Abstract

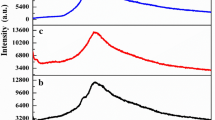

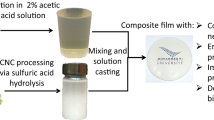

Moisture absorption, thermal and biodegradation properties of nanocellulose (NC) reinforced bionanocomposite tapioca starch (TS) films crosslinked with Citrus aurantifolia or lime juice (LJ) were investigated for food packaging applications. The films were synthesized by solvent casting using different amounts of nanocellulose and crosslinkers: lime juice and a commercial citric acid (CA). Nanocellulose as reinforcing filler was obtained from oil palm empty fruit bunches through acid hydrolysis. Crystallinity of all TS bionanocomposites was determined using X-ray diffractometry. TS bionanocomposites interaction with water was studied by means of moisture absorption, moisture content and swelling. Flory-Huggin model was used to measure the crosslinked density of crosslinked TS bionanocomposites which indicated successful crosslinking using LJ and CA for TS. The crystallinity of TS film increased from 43.5% for neat TS to 51.6% for TS film with inclusion of NC. LJ-crosslinked TS film with 1 wt% of NC (based on starch content) had the lowest moisture absorption and swelling ratio. TS bionanocomposites with LJ had better thermal and biodegradation properties compared to commercial CA-crosslinked TS biocomposites, which can be a potential food packaging material among the tested bionanocomposites.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this published article.

References

Jacob J, Peter G, Thomas S, Haponiuk JT, Gopi S (2019) In-situ synthesis and characterization of biocompatible magnetic ginger nanofiber composites for copper (II) removal from water. Mater Today Commun 21:100690

Gopi S, Amalraj A, Jude S, Benson KT, Balakrishnan P, Haponiuk JT, Thomas S (2019) Isolation and characterization of stable nanofiber from turmeric spent using chemical treatment by acid hydrolysis and its potential as antimicrobial and antioxidant activities. J Macromol Sci A 56:327–340

Jacob J, Haponiuk JT, Thomas S, Peter G, Gopi S (2018) Use of ginger nanofibers for the preparation of cellulose nanocomposites and their antimicrobial activities. Fibers 6:79

Gopi S, Amalraj A, Jacob J, Kalarikkal N, Thomas S, Guo Q (2018) Preparation, characterization and in vitro study of liposomal curcumin powder by cost effective nanofiber weaving technology. New J Chem 42:5117–5127

Gopi S, Amalraj A, Varma K, Jude S, Reddy PB, Divya C, Haponiuk JT, Thomas S (2018) Turmeric nanofiber-encapsulated natural product formulation act as a phytogenic feed additive - A study in broilers on growth performance, biochemical indices of blood, and E. coli in cecum. Int J Polym Mater PO 67:581–588

Jacob J, Haponiuk JT, Thomas S, Gopi S (2018) Biopolymer based nanomaterials in drug delivery systems: A review. Mater Today Chem 9:43–55

Li M, Tian X, Jin R, Li D (2018) Preparation and characterization of nanocomposite films containing starch and cellulose nanofibers. Ind Crop Prod 123:654–660

Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES (2018) Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohyd Polym 202:186–202

Jacob J, Peter G, Thomas S, Haponiuk JT, Gopi S (2019) Chitosan and polyvinyl alcohol nanocomposites with cellulose nanofibers from ginger rhizomes and its antimicrobial activities. Int J Biol Macromol 129:370–376

Gopi S, Amalraj A, Kalarikkal N, Zhang J, Thomas S, Guo Q (2019) Preparation and characterization of nanocomposite films based on gum arabic, maltodextrin and polyethylene glycol reinforced with turmeric nanofiber isolated from turmeric spent. Mater Sci Eng C 97:723–729

Gopi S, Amalraj A, Jude S, Thomas S, Guo Q (2019) Bionanocomposite films based on potato, tapioca starch and chitosan reinforced with cellulose nanofiber isolated from turmeric spent. J Taiwan Inst Chem E 96:664–671

López-Córdoba A, Medina-Jaramillo C, Piñeros-Hernandez D, Goyanes S (2017) Cassava starch films containing rosemary nanoparticles produced by solvent displacement method. Food Hydrocolloid 71:26–34

Cuevas-Carballo ZB, Duarte-Aranda S, Canché-Escamilla G (2019) Properties and biodegradation of thermoplastic starch obtained from grafted starches with poly(lactic acid). J Polym Environ 27:2607–2617

Hejna A, Lenża J, Formela K, Korol J (2019) Studies on the combined impact of starch source and multiple processing on selected properties of thermoplastic starch/ethylene-vinyl acetate blends. J Polym Environ 27:1112–1126

