Abstract

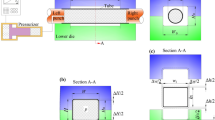

The current work presents numerical modeling of cold expansion of down-hole expandable tubular through the multistage solid metallic mandrel. Down-hole tubular has demonstrated to be a promising technology in the oil and gas industry by providing optimum solutions for multiple unsolved issues. One of the challenges still confronting by researchers and field engineers is implementing and making this technology cost-effective while conserving tubular structural integrity. Furthermore, the requirement of a high expansion ratio (\(\sim \) 30%) by the field engineers also increases the cost of expansion. This ratio is practically not achievable in the one-pass of the expansion process, though multiple passes through single-stage mandrels are currently using to obtain the required expansion ratio. As a result, the cost of expansion and the probability of errors become higher. In the present work, the expansion of down-hole tubular through multistage mandrel is numerically investigated. Firstly, multistage tubular–mandrel is modeled, based on the concept of a single-stage system, to achieve expansion ratios of 16%, 20%, and 24% in one pass. The models are developed so that 16%, 20%, and 24% of expansion ratios can be achieved in the first, second, and third stages. Secondly, the multistage system’s finite element model is validated and found to be in good agreement with the experimental and simulation results. Thirdly, the multistage mandrel geometry is optimized based on the results of contact pressure, expansion force, and equivalent stress in tubular material. Finally, further simulations are performed to analyze equivalent plastic strain, thickness reduction, and length shortening. It is observed that the expansion force in the case of the multistage mandrel is approximately reduced by 57% as compared to three single-stage expansions. Moreover, maximum equivalent stress and contact pressure are 650 MPa and 620 MPa, respectively. These are within the allowable limits.

Similar content being viewed by others

Notes

Target represents an endpoint of well where the oil or gas is present in an optimum quantity.

Model 1.

Model 2.

Model 3.

References

Yuan, B.; Wood, D.A.: A comprehensive review of formation damage during enhanced oil recovery. J. Petrol. Sci. Eng. 167, 287–299 (2018)

Esene, C.; Rezaei, N.; Aborig, A.; Zendehboudi, S.: Comprehensive review of carbonated water injection for enhanced oil recovery. Fuel 237, 1086–1107 (2019)

Bullock, M.; Grant, T.; Sizemore, R.; Daigle, C.; York, P.: Using expandable solid tubulars to solve well construction challenges in deep waters and maturing properties. In: Rio Oil and Gas Expo and Conference, Brazil (2000)

Cales, J.; Shepherd, D.; Wiest, B.; York, P.L.; Daigle, C.; Rose, L.; Patterson, M.: Subsidence remediation-extending well life through the use of solid expandable casing systems. In: AADE Houston Chapter Conference (2001)

van Noort, R.; Rivenbark, M.; Jones, M.: Using solid expandable tubulars for openhole water shutoff. In: Abu Dhabi International Petroleum Exhibition and Conference (2002)

Cales, G. L.: The development and applications of solid expandable tubular technology. In: Canadian International Petroleum Conference, Calgary, Canada (2003)

Demong, K.; Rivenbark, M.; Mason, D.: Breakthroughs using solid expandable tubulars to construct extended reach wells. In: IADC/SPE Drilling Conference, Dallas, Texas, USA (2004)

Binggui, X.; Yanping, Z.; Hui, W.; Hongwei, Y.; Tao, J.: Application of numerical simulation in the solid expandable tubular repair for casing damaged wells. Petrol. Explor. Dev. 36, 651–657 (2009)

Benzie, S.; Burge, P.; Dobson, A.: Towards a Mono-Diameter Well- Advances in Expanding Tubing Technology, p. 7. Society of Petroleum Engineers, Paris (2000)

Carstens, C.; Strittmatter, K.: The value of planned installations vs contingencies. J. SPE Drill. Complet. 21, 279–286 (2006)

Dupal, K.; Campo, D.B.; Andrews, C.J.; Cook, R.L.; Ring, L.M.; York, P.L.: Realization of the mono-diameter well: evolution of game changing technology. In: Offshore Technology Conference, Houston, Texas (2002)

Mack, R.D.: The effect of tubular expansion on the mechanical properties and performance of selected OCTG—results of laboratory studies. In: Offshore Technology Conference, Houston, Texas (2005)

