Abstract

The use of microreactors in the continuous fluidic system has been rapidly expanded over the past three decades. Developments in materials science and engineering have accelerated the advancement of the microreactor technology, enabling it to play a critical role in chemical, biological, and energy applications. The emerging paradigm of digital additive manufacturing broadens the range of the material flexibility, innovative structural design, and new functionality of the conventional microreactor system. The control of spatial arrangements with functional printable materials determines the mass transport and energy transfer within architected microreactors, which are significant for many emerging applications, including use in catalytic, biological, battery, or photochemical reactors. However, challenges such as lack of design based on multiphysics modeling and material validation are currently preventing the broader applications and impacts of functional microreactors conjugated with digital manufacturing beyond the laboratory scale. This review covers a state-of-the-art of research in the development of some of the most advanced digital manufactured functional microreactors. We then the outline major challenges in the field and provide our perspectives on future research and development directions.

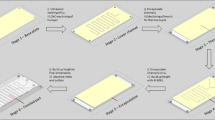

(Reprinted from reference [11] with permission)

(a Reprinted from reference [47] with permission. b Reprinted from reference [48] with permission. c Reprinted from reference [34] with permission. d Reprinted from reference [49] with permission. e Reprinted from reference [50] with permission. f Reprinted from reference [51] with permission. g Reprinted from reference [52] with permission)

Similar content being viewed by others

References

Ehrfeld, W., Hessel, V., & Lowe, H. (2000). Microreactors: new technology for modern chemistry. Weinheim: WILEY-VCH Verlag GmbH.

Yazdi, A., Popma, A., Wong, A., Nguyenm, W., Pan, T., Y., and Xu, J. (2016). 3D printing: an emerging tool for novel microfluidics and lab-on-a-chip applications. Microfluid Nanofluid, 20(3), 50.

Ikuta, K., Maruo, S., Fujisawa, T., & Tamada, A. (1999). Micro concentrator with opto-sense micro reactor for biochemical IC chip family. 3D composite structure and experimental verification. In: International workshop on micro electro mechanical systems, MEMS 12, pp. 376–381.

Ikuta, K., Ogata, T., Tsubio, M., & Kojima, S. (1996). Development of mass productive micro stereo lithography (Mass-IH process). In: Proceedings of ninth international workshop on micro electromechanical systems, pp. 301–306.

Ikuta, K., Hirowatari, K., & Ogata, T. (1994). Three dimensional micro integrated fluid systems (MIFS) fabricated by stereo lithography. In: Proceedings IEEE micro electro mechanical systems an investigation of micro structures, sensors, actuators, machines and robotic systems, pp. 1–6.

Ikuta, K., Maruo, T., Fukaya, Y., & Fujisawa, T. (1998). Biochemical IC chip toward cell free DNA protein synthesis. In: Proceedings MEMS 98. IEEE. Eleventh annual international workshop on micro electro mechanical systems. An investigation of micro structures, sensors, actuators, machines and systems, 98CH36176, pp. 131–136.

Teh, K. (2017). Additive direct-write microfabrication for MEMS: a review. Frontiers of Mechanical Enginerring, 12(4), 490–509.

Parra-Cabrera, C., Achille, C., Kuhn, S., & Ameloot, R. (2018). 3D printing in chemical engineering and catalytic technology: structured catalysts, mixers and reactors. Chemical Society Reviews, 47(1), 209–230.

Surjadi, J. U., Gao, L., Du, H., Li, X., Xiong, X., Fang, N. X., et al. (2019). Mechanical metamaterials and their engineering applications. Advanced Engineering Materials, 21(3), 1800864.

Parra-Cabrera, C., Achille, C., Kuhn, S., & Ameloot, R. (2018). 3D printing in chemical engineering and catalytic technology: structured catalysts, mixers and reactors. Chemical Society Reviews, 47(1), 209–230.

