Abstract

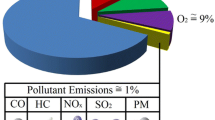

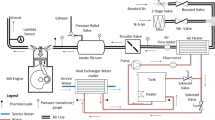

It is well known that acetylene has a wide flammability and is readily available and low-cost non-crude oil derivative fuel. According to the property of low motor octane number, the acetylene cannot be used alone in the internal combustion engine. Research has shown that the introduction of biodiesel results in a substantial reduction in the use of conventional fossil fuels and also in the amount of emissions. This study focuses on performance improvement and emission reduction of conventional diesel engine using acetylene gas as a low-reactivity fuel (LRF) and B20 mahua biodiesel as a high-reactivity fuel (HRF) in the reactivity controlled compression ignition (RCCI) mode. The computational fluid dynamics (CFD) principle is used to evaluate the optimal angle of the LRF injector to achieve better fluid flow mixing pattern in the inlet manifold. From the CFD simulation, an optimal LRF injection angle of 45° is defined in the intake manifold. The modified intake manifold engine is tested for performance, emission and combustion characteristics at different flow rates of acetylene through the injector. It is observed that the brake thermal efficiency (BTE) is increased by about 3.7% at a flow rate of 4 liters per minute (LPM) of acetylene injection in RCCI combustion mode compared to conventional biodiesel operation and significant decreases in polluting components such as smoke opacity, oxides of nitrogen (NOx), hydrocarbon (HC) and carbon monoxide (CO) are reduced by about 10%, 7.6%, 13.4% and 28.7%.

Graphic abstract

Similar content being viewed by others

References

Alagumalai A (2020) Reduced smoke and nitrogen oxide emissions during low-temperature combustion of ethanol and waste cooking oil. Environ Chem Lett 18(2):511–516

Basha S, Rao P, Rajagopal K, Kotturi R (2017) Design and analysis of swirl in acetylene aspirated diesel engine and its effects on performance & emissions. Int J Latest Trends Eng Technol 8(2):390–399

Brusca S, Lanzafame R, Garrano AMC, Messina M (2014) On the possibility to run an internal combustion engine on acetylene and alcohol. Energy Procedia 45:889–898

Bryant DB, Sparrow EM, Gorman JM (2018) Turbulent pipe flow in the presence of centerline velocity overshoot and wall-shear undershoot. Int J Therm Sci 125:218–230

Cebula A, Świątek P, Kowalczyk S (2019) A numerical analysis of the air flow through the IC engine intake manifold. Progress Comput Fluid Dyn Int J 19(1):63–68

Charitha V, Thirumalini S, Prasad M, Srihari S (2019) Investigation on performance and emissions of RCCI dual fuel combustion on diesel-biodiesel in a light duty engine. Renewable Energy 134:1081–1088

Chintala V, Subramanian KA (2013) A CFD (computational fluid dynamics) study for optimization of gas injector orientation for performance improvement of a dual-fuel diesel engine. Energy 57:709–721

De Souza GR, de Castro Pellegrini C, Ferreira SL, Pau FS, Armas O (2019) Study of intake manifolds of an internal combustion engine: a new geometry based on experimental results and numerical simulations. Thermal Sci Eng Progress 9:248–258

Deivajothi P, Manieniyan V, Sivaprakasam S (2018) An impact of ethyl esters of groundnut acid oil (vegetable oil refinery waste) used as emerging fuel in DI diesel engine. Alexandria Eng J 57(4):2215–2223

Deivajothi P, Manieniyan V, Sivaprakasam S (2019) Experimental investigation on DI diesel engine with fatty acid oil from by-product of vegetable oil refinery. Ain Shams Eng J 10(1):77–82

Dhas AG, Arul Gnana Dhas A, Devarajan Y, Nagappan B (2018) Analysis of emission reduction in ethyne–biodiesel-aspirated diesel engine. Int J Green Energy 15(7):436–440

Dimitriou P, Tsujimura T (2017) A review of hydrogen as a compression ignition engine fuel. Int J Hydrogen Energy 42(38):24470–24486

Duraisamy G, Rangasamy M, Govindan N (2020) A comparative study on methanol/diesel and methanol/PODE dual fuel RCCI combustion in an automotive diesel engine. Renew Energy 145:542–556

Ebrahimi M, Jazayeri SA (2019) Effect of hydrogen addition on RCCI combustion of a heavy duty diesel engine fueled with landfill gas and diesel oil. Int J Hydrogen Energy 44(14):7607–7615

Jemni MA, Kantchev G, Abid MS (2011) Influence of intake manifold design on in-cylinder flow and engine performances in a bus diesel engine converted to LPG gas fuelled, using CFD analyses and experimental investigations. Energy 36(5):2701–2715

