Abstract

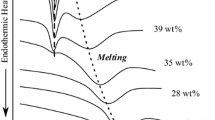

In this work the effects of testing temperature and drawing orientation on the fracture behaviour of biobased and biodegradable thermoplastic starch based films, currently applied in the food packaging field, were investigated. At this aim, the Essential Work of Fracture (EWF) approach was applied on samples tested at 0 °C, 25 °C and 50 °C both in machine (MD) and in cross (CD) directions. The specific essential work of fracture (we) values strongly decreased with the testing temperature, and we values of CD samples were systematically higher than those of the corresponding MD samples. Considering that photograms of the CD samples taken during the EWF tests highlighted that the yielding zone became progressively opaque as an effect of the strain induced crystallization, it was hypothesized that in CD specimens part of the tensile energy applied during the straining process was utilized for the orientation of the macromolecules along the strain direction, rather than for the propagation of the crack in the ligament zone. Tensile tests under quasi-static conditions on dumbbell specimens highlighted that, regardless to the drawing direction, the stiffness and the resistance at yield and at break decreased with the temperature, while the strain at break was considerably enhanced. Moreover, because of the strong anisotropy induced by the molecular orientation in the drawing direction, MD tested samples had higher elastic modulus, yield resistance, and stress at break compared to CD samples.

Similar content being viewed by others

Abbreviations

- DENT:

-

Double edge notched tension

- E:

-

Tensile modulus

- β:

-

Plastic shape factor

- σy :

-

Yield stress

- L:

-

Ligament length

- \({\overline{\text{L}}}\) :

-

Arithmetic mean of the ligament length

- W:

-

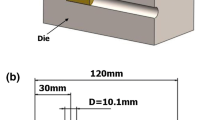

Width of the DENT specimens

- t:

-

Thickness of the DENT specimens

- n:

-

Number of specimens

- R2 :

-

Coefficient of determination

- S:

-

Standard error of the linear regression

- \({\overline{\text{S}}}\) :

-

Standard deviation of Wf values

- S11, S12, S22 :

-

Parameters of the linear regression

- Wf :

-

Total work of fracture

- wf :

-

Specific total work of fracture

- \(\overline{{\text{W}}}_{{\text{f}}}\) :

-

Arithmetic mean of Wf values

- \({\text{W}}_{{\text{e}}}\) :

-

Essential work of fracture

- \({\text{w}}_{{\text{e}}}\) :

-

Specific essential work of fracture

- \({\text{W}}_{{\text{p}}}\) :

-

Non-essential work of fracture

- \({\text{w}}_{{\text{p}}}\) :

-

Specific non-essential work of fracture

- \({\text{w}}_{{{\text{prop}}}}\) :

-

Specific essential work for crack propagation

- \({\text{w}}_{{{\text{ini}}}}\) :

-

Specific essential work for crack initiation

References

Hottle TA, Bilec MM, Landis AE (2013) Polym Degrad Stab 98:1898

Thakur S, Chaudhary J, Sharma B, Verma A, Tamulevicius S, Thakur VK (2018) Curr Opin Green Sustain Chem 13:68

Albuquerque PBS, Malafaia CB (2018) Int J Biol Macromol 107:615

Ryberg M, Laurent A, Hauschild MZ (2018) Mapping of global plastic value chain and plastic losses to the environment: with a particular focus on marine environment. United Nations Environment Programme, Nairobi

Drzyzga O, Prieto A (2019) Microb Biotechnol 12:66

Agarski B, Vukelic D, Micunovic MI, Budak I (2019) J Environ Manage 245:55

Verma R, Vinoda KS, Papireddy M, Gowda ANS (2016) Waste Manag Resour Util 35:701

Wright SL, Kelly FJ (2017) Environ Sci Technol 51:6634

Benobeidallah B, Benhamida A, Dorigato A, Sola A, Messori M, Pegoretti A (2019) J Renew Mater 7:89

Oulmou F, Benhamida A, Dorigato A, Sola A, Messori M, Pegoretti A (2019) J Elastomers Plast 51:175

Tait M, Pegoretti A, Dorigato A, Kalaitzidou K (2011) Carbon 49:4280

Dorigato A, Sebastiani M, Pegoretti A, Fambri L (2012) J Polym Environ 20:713

Goncalves I, Vasconcelos A, Machado ASL, Alves AV (2017) Bioplastics from agro-wastes for food packaging application. In: Grumezescu AM (ed) Food packaging, 1st edn. Academic Press, Cambridge, pp 223-263

Reddy MM, Misra M, Mohanty AK (2012) Chem Eng Prog 108:37

Ludevese-Pascual G, Laranja JL, Amar E, Bossier P, De Schryver P (2019) Aquac Res 50:1269

Xie FW, Zhang TL, Bryant P, Kurusingal V, Colwell JM, Laycock B (2019) Prog Polym Sci 90:211

Haider TP, Volker C, Kramm J, Landfester K, Wurm FR (2019) Angew Chem Int Ed 58:50

Dorigato A, Pegoretti A (2012) Colloid Polym Sci 290:359

Byun Y, Kim YT (2014) Bioplastics for food packaging. In: Han JH (ed) Innovations in food packaging. Academic Press, San Diego, p 353

Peelman N, Ragaert P, De Meulenaer B, Adons D, Peeters R, Cardon L, Van Impe F, Devlieghere F (2013) Trends Food Sci Technol 32:128