Moroni, L., Boland, T., Burdick, J. A., Maria, C., Derby, B., Forgacs, C., et al. (2018). Biofabrication: a guide to technology and terminology. Trends in Biotechnology, 36(4), 384–402.

Simpson, R. L., Wiria, F. E., Amis, A. A., Chua, C. K., Leong, K. F., Hansen, U. N., Chandrasekaran, M., & Lee, M. W. (2008). Development of a 95/5 poly (L-lactide‐co‐glycolide)/hydroxylapatite and β‐tricalcium phosphate scaffold as bone replacement material via selective laser sintering. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 84(1), 17–25.

Zhou, W. Y., Lee, S. H., Wang, M., Cheung, W. L., & Ip, W. Y. (2008). Selective laser sintering of porous tissue engineering scaffolds from poly (L-lactide)/carbonated hydroxyapatite nanocomposite microspheres. Journal of Materials Science: Materials in Medicine, 19(7), 2535–2540.

Wang, Z., Abdulla, R., Parker, B., Samanipour, R., Ghosh, S., & Kim, K. (2015). A simple and high-resolution stereolithography-based 3D bioprinting system using visible light crosslinkable bioinks. Biofabrication, 7(4), 045009.

Schaedler, T. A., & Carter, W. B. (2016). Architected cellular materials. Annual Review of Materials Research, 46, 187–210.

Ge, Q., Li, Z., Wang, Z., Zhang, W., He, X., Zhou, J., & Fang, N. (2020). Projection micro stereolithography based 3D printing and its applications. International Journal of Extreme Manufacturing. https://doi.org/10.1088/2631-7990/ab8d9a

Ovsianikov, A., & Chichkov, B. N. (2012). Three-dimensional microfabrication by two-photon polymerization technique. Methods in Molecular Biology, 868, 311–325.

Ge, Q., Sakhaei, A. H., Lee, H., Dunn, C. K., Fang, N. X., & Dunn, M. L. (2016). Multimaterial 4D printing with tailorable shape memory polymers. Scientific Reports, 6, 31110.

Sun, C., Fang, N., Wu, D. M., & Zhang, X. (2005). Projection micro-stereolithography using digital micro-mirror dynamic mask. Sensors and Actuators A: Physical, 121(1), 113–120.

Gauvin, R., Chen, Y. C., Lee, J. W., Soman, P., Zorlutuna, P., Nichol, J. W., Bae, H., Chen, S., & Khademhosseini, A. (2012). Microfabrication of complex porous tissue engineering scaffolds using 3D projection stereolithography. Biomaterials, 33(15), 3824–3834.

Tumbleston, J. R., Shirvanyants, D., Ermoshkin, N., Janusziewicz, R., Johnson, A. R., Kelly, D., et al. (2015). Continuous liquid interface production of 3D objects. Science, 347(6228), 1349–1352.

Jacobsen, A. J., Barvosa-Carter, W., & Nutt, S. (2007). Micro‐scale truss structures formed from self‐propagating photopolymer waveguides. Advanced Materials, 19(22), 3892–3896.

Moroni, L., De Wijn, J. R., & Van Blitterswijk, C. A. (2006). 3D fiber-deposited scaffolds for tissue engineering: influence of pores geometry and architecture on dynamic mechanical properties. Biomaterials, 27(7), 974–985.

Giordano, R. A., Wu, B. M., Borland, S. W., Cima, L. G., Sachs, E. M., & Cima, M. J. (1997). Mechanical properties of dense polylactic acid structures fabricated by three dimensional printing. Journal of Biomaterials Science, Polymer Edition, 8(1), 63–75.

Pfister, A., Landers, R., Laib, A., Hübner, U., Schmelzeisen, R., & Mülhaupt, R. (2004). Biofunctional rapid prototyping for tissue-engineering applications: 3D bioplotting versus 3D printing. Journal of Polymer Science Part A: Polymer Chemistry, 42(3), 624–638.

Deitzel, J. M., Kleinmeyer, J., Harris, D. E. A., & Tan, N. B. (2001). The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer, 42(1), 261–272.

