Abstract

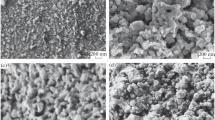

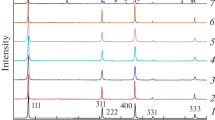

Li4Ti5O12/C anode materials of different particle size have been prepared by a sol–gel process, followed by mechanical processing in a planetary mill. Carbon was introduced both by an in situ process and by mechanically mixing lithium titanate with carbon black (Timcal). The materials thus prepared have been characterized by X-ray diffraction, electron microscopy, and low-temperature nitrogen adsorption measurements and electrochemically tested. The decrease in the particle size of Li4Ti5O12 with increasing milling rate is larger in the case of the composites containing carbon black (Timcal). At a low charge/discharge rate (0.1C), the electrochemical capacity of the composites processed in a planetary mill at rotation rates of ≤400 rpm exceeds that of the pristine Li4Ti5O12. At high current densities (18C), the Li4Ti5O12/carbon black (Timcal) composite processed at 200 rpm exhibits the highest electrochemical capacity (107 mAh/g).

Similar content being viewed by others

REFERENCES

Cebulla, F., Naegler, T., and Pohl, M., Electrical energy storage in highly renewable european energy systems: capacity requirements, spatial distribution, and storage dispatch, J. Energy Storage, 2017, vol. 14, pp. 211–223. https://doi.org/10.1016/j.est.2017.10.004

Zubi, G., Dufo-López, R., Carvalho, M., and Pasaoglu, G., The lithium-ion battery: state of the art and future perspectives, Renewable Sustainable Energy Rev., 2018, vol. 89, pp. 292–308. https://doi.org/10.1016/j.rser.2018.03.002

Paterakis, N.G., Erdinc, O., and Catalão, J.P.S., An overview of demand response: key-elements and international experience, Renewable Sustainable Energy Rev., 2017, vol. 69, pp. 871–891. https://doi.org/10.1016/j.rser.2016.11.167

Stenina, I.A. and Yaroslavtsev, A.B., Nanomaterials for lithium-ion batteries and hydrogen energy, Pure Appl. Chem., 2017, vol. 89, no. 8, pp. 1185–1194. https://doi.org/10.1515/pac-2016-1204

Yi, T.-F., Jiang, L.-J., Shu, J., Yue, C.-B., Zhu, R.-S., and Qiao, H.-B., Recent development and application of Li4Ti5O12 as anode material of lithium ion battery, J. Phys. Chem. Solids, 2010, vol. 71, pp. 1236–1242. https://doi.org/10.1016/j.jpcs.2010.05.001

Han, C., He, Y.-B., Liu, M., Li, B., Yang, Q.-H., Wong, C.-P., and Kang, F., A review of gassing behavior in Li4Ti5O12-based lithium ion batteries, J. Mater. Chem. A, 2017, vol. 5, pp. 6368–6381. https://doi.org/10.1039/C7TA00303J

Sun, X., Radovanovic, P.V., and Cui, B., Advances in spinel Li4Ti5O12 anode materials for lithium-ion batteries, New J. Chem., 2015, vol. 39, pp. 38–63. https://doi.org/10.1039/C4NJ01390E

Ohzuku, T., Ueda, A., and Yamamoto, N., Zero-strain insertion material of Li[Li1/3Ti5/3]O4 for rechargeable lithium cells, J. Electrochem. Soc., 1995, vol. 142, pp. 1431–1435. https://doi.org/10.1149/1.2048592

Xu, G., Han, P., Dong, S., Liu, H., Cui, G., and Chen, L., Li4Ti5O12-based energy conversion and storage systems: Status and prospects, Coord. Chem. Rev., 2017, vol. 343, pp. 139–184. https://doi.org/10.1016/j.mser.2015.10.001

Yi, T.-F., Yang, S.-Y., and Xie, Y., Recent advances of Li4Ti5O12 as promising next generation anode material for high power lithium-ion batteries, J. Mater. Chem. A, 2015, vol. 3, pp. 5750–5777. https://doi.org/10.1039/C4TA06882C

