Abstract

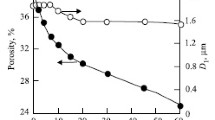

Sintering of powder compacts can lead to an increase in their density, with the neck between the particles growing. Powder sintering diagrams are constructed in the following coordinates: the relative size of the particle radius (the size of the neck between the sintered particles divided by the particle radius) and the homological melting temperature of the material. To construct sintering diagrams, it is necessary to solve a system of pairs of rate equations for the existing sintering mechanisms. The solution gives the equations of the boundaries separating the regions on the graph “relative radius of the particles–homological temperature,” in which the sintering rate by one mechanism is greater than the other. At these boundaries, the two selected sintering mechanisms make equal contributions to the growth rate of the neck between particles. Sintering diagrams of titanium powders of various dispersions were constructed (with an average particle size of 0.1, 1, 5, and 10 μm.). The sintering diagrams show that the dominant mechanisms of the sintering of titanium micro- and nanopowders in the temperature range of 0.6–0.9 of the absolute melting temperature are surface diffusion from the surface and volume diffusion of the substance from the sources at the boundaries of grains.

Similar content being viewed by others

REFERENCES

Ashby, M.F., A first report on sintering diagrams, Acta Metall., 1974, vol. 22, pp. 275–289.

Alymov, M.I., Evstratov, E.V., Ankudinov, A.B., Ze-lensky, V.A., Golosova, O.A., and Kolobova, A.Yu., Preparation, structure, and properties of porous materials based on titanium, Inorg. Mater.: Appl. Res., 2016, vol. 7, no. 3, pp. 425–428.

Smithells, C.J., Metals Reference Book, Amsterdam: Elsevier, 1976, 5th ed.

Missol, W., Energia Powierzchni Rozdziału Faz w Metalach, Katowice: Śląsk, 1975.

Handbook of Physical Quantities, Grigor’ev, I.S. and Meilikhov, E.Z., Eds., Boca Raton, FL: CRC Press, 1996.

German, R.M., Sintering Theory and Practice, New York: Wiley, 1996.

Andreev, N.H., Malakhov, A.I., and Fufaev, L.S., Novye materialy v tekhnike (New Material in Engineering), Moscow: Vysshaya Shkola, 1968.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Gumerov

Rights and permissions

About this article

Cite this article

Alymov, M.I., Averin, S.I. & Semichev, S.V. Sintering Diagrams of Titanium Powders. Inorg. Mater. Appl. Res. 11, 1041–1044 (2020). https://doi.org/10.1134/S2075113320050032

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320050032