Abstract

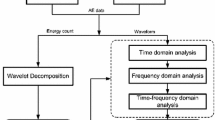

This study characterized 345 MPa normal-strength steel (NSS) and 460 MPa high-strength steel (HSS) with the acoustic emission (AE) technique. Pencil lead break (PLB) and tensile tests were performed, and the generated AE signals were recorded. The AE signals from the PLB tests were converted into the frequency and time-frequency domains via a fast Fourier transform (FFT) and wavelet transform. The AE signals generated during the tensile process were divided into four stages for analysis. The AE parameters, such as the counts, amplitude, hit and duration, were extracted from the signals. An FFT was conducted to obtain the features of frequency spectrum at each stage. The comparisons revealed the similarities and differences in the AE characteristics between the two steels. It was found that the energy of the AE signals for the 460 MPa HSS was less overall than that of the 345 MPa NSS. The analysis results indicated that the AE technique is a method that can potentially be used to distinguish the two steels, and additional studies for accurate identification are needed. As 460 MPa HSS is being widely used but related AE studies are limited, this study provides data for additional investigations of the damage in HSS structures with the AE method.

Similar content being viewed by others

References

ASTM E976-15. (2015). Standard guide for determining the reproducibility of acoustic emission sensor response. West Conshohocken: American Society of Testing Materials.

Babu, M. N., Mukhopadhyay, C. K., Sasikala, G., Albert, S. K., Bhaduri, A. K., Jayakumar, T., et al. (2016). Study of fatigue crack growth in RAFM steel using acoustic emission technique. Journal of Constructional Steel Research, 126, 107–116.

Dou, Y. T., Xu, X. L., Wang, W., & Pang, S. Q. (2011). The study of identification method for the welding defect source of low-alloy high-strength steel based on AE technology. Key Engineering Materials, 467–469, 1580–1585.

Droubi, M. G., Faisal, N. H., Orr, F., Steel, J. A., & El-Shaib, M. (2017). Acoustic emission method for defect detection and identification in carbon steel welded joints. Journal of Constructional Steel Research, 134, 28–37.

Fan, X., Hu, S., Lu, J., & Wei, C. (2016). Acoustic emission properties of concrete on dynamic tensile test. Construction and Building Materials, 114, 66–75.

GB/T 228.1-2010. (2010). Metallic materials-tensile testing-part1: Method of test at room temperature. Beijing: Standards Press of China. (in Chinese).

GB/T 2975-2018. (2018). Steel and steel products-location and preparation of test pieces for mechanical testing. Beijing: Standards Press of China. (in Chinese).

Han, Z., Luo, H., Cao, J., & Wang, H. (2011). Acoustic emission during fatigue crack propagation in a micro-alloyed steel and welds. Materials Science and Engineering: A, 528(25–26), 7751–7756.

He, K., Liu, X., Yang, Q., & Chen, Y. (2017). An extraction method of welding crack acoustic emission signal using harmonic analysis. Measurement, 103, 311–320.

Hensman, J., Worden, K., Eaton, M., Pullin, R., Holford, K., & Evans, S. (2011). Spatial scanning for anomaly detection in acoustic emission testing of an aerospace structure. Mechanical Systems and Signal Processin, 25(7), 2462–2474.

Hopwood, T., II., & Havens, J. H. (1978). Acoustic emission monitoring of weldments. Journal of Testing & Evaluation, 7(4), 7.

Hsu, N. N., & Breckenridge, F. R. (1981). Characterization and calibration of acoustic emission sensors. Materials Evaluation, 39(1), 60–68.

Izotov, V. I., & Pozdnyakov, V. A., Yanenko, L., Getmanova, E. V., M. E., and Philippov, G. A. (2008). Evolution of the dislocation structure and the formation of fatigue microcracks in pearlitic-ferritic steels. The Physics of Metals and Metallography, 105(5), 517–527.

Kasai, N., Utatsu, K., Park, S., Kitsukawa, S., & Sekine, K. (2009). Correlation between corrosion rate and AE signal in an acidic environment for mild steel. Corrosion Science, 51(8), 1679–1684.

Lee, C. S., Huh, J. H., Li, D. M., & Shin, D. H. (1999). Acoustic emission behavior during tensile tests of low carbon steel welds. ISIJ International, 39(4), 365–370.

Long, X., Li, Q., & He, C., et al. (2017). Acoustic emission monitoring and evaluation for rolled steel damage under different tensile rates. Journal of Vibration and Shock, 36, 219–225. (in Chinese).

Mao, W., Yang, Y., & Lin, W. (2019). An acoustic emission characterization of the failure process of shallow foundation resting on sandy soils. Ultrasonics, 93, 107–111.

Merson, E. D., Krishtal, M. M., & Merson, D. L., et al. (2012). Effect of strain rate on acoustic emission during hydrogen assisted cracking in high carbon steel. Materials Science and Engineering: A, 550, 408–417.

Nguyen-Tat, T., Ranaivomanana, N., & Balayssac, J. (2018). Characterization of damage in concrete beams under bending with acoustic emission technique (AET). Construction and Building Materials, 187, 487–500.

Shi, G., Hu, F., & Shi, Y. (2014). Recent research advances of high strength steel structures and codification of design specification in China. International Journal of Steel Structures, 14, 873–887.

Thirumalaiselvi, A., & Sasmal, S. (2019). Acoustic emission monitoring and classification of signals in cement composites during early-age hydration. Construction and Building Materials, 196, 411–427.

Ucak, A., & Tsopelas, P. (2011). Constitutive model for cyclic response of structural steels with yield plateau. Journal of Structural Engineering, 137(2), 195–206.

Ucak, A., & Tsopelas, P. (2012). Accurate modeling of the cyclic response of structural components constructed of steel with yield plateau. Engineering Structures, 35, 272–280.

Wang, W., Zhang, L., & He, P. (2018). A numerical investigation on restrained high strength Q460 steel beams including creep effect. International Journal of Steel Structures, 18, 1497–1507.

Wevers, M. (1997). Listening to the sound of materials: Acoustic emission for the analysis of material behavior. NDT and E International, 30(02), 99–106.

Yang, Y., Wang, Y., Yang, F., & An, Q. (2019). Influence of weld details on fracture behavior of connections using high-strength steel. Journal of Constructional Steel Research, 153, 578–587.

Yu, J., Ziehl, P., Matta, F., & Pollock, A. (2013). Acoustic emission detection of fatigue damage in cruciform welded joints. Journal of Constructional Steel Research, 86, 85–91.

Yu, J., Ziehl, P., Zárate, B., & Caicedo, J. (2011). Prediction of fatigue crack growth in steel bridge components using acoustic emission. Journal of Constructional Steel Research, 67, 1254–1260.

Acknowledgements

The research presented in the study is supported by the National Natural Science Foundation of China (51908306), the China Postdoctoral Science Foundation (2017M622157) and the Project of Shandong Province Higher Educational Science and Technology Program (J17K205).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that there are no conflicts of interest regarding this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, Y., Wang, Y. & Li, K. Differences in the Acoustic Emission Characteristics of 345 MPa Normal-Strength Steel and 460 MPa High-Strength Steel. Int J Steel Struct 21, 154–166 (2021). https://doi.org/10.1007/s13296-020-00423-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-020-00423-4