Abstract

This work investigates the flow and heat transfer on the gas side of a heat recovery steam generator. During the operation of a power plant, off-design conditions that significantly impact the steam generator efficiency, caused by variations in the gas flow, corrosion and fouling of tube walls, may be encountered. In addition, passages around the heat exchanger modules develop along the equipment lifetime, allowing the bypass of flowing gas into zones of the boiler of low heat transfer effectiveness. These issues are here addressed via computational simulations, using a commercial software application for solving the mass, momentum, and energy conservation equations. The boiler geometry and the boundary conditions for the simulations are taken from a real, typical industrial heat recovery steam generator fed by gas turbines exhaust gases. Flow turbulence is modeled using the k-\({\epsilon}\) model, and heat exchanger modules are considered as porous media, through which the exhaust gases flow while supplying heat to the water. The water flow properties are specified from process data. Numerical results for thirteen realistic off-design conditions are compared to those for the boiler normal operation point. It is found that the cases considering deviation of gas to the trapdoors and lateral passages have the greatest impact on the boiler efficiency. Results indicate an efficiency drop from 86% for the base case to 48% for the case with gas deviations. In addition, a reduction in the gas flow or the plugging of the low-pressure economizer tubes may decrease the boiler efficiency by more than 10% points.

Similar content being viewed by others

Abbreviations

- HRSG:

-

Heat recovery steam generator

- LP:

-

Low pressure

- IP:

-

Intermediate pressure

- HP:

-

High pressure

- \(A\) :

-

Total heat transfer area, \({\text{m}}^{2}\)

- \(A_{c}\) :

-

Free flow area, \({\text{m}}^{2}\)

- \(C_{\mu }\) :

-

k-\({\epsilon}\)model dimensionless constant

- \(f\) :

-

Flow friction factor, dimensionless

- \(G\) :

-

Velocity, \({\text{m/s}}\)

- \(G_{k}\) :

-

Volumetric production rate of turbulent kinetic energy, \({\text{W/m}}^{3}\)

- \(k\) :

-

Turbulent kinetic energy, \({\text{J/kg}}\)

- \(k_{\text{T}}\) :

-

Thermal conductivity, \({\text{W/}}\left( {{\text{m}}\;{\text{K}}} \right)\)

- \(K_{c}\) :

-

Inlet loss coefficient, dimensionless

- \(K_{\text{e}}\) :

-

Exit loss coefficient, dimensionless

- \(p\) :

-

Pressure, manometric pressure, \({\text{kPa}} = 10^{3} \cdot {\text{kg/}}\left( {{\text{m}}\;{\text{s}}^{2} } \right)\)

- \(P_{1}\) :

-

Heat exchanger inlet pressure, \({\text{kPa}}\)

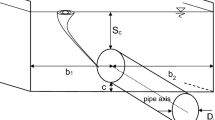

- \({\mathbf{S}}_{\text{M}}\) :

-

Volumetric source term for momentum, \({\text{N/m}}^{3} = {\text{kg/}}\left( {{\text{m}}^{2} \;{\text{s}}^{2} } \right)\)

- \(S_{u}\) :

-

Internal energy source term, \({\text{W/m}}^{3}\)

- \(T\) :

-

Temperature, \({\text{K}}\)

- \(u\) :

-

Internal energy, \({\text{J/kg}}\)

- \(v_{1}\) :

-

Specific volume at point 1 of the flow, \({\text{m}}^{3} / {\text{kg}}\)

- \(v_{2}\) :

-

Specific volume at point 2 of the flow, \({\text{m}}^{3} / {\text{kg}}\)

- \(v_{m}\) :

-

Average specific volume (\(v_{1} + v_{2}\))/2, \({\text{m}}^{3} / {\text{kg}}\)

- \({\mathbf{v}}\) :

-

Local velocity vector, \({\text{m/s}}\)

- \(v_{\text{avg}}\) :

-

Cross section average velocity, \({\text{m/s}}\)

- \(W\) :

-

Volumetric flow rate, \({\text{m}}^{3} / {\text{s}}\)

- \(\alpha\) :

-

Numerical method apparent order

- \(\beta\) :

-

Boiler efficiency

- \(\Delta P\) :