Bashur, C. A., et al. (2006). Effect of fiber diameter and orientation on fibroblast morphology and proliferation on electrospun poly(D,L-lactic-co-glycolic acid) meshes. Biomaterials, 27, 5681–5688.

Shusteff, M., Browar, A. E. M., Kelly, B. E., Henriksson, J., Weisgraber, T. H., & Panas, R. M. (2017). One-step volumetric additive manufacturing of complex polymer structures. Science Advances, 3(12), eaao5496.

Kelly, B. E., Bhattacharya, I., Heidari, H., Shusteff, M., Spadaccini, C. M., & Taylor, H. K. (2019). Volumetric additive manufacturing via tomographic reconstruction. Science, 363(6431), 1075–1079.

Beer, M. P., Laan, H. L., Cole, M. A., Whelan, R. J., Burns, M. A., & Scott, T. F. (2019). Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Science Advances, 5(1), eaau8723.

Leung, Y. S., Kwok, T. H., Li, X., Yang, Y., Wang, C. C., & Chen, Y. (2019). Challenges and status on design and computation for emerging additive manufacturing technologies. Journal of Computing and Information Science in Engineering, 19(2), 021013.

Guzzi, E. A., & Tibbitt, M. W. (2020). Additive manufacturing of precision biomaterials. Advanced Materials, 32(13), 1901994.

Chen, X., Liu, W., Dong, B., Lee, J., Ware, H. O. T., Zhang, H. F., et al. (2018). High-speed 3D printing of millimeter‐size customized aspheric imaging lenses with sub 7 nm surface roughness. Advanced Materials, 30(18), 1705683.

Urrios, A., Parra-Cavrera, C., Bhattacharjee, N., Gonzalez-Suarez, A. M., Rigat-Brugarolas, L. G., Nallapatti, U., et al. (2016). 3D-printing of transparent bio-microfluidic devices in PEG-DA. Lab on a Chip, 16(12), 2287–2294.

Cutmann, B., Kockinger, M., Glotz, G., Ciaglia, T., Slama, E., Zadravec, M., et al. (2017). Design and 3D printing of a stainless steel reactor for continuous difluoromethylations using fluoroform. Reaction Chemistry & Engineering, 2(6), 919–927.

Osanov, M., & Guset, J. K. (2016). Topology optimization for architected materials design. Annual Review of Materials Research, 46, 211–233.

Okkels, F., & Bruus, H. (2007). Scaling behavior of optimally structured catalytic microfluidic reactors. Physical Review E, 75(1), 016301.

Bai, H., Theuerkauf, J., Gillis, P. A., & Witt, P. M. (2009). A coupled DEM and CFD simulation of flow field and pressure drop in fixed bed reactor with randomly packed catalyst particles. Industrial & Engineering Chemistry Research, 48(8), 4060–4074.

Torre, A. D., Montenegro, G., Onroati, A., & Tabor, G. (2015). CFD characterization of pressure drop and heat transfer inside porous substrates. Energy Procedia, 81, 836–845.

Kao, P.-H., Ren, T.-F., & Yang, R.-J. (2007). An investigation into fixed-bed microreactors using lattice Boltzmann method simulations. International Journal of Heat and Mass Transfer, 50(21–22), 4243–4255.

Ortega-Casanova, J. (2017). Application of CFD on the optimization by response surface methodology of a micromixing unit and its use as a chemical microreactor. Chemical Engineering and Processing: Process Intensification, 117, 18–26.

Tonomura, O., Tanaka, S., & Noda, M. (2004). CFD-based optimal design of manifold in plate-fin microdevices. Chemical Engineering Journal, 101(1–3), 397–402.

Schapper, D., Fernandes, R. L., Lantz, A. E., Okkels, F., Bruus, H., & Gernaeym, K. V. (2010). Topology optimized microbioreactors. Biotechnology and Bioengineering, 108(4), 786–796.

