Abstract

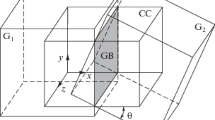

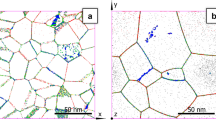

The impurity effect of light elements (carbon, nitrogen, and oxygen) on nickel crystallization in the triple junction region of grain boundaries is studied by the molecular dynamics method. The tilt grain boundaries with disorientation axis 〈111〉 are considered as grain boundaries. The computational cell is a cylinder, the axis of which coincided with the triple junction and the disorientation axis of grains. Periodic boundary conditions are imposed along the cylinder axis; the atoms on the lateral surface of the cylinder are stationary. To simulate crystallization, the computational cell was melted by heating to a temperature significantly higher than the melting point of nickel. After the simulated polycrystal became liquid, the thermostat was turned on and the polycrystal was kept at a constant temperature less than melting point. In this case, the rigid boundary conditions on the lateral surface of a cylindrical computational cell simulated the crystallization fronts from three crystallization centers. The area near the triple junction crystallized in the last turn. Defects and free volume are concentrated in this area. The impurities significantly slowed down the crystallization rate. The addition of 10% impurity atoms slowed down the rate of the crystallization front by several times. The impurity effect on the crystallization rate increased in the direction C–N–O. This is due to the difference in the deformation of the crystal lattice caused by impurity atoms: the greater this deformation, the more impurity atoms slow down the crystallization front. Impurity carbon atoms formed aggregates of crystal grains at rather high concentrations. Crystallization front remained on these aggregates. Oxygen atoms and nitrogen atoms did not form aggregates; nevertheless, they distorted the crystal lattice and significantly slowed down the crystallization front.

Similar content being viewed by others

REFERENCES

Palumbo, G. and Aust, K.T., A coincident axial direction (CAD) approach to the structure of triple junctions in polycrystalline materials, Scr. Metall. Mater., 1990, vol. 24, no. 9, pp. 1771–1776.

Bokstein, B., Ivanov, V., Oreshina, O., Peteline, A., and Peteline, S., Direct experimental observation of accelerated Zn diffusion along triple junctions in Al, Mater. Sci. Eng., A, 2001, vol. 302, no. 1, pp. 151–153.

Bokstein, B.S., Rodin, A.O., and Straumal, B.B., Diffusion controlled grain triple junctions wetting in metals, Defect Diffus. Forum, 2011, vols. 309–310, pp. 231–238.

Wegner, M., Leuthold, J., Peterlechner, M., Song, X., Divinski, S.V., and Wilde, G., Grain boundary and triple junction diffusion in nanocrystalline copper, J. Appl. Phys., 2014, vol. 116, pp. 093514-1–093514-7.

Beke, D.L., Lakatos, A., Erdélyi, G., Makovecz, A., Langer, G.A., Daróczi, L., Vad, K., and Csik, A., Investigation of grain boundary diffusion in thin films by SNMS technique, Defect Diffus. Forum, 2011, vols. 312–315, pp. 1208–1215.

Fedorov, A.A., Gutkin, M.Yu., and Ovid’ko, I.A., Triple junction diffusion and plastic flow in fine-grained materials, Scr. Mater., 2002, vol. 47, pp. 51–55.

Gusev, A.I., Effects of the nanocrystalline state in solids, Phys.-Usp., 1998, vol. 41, no. 1, pp. 49–76.

Li, M. and Xu, T., Topological and atomic scale characterization of grain boundary networks in polycrystalline and nanocrystalline materials, Prog. Mater. Sci., 2011, vol. 56, no. 6, pp. 864–899.

Gutkin, M.Yu. and Ovid’ko, I.A., Yield strength and plastic deformation of nanocrystalline materials, Usp. Mekh., 2003, no. 1, pp. 68–125.

Rodriguez, P., Sundararaman, D., Divakar, R., and Raghunathan, V.S., Structure of grain boundaries in nanocrystalline and quasicrystalline materials, Chem. Sustainable Dev., 2000, vol. 8, pp. 69–72.