Song, M.-S., Kim, R.-H., Baek, S.-W., Lee, K.-S., Park, K., and Benayad, A., Is Li4Ti5O12 a solid-electrolyte-interphase-free electrode material in Li-ion batteries? Reactivity between the Li4Ti5O12 electrode and electrolyte, J. Mater. Chem. A, 2014, vol. 2, pp. 631–636. https://doi.org/10.1039/C3TA12728A

Aravindan, V., Lee, Y.-S., and Madhavi, S., Research progress on negative electrodes for practical Li-ion batteries: beyond carbonaceous anodes, Adv. Energy Mater., 2015, vol. 5, no. 13, paper 1402225. https://doi.org/10.1002/aenm.201402225

Sandhya, C.P., John, B., and Gouri, C., Lithium titanate as anode material for lithium-ion cells: a review, Ionics, 2014, vol. 20, no. 5, pp. 601–620. https://doi.org/10.1007/s11581-014-1113-4

Yaroslavtsev, A.B., Kulova, T.L., and Skundin, A.M., Electrode nanomaterials for lithium-ion batteries, Russ. Chem. Rev., 2015, vol. 84, no. 8, pp. 826–852.

Stenina, I.A., Sobolev, A.N., Yaroslavtsev, S.A., Rusakov, V.S., Kulova, T.L., Skundin, A.M., and Yaroslavtsev, A.B., Influence of iron doping on structure and electrochemical properties of Li4Ti5O12, Electrochim. Acta, 2016, vol. 219, pp. 524–530. https://doi.org/10.1016/j.electacta.2016.10.034

Kulova, T.L., Kreshchenova, Yu.M., Kuz’mina, A.A., Skundin, A.M., Stenina, I.A., and Yaroslavtsev, A.B., New high-capacity anode materials based on gallium-doped lithium titanate, Mendeleev Commun., 2016, vol. 26, no. 3, pp. 238–239. https://doi.org/10.1016/j.mencom.2016.05.005

Qian, D., Gu, Y., Chen, Y., Liu, H., Wang, J., and Zhou, H., Ultra-high specific capacity of Cr3+-doped Li4Ti5O12 at 1.55 V as anode material for lithium-ion batteries, Mater. Lett., 2019, vol. 238, pp. 102–106. https://doi.org/10.1016/j.matlet.2018.11.163

Guo, M., Wang, S., Ding, L.-X., Huang, C., and Wang, H., Tantalum-doped lithium titanate with enhanced performance for lithium-ion batteries, J. Power Sources, 2015, vol. 283, pp. 372–380. https://doi.org/10.1016/j.jpowsour.2015.02.154

Cho, H., Son, H., Kim, D., Lee, M., Boateng, S., Han, H., Kim, K.M., Kim, S., Choi, H., Song, T., and Lee, K.H., Impact of Mg-doping site control in the performance of Li4Ti5O12 Li-ion battery anode: first-principles predictions and experimental verifications, J. Phys. Chem. C, 2017, vol. 121, pp. 14994–15001. https://doi.org/10.1021/acs.jpcc.7b01475

Stenina, I.A., Kulova, T.L., Skundin, A.M., and Yaroslavtsev, A.B., Carbon composites as anode materials for lithium-ion batteries, Rev. Adv. Mater. Sci., 2017, vol. 49, pp. 140–149.

Cheng, Q., Tang, S., Liang, J., Zhao, J., Lan, Q., Liu, C., and Cao, Y.-C., High rate performance of the carbon encapsulated Li4Ti5O12 for lithium ion battery, Results Phys., 2017, vol. 7, pp. 810–812. https://doi.org/10.1016/j.rinp.2017.01.040

Park, J.-H., Kang, S.-W., Kwon, T.-S., and Park, H.S., Spray-drying assisted synthesis of a Li4Ti5O12/C composite for high rate performance lithium ion batteries, Ceram. Int., 2018, vol. 44, pp. 2683–2690. https://doi.org/10.1016/j.ceramint.2017.10.217

