Abstract

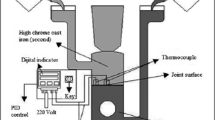

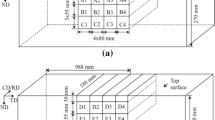

The shallow cryogenic (subzero) treatment (SCT) effect on the mechanical properties of the bimetallic casting used in the crushing industry has been investigated. Examination methods include sand casting, heat treatment and SCT, Charpy impact test, optical microscope, scanning electron microscope, microanalysis of the chemical composition (energy dispersive spectroscopy—EDS), x-ray diffraction, and hardness measurement. Two bimetallic castings (single casting containing two layers, one of low-carbon cast steel-LCCS-back up part and other high Cr cast iron-HCCI-working part) have been prepared by the sand casting method. They have been subjected to diffusion annealing at 1040 °C for 5 h. One of them was quenched in pressurized air till 100 °C and was tempered at 270 °C for 3 h and, and the other one has been subjected to SCT at − 84 °C for 24 h and then tempered at 270 °C for 3 h. The impact toughness values before and after SCT are determined five Charpy specimens per point. Hardness values and metallography of samples have been analyzed and compared. A remarkable change was observed in hardness and impact energy/toughness before and after SCT.

Similar content being viewed by others

Notes

Because of the being a trade secret of casting company, not so many details could be given about the activator.

References

T. Wróbel, Characterization of bimetallic castings with an austenitic working surface layer and an unalloyed cast steel base. J. Mater. Eng. Perform. 23, 1711–1717 (2014)

S. Zic, I. Dzambas, M. Ikonic, Possibilities of implementing bimetallic hammer castings in crushing industries. Metalurgija 48(1), 51–54 (2009)

X. Xiaofeng, Y. Shengping, Z. Xiaoguang, X. Qiong, High Cr white cast iron/carbon steel bimetal liner by lost foam casting with liquid–liquid composite process. China Foundry 9(2), 136–142 (2012)

X. Xiao-Feng, Y. Sheng-Ping, Y. Wei-Xin, X. Qiong, HCWCI/Carbon steel bimetal liner by liquid-liquid compound lost foam casting. J. Iron. Steel Res. Int. 19, 13–19 (2012)

E. Marukovich, A. Branovitsky, Y. Na, J. Lee, K. Choi, Study on the possibility of continuous-casting of bimetallic components in condition of direct connection of metals in a liquid state. Mater. Des. 27(10), 1016–1026 (2006)

T. Heijkoop, I. Sare, Cast-bonding—a new process for manufacturing composite wear products. Cast Metals 2(3), 160–168 (1989)

T. Wrobel, Ni and Cr base layers in bimetallic castings. In: METAL 2011: 20th Anniversary International Conference on Metallurgy and Materials, May 18–20, (Brno, Czech Republic), Tanger, 2011, pp. 758–764. (2011)

B. Xiong, C. Cai, B. Lu, Effect of volume ratio of liquid to solid on the interfacial microstructure and mechanical properties of high chromium cast iron and medium carbon steel bimetal. J. Alloy. Compd. 509(23), 6700–6704 (2011)

ASM Handbook Volume 4, Heat Treating ASM Handbook, Volume 4A, Steel Heat Treating Fundamentals and Processes. ASM International. pp. 382–386. ISBN 978-1-62708-011-8. (2013)

K. Kamei, A.G. William, L.S. Koveile, N. Ahmad, A. Chakravorty, R. Davis, An experimental study of the effect of thermal treatments & charpy ımpact test parameters on ımpact toughness of EN31 steel. J. Mech. Civil Eng. 11(3), 17–22 (2014)

I. Reddy, Y.S. Rao, A.S.P. Seshank, V. Inturi, Characterization and performance evaluation of HSS cutting tools under deep cryogenic treatment. Int. J. Eng. Sci. 5(10), 13–19 (2015)

E. Demir, İ. Toktaş, The effects of deep cryogenic treatment ın various holding times on surface roughness of AISI D2 Steel. In: 2nd Int.Symposium On Innovative Tech.In Eng.Sci., pp. 2038–2049, (2014)

Z. Zurecki, Cryogenic quenching of steel revisited. Air Products and Chemicals, Inc., Pub. No. 330-05-019-GLB, (2005)

K. Prudhvi, V.V. Lakshmi, Cryogenic tool treatment. Imperial J. Interdisciplin. Res. 2(9), 1204–1211 (2016)

T. Yugandhar, P. K. Krishnan, C. V. B. Rao and R. Kalidas, Cryogenic treatment and ıt’s effect on tool steel. In: 6th International Tooling Conference, Vol 2, pp. 672–683, (2002)

T. Kıvak, U. Eker, Effect of cryogenic treatment applied to M42 HSS drills on the machinability of Ti-6Al-4 V alloy. Mater. Tehnol. Mater. Technol. 49(6), 949–956 (2015)

D. L. Smith (2009) The effect of cryogenic treatment on the fatigue life of chrome silicon steel compression springs. Ph.D.Dissertation, Marquette University, USA, (2009)

K. Amini, M. Negahbani, H. Ghayour, The effect of deep cryogenic treatment on hardness and wear behavior of the h13 tool steel. La Metallurgia Italiana, Vol. 3, pp. 53–58, (2015)

V. Matteo, P. Karen, S. Marcel, Sub-zero austenite to martensite transformation in a Fe-Ni-0.6 wt% C alloy. In: IFHTSE 19th Congress, (2011)

N. Poulose, M.P. Kumar, Performance parameter of cryogenically treated and detonation coated HSS. Int. J. Eng. Trends Technol. 17(8), 395–405 (2014)

