Abstract

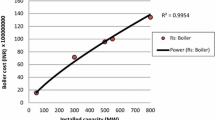

There are plans to do away with firing coal at the Kashira State District Power Plant (SDPP). In 2018, its coal-fired power units nos. 1 and 2 were decommissioned. Power unit no. 3, whose boiler can operate both on coal and natural gas, is being shifted to operate fully on natural gas, and fuel oil is supposed to be used as backup fuel. According to the design, the P-50R boiler, which is part of this power unit, can use fuel oil only as startup fuel during operation at loads up to 30%. In the article, the possibility of boiler operation on fuel oil in the entire working range of loads is substantiated. The boiler’s adaptive model has been developed using the Boiler Designer software and the experimental data obtained in the course of experiments on firing fuel oil. The results from numerical investigations have shown the possibility to use fuel oil as backup fuel in the P-50R boiler without modernizing its heating surfaces and draft equipment. It has been determined that it becomes possible to obtain a noticeably lower temperature of medium downstream of the middle radiant part, divided waterwalls, and further along the high-pressure path by admission of recirculation gases in an amount of around 180 000 m3/h (approximately 15% in the nominal mode). An analysis of the temperature operation conditions of radiant heating surfaces in firing fuel oil with such flowrate of recirculation gases has shown that reliable operation of all boiler heating surfaces is secured taking into account the scale formation condition and sufficient mechanical strength safety margin in the load range 100–60%. It has been determined that an essentially larger flowrate of medium goes through the steam-to-steam heat exchanger (SSHE) bypass in the entire design range of loads during operation with recirculation of gases. Therefore, the reheat steam temperature at a level of 545°C can be achieved even at decreased loads. The use of gas recirculation as a technological method for suppressing the generation of nitrogen oxides in the P-50R boiler makes it possible to keep the NOх concentrations in the fuel oil combustion products in compliance with the relevant regulations (less than 250 mg/m3). It has been determined from the calculation results that admission of recirculation gases in an amount of 180 000 m3/h does not have a significant influence on the economic indicators of boiler operation.

Similar content being viewed by others

REFERENCES

A. M. Zykov, S. N. Anichkov, O. N. Bragina, A. M. Tikhomirov, O. N. Kulish, S. A. Kuzhvatov, I. Sh. Gleizer, and S. F. Torkhunov, “Experience of implementation of a selective non-catalytic reduction unit at a 300 MW power unit of Kashira GRES,” Elektr. Stn., No. 6, 27–31 (2012).

Report on the Functioning of the Unified Power System of Russia in2018. http://www.so-ups.ru

S. F. Torkhunov, A. L. Shvarts, G. D. Avrutskii, E. Kh. Verbovetskii, A. K. Boksha, V. A. Vereshchetin, A. A. Somov, and A. A. Chugreev, “Mastering and operation of unit 3 of Kashira GRES,” Elektr. Stn., No. 6, 13–22 (2012).

D. L. Itman, A. L. Shvarts, A. D. Gorbanenko, and Yu. P. Enyakin, “The reliability issues of high-power pulverized coal boilers of supercritical pressure after conversion to firing fuel oil,” Teploenergetika, No. 12, 12–15 (1972).

A. N. Tugov, V. M. Supranov, M. A. Izyumov, V. A. Vereshchetin, Yu. M. Usman, and A. S. Natal’in, “Assessment of the potential for conversion of TP-108 boilers to firing natural gas and fuel oil,” Therm. Eng. 64, 216–223 (2017). https://doi.org/10.1134/S0040601517030090

A. N. Tugov, V. M. Supranov, M. A. Izyumov, V. A. Vereshchetin, Yu. M. Usman, and A. S. Natal’in, “Experience of implementation of in-furnace methods of decreasing NOx in E-320-13.8-560GM boilers: Problems and ways for their solution,” Therm. Eng. 64, 884–890 (2017). https://doi.org/10.1134/S0040601517120096

G. I. Doverman, B. L. Shelygin, A. V. Moshkarin, and Yu. V. Mel’nikov, Calculation of Boiler Units Using Modern Software Products (Ivanov. Gos. Energ. Univ., Ivanovo, 2007) [in Russian].

Thermal Calculation of Boiler Units (Normative Method), Ed. by N. V. Kuznetsov (Energiya, Moscow, 1973) [in Russian].

SO 153-34.20.501-2003. Rules Governing Technical Operation of Electric Power Plants and Grids of the Russian Federation (Energoservis, Moscow, 2003) [in Russian].

O. M. Baldina, V. A. Lokshin, D. F. Peterson, I. E. Semenovker, and A. L. Shvarts, Hydraulic Calculation of Boiler Units. Normative Method, Ed. by V. A. Lokshin, D. F. Peterson, and A. L. Shvarts (Energiya, Moscow, 1978) [in Russian].

GOST R 50831-95. Boiler Plants. Heat-Mechanical Equipment. General Technical Requirements (Gosstand. Ross., Moscow, 1997) [in Russian].

SO 153-34.02.304-2003. Guidelines for the Calculation of Nitrogen Oxides Emission with Flue Gases from Boilers of Thermal Power Plants (Vseross. Teplotekh. Inst., Moscow, 2005) [in Russian].

P. V. Roslyakov, Methods of Environmental Protection: Textbook (Mosk. Energ. Inst., Moscow, 2007) [in Russian].

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Tugov, A.N., Supranov, V.M., Izyumov, M.A. et al. Substantiating the Possibility of Firing Fuel Oil as Backup Fuel in the P-50R Coal-Fired Boiler at the Kashira State District Power Plan. Therm. Eng. 67, 805–812 (2020). https://doi.org/10.1134/S0040601520110105

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520110105