Egan, P. F., Gonella, V. C., Engensperger, M., Ferguson, S. J., & Shea, K. (2017). Computationally designed lattices with tuned properties for tissue engineering using 3D printing. PLOS One, 12(8), e0182902.

Kitson, P. J., Marshall, R. J., Long, D., Forgan, R. S., & Cronin, L. (2014). 3D printed high-throughput hydrothermal reactionware for discovery, optimization, and scale‐up. Angewandte Chemie International Edition in English, 53(47), 12723–12728.

Capel, A. J., Edmondson, S., Christie, S. D. R., Goodridge, R. D., Bibb, R. J., & Thurstans, M. (2013). Design and additive manufacture for flow chemistry. Lab on a Chip, 13(23), 4583–4590.

Rossi, S., Porta, R., Brenna, D., Puglisi, A., & Benaglia, M. (2017). Stereoselective catalytic synthesis of active pharmaceutical ingredients in homemade 3D-printed mesoreactors. Angewandte Chemie, 56(15), 4290–4294.

Sochol, R. D., Sweet, E., Glick, C. C., Venkatesh, S., Avetisyan, A., Ekman, K. F., et al. (2016). 3D printed microfluidic circuitry via multijet-based additive manufacturing. Lab on a Chip, 16(4), 668–678.

Gong, H., Woolley, A. T., & Nordin, G. P. (2016). High density 3D printed microfluidic valves, pumps, and multiplexers. Lab on a Chip, 16(13), 2450–2458.

Bhargava, K. C., Thompson, B., & Malmstadt, N. (2014). Discrete elements for 3D microfluidics. Proceedings of the National Academy of Sciences, 111(42), 15013–15018.

Symes, M. D., Kitson, P. J., Yan, J., Richmond, C. J., Cooper, G. J. T., Bowman, R. W., et al. (2012). Integrated 3D-printed reactionware for chemical synthesis and analysis. Nature Chemistry, 4(5), 349–354.

Xia, C., & Fang, N. X. (2009). 3D microfabricated bioreactor with capillaries. Biomedical Microdevices, 11(6), 1309–1315.

Roper, C. S., Schubert, R. C., Maloney, K. J., Page, D., Ro, C. J., Yang, S. S., et al. (2015). Scalable 3D bicontinuous fluid networks: polymer heat exchangers toward artificial organs. Advanced Materials, 27(15), 2479–2484.

Espinosa-Hoyos, D., Jagielska, A., Homan, K. A., Du, H., Busbee, T., Anderson, D. G., et al. (2018). Engineered 3D-printed artificial axons. Scientific Reports, 8(1), 478.

Ma, X., Qu, X., Zhu, W., Li, Y., Yuan, S., Zhang, H., et al. (2016). Deterministically patterned biomimetic human iPSC-derived hepatic model via rapid 3D bioprinting. Proceedings of the National Academy of Sciences of the United States of America, 113(8), 2206–2211.

Zhao, Y., Yao, R., Ouyang, L., Ding, H., Zhnag, T., Zhang, K., et al. (2014). Three-dimensional printing of Hela cells for cervical tumor model in vitro. Biofabrication, 6(3), 035001.

Yang, D., Niu, X., Liu, Y., Wang, T., Gu, X., Song, L., et al. (2018). Electrospun nanofibrous membranes: a novel solid substrate for microfluidic immunoassays for HIV. Advanced Materials, 20(24), 4770–4775.

Lee, H., & Cho, D. (2016). One-step fabrication of an organ-on-a-chip with spatial heterogeneity using a 3D bioprinting technology. Lab on a Chip, 16(14), 2618–2625.

Li, H., Tan, C., & Li, L. (2018). Review of 3D printable hydrogels and constructs. Materials & Design, 159, 20–38.

Leon, C. P., Hussey, W., Frazao, F., Jones, D., Ruggeri, E., Tzortzatos, S., et al. (2014). The 3D printing of a polymeric electrochemical cell body and its characterisation. Chemical Engineering Transactions, 41, 1–6.