Bufalini, A.; Morana, R.; Nice, P.I.; Nasvik, H.; Kjrholt, H.; Bailey, B.M.; Adam, M.K.; Jiral, D.J.; Ross, R.C.; Smith, R.C.; Ueda, M.; Ohe, T.: Evaluation of mechanical properties and stress-corrosion-cracking resistance of post expanded carbon steel and cra casing grades. In: SPE Annual Technical Conference and Exhibition, Florence, Italy. SPE 133382 (2010)

Bufalini, A.; Morana, R.; Nice, P.I.; Nasvik, H.; Kjrholt, H.; Bailey, B.M.; Adam, M.K.; Jiral, D.J.; Ross, R.C.; Smith, R.C.; Ueda, M.; Ohe, T.: Testing methodology for the preliminary assesment of mechanical performance of materials for expandable applications. In: SPE Annual Technical Conference and Exhibition, Florence, Italy. SPE 133412 (2010)

Butterfield, C.; Flaming, S.; Lebedz, R.; Thigpen, M.; Hill, R.: Understanding post-expansion properties of solid expandable tubulars. In: SPE Annual Technical Conference and Exhibition, California, USA. SPE 110622 (2007)

Pervez, T.; Qamar, S.Z.; Al-Abri, O.S.; Khan, R.: Experimental and numerical simulation of in-situ tube expansion for deep gas-wells. J. Mater. Manuf. Process. 27, 727–732 (2011)

Al-Abri, O.S.; Pervez, T.; Al-Maharbi, M.H.; Khan, R.: Microstructure evolution of ultra-fine grain low-carbon steel tubular undergoing radial expansion process. Mater. Sci. Eng. A 654, 94–106 (2016)

Al-Abri, O.S.; Pervez, T.; Qamar, S.Z.; Khan, R.: On the performance analysis of AHSS with an application to SET technology FEM simulations and experimental measurements. Thin Walled Struct. 101, 58–74 (2016)

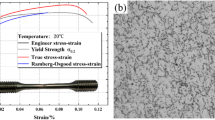

Khan, R.; Almeshaal, M.: Characterization of pre- and post-expansion material properties of down-hole tubular. Arab. J. Sci. Eng. 44(12), 10219–10229 (2019)

Kuziak, R.; Kawalla, R.; Waengler, S.: Advanced high strength steels for automotive industry. Arch. Civ. Mech. Eng. 8(2), 103–117 (2008)

Galan, J.; Samek, L.; Verleysen, P.; Verbeken, K.; Houbert, Y.: Advanced high strength steels for automotive industry. Rev. Metal. 48(2), 118–131 (2012)

Tamarelli, C.M.: The evolving use of advanced high strength steels for automotive applications. Technical report (2011)

Schmitt, J.H.; Iung, T.: New developments of advanced high-strength steels for automotive applications. C. R. Phys. 19(8), 641–656 (2018)

Demeri, M.Y.: Advanced High-Strength Steels: Science, Technology, and Applications. ASM International (2013)

Grässel, O.; Kröger, L.; Frommeyer, G.; Meyer, L.W.: High strength Fe–Mn–Al–Si TRIP/TWIP steels development: properties & application. Int. J. Plast 16(10–11), 1391–1409 (2000)

Grajcar, A.; Kuziak, R.; Zalecki, W.: Third generation of AHSS with increased fraction of retained austenite for the automotive industry. Arch. Civ. Mech. Eng. 12(3), 334–341 (2012)

He, B.B.; Huang, M.X.; Liang, Z.Y.; Ngan, A.H.W.; Luo, H.W.; Shi, J.; Cao, W.Q.; Dong, H.: Nanoindentation investigation on the mechanical stability of individual austenite grain in a medium Mn transformation-induced plasticity steel. Scripta Mater. 69(3), 215–218 (2013)

Martin, S.; Wolf, S.; Martin, U.; Krüger, L.; Rafaja, D.: Deformation mechanisms in austenitic TRIP/TWIP steel as a function of temperature. Metall. Mater. Trans. A 47(1), 49–58 (2016)

Guimaräes, J.R.C.: Stress assisted martensite: pre-strain, grain-size and strain-rate effects. Mater. Sci. Eng. A 475(1–2), 343–347 (2008)