-

Stream pressure drop, \({\text{kPa}}\)

- \({\epsilon}\) :

-

Turbulent rate of viscous dissipation, \({\text{J/}}\left( {{\text{kg}}\;{\text{s}}} \right)\)

- \(\rho\) :

-

Fluid density, kg/m3

- \(\mu\) :

-

Dynamic viscosity, \({\text{Pa}}\;{\text{s}} = {\text{kg/}}\left( {{\text{m}}\;{\text{s}}} \right)\)

- \(\mu_{\text{t}}\) :

-

Eddy viscosity, \({\text{Pa}}\;{\text{s}} = {\text{kg/}}\left( {{\text{m}}\;{\text{s}}} \right)\)

- \(\sigma_{k}\) :

-

Turbulent Prandtl number for \(k\)

- \(\sigma_{\epsilon}\) :

-

Turbulent Prandtl number for \({\epsilon}\)

- \(\sigma\) :

-

Porosity, dimensionless

- \({\varvec{\Phi}}\) :

-

Dissipation function, \({\text{W/m}}^{3}\)

- i, j, k :

-

Indices

- \({\text{t}}\) :

-

Turbulent flow

- \(m\) :

-

Average value

References

Coelho PJ (1999) Mathematical modeling of the convection chamber of a utility boiler—an application. Numer Heat Transf Part A Appl 36(4):411–428. https://doi.org/10.1080/104077899274723

Yang J, Maa L, Bock J, Jacobi AM, Liu W (2014) A comparison of four numerical modeling approaches for enhanced shell-and-tube heat exchangers with experimental validation. Appl Therm Eng 65(1–2):369–383. https://doi.org/10.1016/j.applthermaleng.2014.01.035

Gómez A, Fueyo N, Díez LI (2008) Modelling and simulation of fluid flow and heat transfer in the convective zone of a power-generation boiler. Appl Therm Eng 28(5–6):532–546. https://doi.org/10.1016/j.applthermaleng.2007.04.019

Zima W (2019) Simulation of rapid increase in the steam mass flow rate at a supercritical power boiler outlet. Energy 173:995–1005. https://doi.org/10.1016/j.energy.2019.02.127

Taler J, Zima W, Ocłoń P, Grądziel S, Taler D, Cebula A, Jaremkiewicz M, Korzeń A, Cisek P, Kaczmarski K, Majewskic K (2019) Mathematical model of a supercritical power boiler for simulating rapid changes in boiler thermal loading. Energy 175:580–592. https://doi.org/10.1016/j.energy.2019.03.085

Mertens N, Alobaid F, Starkloff R, Epple B, Kim H-G (2015) Comparative investigation of drum-type and once-through heat recovery steam generator during start-up. Appl Energy 144:250–260. https://doi.org/10.1016/j.apenergy.2015.01.065

Mertens N, Alobaid F, Lanz T, Epple B, Kim H-G (2016) Dynamic simulation of a triple-pressure combined-cycle plant: hot start-up and shutdown. Fuel 167:135–148. https://doi.org/10.1016/j.fuel.2015.11.055

Benato A, Stoppato A, Mirandola A (2015) Dynamic behavior analysis of a three pressure level heat recovery steam generator during transient operation. Energy 90(Part 2):1595–1605. https://doi.org/10.1016/j.energy.2015.06.117

Manassaldi JI, Arias AM, Scenna NJ, Mussati MC, Mussati SF (2016) A discrete and continuous mathematical model for the optimal synthesis and design of dual pressure heat recovery steam generators coupled to two steam turbines. Energy 103:807–823. https://doi.org/10.1016/j.energy.2016.02.129

Hanafizadeh P, Falahatkar S, Ahmadi P, Siahkalroudi MM (2015) A novel method for inlet duct geometry improvement of heat recovery steam generators. Appl Therm Eng 89:125–133. https://doi.org/10.1016/j.applthermaleng.2015.05.075

Hanafizadeh P, Siahkalroudi MM, Ahmadi P (2016) Experimental and numerical investigation of optimum design of semi industrial heat recovery steam generator inlet duct. Appl Therm Eng 104:375–385. https://doi.org/10.1016/j.applthermaleng.2016.05.024

