Abstract

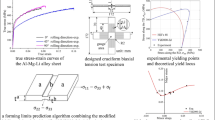

Al-Mg alloys have the properties of anisotropy, temperature softening and strain rate hardening in warm forming conditions. The former could be modeled by an advanced non-quadratic yield function. The rate-dependent characteristic could be modeled by viscoplastic constitutive models. Up to now, few investigations have combined a viscoplastic model with advanced yield functions for warm forming simulation, especially by an implicit finite element (FE) program. In this investigation, the warm forming simulation of AA5182-O alloy was presented via Abaqus/Standard, considering the viscoplasticity and anisotropy. The established viscoplastic model could well reflect the nearly rate-independent initial yield stress of the selected material, and its parameters could be easily calibrated. The numerical implementation of the viscoplastic model associated with Yld2000 and Yld2004 yield functions was carried out using an implicit integration algorithm, and the algorithmic tangent was deduced. Results accordance between the simulation and experiment, including warm uniaxial tension test and warm deep drawing test of AA5182-O, showed the rationality of the established material model and the corresponding implicit implementation scheme.

Similar content being viewed by others

References

Hirsch J (2014) Recent development in aluminium for automotive applications. T Nonferr Metal Soc 24(7):1995–2002. https://doi.org/10.1016/s1003-6326(14)63305-7

Mahabunphachai S, Koç M (2010) Investigations on forming of aluminum 5052 and 6061 sheet alloys at warm temperatures. Mater Des (1980-2015) 31(5):2422–2434. https://doi.org/10.1016/j.matdes.2009.11.053

Panicker SS, Singh HG, Panda SK, Dashwood R (2015) Characterization of tensile properties, limiting strains, and deep drawing behavior of AA5754-H22 sheet at elevated temperature. J Mater Eng Perform 24(11):4267–4282. https://doi.org/10.1007/s11665-015-1740-6

Simões V, Laurent H, Oliveira M, Menezes L (2018). The influence of warm forming in natural aging and springback of Al-Mg-Si alloys. Int J Mater Form doi:https://doi.org/10.1007/s12289-018-1406-7, 12, 1

Kabirian F, Khan AS, Pandey A (2014) Negative to positive strain rate sensitivity in 5xxx series aluminum alloys: experiment and constitutive modeling. Int J Plast 55:232–246. https://doi.org/10.1016/j.ijplas.2013.11.001

Laurent H, Coër J, Manach PY, Oliveira MC, Menezes LF (2015) Experimental and numerical studies on the warm deep drawing of an Al–mg alloy. Int J Mech Sci 93:59–72. https://doi.org/10.1016/j.ijmecsci.2015.01.009

Barlat F, Kim D-J (2016) Advanced constitutive modeling and application to industrial forming processes. MATEC Web of Conferences 80:15013. https://doi.org/10.1051/matecconf/20168015013

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi SH, Chu E (2003) Plane stress yield function for aluminum alloy sheets—part 1: theory. Int J Plast 19(9):1297–1319. https://doi.org/10.1016/s0749-6419(02)00019-0

Barlat F, Aretz H, Yoon JW, Karabin ME, Brem JC, Dick RE (2005) Linear transfomation-based anisotropic yield functions. Int J Plast 21(5):1009–1039. https://doi.org/10.1016/j.ijplas.2004.06.004

Cai Z, Wan M, Liu Z, Wu X, Ma B, Cheng C (2017) Thermal-mechanical behaviors of dual-phase steel sheet under warm-forming conditions. Int J Mech Sci 126:79–94. https://doi.org/10.1016/j.ijmecsci.2017.03.009

Tian H, Brownell B, Baral M, Korkolis YP (2016) Earing in cup-drawing of anisotropic Al-6022-T4 sheets. Int J Mater Form 10(3):329–343. https://doi.org/10.1007/s12289-016-1282-y

Charoensuk K, Panich S, Uthaisangsuk V (2017) Damage initiation and fracture loci for advanced high strength steel sheets taking into account anisotropic behaviour. J Mater Process Technol 248:218–235. https://doi.org/10.1016/j.jmatprotec.2017.05.035

Kuwabara T, Mori T, Asano M, Hakoyama T, Barlat F (2017) Material modeling of 6016-O and 6016-T4 aluminum alloy sheets and application to hole expansion forming simulation. Int J Plast 93:164–186. https://doi.org/10.1016/j.ijplas.2016.10.002

Yoon J, Barlat F, Dick R, Karabin M (2006) Prediction of six or eight ears in a drawn cup based on a new anisotropic yield function. Int J Plast 22(1):174–193. https://doi.org/10.1016/j.ijplas.2005.03.013

Lee J-Y, Lee K-J, Lee M-G, Kuwabara T, Barlat F (2019) Numerical modeling for accurate prediction of strain localization in hole expansion of a steel sheet. Int J Solids Struct 156-157:107–118. https://doi.org/10.1016/j.ijsolstr.2018.08.005

Abedrabbo N, Pourboghrat F, Carsley J (2006) Forming of aluminum alloys at elevated temperatures – part 1: material characterization. Int J Plast 22(2):314–341. https://doi.org/10.1016/j.ijplas.2005.03.005

