Abstract

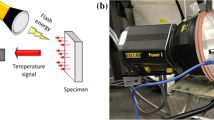

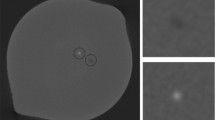

Additive manufacturing (AM) of high-strength metals is currently based on the laser powder bed fusion (LPBF) process, which can introduce internal material flaws, such as pores and anisotropy. Quality control (QC) requires nondestructive evaluation of actual AM structures. Flash thermography is a potentially promising QC technique because it is scalable to arbitrary structure size. However, the detection sensitivity of this method is limited by noise. We investigate separation of signal from noise in thermography images using several machine learning (ML) methods, including new spatial–temporal blind source separation and spatial–temporal sparse dictionary learning methods. Performance of the ML methods is benchmarked using thermography data obtained from imaging stainless steel 316L and Inconel 718 specimens produced by the LPBF method with imprinted calibrated porosity defects. The ML methods are ranked by F-score and execution runtime. The ML methods with higher accuracy require a longer runtime. However, this runtime is sufficiently short to perform QC within a realistic time frame.

Similar content being viewed by others

References

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang, Prog. Mater Sci. 92, 112–224 (2018).

X. Lou and D. Gandy, JOM 71, 2834–2836 (2019).

S.A. Khairallah, A.T. Anderson, A. Rubenchik, and W.E. King, Acta Mater. 108, 36–45 (2016).

W.E. King, A.T. Anderson, R.M. Ferencz, N.E. Hodge, C. Kamath, S.A. Khairallah, and A.M. Rubenchik, Appl. Phys. Rev. 2, 041304 (2015).

Y. Kok, X.P. Tan, P. Wang, M.L.S. Nai, N.H. Loh, E. Liu, and S.B. Tor, Mater. Des. 139, 565–586 (2018).

R. Cunningham, R. Narra, S.P. Montgomery, C.J. Beuth, and A.D. Rollett, JOM 69, 479–484 (2017).

C. Zhao, K. Fezzaa, R.W. Cunningham, H. Wen, F. De Carlo, L. Chen, A.D. Rollett, and T. Sun, Sci. Rep. 7, 3602 (2017).

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, and S.S. Babu, Int. Mater. Rev. 61, 315–360 (2016).

J.J. Lewandowski and M. Seifi, Annu. Rev. Mater. Res. 46, 151–186 (2016).

Q.Y. Lu and C.H. Wong, Virtual Phys. Prototyp. 12, 301–321 (2017).

L. Meng, B. Mcwilliams, W. Jarosinski, H.-Y. Park, Y.-G. Jung, J. Lee, and J. Zhang, JOM 72, 2363–2377 (2020).

L. Meng and J. Zhang, JOM 72, 420–428 (2020).

X. Qi, G. Chen, Y. Li, X. Cheng, and C. Li, Engineering 5, 721–729 (2019).

C. Goberta, E.W. Reutzelb, J. Petrichc, A.R. Nassarb, and S. Phohac, Additive Manuf. 21, 517–528 (2018).

A. Thompson, I. Maskery, and R. Leach, Meas. Sci. Technol. 27, 072001 (2016).

J. Raplee, A. Plotkowski, M.M. Kirka, R. Dinwiddie, A. Okello, R.R. Dehoff, and S.S. Babu, Sci. Rep. 7, 43554 (2017).

S.D. Holland and R.S. Reusser, Ann. Rev. Mater. Res. 46, 287–303 (2016).

A. Heifetz, D. Shribak, T. Liu, T.W. Elmer, P. Kozak, S. Bakhtiari, B. Khaykovich, and W. Cleary, Transactions of the American nuclear society 121, 589–591 (2019).

Q. Luo, B. Gao, W.L. Woo, and Y. Yang, NDT&E Int. 108, 102164 (2019).

J.E. Siegel, M.F. Beemer, and S.M. Shepard, Additive Manuf. 31, 100923 (2020).

X. Zhang, J. Saniie, A. Heifetz, Neural Learning Based Blind Source Separation for Detection of Material Defects in Pulsed Thermography Images, to appear in Proceedings of IEEE International Conference on Electro-Information Conference (EIT), (2020).

T. DebRoy, W. Zhang, J. Turner, and S.S. Babu, Scripta Mater. 135, 119–124 (2017).

C.S. Kim, ANL-75-55 (1975).

D.G. Farwick and R.N. Johnson, HEDL-TME 79-6 (1980).

G. Hinton and T. Sejnowski, eds., Unsupervised learning: Foundations of neural computation (Boston: MIT Press, 1999).

R. Xu and D. Wunsch, IEEE Trans. Neural Netw. 16, 645–678 (2005).

K. Sikka and G. Sharma, IEEE Trans. Pattern Anal. Mach. Intell. 25, 1829–1844 (2017).

Z.H. Lai, Y. Xu, Q.C. Chen, J. Yang, and D. Zhang, IEEE Trans. Neural Netw. Learn. Syst. 25, 1942–1950 (2014).

J. Lucke, AS. Sheikh, Proceedings of International Conference on Latent Variable Analysis and Signal Separation 213–221 (2012).

Y. Bengio, A. Courville, and P. Vincent, IEEE Trans. Pattern Anal. Mach. Intell. 35, 1798–1828 (2013).

W. Q. Fan and W. S. Xiao, J. Eng. 6012–6015 (2019).

N. Rajic, Compos. Struct. 58, 521–528 (2002).

V. Strela and A. T. Walden, Imperial College, Statistics Section, London, U.K., Tech. Rep. TR-98-01 (1998).

X. Zhang, T. Gonnot, and J. Saniie, J. Signal Inf. Process. 8, 99–112 (2017).

A. Hyvärinen, J. Neural Process. Lett. 10, 1–5 (1999).

N. Y. Wang, T. S. Yao, J. D. Wang and D. Y. Yeung, European Conference on Computer Vision 126–139 (2012).

Acknowledgements

This work was supported by the US Department of Energy, Office of Nuclear Energy, Nuclear Energy Enabling Technology (NEET) Advanced Methods of Manufacturing (AMM) program, under Contract DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, X., Saniie, J., Cleary, W. et al. Quality Control of Additively Manufactured Metallic Structures with Machine Learning of Thermography Images. JOM 72, 4682–4694 (2020). https://doi.org/10.1007/s11837-020-04408-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04408-w