Choi SM, Moon H, Kim SH, Park JS, Cho HH (2016) The effects of thermal spreaders on reducing thermal cracks in heat recovery steam generators. Appl Therm Eng 108:1251–1260. https://doi.org/10.1016/j.applthermaleng.2016.08.003

Ata AB, Alobaid F, Heinze C, Almoslh A, Sanfeliu A, Epple B (2020) Comparison and validation of three process simulation programs during warm start-up procedure of a combined cycle power plant. Energy Convers Manag 207:112547. https://doi.org/10.1016/j.enconman.2020.112547

Li D, Hu Y, Li D, Wang J (2019) Combined-cycle gas turbine power plant integration with cascaded latent heat thermal storage for fast dynamic responses. Energy Convers Manag 183:1–13. https://doi.org/10.1016/j.enconman.2018.12.082

Li Y, Zhang G, Wang L, Yang Y (2020) Part-load performance analysis of a combined cycle with intermediate recuperated gas turbine. Energy Convers Manag 205:112346. https://doi.org/10.1016/j.enconman.2019.112346

Sabia G, Heinze C, Alobaid F, Martelli E, Epple B (2019) ASPEN dynamics simulation for combined cycle power plant—validation with hot start-up measurement. Energy 187:115897. https://doi.org/10.1016/j.energy.2019.115897

Sharma A, Sharma M, Shukla AK, Negi N (2019) Evaluation of heat recovery steam generator for gas/steam combined cycle power plants. In: Saha P, Subbarao P, Sikarwar B (eds) Advances in fluid and thermal engineering: Lecture notes in mechanical engineering. Springer, Singapore, pp 189–200. https://doi.org/10.1007/978-981-13-6416-7_18

Zhang G, Zheng J, Yang Y, Liu W (2016) Thermodynamic performance simulation and concise formulas for triple-pressure reheat HRSG of gas-steam combined cycle under off-design condition. Energy Convers Manag 122:372–385. https://doi.org/10.1016/j.enconman.2016.05.088

Vytla VVSK (2005) CFD modeling of heat recovery steam generator and its components using fluent. Master’s thesis dissertation. University of Kentucky. https://uknowledge.uky.edu/gradschool_theses/336

Torresi M, Saponaro A, Camporeale SM, Fortunato B (2008) CFD analysis of the flow through tube banks of HRSG. In: Proceedings of ASME Turbo Expo 2008: power for land, sea, and air. Paper no. GT2008-51300, Berlin, Germany, pp 327–337. https://doi.org/10.1115/GT2008-51300

Rad SE, Afshin H, Farhanieh B (2015) Heat transfer enhancement in shell-and-tube heat exchangers using porous media. Heat Transf Eng 36(3):262–277. https://doi.org/10.1080/01457632.2014.916155

Silva PRS (2020) Evaluation of the efficiency and performance of a heat recovery steam generator via computational simulations of off-design operation. D.Sc. thesis. Mechanical Engineering Program, COPPE, Federal University of Rio de Janeiro, Brazil

HANGZHOU Boiler Group CO., LTD. (2013) HRSG—operation & maintenance manual, China

ANSYS, Inc. (2011) ANSYS FLUENT theory guide, Canonsburg, PA

Versteeg HK, Malalasekera W (2007) An introduction to computational fluid dynamics, 2nd edn. Pearson Education Limited, Essex

Kays WM, London AL (1984) Compact heat exchangers, 3rd edn. McGraw-Hill, New York

ASME (2009) Standard for verification and validation in computational fluid dynamics and heat transfer. ASME V V 20-2009 (R2016)

Acknowledgements

The authors gratefully acknowledge the support provided by CNPq—Brazilian National Council for Scientific and Technological Development (Projects Nos. 303208/2014-7 and 308849/2018-3).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Jader Barbosa.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Silva, P.R.S., Leiroz, A.J.K. & Cruz, M.E.C. Evaluation of the efficiency of a heat recovery steam generator via computational simulations of off-design operation. J Braz. Soc. Mech. Sci. Eng. 42, 569 (2020). https://doi.org/10.1007/s40430-020-02655-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02655-1