Abstract

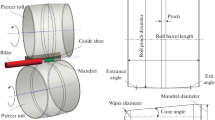

Requirements for the process of pipe production operations, which reduce the formation of hard-to-remove scale on internal surface, have been developed. According to the study results of chemical reaction features of deoxidizing materials with scale on the internal shell surface, these requirements are based on the flow process analysis of the production of seamless hot-rolled pipes in the lines of contemporary pipe-rolling plants with mandrel mills and in heat treatment areas. A series of experimental pipe rolling has been carried out on the plants of PAO TMK using the INCOAT technology and equipment of SMS group Company (Germany). The results of the work have confirmed the inhibition effectiveness of active scale formation on the internal shell surface through combination of piercing and treatment of the internal shell surface with deoxidizing material.

Similar content being viewed by others

Notes

Under active participation of the Researcher of the Laboratory of development and testing of rolling equipment, process lubrication, and coatings of OAO RosNITI E.Yu. Pashkina.

REFERENCES

Aleshchenko, A.S., Gamin, Yu.V., Chan, B.Kh., and Tsyutsyura, V.Yu., Wear of the working tool during piercing of heat-resistant alloys, Chern. Met., 2018, no. 8, pp. 63–70.

Romantsev, B.A., Goncharuk, A.V., Aleshchenko, A.S., et al., Development of multipass skrew rolling technology for stainless steel and alloy pipes’ production, Int. J. Adv. Manuf. Technol., 2018, vol. 97, nos. 9–12, pp. 3223–3230.

Glazunova, N.A., Rozhkova, O.V., and Kovaleva, I.A., Classification of guide scratch defects on the inner surface of hot-rolled pipes, Lit’e Metall., 2014, no. 1, pp. 28–32.

Severdenko, V.P., Makushok, E.M., and Ravin, A.N., Okalina pri goryachei obrabotke metallov davleniem (Furnace Clinker in Hot Metal Forming by Pressure), Moscow: Metallurgiya, 1977.

Kovaleva, I.A., Kuchkov, A.A., Vengura, A.V., et al., Analysis of the effect of furnace clinker formation on the surface condition of billets to improve the quality of hot-rolled seamless pipes, Lit’e Metall., 2014, no. 3, pp. 53–57.

Toporov, V.A., Panasenko, O.A., and P’yankova, A.A., The mechanism of formation of non-removable furnace clinker on the inner surface of pipes made of steel grade 13KhFA, Materialy XXII Mezhdunarodnoi nauchno-prakticheskoi konferentsii “Innovatsii i importozameshchenie v trubnoi promyshlennosti” (Proc. XXII Int. Sci.-Pract. Conf. “Innovations and Import Substitution in Pipe Industry”), Pyshmintsev, I.Yu., Ed., Chelyabinsk: Ross. Nauchno-Issled. Inst. Trubn. Prom., 2016, pp. 19-22.

Garber, E.A. and Gatiyatullin, D.Z., The reasons of formation of “residual furnace clinker” on the surface of hot-rolling steel wide strips and its elimination, Mekh. Oborud. Metall. Zavodov, 2017, no. 2, pp. 18–21.

Kirillov, Yu.Z., Comprehensive study of furnace clinker formation on carbon and low-alloy steels and optimization of heating during hot plastic deformation, Extended Abstract of Cand. Sci. (Eng.) Dissertation, St. Petersburg: KopiServis, 1998.

Temlyantsev, M.V., Konoz, K.S., Kuznetsova, O.V., et al., Investigation of furnace clinker formation of 40C2 steel at high-temperature heating, Materialy II Mezhdunarodnoi nauchno-prakticheskoi konferentsii “Sovremennye nauchnye dostizheniya metallurgicheskoi teplotekhniki i ikh realizatsiya v promyshlennosti” (Proc. II Int. Sci.-Pract. Conf. “Modern Scientific Achievements in Metallurgical Thermal Engineering and Their Implementation in Industry”), Yekaterinburg: Ural. Fed. Univ., 2018, pp. 166–171.

Timofeeva, A.S., Nikitenko, T.V., and Urazova, L.F., Influence of the composition of the gas medium in the furnace on the oxidation of steel, Stal’, 2015, no. 11, pp. 69–70.

Gol’dshtein, M.I., Grachev, S.V., and Veksler, Yu.G., Spetsial’nye stali (Specific Steels), Moscow: Metallurgiya, 1985.

SMS group official website. https://www.smsgroup.com. Accessed April 27, 2020.

Wagner, T., Topiith, M., Lacapruccia, F., and Sauerland, M., Innovative solutions for improvements in seamless tube production, Proc. AISTech-Iron and Steel Technology Conf., Indianapolis, 2014, vol. 3, pp. 2767–2774.

Leferink, M. and Peters, K., Innovative and effective solutions for production of high-quality pipes, Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii “Trubnaya promyshlennost’ Rossii. Vektor innovatsii” (Proc. Int. Sci.-Pract. Conf. “Pipe Industry of Russia. Trends of Innovations”), Pyshmintsev, I.Yu., Ed., Chelyabinsk: Ross. Nauchno-Issled. Inst. Trubn. Prom., 2014, pp. 31–36.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Muravev

About this article

Cite this article

Emel’yanov, A.V., Lube, I.I., Kuznetsov, V.I. et al. Scale Formation Minimization on Internal Surface of Seamless Hot-Rolled Pipes. Steel Transl. 50, 340–346 (2020). https://doi.org/10.3103/S0967091220050046

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220050046