Abstract

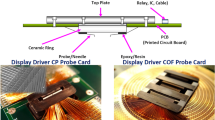

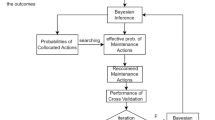

Probe card that serves as the carrier of die and the transmitter of information is an indispensable test interface for integrated circuit testing. The probe card extracts the electrical signal of chip and sends it to the prober to screen defectives. In the process of interface transmission, signal disturbance or attenuation will lead to functional errors, and the output result will be different from the expected one to the screen of selected known good dies for integrated circuit packaging and final test. If abnormal situations happen with probe cards, the engineers will eliminate potential fault causes by trial and error method according to domain knowledge and personal experience for troubleshooting. As semiconductor industry is continuously migrating with shrinking feature size, the diagnosing and troubleshooting procedure for probe card is exponentially complicated and time-consuming. To enhance data integrity of circuit probe testing, this study aims to develop a Bayesian network for probe card fault diagnosis and troubleshooting via the integrated data-driven solutions considering potential rules derived from domain knowledge and manufacturing big data to empower Industry 3.5 smart production. An empirical study is conducted in a leading semiconductor testing company for validation. The experiment results show that the proposed approach can improve one-shot probability from 0.13 to 0.36 to improve one-shot success chance in troubleshooting process. The expected shooting times for probe faults have been reduced from 11 times to 3.96 times on average to save 63.97% of fault troubleshooting efforts in testing process. The proposed approach can provide effective suggestions to shorten troubleshooting time for yield improvement and subsequent packaging cost reduction to empower flexible decision-making for smart production. The results have shown practical viability of proposed approach for Industry 3.5. Indeed, the developed solutions have been implemented in real settings.

Similar content being viewed by others

References

Agarwal, K., & Shivpuri, R. (2015). On line prediction of surface defects in hot bar rolling based on Bayesian hierarchical modeling. Journal of Intelligent Manufacturing, 26(4), 785–800.

Cai, B., Huang, L., & Xie, M. (2017). Bayesian networks in fault diagnosis. IEEE Transactions on Industrial Informatics, 13(5), 2227–2240.

Carrera, Á, Alonso, E., & Iglesias, C. A. (2019). A Bayesian argumentation framework for distributed fault diagnosis in telecommunication networks. Sensors (Basel, Switzerland), 19(15), 3408.

Cheon, S., Lee, H., Kim, C. O., & Lee, S. H. (2019). Convolutional neural network for wafer surface defect classification and the detection of unknown defect class. IEEE Transactions on Semiconductor Manufacturing, 32(2), 163–170.

Chien, C.-F., Chen, S.-L., & Lin, Y.-S. (2002). Using Bayesian network for fault location on distribution feeder. IEEE Transactions on Power Delivery, 17(3), 785–793.

Chien, C.-F., Chen, Y.-H., & Lo, M.-F. (2020a). Advanced quality control of silicon wafer specifications for yield enhancement for smart manufacturing. IEEE Transactions on Semiconductor Manufacturing. https://doi.org/10.1109/TSM.2020.3010200.

Chien, C.-F., & Chuang, S.-C. (2014). A framework for root cause detection of sub-batch processing system for semiconductor manufacturing big data analytics. IEEE Transactions on Semiconductor Manufacturing, 27(4), 475–488.

Chien, C.-F., & Hsu, C.-Y. (2011). UNISON analysis to model and reduce step-and-scan overlay errors for semiconductor manufacturing. Journal of Intelligent Manufacturing, 22(3), 399–412.

Chien, C.-F., Hsu, C.-Y., & Chen, P.-N. (2013). Semiconductor fault detection and classification for yield enhancement and manufacturing intelligence. Flexible Services and Manufacturing Journal, 25(3), 367–388.

Chien, C.-F., Chang, K.-H., & Wang, W.-C. (2014). An empirical study of design-of-experiment data mining for yield-loss diagnosis for semiconductor manufacturing. Journal of Intelligent Manufacturing, 25(5), 961–972.

