samples at 50% ≤ RH ≤ 85% affects effective CO2 diffusion coefficients in two ways: (i) the coarsened pore structure opens the path for CO2 diffusion, as the capillary pores are the decisive pores for high diffusion rates; and (ii) the degree of saturation is reduced in the relative humidity ranges expected under common site conditions.

Effective CO2 diffusion coefficients in non- and fully carbonated pastes, mortars and concretes have been determined experimentally under different conditions [21, 38, 39, 44, 78, 105, 182, 187, 189,190,191].

Prior to carbonation it was found that the effective CO2 diffusion coefficient decreases with:

-

Decreasing w/b (decreasing capillary porosity) [21, 39, 78, 105].

-

Increasing relative humidity above 40% RH, which increases the degree of water saturation [38, 105, 182, 187, 189].

-

Increasing PC replacement level by FA, SF or BFS, respectively increasing the fraction of the binder that is C(-A)-S–H [21, 78, 182, 189].

-

Increasing degree of hydration [182].

Upon carbonation the effective diffusion coefficient was found to:

-

Decrease in the case of plain cementitious materials and blends with portlandite or LS, with increasing ratio of portlandite carbonation [21, 38, 39, 44, 78, 105, 182, 187, 189,190,191] for RH > 30% [182].

-

Increase with increasing cement replacement level by SF, FA, calcined clay, or mostly for BFS, due to increasing C(-A)-S–H carbonation [21, 78, 182, 190, 191]. The difference becomes more pronounced with increasing degree of water saturation.

-

Increase with carbonation degree at constant high RH (93%) for all mix design unless the water to cement ratio is very low (< 0.4) [191].

In water CO2 diffusion coefficients have been found to be < 10-9 m2/s [192]. Water vapour diffusion coefficients are up to two orders of magnitude higher and increase with the difference in relative humidity, increasing w/b ratio and decrease with increasing replacement by SF or BFS [193]. As CO2 is consumed by the carbonation reaction, CO2 diffusion coefficients are often derived from O2, N2 or He diffusion coefficients [182, 187, 189]. The value of the corresponding CO2 diffusion coefficient depends on whether the process is limited by the molecular mass (molecular diffusion dominating in larger pores) or by the Knudsen diffusion (i.e. diffusion in small pores, where the diffusion resistance is dominated by collisions with the pore walls). Furthermore, transport may also occur as surface diffusion, if the gas interacts by a succession of adsorption–desorption reactions with the surfaces [187, 194]. According to [187, 189] the CO2 diffusion through non-carbonated cementitious materials is both a Knudsen and molecular diffusion process over the entire range of water saturation degree. However, upon carbonation this only holds for plain cements. For slag (approximately 80% replacement level) or FA and SF blended cements (replacement level > 44%) the pores can coarsen sufficiently that Knudsen processes involving pore walls are less important, and so transport instead becomes molecular diffusion controlled [182, 192].

Figure 14 shows effective O2 diffusion coefficients (DCO2/DO2 ≈ 1.4) determined by Leemann et al. [21, 78] after oven drying. The determined effective diffusion coefficients are smaller or similar after carbonation for plain PC, portlandite-blended and limestone-blended cements, but higher for silica fume and slag blends, consistent with the preceding discussion for the rates of carbonation of cements containing these SCMs.

In some carbonation exposure conditions involving high pressure differences, both diffusive and convective transport coexist, and permeability may become dominant [195]. Gas permeability of carbonated and non-carbonated cementitious materials has been reported e.g. in [75, 104, 196,197,198,199,200,201,202] under the assumption of laminar flow. Gas permeability was in the range of 0.1 × 10− 9 m/s < ke < 10 × 10-9 m/s. The gas permeability decreased with decreasing w/b ratio and increasing relative humidity or increasing cement replacement by SF, FA or BFS. Upon carbonation, gas permeability was increased or at least similar as prior to carbonation. But the increase was more pronounced for BFS blended cement systems with replacement levels of 75 wt% to 90 wt% [75, 198].