Girault, E.; Jacques, P.; Ratchev, P.; van Humbeeck, J.; Verlinden, B.; Aernoudt, E.: Study of the temperature dependence of the bainitic transformation rate in a multiphase TRIP-assisted steel. Mater. Sci. Eng. A 273–275, 471–474 (1999)

Cherkaoui, M.; Berveiller, M.: Lemoine: couplings between plasticity and martensitic phase transformation: overall behavior of polycrystalline TRIP steels. Int. J. Plast 16(10–11), 1215–1241 (2000)

Liu, Y.C.; Sommer, F.; Mittemeijer, E.J.: Austenite-ferrite transformation kinetics under uniaxial compressive stress in Fe 2.96% Ni alloy. Acta Mater. 57(9), 2858–2868 (2009)

Iwamoto, T.: Multiscale computational simulation of deformation behavior of TRIP steel with growth of martensitic particles in unit cell by asymptotic homogenization method. Int. J. Plast 20(4–5), 841–869 (2009)

Turteltaub, S.; Suiker, A.S.J.: A multiscale thermomechanical model for cubic to tetragonal martensitic phase transformations. Int. J. Solids Struct. 43(14–15), 4509–4545 (2009)

Hore, S.; Das, S.K.; Banerjee, S.; Mukherjee, S.: A multiscale coupled Monte Carlo model to characterize microstructure evolution during hot rolling of Mo-TRIP steel. Acta Mater. 61(19), 7251–7259 (2009)

Papatriantafillou, I.C.: TRIP steels: constitutive modeling and computational issues. Ph.D Thesis, Mechanical and Industrial Engineering Department, University of Thessaly, France (2005)

Tjahjanto, D.D.; Suiker, A.S.J.; Turteltaub, S.; Rivera, P.E.J.; van der Zwaag, S.: Micromechanical predictions of TRIP steel behavior as a function of microstructural parameters. Comput. Mater. Sci. 41(1), 107–116 (2007)

Khan, Rashid; Pervez, Tasneem; Qamar, Sayyad Zahid: Modeling and simulations of transformation and twinning induced plasticity in advanced high strength austenitic steels. Mech. Mater. 95, 83–101 (2016)

Khan, Rashid; Alfozan, Adel: Modeling of twinning-induced plasticity using crystal plasticity and thermodynamic framework. Acta Mech. 230(8), 2687–2715 (2019)

Roy, A.M.: Effects of interfacial stress in phase field approach for martensitic phase transformation in NiAl shape memory alloys. Appl. Phys. A 126, 1–12 (2020)

Rashid, K.; Fahad, I.Z.; Ali, K.S.: Numerical modeling of twinning induced plasticity in austenite based advanced high strength steels. Procedia Manuf. 5, 772–786 (2016)

Chattopadhyay, J.; Khushwaha, H.S.; Roos, E.: Some recent developments on integrity assessment of pipes and elbows. Part II: theoretical investigations. Int. J. Solids Struct. 43(10), 2904–2931 (2006)

Chattopadhyay, J.; Kushwaha, H.S.; Roos, E.: Some recent developments on integrity assessment of pipes and elbows. Part I: experimental investigations. Int. J. Solids Struct. 43(10), 2932–2958 (2006)

Pervez, T.: Experimental and numerical investigations of expandable tubular structural integrity for well applications. J. Ach. Mater. Manuf. Eng. 41, 147–154 (2010)

Agata, J.; Tsuru, E.; Sawamura, M.; Asahi, H.; Tsugihara, H.: An experimental and numerical approach to the prediction of collapse resistance for expandable tubulars. In: IADC/SPE Drilling Conference and Exhibition, New Orleans, Louisiana. SPE 128266 (2010)

Staat, M.: Local and global collapse pressure of longitudinally flawed pipes and cylindrical vessels. Int. J. Press. Vessels Pip. 82(3), 217–225 (2005)

Sakakibara, N.; Kyriakides, S.; Corona, E.: Collapse of partially corroded or worn pipe under external pressure. Int. J. Mech. Sci. 50(12), 1586–1597 (2008)

Wang, L.; Zhang, Y.: Plastic collapse analysis of thin-walled pipes based on unified yield criterion. Int. J. Mech. Sci. 53(5), 348–354 (2011)

Zhu, X.K.; Leis, B.N.: Evaluation of burst pressure prediction models for line pipes. Int. J. Press. Vessels Pip. 89, 85–97 (2012)