Chien, C.-F., Liu, C.-W., & Chuang, S.-C. (2017). Analysing semiconductor manufacturing big data for root cause detection of excursion for yield enhancement. International Journal of Production Research, 55(17), 5095–5107.

Chien, C.-F., Dou, R., & Fu, W. (2018). Strategic capacity planning for smart production: Decision modeling under demand uncertainty. Applied Soft Computing, 68, 900–909.

Chien, C.-F., Lin, Y.-S., & Lin, S.-K. (2020b). Deep reinforcement learning for selecting demand forecast models to empower Industry 3.5 and an empirical study for a semiconductor component distributor. International Journal of Production Research, 58(9), 2784–2804.

Chien, C.-F., Wang, H.-J., & Wang, M. (2007). A UNISON framework for analyzing alternative strategies of IC final testing for enhancing overall operational effectiveness. International Journal of Production Economics, 107(1), 20–30.

Darwiche, A. (2009). Modeling and reasoning with Bayesian networks. Cambridge: Cambridge University Press.

Fan, S.-K. S., Hsu, C.-Y., Tsai, D.-M., He, F., & Cheng, C.-C. (2020). Data-driven approach for fault detection and diagnostic in semiconductor manufacturing. IEEE Transactions on Automation Science and Engineering, 1–12.

Fu, W., & Chien, C.-F. (2019). UNISON data-driven intermittent demand forecast framework to empower supply chain resilience and an empirical study in electronics distribution. Computers & Industrial Engineering, 135, 940–949.

Hänninen, M., & Kujala, P. (2012). Influences of variables on ship collision probability in a Bayesian belief network model. Reliability Engineering & System Safety, 102, 27–40.

Hsu, S.-C., & Chien, C.-F. (2007). Hybrid data mining approach for pattern extraction from wafer bin map to improve yield in semiconductor manufacturing. International Journal of Production Economics, 107(1), 88–103.

Hsu, C.-Y., Chen, W.-J., & Chien, J.-C. (2020). Similarity matching of wafer bin maps for manufacturing intelligence to empower industry 3.5 for semiconductor manufacturing. Computers & Industrial Engineering, 142, 106358.

Hu, Y.-F., Hou, J.-L., & Chien, C.-F. (2019). A UNISON framework for knowledge management of university-industry collaboration and an illustration. Computers & Industrial Engineering, 129, 31–43.

Huang, Y., McMurran, R., Dhadyalla, G., & Jones, P., R (2008). Probability based vehicle fault diagnosis: Bayesian network method. Journal of Intelligent Manufacturing, 19(3), 301–311.

Jang, J., Min, B. W., & Kim, C. O. (2019). Denoised residual trace analysis for monitoring semiconductor process faults. IEEE Transactions on Semiconductor Manufacturing, 32(3), 293–301.

Kang, S. (2020). Joint modeling of classification and regression for improving faulty wafer detection in semiconductor manufacturing. Journal of Intelligent Manufacturing, 31(2), 319–326.

Khakifirooz, M., Chien, C.-F., & Chen, Y.-J. (2018). Bayesian inference for mining semiconductor manufacturing big data for yield enhancement and smart production to empower industry 4.0. Applied Soft Computing, 68, 990–999.

Khakifirooz, M., Chien, C.-F., & Fathi, M. (2019). Compensating misalignment using dynamic random-effect control system: A case of high-mixed wafer fabrication. IEEE Transactions on Automation Science and Engineering, 16(4), 1788–1799.

Kim, G.-Y., Kang, S.-H., & Nah, W. (2017). Novel TDR test method for diagnosis of interconnect failures using automatic test equipment. IEEE Transactions on Instrumentation Measurement, 66(10), 2638–2646.

Kim, E., Cho, S., Lee, B., & Cho, M. (2019). Fault detection and diagnosis using self-attentive convolutional neural networks for variable-length sensor data in semiconductor manufacturing. IEEE Transactions on Semiconductor Manufacturing, 32(3), 302–309.