Guo, N., Leu, M. C., & Koylu, U. O. (2014). Bio-inspired flow field designs for polymer electrolyte membrane fuel cells. International Journal of Hydrogen Energy, 39(36), 21185–21195.

Chisholm, G., Kitson, P. J., Kirkaldy, N. D., Bloor, L. G., & Cronin, L. (2018). 3D printed flow plates for the electrolysis of water: an economic and adaptable approach to device manufacture. Energy & Environmental Science, 7(9), 3026–3032.

Hashemi, S. M. H., Karnakov, P., Hadikhani, P., Chinello, E., Litvinov, S., Moser, C., et al. (2019). A versatile and membrane-less electrochemical reactor for the electrolysis of water and brine. Energy & Environmental Science, 12(5), 1592–1604.

Lee, C., Taylor, A. C., Beirne, S., & Wallace, G. G. (2017). 3D-printed conical arrays of TiO2 electrodes for enhanced photoelectrochemical water splitting. Advanced Energy Materials, 7(21), 1701060.

Zhu, C., Qi, Z., Beck, V. A., Luneau, m, Lattimer, J., Chen, W., et al. (2018). Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing. Science Advances, 4(8), eaas9459.

Tian, X., Jin, J., Yuan, S., Chua, C. K., Tor, S. B., & Zhou, K. (2017). Emerging 3D-printed electrochemical energy storage devices: a critical review. Advanced Energy Materials, 7(17), 1700127.

Yuan, S., Shen, F., Chua, C. K., & Zhou, K. (2019). Polymeric composites for powder-based additive manufacturing: materials and applications. Progress in Polymer Science, 91, 141–168.

Li, R., Yuan, S., Zhang, W., Zheng, H., Zhu, W., Li, B., et al. (2019). 3D printing of mixed matrix films based on metal–organic frameworks and thermoplastic polyamide 12 by selective laser sintering for water applications. ACS Applied Materials & Interfaces, 11(43), 40564–40574.

Kotz, F., Risch, P., Helmer, D., & Rapp, B. E. (2019). High-performance materials for 3D printing in chemical synthesis applications. Advanced Materials, 31(26), 1805982.

https://www.car-engineer.com/cordierite-for-catalytic-converters/.

U.S. EPA Tier 3, https://www.epa.gov/regulations-emissions-vehicles-and-engines/final-rule-control-air-pollution-motor-vehicles-tier-3.

Tubio, C. R., Azuaje, J., Escalante, L., Coelho, A., Guitian, F., Sotelo, E., et al. (2016). 3D printing of a heterogeneous copper-based catalyst. Journal of Catalysis, 334, 110–115.

Konarova, M., Aslam, W., Ge, L., Ma, Q., Tang, F., Rudolph, V., et al. (2017). Enabling process intensification by 3D printing of catalytic structures. ChemCatChem, 9(21), 4132–4138.

Al-Ketan, O., Pelanconi, M., Ortona, A., & Al-Rub, R. K. A. (2019). Additive manufacturing of architected catalytic ceramic substrates based on triply periodic minimal surfaces. Journal of the American Ceramic Society, 102(10), 6176–6193.

Zhou, X., & Liu, C. (2017). Three-dimensional printing for catalytic applications: current status and perspectives. Advanced Functional Materials, 27(30), 1701134.

Hensleigh, R. M., Cui, H., Oakdale, J. S., Ye, J. C., Campbell, P. G., Duoss, E. B., et al. (2018). Additive manufacturing of complex micro-architected graphene aerogels. Materials Horizons, 5(6), 1035–1041.

Zhu, C., Han, Y., Duoss, E. B., Golobic, A. M., Kuntz, J. D., Spadaccini, C. M., et al. (2015). Highly compressible 3D periodic graphene aerogel microlattices. Nature Communications, 6(1), 6962.