Schaefer, H.-E., Wurschum, R., Birringer, R., and Gleiter, H., Structure of nanometer-sized polycrystalline iron investigated by positron lifetime spectroscopy, Phys. Rev. B, 1988, vol. 38, nos. 14–15, art. ID 9545.

Muktepavela, F., Bakradze, G., and Sursaeva, V., Micromechanical properties of grain boundaries and triple junctions in polycrystalline metal exhibiting grain-boundary sliding at 293 K, J. Mater. Sci., 2008, vol. 43, pp. 3848–3854.

Poletaev, G.M., Novoselova, D.V., Zorya, I.V., and Starostenkov, M.D., Formation of the excess free volume in triple junctions during nickel crystallization, Phys. Solid State, 2018, vol. 60, no. 5, pp. 847–851.

Psakhie, S.G., Zolnikov, K.P., Kryzhevich, D.S., and Korchuganov, A.V., Key role of excess atomic volume in structural rearrangements at the front of moving partial dislocations in copper nanocrystals, Sci. Rep., 2019, vol. 9, pp. 3867-1–3867-6.

Poletaev, G., Zorya, I., and Rakitin, R., Molecular dynamics study of migration mechanism of triple junctions of tilt boundaries in FCC metals, Comput. Mater. Sci., 2018, vol. 148, pp. 184–189.

Kozlov, E.V., Koneva, N.A., and Popova, N.A., Grain structure, geometrically necessary dislocations and second-phase particles in polycrystals of micro- and mesolevels, Phys. Mesomech., 2009, vol. 12, nos. 5–6, pp. 280–292.

Goldschmidt, H.J., Interstitial Alloys, London: Butterworth-Heinemann, 1967.

Toth, L.E., Transition Metal Carbides and Nitrides, New York: Academic, 1971.

Cleri, F. and Rosato, V. Tight-binding potentials for transition metals and alloys, Phys. Rev. B, 1993, vol. 48, no. 1, pp. 22–33.

Poletaev, G.M., Zorya, I.V., Rakitin, R.Y., and Iliina, M.A., Interatomic potentials for describing impurity atoms of light elements in FCC metals, Mater. Phys. Mech., 2019, vol. 42, no. 4, pp. 380–388.

Poletaev, G.M., Zorya, I.V., Novoselova, D.V., and Starostenkov, M.D., Molecular dynamics simulation of hydrogen atom diffusion in crystal lattice of fcc metals, Int. J. Mater. Res., 2017, vol. 108, no. 10, pp. 785–790.

Poletaev, G.M., Zorya, I.V., Starostenkov, M.D., Rakitin, R.Yu., and Tabakov, P.Ya., Molecular dynamics simulation of the migration of tilt grain boundaries in Ni and Ni3Al, J. Exp. Theor. Phys., 2019, vol. 128, no. 1, pp. 88–93.

Ruda, M., Farkas, D., and Garcia, G., Atomistic simulations in the Fe–C system, Comput. Mater. Sci., 2009, vol. 45, no. 2, pp. 550–560.

Vashishta, P., Kalia, R.K., Nakano, A., and Rino, J.P., Interaction potentials for alumina and molecular dynamics simulations of amorphous and liquid alumina, J. Appl. Phys., 2008, vol. 103, no. 8, art. ID 083504.

San Miguel, M.A. and Sanz, J.F. Molecular-dynamics simulations of liquid aluminum oxide, Phys. Rev. B, 1998, vol. 58, pp. 2369–2371.

Chan, W.-L., Averback, R.S., Cahill, D.G., and Ashkenazy, Y., Solidification velocities in deeply undercooled silver, Phys. Rev. Lett., 2009, vol. 102, no. 9, art. ID 095701.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. Obrezanova

About this article

Cite this article

Zorya, I.V., Poletaev, G.M., Starostenkov, M.D. et al. Impurity Effect of Light Elements on the Nickel Crystallization in the Triple Junction Region of Grain Boundaries: Molecular Dynamics Simulation. Steel Transl. 50, 303–308 (2020). https://doi.org/10.3103/S0967091220050137

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220050137