Abedrabbo N, Pourboghrat F, Carsley J (2007) Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models. Int J Plast 23(5):841–875. https://doi.org/10.1016/j.ijplas.2006.10.005

Suttner S, Merklein M (2016) Experimental and numerical investigation of a strain rate controlled hydraulic bulge test of sheet metal. J Mater Process Technol 235:121–133. https://doi.org/10.1016/j.jmatprotec.2016.04.022

Cowper GR, Symonds PS (1957). Strain hardening and strain rate effect in the impact loading of cantilever beams

Liu Y, Zhu Z, Wang Z, Zhu B, Wang Y, Zhang Y (2018) Flow and friction behaviors of 6061 aluminum alloy at elevated temperatures and hot stamping of a B-pillar. Int J Adv Manuf Technol 96(9–12):4063–4083. https://doi.org/10.1007/s00170-018-1790-7

Panicker SS, Kumar Panda S (2016) Improvement in material flow during nonisothermal warm deep drawing of nonheat treatable aluminum alloy sheets. J Manuf Sci E 139(3):031013. https://doi.org/10.1115/1.4034594

Zhang N (2016). Material characterization and finite element simulations of aluminum alloy sheets during non-isothermal forming process. Dissertations

Lee MG, Kim C, Pavlina EJ, Barlat F (2011) Advances in sheet forming—materials modeling, numerical simulation, and press technologies. J Manuf Sci E 133(6):061001. https://doi.org/10.1115/1.4005117

Liu W, Chen BK, Pang Y (2018). A new temperature-dependent anisotropic constitutive model for predicting deformation and spring-back in warm deep drawing of automotive AA5086-H111 aluminium alloy sheet. Int J Adv Manuf Technol doi:https://doi.org/10.1007/s00170-018-2161-0, 97, 9-12

Neto DM, Martins JMP, Cunha PM, Alves JL, Oliveira MC, Laurent H, Menezes LF (2017). Thermo-mechanical finite element analysis of the AA5086 alloy under warm forming conditions. Int J Solids Struct doi:https://doi.org/10.1016/j.ijsolstr.2017.06.011, 151

Kurukuri S, Miroux A, Ghosh M, van den Boogaard AH (2009) Effect of temperature on anisotropy in forming simulation of aluminum alloys. Int J Mater Form 2(S1):387–390. https://doi.org/10.1007/s12289-009-0462-4

Vegter H, van den Boogaard AH (2006) A plane stress yield function for anisotropic sheet material by interpolation of biaxial stress states. Int J Plast 22(3):557–580. https://doi.org/10.1016/j.ijplas.2005.04.009

Marthinsen K, Nes E (2001) Modelling strain hardening and steady state deformation of Al–mg alloys. Mater Sci Technol 17(4):376–388. https://doi.org/10.1179/026708301101510096

Ghavam K, Bagheriasl R, Worswick MJ (2013) Analysis of nonisothermal deep drawing of aluminum alloy sheet with induced anisotropy and rate sensitivity at elevated temperatures. J Manuf Sci E 136(1):011006. https://doi.org/10.1115/1.4025407

Bagheriasl R, Ghavam K, Worswick MJ (2014) Formability improvement with independent die and punch temperature control. Int J Mater Form 7(2):139–154. https://doi.org/10.1007/s12289-012-1115-6

van den Boogaard T, Havinga J, Belin A, Barlat F (2016) Parameter reduction for the Yld2004-18p yield criterion. Int J Mater Form 9(2):175–178. https://doi.org/10.1007/s12289-015-1221-3

Dunne F, Petrinic N (2005). Introduction to computational plasticity. Oxford University Press,

Safaei M, Yoon JW, De Waele W (2014) Study on the definition of equivalent plastic strain under non-associated flow rule for finite element formulation. Int J Plast 58:219–238. https://doi.org/10.1016/j.ijplas.2013.09.010

Scherzinger WM (2017) A return mapping algorithm for isotropic and anisotropic plasticity models using a line search method. Comput Method Appl M 317:526–553. https://doi.org/10.1016/j.cma.2016.11.026

Neto ES, Peric D, Owen D (2008) Computational methods for plasticity: theory and applications. Wiley, Chichester

Coër J, Bernard C, Laurent H, Andrade-Campos A, Thuillier S (2010) The effect of temperature on anisotropy properties of an aluminium alloy. Exp Mech 51(7):1185–1195. https://doi.org/10.1007/s11340-010-9415-6

Kim HS, Koc M (2008) Numerical investigations on springback characteristics of aluminum sheet metal alloys in warm forming conditions. J Mater Process Technol 204(1):370–383. https://doi.org/10.1016/j.jmatprotec.2007.11.059

Billur E (2013). Fundamentals and applications of hot stamping technology for producing crash-relevant automotive parts. The Ohio State University,

Funding

This study was funded by Science and Technology Research Project of Jiangxi Provincial Department of Education (grant number GJJ170631).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Q., Zhang, Y., Sun, Y. et al. Warm forming simulations of Al-Mg alloy sheet using a viscoplastic model and advanced yield functions. Int J Mater Form 14, 449–465 (2021). https://doi.org/10.1007/s12289-020-01587-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-020-01587-4