Drumright RE, Gruber PR, Henton DE (2000) Adv Mater 12:1841

Massardier-Nageotte V, Pestre C, Cruard-Pradet T, Bayard R (2006) Polym Degrad Stab 91:620

Valentini F, Dorigato A, Rigotti D, Pegoretti A (2019) J Polym Environ 27:1333

Dorigato A, Negri M, Pegoretti A (2018) J Renew Mater 6:493

Dorigato A, Fredi G, Pegoretti A (2019) Thermo-mechanical behavior of novel wood laminae-thermoplastic starch biodegradable composites with thermal energy storage/release capability. Front Mater 6:76

Halley PJ, Avérous L (2014) Chapter 5—Starch modification to develop novel starch-biopolymer blends: state of art and perspectives. In: Halley PJ, Avérous L (eds) Starch polymers from genetic engineering to green applications. Elsevier, Amsterdam, p 105

Averous L, Fauconnier N, Moro L, Fringant C (2000) J Appl Polym Sci 76:1117

Maharana T, Singh BC (2006) J Appl Polym Sci 100:3229

Nayak PL (1999) J Macromol Sci Rev Macromol Chem Phys C39:481

Doi Y, Fukuda K (1994) Biodegradable plastics and polymers, vol 12. Elsevier, Amsterdam

Lawton JW (1996) Carbohyd Polym 29:203

Yew GH, Chow WS, Ishak ZAM, Yusof AMM (2009) J Elastomers Plast 41:369

Ayucitra A (2012) Int J Chem Eng Appl 3:156

Chi H, Xu K, Wu X, Chen Q, Xue D, Song C, Zhang W, Wang P (2008) Food Chem 106:923

Kaseem M, Hamad K, Deri F (2012) Polym Sci Ser A 54:165

Bastioli C (1998) Polym Degrad Stab 59:263

Colonna P, Mercier C (1985) Phytochemistry 24:1667

Ibrahim MIJ, Sapuan SM, Zainudin ES, Zuhri MYM (2019) Int J Food Prop 22:925

Ali R, Iannace S, Nicolais L (2003) J Appl Polym Sci 88:1637

Laftah WA, Rahman WAWA (2019) Polytechnica 2:51

Thunwall M, Kuthanová V, Boldizar A, Rigdahl M (2008) Carbohyd Polym 71:583

Zhang Y, Rempel C, Liu Q (2014) Crit Rev Food Sci Nutr 54:1353

Williams JG, Rink M (2007) Eng Fract Mech 74:1009

Prashantha SH, Lacrampe MF, Krawczak P (2011) Compos Sci Technol 71:1859

Bárány T, Czigány T, Karger-Kocsis J (2010) Prog Polym Sci 35:1257

Clutton EQ (2000) ESIS TC4 experience with the essential work of fracture method. In: Williams JG, Pavan A (eds) Fracture of polymers, composites and adhesives, second ESIS TC4 conference on fracture of polymers, composites and adhesives. Elsevier, New York, p 187

Dorigato A, Pegoretti A (2012) Eng Fract Mech 79:213

Musto P, Ragosta G, Scarinzi G, Mascia L (2004) Polymer 45:4265

Zhang H, Zhang Z, Yang JL, Friedrich K (2006) Polymer 47:679

Mai YW, Wong SC, Chen X (2000) Polymer blends: formulations and performance. Wiley, New York, p 172

Rodolfo A (2018) J Vinyl Additive Technol 25:3

Benavente R, Perez E, Quijada R (2001) J. Polym Sci Pol Phys 39:277

Zhang Y, Rempel C, McLaren D (2014) Chapter 16—Thermoplastic starch. In: Han JH (ed) Innovations in food packaging, 2nd edn. Academic Press, San Diego, p 391

Dunn T (2015) Oriented plastic films. In: Dunn T (ed) Flexible packaging. William Andrew Publishing, Oxford, p 177

Fambri L, Lutterotti L (2019) Effect of Processing and orientation on structural and mechanical properties of polypropylene products. In: Wang W (ed) Polypropylene. IntechOpen, Hamilton

Hashemi S (2000) Polym Eng Sci 40:798

Selling GW, Sessa DJ (2007) Ind Crops Prod 25:266

Kumaraswamy G, Kornfield JA, Yeh FJ, Hsiao BS (2002) Macromolecules 35:1762

Kimata S, Sakurai T, Nozue Y, Kasahara T, Yamaguchi N, Karino T, Shibayama M, Kornfield JA (2007) Science 316:1014

Nagasawa T, Shimomura Y (1974) J Polym Sci Polym Phys Edit 12:2291

Somani RH, Yang L, Zhu L, Hsiao BS (2005) Polymer 46:8587

Larrañaga A, Lizundia E (2018) Strain-induced crystallization. In: Thomas S et al (eds) Crystallization in multiphase polymer systems. Elsevier, Amsterdam, p 471

Chaléat CM, Halley PJ, Truss RW (2008) Carbohyd Polym 71:535

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dorigato, A., Perin, D. & Pegoretti, A. Effect of the Temperature and of the Drawing Conditions on the Fracture Behaviour of Thermoplastic Starch Films for Packaging Applications. J Polym Environ 28, 3244–3255 (2020). https://doi.org/10.1007/s10924-020-01843-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01843-3