Klever, F.J.; Stewart, G.: Analytical burst strength prediction of octg with and without defects. In: SPE Applied Technology Workshop on Risk-Based Design of Well Casing and Tubing, Woodlands, Texas, USA. SPE 48329 (1998)

Gao, C.Y.; Zhang, L.C.: Constitutive modelling of plasticity of fcc metals under extremely high strain rates. Int. J. Plast 32–33, 121–133 (2012)

Becker, R.: Effects of crystal plasticity on materials loaded at high pressures and strain rates. Int. J. Plast 20(11), 1983–2006 (2004)

Lu, Y.H.: Study of tube flaring ratio and strain rate in the tube flaring process. Finite Elem. Anal. Des. 40, 305–318 (2004)

Khan, R.; Pervez, T.; Alrasheedi, N.H.; Al-Abri, O.; Sajid, A.: Effects of expansion rate on plasticity and structural integrity of downhole tubular. Int. J. Press. Vessels Pip. 151, 1–10 (2017)

Khan, R.; Pervez, T.; Qamar, S.Z.: Effects on plasticity and structural integrity of tube expansion. In: Pressure Vessels & Piping Conference, Toronto, Canada, July 2012, 55027, pp. 607–616 (2012). https://doi.org/10.1115/PVP2012-78654

Pervez, T.; Seibi, A.; Al-Hiddabi, S.A.; Karrech, A.: Simulation of solid tubular expansion in well drilling using finite element method. J. Pet. Sci. Technol. 23, 775–794 (2005)

Pervez, T.; Seibi, A.C.; Al-Hiddabi, S.A.; Al-Jahwari, F.; Qamar, S.Z.; Marketz, F.: Solid tubular expansion in horizontal wells. In: 15th SPE Middle East Oil & Gas Show and Conference, Bahrain. SPE 105704 (2007)

Pervez, T.; Qamar, S.Z.; Seibi, A.C.; Al-Jahwari, F.: Use of set in cased and open holes: comparison between aluminum and steel. Mater. Des. 29, 811–817 (2008)

Pervez, T.; Seibi, A.C.; Karrech, A.: Simulation of solid tubular expansion in well drilling using finite element method. J. Pet. Sci. Technol. 23, 775–794 (2005)

Seibi, A.C.; et al.: Structural behavior of solid tubular expansion under large plastic deformation. ASME J. Energy Resour. Technol. 127(4), 323–326 (2005)

Seibi, A.C.; Pervez, T.; Karrech, A.; Al-Hiddabi, S.: Coupled stress and pressure waves propagation in an elastic solid tube submerged in fluids. J. Energy Res. Technol. 128(4), 247–256 (2006). https://doi.org/10.1115/1.2358139

Pervez, T.; Qamar, S.Z.: Finite element analysis of tubular ovality in oil well. Adv. Mater. Res. 264–265, 1654–1659 (2011)

Pervez, T.; Qamar, S.Z.; Al-Hiddabi, S.A.; Al-Jahwari, F.K.; Marketz, F.; Al-Houqani, S.; Velden, M.V.D.: Tubular expansion in irregularly shaped boreholes: computer simulation and field measurement. Pet. Sci. Technol. 29(7), 735–744 (2011)

Li, T.: Solid expandable tubular patching technique for high-temperature and high-pressure casing damaged wells. Petrol. Explor. Dev. 42(3), 408–413 (2015)

Fu, J.; Tang, X.; Zhou, W.; Yang, L.: Dynamic analysis of solid expandable tubular and its applications in tahe oilfield. Arab. J. Sci. Eng. 40(8), 2437–2446 (2015)

Al-Abri, O.S.; Pervez, T.; Al-Hiddabi, S.A.; Qamar, S.Z.: Analytical model for stick-slip phenomenon in solid tubular expansion. J. Petrol. Sci. Eng. 125, 218–233 (2015)

Acknowledgements

The author acknowledges the support of Al Imam Mohammad Ibn Saud Islamic University and Sultan Qaboos University for this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, R. Design and Optimization of Multistage Tubular–Mandrel System for Down-Hole Expandable Tubular. Arab J Sci Eng 46, 2083–2095 (2021). https://doi.org/10.1007/s13369-020-05005-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05005-4