Abstract

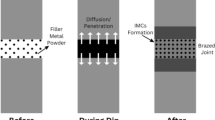

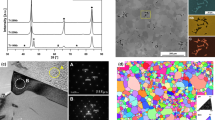

Ti-16.5Zr-13.5Cu-8.5Ni (wt.%) as a filler and brazing process as 950 °C/60 min were supplied in this study for brazing cast TiAl alloys with fully lamella structure. The interface microstructure and element diffusion were analyzed and measured by SEM, EBSD, and EPAM. And the mechanical properties of joints were evaluated. The sound joints were achieved with strength as 575 MPa at room temperature and remained as 410 MPa and 385 MPa in average at 700 °C and 760 °C, respectively. It was attributed to lots of fine grains with soft orientation as BCC [120] in the joint to the tensile direction. It was found that the fracture happened in the local zones with very large grains and the extreme misorientation between grains in the joint. Even though most grains as Ti3Al phase were found in the joint, there was no sign indicating the formed IMC related to the fracture.

Similar content being viewed by others

Data availability

The data that supports the findings of this study are available within the article and the reference.

References

Tetsui T (1999) Gamma Ti aluminides for non-aerospace applications. Curr Opin Solid State Mater Sci 4:243–248

Noda T (1998) Application of cast gamma TiAl for automobiles. Intermetallics. 6:709–713

Xiaoqiang L, Li L, Hu K, Shengguan Q (2015) Vacuum brazing of TiAl-based intermetallics with TiZrCuNiCo amorphous alloy as filler metal. Intermetallics. 57:7–16

Cai YS, Liu RC, Zhu ZW, Cui YY, Yang R (2017) Effect of brazing temperature and brazing time on the microstructure and tensile strength of TiAl-based alloy joints with Ti-Zr-Cu-Ni amorphous alloy as filler metal. Intermetallics. 91:35–44

Qiwen Q, Wang Y, Yang Z, Hu X, Dongpo W (2016) Microstructure and mechanical properties of TiAl alloy joints vacuum brazed with Ti–Zr–Ni–Cu brazing powder without and with Mo additive. Mater Des 90:650–659

Jing Y, Gao X, Yue X et al (2016) The influence of Zr content on the performance of TiZrCuNi brazing filler. Mater Sci Eng A 678:190–196

Jing Y, Xiong H, Shang Y et al (2020) Design TiZrCuNi filler materials for vacuum brazing TA15 alloy. J Manuf Process 53:328–335

Yongjuan J, Diyao S, Xishan Y (2018) The effects of Zr level in Ti-Zr-Cu-Ni brazing fillers for brazing Ti-6Al-4V. J Manuf Process 31:124–130

Li L, Lin X, Hu K, Shengguan Q, Yang C, Li Z (2015) Effects of brazing temperature and testing temperature on the microstructure and shear strength of γ-TiAl joints. Mater Sci Eng A 634:91–98

Jing Y, Shang Y, Xiong H (2020) Simulation on Ti-based filler and vacuum brazing for TA15 alloy. Weld World 64(7):1261–1268

Shan Y, Xie Z, Yongjuan J (2017) Simulation of Zr content in TiZrCuNi brazing filler metal for Ti6Al4V alloy. Appl Phys A 123:471

Pang S, Sun L, Xiong H, Chen C, Liu Y, Li H, Zhang T (2016) A multicomponent TiZr-based amorphous brazing filler metal for high-strength joining of titanium alloy. Scr Mater 117:55–59

Yongjuan J, Diyao S, Xishan Y, Ben BT, Jun J (2017) The development of high strength brazing technique for Ti-6Al-4V using TiZrCuNi amorphous filler. Mater Charact 131:526–531

Botstein O (1994) Brazing of titanium-based alloys with amorphous 25wt.%Ti-25wt.%Zr-50wt.%Cu filler Metal. Mater Sci Eng A 188:305–315

Chang CT, Wu ZY, Shiue RK, Chang CS (2007) Infrared brazing Ti–6Al–4V and SP-700 alloys using the Ti–20Zr–20Cu–20Ni braze alloy. Mater Lett 61:842–845

Lee MK, Lee JG (2013) Mechanical and corrosion properties of Ti–6Al–4V alloy joints brazed with a low-melting-point 62.7Zr–11.0Ti–13.2Cu–9.8Ni–3.3Be amorphous filler metal. Mater Charact 81:19–27

Liu Y, Hu J, Zhang Y, Guo Z (2013) Interface microstructure of the brazed zirconia and Ti-6Al-4V using Ti-based amorphous filler metal. Sci Sinter 45:313–321

Ganjeh E, Sarkhosh H (2013) Microstructural mechanical and fractographical study of titanium-CP and Ti–6Al–4V similar brazing with Ti-based filler. Mater Sci Eng A 559:119–129

Acknowledgments

This research work was sponsored by the National Natural Science Foundation of China under grant number 51804286.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Electronic supplementary material

ESM 1

(DOCX 110 kb)

Rights and permissions

About this article

Cite this article

Jing, Y., Xiong, H., Shang, Y. et al. Interfacial microstructure and tensile strength of TiAl joint brazed with an improved Ti-Zr-Cu-Ni filler. Weld World 65, 345–352 (2021). https://doi.org/10.1007/s40194-020-01015-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01015-w