Kanawade N, Siras O (2015) Design, analysis, and development of 4-cylinder IC engine exhaust manifold. Int Eng Res J 6(1):472–478

Kokjohn S, Hanson R, Splitter D, Kaddatz J, Reitz R (2011) Fuel reactivity controlled compression ignition (RCCI) combustion in light-and heavy-duty engines. SAE Int J Eng 4(1):360–374

Lakshmanan T, Nagarajan G (2010) Experimental investigation of timed manifold injection of acetylene in direct injection diesel engine in dual fuel mode. Energy 35(8):3172–3178

Li Y, Jia M, Chang Y, Xu Z, Xu G, Liu H, Wang T (2018) Principle of determining the optimal operating parameters based on fuel properties and initial conditions for RCCI engines. Fuel 216:284–295

Manieniyan V, Sukumar V, Senthilkumar R, Sivaprakasam S (2019). Emission reduction using biodiesel blends with nano-additives and reformed exhaust gas recirculation (REGR) in DI diesel engine. Int J Ambient Energy 1–7

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Thermal Fluid Sci 1(1):3–17

Murugesan A, Subramaniam D, Avinash A, Nedunchezhian N (2015) Quantitative and qualitative analysis of biodiesel–an in-depth study. Int J Ambient Energy 36(1):19–30

Nazemi M, Shahbakhti M (2016) Modeling and analysis of fuel injection parameters for combustion and performance of an RCCI engine. Appl Energy 165:135–150

No SY (2019) Application of bioethanol to advanced CI engines; dual fuel and RCCI combustion modes–a review. Int J Green Energy 16(14):1105–1130

Raman R, Kumar N (2019) The utilization of n-butanol/diesel blends in acetylene dual fuel engine. Energy Reports 5:1030–1040

Saravanakumar A, Avinash A, Saravanakumar R (2016) Optimization of biodiesel production from Pungamia oil by Taguchi’s technique. Energy Sources Part A Recovery Utilization Environ Effects 38(17):2524–2529

Schmidt DP, Rutland CJ (2000) A new droplet collision algorithm. J Comput Phys 164(1):62–80

Silambarasan R, Senthilkumar R, Manieniyan V, Sivaprakasam S (2017) Performance and emission analysis in DI diesel engine using biodiesel with bio additive. Int J Eng Trends Technol (IJETT) 4(5):865–868

Srivastava AK, Soni SL, Sharma D, Sonar D, Jain NL (2017) Effect of compression ratio on performance, emission and combustion characteristics of diesel–acetylene-fuelled single-cylinder stationary CI engine. Clean Technol Environ Policy 19(5):1361–1372

Subramaniam D, Murugesan A, Avinash A (2013) An inclusive view on biodiesel production by heterogeneous catalyst and its engine operational characteristics. J Renew Sustain Energy 5(3):033135

Sukumar V, Manieniyan V, Sivaprakasam S (2019) Experimental studies on DI diesel engine fueled in sweet lime pyrolysis oil with biodiesel. Int J Appl Eng Res 14(5):1145–1150

Sukumar V, Manieniyan V, Senthilkumar R, Sivaprakasam S (2020) Production of bio oil from sweet lime empty fruit bunch by pyrolysis. Renew Energy 146:309–315

Suryawanshi UK, Paikra AS, Mondloe D (2018) Comparative analysis of different type of biodiesel blend with diesel. Int Res J Eng Technol (IRJET) 5(9):406–413

Tirkey JV, Kumar A, Shukla SK (2018) Comparative analysis of engine performance and emission characteristics of different biodiesels. Biofuels, 1–9

Veerabadran V, Veerasigamani M, Shanmugam S (2020) Effect of carbon nanotube material in diesel engine with exhaust gas recirculation. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, pp 1–14

Wei T (2018) Integral properties of turbulent-kinetic-energy production and dissipation in turbulent wall-bounded flows. J Fluid Mech 854:449–473

Wu F, Wang J, Chen W, Shuai S (2009) A study on emission performance of a diesel engine fueled with five typical methyl ester biodiesels. Atmos Environ 43(7):1481–1485

Yang B, Duan Q, Liu B, Zeng K (2020) Parametric investigation of low pressure dual-fuel direct injection on the combustion performance and emissions characteristics in a RCCI engine fueled with diesel and CH4. Fuel 260:116408

Zheng Z, Xia M, Liu H, Wang X, Yao M (2018) Experimental study on combustion and emissions of dual fuel RCCI mode fueled with biodiesel/n-butanol, biodiesel/2, 5-dimethylfuran and biodiesel/ethanol. Energy 148:824–838

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sonachalam, M., PaulPandian, P. & Manieniyan, V. Emission reduction in diesel engine with acetylene gas and biodiesel using inlet manifold injection. Clean Techn Environ Policy 22, 2177–2191 (2020). https://doi.org/10.1007/s10098-020-01968-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-020-01968-y