Zhakeyev, A., Wang, P., & Zhang, L. (2017). Additive manufacturing unlocking the evolution of energy materials. Advanced Science, 4(10), 1700187.

Sun, K., Wei, T., Ahn, B. Y., Seo, J. Y., Dillon, S. J., & Lewis, J. A. (2013). 3D printing of interdigitated Li-ion microbattery architectures. Advanced Materials, 25(33), 4539–4543.

Saleh, M. S., Li, J., Park, J., & Panat, R. (2018). 3D printed hierarchically-porous microlattice electrode materials for exceptionally high specific capacity and areal capacity lithium ion batteries. Additive Manufacturing, 23, 70–78.

Xu, C., Gallant, B. M., Wunderlich, P. U., Lohmann, T., & Greer, J. R. (2015). Three-dimensional Au microlattices as positive electrodes for Li–O2 batteries. ACS nano, 9(6), 5876–5883.

Cambie, D., Zhao, F., Hessel, V., Debije, M. G., & Noel, T. (2016). A leaf-inspired luminescent solar concentrator for energy‐efficient continuous‐flow photochemistry. Angewandte Chemie International Edition, 56(4), 1050–1054.

Zhao, F., Cambie, D., Janse, J., Wieland, E. W., Kuijpers, K. P. L., Hessel, V., et al. (2018). Scale-up of a luminescent solar concentrator-based photomicroreactor via numbering-up. ACS Sustainable Chemistry & Engineering, 6(1), 422–429.

Leung, Y.-S., Kwok, T.-H., Li, X., Yang, Y., Wang, C. C. L., & Chen, Y. (2019). Challenges and status on design and computation for emerging additive manufacturing technologies. Journal of Computing and Information Science in Engineering, 19(2), 021013.

Vaezi, M., Chianrabutra, S., Mellor, B., & Yang, S. (2013). Multiple material additive manufacturing – part 1: a review. Virtual and Physical Prototyping, 8(1), 19–50.

Lind, J. U., Busbee, T. A., Valentine, A. D., Pasqualini, F. S., Yuan, H., Yadid, M., et al. (2016). Instrumented cardiac microphysiological devices via multimaterial three-dimensional printing. Nature Materials, 16, 303–308.

Mayer, F., Richter, S., Westhauser, J., Blasxo, E., Barner-Kowollik, C., & Wegener, M. (2019). Multimaterial 3D laser microprinting using an integrated microfluidic system. Science Advances, 5(2), eaau9160.

MacDonald, E., & Wicker, R. (2016). Multiprocess 3D printing for increasing component functionality. Science, 353(6307), aaf2093.

Chu, W.-S., Kim, M.-S., Jang, K.-H., Song, J.-H., Rodrigue, H., Chun, D.-M., et al. (2016). From design for manufacturing (DFM) to manufacturing for design (MFD) via hybrid manufacturing and smart factory: a review and perspective of paradigm shift. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(2), 209–222.

Yoon, H.-S., Jang, K.-H., Kim, E., Lee, H.-T., & Ahn, S.-H. (2017). Hybrid 3D printing by bridging micro/nano processes. International Journal of Precision Engineering and Manufacturing-Green Technology, 27(6), 065006.

Yoon, H.-S., Lee, H.-T., Jang, K.-H., Kim, C.-S., Park, H., Kim, D.-W., et al. (2017). CAD/CAM for scalable nanomanufacturing: a network-based system for hybrid 3D printing. Microsystems & Nanoengineering, 3, 17072.

Lim, J., Kim, Y. K., Won, D. J., Choi, I. H., Lee, S., & Kim, J. (2019). 3D printing of freestanding overhanging structures utilizing an in situ light guide. Advanced Materials Technologies, 4(8), 1900118.

Kim, D.-H., Kim, T. J. Y., Wang, X., Kim, M., Quan, Y.-J., Oh, J. W., et al. (2018). Smart machining process using machine learning: a review and perspective on machining industry. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(4), 555–568.