Piñeros-Hernandez D, Medina-Jaramillo C, López-Córdoba A, Goyanes S (2017) Edible cassava starch films carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocoll 63:488–495

Fan H, Ji N, Zhao M, Xiong L, Sun Q (2016) Characterization of starch films impregnated with starch nanoparticles prepared by 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO)-mediated oxidation. Food Chem 192:865–872

Karimi S, Dufresne A, Md. Tahir P, Karimi A, Abdulkhani A (2014) Biodegradable starch-based composites: effect of micro and nanoreinforcements on composite properties. J Mater Sci 49(13):4513–4521

Goudarzi V, Shahabi-Ghahfarrokhi I, Babaei-Ghazvini A (2017) Preparation of ecofriendly UV-protective food packaging material by starch/TiO2 bio-nanocomposite: characterization. Int J Biol Macromol 95:306–313

Edhirej A, Sapuan SM, Jawaid M, Zahari NI (2017) Preparation and characterization of cassava bagasse reinforced thermoplastic cassava starch. Fiber Polym 18(1):162–171

Versino F, García MA (2014) Cassava (Manihot esculenta) starch films reinforced with natural fibrous filler. Ind Crop Prod 58:305–314

Lv S, Zhang Y, Gu J, Tan H (2018) Soil burial-induced chemical and thermal changes in starch/poly (lactic acid) composites. Int J Biol Macromol 113:338–344

Gray N, Hamzeh Y, Kaboorani A, Abdulkhani A (2018) Influence of cellulose nanocrystal on strength and properties of low density polyethylene and thermoplastic starch composites. Ind Crop Prod 115:298–305

Priya B, Gupta VK, Pathania D, Singha AS (2014) Synthesis, characterization and antibacterial activity of biodegradable starch/PVA composite films reinforced with cellulosic fibre. Carbohyd Polym 109:171–179

Montero B, Rico M, Rodríguez-Llamazares S, Barral L, Bouza R (2017) Effect of nanocellulose as a filler on biodegradable thermoplastic starch films from tuber, cereal and legume. Carbohyd Polym 157:1094–1104

Gilfillan WN, Nguyen DMT, Sopade PA, Doherty WOS (2012) Preparation and characterisation of composites from starch and sugar cane fibre. Ind Crop Prod 40(1):45–54

Kaushik A, Singh M, Verma G (2010) Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohyd Polym 82(2):337–345

Wan YZ, Luo H, He F, Liang H, Huang Y, Li XL (2009) Mechanical, moisture absorption, and biodegradation behaviours of bacterial cellulose fibre-reinforced starch biocomposites. Compos Sci Technol 69(7–8):1212–1217

Gilfillan WN, Moghaddam L, Doherty WOS (2014) Preparation and characterization of composites from starch with sugarcane bagasse nanofibres. Cellulose 21(4):2695–2712

Teacă CA, Bodîrlău R, Spiridon I (2013) Effect of cellulose reinforcement on the properties of organic acid modified starch microparticles/plasticized starch bio-composite films. Carbohyd Polym 93(1):307–315

Aila-Suárez S, Palma-Rodríguez HM, Rodríguez-Hernández AI, Hernández-Uribe JP, Bello-Pérez LA, Vargas-Torres A (2013) Characterization of films made with chayote tuber and potato starches blending with cellulose nanoparticles. Carbohyd Polym 98(1):102–107

Rol F, Belgacem MN, Gandini A, Bras J (2019) Recent advances in surface-modified cellulose nanofibrils. Prog Polym Sci 88:241–264

Owi WT, Lin OH, Sam ST, Villagracia AR, Santos GNC (2017) Tapioca starch based green nanocomposites with environmental friendly cross-linker. Chem Eng Trans 56:463–468

Colivet J, Carvalho RA (2017) Hydrophilicity and physicochemical properties of chemically modified cassava starch films. Ind Crop Prod 95:599–607

Reddy N, Yang Y (2010) Citric acid cross-linking of starch films. Food Chem 118(3):702–711

Mei JQ, Zhou DN, Jin ZY, Xu XM, Chen HQ (2015) Effects of citric acid esterification on digestibility, structural and physicochemical properties of cassava starch. Food Chem 187:378–384

Olsson E, Menzel C, Johansson C, Andersson R, Koch K, Järnström L (2013) The effect of pH on hydrolysis, cross-linking and barrier properties of starch barriers containing citric acid. Carbohyd Polym 98(2):1505–1513

Zain AHM, Ab Wahab MK, Ismail H (2018) Biodegradation behaviour of thermoplastic starch: the roles of carboxylic acids on cassava starch. J Polym Environ 26(2):691–700