Mu, D., Chen, Y., Wu, B., Huang, R., Jiang, Y., Li, L., and Wu, F., Nano-sized Li4Ti5O12/C anode material with ultrafast charge/discharge capability for lithium ion batteries, J. Alloys Compd., 2016, vol. 671, pp. 157–163. https://doi.org/10.1016/j.jallcom.2016.02.095

Sha, Y., Xu, X., Li, L., Cai, R., and Shao, Z., Hierarchical carbon-coated acanthosphere-like Li4Ti5O12 microspheres for high-power lithium-ion batteries, J. Power Sources, 2016, vol. 314, pp. 18–27. https://doi.org/10.1016/j.jpowsour.2016.02.084

Li, D., Zhang, X., Miao, X., Liu, Y., Chen, S., Chen, Y., Wang, W., and Zhang, Y., Solid-state synthesized Li4Ti5O12 for ultrafast lithium ion storage enabled by carbon-coating induced particle size tailoring, J. Alloys Compd., 2019, vol. 797, no. 15, pp. 1258–1267. https://doi.org/10.1016/j.jallcom.2019.05.164

Yao, N.Y., Liu, H.K., Liang, X., Sun, Y., Feng, X.Y., Chen, C.H., and Xiang, H.F., Li4Ti5O12 nanosheets embedded in three-dimensional amorphous carbon for superior-rate battery applications, J. Alloys Compd., 2019, vol. 771, pp. 755–761. https://doi.org/10.1016/j.jallcom.2018.08.001

Guo, X., Xiang, H.F., Zhou, T.P., Ju, X.K., and Wu, Y.C., Morphologies and structures of carbon coated on Li4Ti5O12 and their effects on lithium storage performance, Electrochim. Acta, 2014, vol. 130, pp. 470–476. https://doi.org/10.1016/j.electacta.2014.02.139

Lim, J., Choi, E., Mathew, V., Kim, D., Ahn, D., Gim, J., Kang, S.-H., and Kim, J., Enhanced high-rate performance of Li4Ti5O12 nanoparticles for rechargeable Li-ion batteries, J. Electrochem. Soc., 2011, vol. 158, no. 3, pp. A275–A280. https://doi.org/10.1149/1.3527983

Stenina, I.A., Kulova, T.L., Skundin, A.M., and Yaroslavtsev, A.B., High grain boundary density Li4Ti5O12/ anatase-TiO2 nanocomposites as anode material for Li-ion batteries, Mater. Res. Bull., 2016, vol. 75, pp. 178–184. https://doi.org/10.1016/j.materresbull.2015.11.050

Zhao, S., Ka, O., Xian, X., Sun, L., and Wang, J., Effect of primary crystallite size on the high-rate performance of Li4Ti5O12 microspheres, Electrochim. Acta, 2016, vol. 206, pp. 17–25. https://doi.org/10.1016/j.electacta.2016.04.132

Sandhya, C.P., John, B., and Gouri, C., Surfactant-assisted sol–gel route to lithium titanate and its electrochemical properties, J. Alloys Compd., 2016, vol. 655, pp. 238–243. https://doi.org/10.1016/j.jallcom.2015.09.174

Chauque, S., Oliva, F.Y., Visintin, A., Barraco, D., Leiva, E.P.M., and Camara, O.R., Lithium titanate as anode material for lithium ion batteries: synthesis, post-treatment and its electrochemical response, J. Electroanal. Chem., 2017, vol. 799, pp. 142–155. https://doi.org/10.1016/j.jelechem.2017.05.052

Stenina, I.A., Il’in, A.B., and Yaroslavtsev, A.B., Synthesis and ionic conductivity of Li4Ti5O12, Inorg. Mater., 2015, vol. 51, pp. 62–67. https://doi.org/10.1134/S0020168515010185

ACKNOWLEDGMENTS

The SEM measurements were performed using shared experimental facilities supported by IGIC RAS state assignment.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 20-08-00769.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stenina, I.A., Sobolev, A.N., Kuz’mina, A.A. et al. Influence of Mechanical Processing and the Procedure Used to Introduce a Carbon Material on the Electrochemical Properties of Li4Ti5O12/C Composites. Inorg Mater 56, 1079–1086 (2020). https://doi.org/10.1134/S0020168520090150

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520090150