Qi, X., Chen, G., Li, Y., Cheng, X., & Li, C. (2019). Applying neural-network-based machine learning to additive manufacturing: current applications, challenges, and future perspectives. Engineering, 5(4), 721–729.

Zhou, Z., Li, X., & Zare, R. N. (2017). Optimizing chemical reactions with deep reinforcement learning. ACS Central Science, 3(12), 1337–1344.

Edington, C. D., Chen, W. L. K., Geishecker, E., Kassis, T., Soenksen, L. R., hushan, B. M., et al. (2018). Interconnected microphysiological systems for quantitative biology and pharmacology studies. Scientific Reports, 8, 4530.

Malinauskas, M., Zukauskas, A., Hasegawa, S., Hayasaki, Y., Mizeikis, V., Buividas, R., et al. (2016). Ultrafast laser processing of materials: from science to industry. Light: Science & Applications, 5(8), e16133.

Hansen, C. J., Saksena, R., Kolesky, D. B., Vericella, J. J., Kranz, S. J., Muldowney, G. P., et al. (2012). High-throughput printing via microvascular multinozzle arrays. Advanced Materials, 25(1), 96–102.

Xu, B., Du, W.-Q., Li, J.-W., Hu, Y.-L., Yang, L., Zhang, C.-C., et al. (2016). High efficiency integration of three-dimensional functional microdevices inside a microfluidic chip by using femtosecond laser multifoci parallel microfabrication. Scientific Reports, 6, 19989.

Chang, J., Lee, S., Lee, K. B., Lee, S., Cho, Y. T., Seo, J., et al. (2015). Overlay accuracy on a flexible web with a roll printing process based on a roll-to-roll system. The Review of scientific instruments, 86(5), 055108.

Hempel, M., Lu, A.-Y., Hui, F., Kpulun, T., Lanza, M., Harris, G., et al. (2018). Repeated roll-to-roll transfer of two-dimensional materials by electrochemical delamination. Nanoscale, 10(2), 5522–5531.

Liang, H.-L., Bay, M. M., Vadrucci, R., Barty-King, C. H., Peng, J., Baumberg, J. J., et al. (2018). Roll-to-roll fabrication of touch-responsive cellulose photonic laminates. Nature Communication, 9(1), 4632.

Liedert, H. J., Hiltunen, C., Huttunen, M., Hiitola-Keinanen, O. H., Aikio, J., S., et al (2018). Roll-to-roll fabrication of integrated PDMS-paper microfluidics for nucleic acid amplification. Lab on a Chip, 18(11), 1552–1559.

Wang, Q., Jackson, J. A., Hopkins, G. E. Q., Spadaccini, J. B., & Fang, N. X. (2016). Lightweight mechanical metamaterials with tunable negative thermal expansion. Physical Review Letter, 117, 175901.

Acknowledgements

SK and NXF acknowledge support of a seed grant from the MIT Energy Initiative. NXF acknowledges support by the U. S. Army Research Office through the Institute for Soldier Nanotechnologies at MIT, under Contract Number W911NF-13-D-0001. SK acknowledges the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (NRF-2019R1A5A808320112). DHK, WK, and YTC acknowledge support from the Technology Innovation Program (20007064, Realization of air cleaning mobility HAMA (superHydrophobic Additive Manufactured Air cleaner) Project funded by the Ministry of Trade, Industy and Energy (MOTIE, Korea) and all authors acknowledge support from the Ministry of Trade, Industry and Energy (MOTIE, Korea) under Industrial Technology Innovation Program (No. 20000665, Development of ecofriendly and highly durable surface treatment for superomniphobic substrate on the large area over 4 m2).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, S., Kim, D.H., Kim, W. et al. Additive Manufacturing of Functional Microarchitected Reactors for Energy, Environmental, and Biological Applications. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 303–326 (2021). https://doi.org/10.1007/s40684-020-00277-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-020-00277-5