Lee, K. B., Cheon, S., & Kim, C. O. (2017). A convolutional neural network for fault classification and diagnosis in semiconductor manufacturing processes. IEEE Transactions on Semiconductor Manufacturing, 30(2), 135–142.

Li, B., Han, T., & Kang, F. (2013). Fault diagnosis expert system of semiconductor manufacturing equipment using a Bayesian network. International Journal of Computer Integrated Manufacturing, 26(12), 1161–1171.

Liao, C.-S., Hsieh, T.-J., Huang, Y.-S., & Chien, C.-F. (2014). Similarity searching for defective wafer bin maps in semiconductor manufacturing. IEEE Transactions on Automation Science and Engineering, 11(3), 953–960.

Lin, K.-Y., Chien, C.-F., & Kerh, R. (2016). UNISON framework of data-driven innovation for extracting user experience of product design of wearable devices. Computers & Industrial Engineering, 99, 487–502.

Liu, C.-W., & Chien, C.-F. (2013). An intelligent system for wafer bin map defect diagnosis: An empirical study for semiconductor manufacturing. Engineering Applications of Artificial Intelligence, 26(5), 1479–1486.

Liu, Y., & Jin, S. (2013). Application of Bayesian networks for diagnostics in the assembly process by considering small measurement data sets. The International Journal of Advanced Manufacturing Technology, 65(9–12), 1229–1237.

McNaught, K., & Chan, A. (2011). Bayesian networks in manufacturing. Journal of Manufacturing Technology Management, 22(6), 734–747.

Nawaz, J. M., Arshad, M. Z., & Hong, S. J. (2014). Fault diagnosis in semiconductor etch equipment using Bayesian networks. Journal of Semiconductor Technology Science, 14(2), 252–261.

Rato, T. J., Blue, J., Pinaton, J., & Reis, M. S. (2016). Translation-invariant multiscale energy-based PCA for monitoring batch processes in semiconductor manufacturing. IEEE Transactions on Automation Science and Engineering, 14(2), 894–904.

Rostami, H., Blue, J., & Yugma, C. (2018). Automatic equipment fault fingerprint extraction for the fault diagnostic on the batch process data. Applied Soft Computing, 68, 972–989.

Sata, A., & Ravi, B. (2017). Bayesian inference-based investment-casting defect analysis system for industrial application. The International Journal of Advanced Manufacturing Technology, 90(9), 3301–3315.

Verbert, K., Babuška, R., & De Schutter, B. (2017). Bayesian and Dempster–Shafer reasoning for knowledge-based fault diagnosis–A comparative study. Engineering Applications of Artificial Intelligence, 60, 136–150.

Wang, J., Wang, Z., Stetsyuk, V., Ma, X., Gu, F., & Li, W. (2019). Exploiting Bayesian networks for fault isolation: A diagnostic case study of diesel fuel injection system. ISA Transactions, 86, 276–286.

Yang, L., & Lee, J. (2012). Bayesian Belief Network-based approach for diagnostics and prognostics of semiconductor manufacturing systems. Robotics Computer-Integrated Manufacturing, 28(1), 66–74.

Yu, H., Khan, F., & Garaniya, V. (2015). Modified independent component analysis and Bayesian network-based two-stage fault diagnosis of process operations. Industrial & Engineering Chemistry Research, 54(10), 2724–2742.

Zhou, Z., Wen, C., & Yang, C. (2014). Fault detection using random projections and k-nearest neighbor rule for semiconductor manufacturing processes. IEEE Transactions on Semiconductor Manufacturing, 28(1), 70–79.

Acknowledgements

This research is supported by Ministry of Science and Technology, Taiwan (MOST 108-2634-F-007 -001; MOST 108-2634-F-007 -008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fu, W., Chien, CF. & Tang, L. Bayesian network for integrated circuit testing probe card fault diagnosis and troubleshooting to empower Industry 3.5 smart production and an empirical study. J Intell Manuf 33, 785–798 (2022). https://doi.org/10.1007/s10845-020-01680-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-020-01680-0