Water transport properties of cementitious materials have been reported e.g. in [55, 177, 178]. The coefficient of water permeability is usually up to four orders of magnitude lower than the coefficient of gas permeability and may be related to gas permeability in dependency of the applied pressure head according to Klinkenberg explained in [203]. Upon carbonation the water permeability decreased in the case of plain and LS blended cementitious materials but increased for slag, FA and SF blended cementitious materials with moderate to high replacement levels [55, 177, 178]. Similarly, capillary sorption describes permeability of concrete where the pressure head is replaced by the capillary forces including water and water vapour transport [204, 205].

Figure 15 shows coefficients of water sorptivity determined by Jansson et al. [101] for non- and partly-carbonated cementitious materials. He observed for non-carbonated samples a decrease in sorptivity from plain PC over blends with 20 or 35 wt% FA, or 35, 50, or 65 wt% BFS. After carbonation, the sorptivity was significantly reduced for PC samples, slightly reduced for samples containing 20 wt% or 35 wt% FA, or 35 wt% or 50 wt% BFS and increased for samples containing 65 wt% BFS where a pronounced C-A-S–H carbonation can be expected. Similarly, a decrease in capillary sorptivity with carbonation has been observed for plain cement materials [204].

Coefficients of sorptivity reported in [101] for non- carbonated and partly carbonated concretes along with the carbonation depth (small squares), the notation shows the cement type respectively the amount and type of addition and the w/b ratio

Gas permeability data shows an increase upon carbonation for most binder types, while both the effective diffusion coefficients and the sorptivity coefficients show a decrease upon carbonation except for SF or BFS blended cementitious materials. Hence it can be assumed, that the induced pressure in gas permeability experiments alters the pore structure and mirrors mainly the transport in larger pores. Moisture transport (sorption, capillary suction and water permeability) strongly depends on the initial moisture conditions. Additionally, moisture transport may be altered by chemical interaction of water with the cement, such as re-hydration of unreacted cement and dehydrated cement pastes, changes of microstructure of C–A–S–H and secondary reaction products (depending on the type of SCM used) during moisture transport, drying shrinkage induced by the microscopic damage to pores due to capillary forces, and swelling associated with the water uptake [204,205,206,207,208,209].

7 General remarks and conclusions

It is clear that the carbonation mechanism in cementitious systems containing SCMs differs from that of plain Portland cement systems, due to the differences in the phase assemblage evolution, pore structure, and pore solution chemistry. The main difference between these systems is the role of portlandite carbonation, as it is expected that the amount of portlandite decreases at higher SCM replacement levels. This is a consequence of the lower amount of Portland clinker in the cement (which produces portlandite during its hydration) and the consumption of portlandite during the pozzolanic reaction. Portlandite carbonation is the main contributor of released water during carbonation, and usually leads to a reduction in pore size and total volume of meso- and macro- pores due to CaCO3 precipitation. However, the literature results are to some extent contradictory, which may be due to the different measurement methods along with the different pore sizes investigated. Portlandite carbonation may furthermore be incomplete due to the covering of portlandite crystals by calcium carbonate.

With the reduced content of portlandite in SCM containing systems, carbonation will happen more rapidly in the main CO2-binding phases, C–S–H in the case of using SF, and C–A–S–H phases in the case of using BFS, FA, MK and other Al-containing SCMs. Carbonation of these hydrates seems to be the main contributor to carbonation shrinkage (polymerisation shrinkage), especially for low Ca/Si C(-A)-S–H and induces coarsening of pore structure upon carbonation and reduction of mechanical strength. This is particularly critical when evaluating carbonation of concretes with SCMs, as carbonation not only reduces the overall pH, but can also lead to a coarsening in pore structure, consequently reducing the ability of these materials to withstand other forms of degradation by chemical or physical attack.

Carbonation of C(-A)-S–H does not seem to contribute to the release of water prior to complete polymerisation, but there is little investigation regarding structural changes and water released in these hydrates upon carbonation, despite their role as the dominant binding phase present in modern cements. There is an urgent need to determine the carbonation mechanism of Al substituted C–S–H phases, and those containing alkalis (C-(N)-A-S–H), as a function of exposure conditions (e.g. temperature, RH and CO2 concentration), as these are the main CO2-binding phases identified in SCM-containing cements, particularly those produced with BFS. The degree of crosslinking in these gels and the reduced Ca/Si ratio compared with the C–S–H formed in plain PC systems will strongly influence how carbonation proceeds.