Abstract

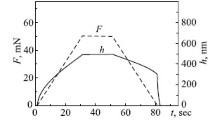

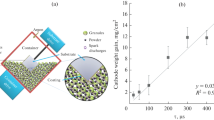

The absolute values of the micromechanical characteristics of the electrospark coating (ESC) obtained by electrospark alloying (ESA) with an electrode made of a serial flux-cored wire (FCW) 80X20R3T have been investigated. Regularities of changes in the magnitude of the wear of ESC applied by electrodes made of flux-cored wire depending on operating parameters and surface roughness in the contact zone during friction without lubrication are established.

Similar content being viewed by others

REFERENCES

Pashechko, M.I., Holubets, V.M., and Chernets, M.V., Formirovanie i friktsionnaya stoikost’ evtekticheskikh pokrytii: monografiya (Formation and Friction Strength of Eutectic Coatings: Monograph), Kyiv: Naukova Dumka, 1993.

Paustovskii, A.V. and Botvinko, V.P., Effect of pulsed laser radiation on the structure and properties of electrospark coatings of type VK and TK alloys, Sov. Powder Metall. Met. Ceram., 1991, vol. 30, no. 2, pp. 139–141.

Burkov, A.A., Zaitsev, A.V., Syui, A.V., Zaikova, E.R., and Kaminskii, O.I., Corrosion, mechanical and catalytic properties of coatings based on FeNiCrWMoCoCB metallic glasses, Prot. Met. Phys. Chem. Surf., 2019, vol. 55, no. 1, pp. 102–108.

Kuznetsov, I.S., Kolomeichenko, A.V., and Pavlov, V.Z., Process of mass transfer of amorphous alloys under low-voltage electric spark treatment, Surf. Eng. Appl. Electrochem., 2017, vol. 53, no. 4, pp. 333–338.

Burkov, A.A., Zaikova, E.R., and Dvornik, M.I., Deposition of Ti–Ni–Zr–Mo–Al–C composite coatings on the Ti6Al4V alloy by electrospark alloying in a granule medium, Surf. Eng. Appl. Electrochem., 2018, vol. 54, no. 6, pp. 546–554.

Pashechko, M., Dziedzic, K., and Barszcz, M., Study of coatings obtained from alloy Fe–Mn–C–B–Si–Ni–Cr, Adv. Sci. Technol. Res. J., 2016, vol. 31, no. 10, pp. 194–198.

Holubets, V.M., Dovgunik, V.M., Pashechko, M.I., Kornii, S.A., and Shpulyar, Yu.S., Frictional behavior of electrospark coatings with limiting lubrication, Fiz.-Khim. Mekh. Mater., 2020, vol. 56, no. 1, pp. 47–52.

Holubets, V.M., Pashechko, M.I., Borc, J., and Barshch, M., Micromechanical characteristics of the surface layer of steel 45 after electrospark treatment, Fiz.-Khim. Mekh. Mater., 2019, vol. 55, no. 3, pp. 102–108.

Kostetskii, B.I., Trenie, smazka i iznos v mahsinakh (Friction, Lubrication, and Wear in Machines), Kiev: Tekhnika, 1970.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Holubets, V.M., Pashechko, M.I., Dzedzic, K. et al. Frictional Strength of Electric Spark Coatings from Powder Wires under Friction without Lubrication. J. Frict. Wear 41, 443–446 (2020). https://doi.org/10.3103/S1068366620050128

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366620050128