Ghosh Dastidar T, Netravali AN (2012) “Green” crosslinking of native starches with malonic acid and their properties. Carbohyd Polym 90(4):1620–1628

Spiridon I, Teacă CA, Bodîrlău R, Bercea M (2013) Behavior of cellulose reinforced cross-linked starch composite films made with tartaric acid modified starch microparticles. J Polym Environ 21(2):431–440

Brima EI, Abbas AM (2014) International journal of chemical studies determination of citric acid in soft drinks, juice drinks and energy drinks using titration. Int J Chem Stud 1(6):30–34

Owi WT, Ong HL, Sam ST, Tsai CK, Akil HM (2019) Unveiling the physicochemical properties of natural Citrus aurantifolia crosslinked tapioca starch/nanocellulose bionanocomposites. Ind Crop Prod 139:111548

Owi WT, Lin OH, Sam ST, Chia CH, Zakaria S, Mohaiyiddin MS, Villagracia AR, Santos GN, Akil HM (2016) Comparative study of microcelluloses isolated from two different biomasses with commercial cellulose. BioResources 11(2):3453–3465

ASTM (2012) ASTM E104–02: standard practice for maintaining constant relative humidity by means of aqueous solutions. ASTM International, West Conshohocken, PA

ASTM (2007) ASTM D644–99: standard test method for moisture content of paper and paperboard by oven drying. ASTM International, West Conshohocken, PA

Mohaiyiddin MS, Ong HL, Othman MBH, Julkapli NM, Villagracia AR, Akil HM (2018) Swelling behavior and chemical stability of chitosan/nanocellulose biocomposites. Polym Compos 39(S1):E561–E572

Sen C, Das M (2018) Biodegradability of starch based self-supporting antimicrobial film and its effect on soil quality. J Polym Environ 26(12):4331–4337

Terrazas-Hernandez JA, Berrios JDJ, Glenn GM, Imam SH, Wood D, Bello-Pérez LA, Vargas-Torres A (2015) Properties of cast films made of chayote (Sechium edule Sw.) tuber starch reinforced with cellulose nanocrystals. J Polym Environ 23(1):30–37

Edhirej A, Sapuan SM, Jawaid M, Zahari NI (2017) Cassava/sugar palm fiber reinforced cassava starch hybrid composites: physical, thermal and structural properties. Int J Biol Macromol 101:75–83

Ghanbarzadeh B, Almasi H, Entezami AA (2011) Improving the barrier and mechanical properties of corn starch-based edible films: effect of citric acid and carboxymethyl cellulose. Ind Crop Prod 33(1):229–235

Merino D, Gutiérrez TJ, Mansilla AY, Casalongué CA, Alvarez VA (2018) Critical evaluation of starch-based antibacterial nanocomposites as agricultural mulch films: study on their interactions with water and light. ACS Sustain Chem Eng 6(11):15662–15672

Iman M, Bania KK, Maji TK (2013) Green jute-based cross-linked soy flour nanocomposites reinforced with cellulose whiskers and nanoclay. Ind Eng Chem Res 52(21):6969–6983

Ma X, Chang PR, Yu J, Stumborg M (2009) Properties of biodegradable citric acid-modified granular starch/thermoplastic pea starch composites. Carbohyd Polym 75(1):1–8

Liu Q, Yang R, Zhang Z, Gao W (2017) Improving the cross-linking degree of oxidized potato starch via addition of nanocrystalline cellulose. Starch 69(11–12):1700042

Jayaramudu J, Reddy GSM, Varaprasad K, Sadiku ER, Sinha Ray S, Varada Rajulu A (2013) Preparation and properties of biodegradable films from Sterculia urens short fiber/cellulose green composites. Carbohyd Polym 93(2):622–627

Babaee M, Jonoobi M, Hamzeh Y, Ashori A (2015) Biodegradability and mechanical properties of reinforced starch nanocomposites using cellulose nanofibers. Carbohyd Polym 132:1–8

Syafri E, Sudirman M, Yulianti E, Deswita AM, Abral H, Sapuan SM, Ilyas RA, Fudholi A (2019) Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J Mater Res Technol 8(6):6223–6231

Acknowledgements

The authors would like to express our gratitude to the Ministry of Education Malaysia by providing the financial support through MyBrain15-MyPhD Scholarship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ong, H.L., Villagracia, A.R., Owi, W.T. et al. Revealing the Water Resistance, Thermal and Biodegradation Properties of Citrus aurantifolia Crosslinked Tapioca Starch/Nanocellulose Bionanocomposites. J Polym Environ 28, 3256–3269 (2020). https://doi.org/10.1007/s10924-020-01852-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01852-2