H. Singh, E.B.S. Ubhi, E.H. Lal, Improvement ın the corrosion rate and mechanical properties of low carbon steel through deep cryogenic treatment. Int. J. Sci. Technol. Res. 2(6), 20–24 (2013)

S. Jagtar, S.L. Pal, K. Ankur, Enhancing wear resistance of en45 spring steel using cryogenic treatment. Frict. Wear Res. 1(2), 22–27 (2013)

H.B. Patil, P.B. Chavan, S.H. Kazı, Effects of cryogenic on tool steels-a review. Int. J. Mech. Prod. Eng. 1(1), 31–36 (2013)

S. Akincioğlu, H. Gökkaya, İ. Uygur, A review of cryogenic treatment on cutting tools. Int. J. Adv. Manuf. Technol. 78, 1609–1627 (2015)

Y. Chang, G. Wang, J.H. Horng, L.M. Chu, Y.C. Hwang, Effects of deep cryogenic treatment on wear mechanisms and microthermal expansion for the material of drive elements. Hindawi Publ. Corp. Adv. Mater. Sci. Eng. (2013). https://doi.org/10.1155/2013/945657

J. Sobotova, M. Ku-Gik, S. Krum, J. Lacza, Effect of sub-zero treatment on the wear resistance of P/M tool steels. J. Appl. Mech. Eng. (2016). https://doi.org/10.4172/2168-9873.1000243

X.H. Lu, W. Li, C.L. Wang, H.S. Zhou, X.J. Jin, Effects of sub-zero celsius treatment and tempering on the stability of retained austenite in bearing steel. Acta Metall. Sin. (Engl. Lett.) (2015). https://doi.org/10.1007/s40195-015-0264-228(6)

Z. Özdemir, Effect of heat treatment on the ımpact toughness of ‘high-chromıum cast ıron—low-carbon cast steel’ bi-metal components. Metal Sci. Heat Treat. 58, 738–741 (2017)

H. Li, L. Zhang, B. Zhang, Q. Zhang, Effect of heat treatment on the microstructure and corrosion resistance of stainless/carbon steel bi-metal plate. Hindawi Adv. Mater. Sci. Eng. (2020). https://doi.org/10.1155/2020/1280761

M.A. Guitar, U.P. Nayak, D. Britz et al. The effect of thermal processing and chemical composition on secondary carbide precipitation and hardness in high-chromium cast irons. Int. J. Metalcast. 14, 755–765 (2020). https://doi.org/10.1007/s40962-020-00407-4

S. Inthidech, Y. Matsubara, Effects of carbon balance and heat treatment on hardness and volume fraction of retained austenite of semi-multi-alloyed white cast ıron. Int. J. Metalcast. 14, 132–143 (2020). https://doi.org/10.1007/s40962-019-00343-y

S. Inthidech, P. Sricharoenchai, Y. Matsubara, Effect of sub-critical heat treat parameters on hardness and retained austenite in mo-containing high chromium cast ırons. Int. J. Metalcast 6, 25–34 (2012). https://doi.org/10.1007/BF03355536

D. Li, C. Sloss, Heat treatment of heat-resistant ferrous cast alloys. Int. J. Metalcast. 9, 7–20 (2015)

R. V. Kahn, P. Haasen, Physical Metallurgy, 4th Edition, North Holland, (1996)

B. Decaudin, C. Djega-Mariadassou, and G. Cizeron, Structural study of M50 steel carbides. Laboratoire de Structure des Matdriaux M ~ talliques, UPS XI, Centre d’Orsay, 91405 Orsay Cgdex, France, (1995)

ASTM E23-02, Standart test methods for notched bar ımpact testing of metallic materials (1982)

ASTM E18-02, Standard test methods for rockwell hardness and rockwell superficial hardness of metallic materials (2004)

ASTM E92-82, Standard test method for Vicker hardness of metallic materials (2004)

H.T. George, Steel Heat Treatment Metallurgy and Technologies, 2nd edn. (Portland State University, Portland, 2006), pp. 148–150

A. Studnicki, J. Kilarski, M. Przybyl, J. Suchon, D. Bartocha, Wear Resistance of Chromium Cast Iron—Research and Application. J. Achiev. Mater. Manuf. Eng. 16(1), 63–73 (2006)

W. Callister, Material Science and Engineering, 2nd edn. (University Of Utah, Utah, 2006), pp. 195–196

http://www.praxis-rus.com/description-of-bimetallic-wear-resistant-products/#:~:text=As%20for %20the%20functional%20characteristics,material%20for%20rotor%20fixture%20areas

Acknowledgements

I am very grateful to the Ti-Hi Textile Co. (Babaeski/Turkey) esp. Chief Eng. Emre ÖZKAN for helping and guiding us at conducting HT and SCT and make time for measuring hardness values, Cemre Casting Diyarbakır/Turkey for helping and guiding us at manufacturing test samples and conducting heat treatments esp. Chief Eng. İsmail AVCU, Duduoğlu Casting Çorum/Turkey for conducting OMs, Hitit University Eğitim Araştırma Hitit University Science and Technology Research Center (Çorum/Turkey) for helping and guiding us at conducting SEM and EDS analysis and Trakya University Technological Research Center (Edirne/Turkey) for helping and guiding us at conducting X-Ray and charpy impact tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Özdemir, Z. Shallow Cryogenic Treatment (SCT) Effects on the Mechanical Properties of High Cr Cast Iron: Low-Carbon Cast Steel Bimetallic Casting. Inter Metalcast 15, 952–961 (2021). https://doi.org/10.1007/s40962-020-00532-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00532-0