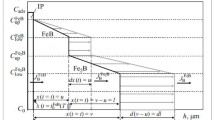

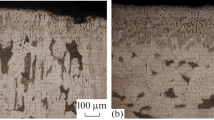

Activation energy of boron diffusion during pack boriding of armco iron with a constant incubation time for boride formation is estimated using a mean diffusion coefficient model. Experimental verification is accomplished for the model by boriding armco iron at 1253 K for 5 h. Good correspondence is obtained between experimental and calculated Fe2B layer thicknesses.

Similar content being viewed by others

References

I. E. Campos-Silva and G. A. Rodríguez-Castro, “Boriding to improve the mechanical properties and corrosion resistance of steels,” in: E. J. Mittemeijer and M. A. J. Somers (eds.), Thermochemical Surface Engineering of Steels, Woodhead-Elsevier Publishing, Cambridge (2015), pp. 651 – 697.

D. N. Tsipas and J. Rus, “Boronizing of alloy steels,” J. Mater. Sci. Lett., 6, 118 – 120. (1987).

J. A. Davies, P. J.Wilbur, D. I. Williamson, et al., “Ion implantation boriding of iron and AISI M2 steel using a high-current density, low energy, broad-beam ion source,” Surf. Coat. Technol., 103 – 104, 52 – 57 (1998).

M. S. Keddam and M. Chentouf, “A diffusion model for describing the bilayer growth (FeB/Fe2B) during the iron powder-pack boriding,” Appl. Surf. Sci., 252, 393 – 399 (2005).

C. I. VillaVelázquez-Mendoza, J. L. Rodríguez-Mendoza, V. Ibarra-Galván, et al. “Effect of substrate roughness, time and temperature on the processing of iron boride coatings: experimental and statistical approaches,” Int. J. Surf. Sci. Eng., 8, 71 – 91 (2014).

I. Campos, M. Islas, E. González, et al., “Use of fuzzy logic for modeling the growth of Fe2B boride layers during boronizing,” Surf. Coat. Technol., 201, 2717 – 2723 (2006).

J. Zuno-Silva, M. Ortiz-Domínguez, M. Keddam, et al., “Boriding kinetics of Fe2B layers formed on AISI 1045 steel,” J. Min. Metall. Sect. B-Metall., 50, 101 – 107 (2015).

M. Keddam, M. Elias-Espinosa, M. Ortiz-Domínguez, et al., “Pack-boriding of AISI P20 steel: Estimation of boron diffusion coefficients in the Fe2B layers and tribological behaviour,” Int. J. Surf. Sci. Eng., 11, 563 – 585 (2017).

M. Keddam, “A diffusion model for the Fe2B layers formed on a ductile cast iron,” Acta Phys. Polonica A, 133, 1174 – 1177 (2018).

M. Keddam and R. Chegroune, “A model for studying the kinetics of the formation of Fe2B boride layers at the surface of a gray cast iron,” Appl. Surf. Sci. 256, 5025 – 5030 (2010).

R. D. Ramdan, T. Takaki, and Y. Tomita, “Free energy problem for the simulations of the growth of Fe2B phase using phase-field method,” Mater. Trans., 49, 2625 – 2631 (2008).

Z. Nait Abdellah, M. Keddam, R. Chegroune, et al. “Simulation of the boriding kinetics of Fe2B layers on iron substrate by two approaches,” Matériaux et Techniques, 100, 581 – 588 (2012).

M. Elias-Espinosa, M. Ortiz-Domínguez, M. Keddam, et al., “Growth kinetics of the Fe2B layers and adhesion on Armco iron substrate,” J. Mater. Eng. Perform., 23, 2943 – 2952 (2014).

M. Keddam and M. Kulka, “Boriding kinetics of AISI D2 steel by using two different approaches,” Metal Sci. Heat Treat., No. 12, 13 – 20 (2018).

L. G. Yu, X. J. Chen, K. A. Khor, and G. Sundararajan, “FeB/Fe2B phase transformation during SPS pack-boriding: Boride layer growth kinetics,” Acta Mater., 53, 2361 – 2368 (2005).

Y. Ugaste, “On the interstitial phase growth kinetics at diffusional precipitation of metals,” in: Chemical and Thermal Treatment of Metals and Alloys [in Russian], Belarus Technical Institute Press, Minsk (1977).

M. Kulka, N. Makuch, A. Pertek, and L. Maldzinski, “Simulation of the growth kinetics of boride layers formed on Fe during gas boriding in H2– BCl3 atmosphere,” J. Solid State Chem., 199, 196 – 203 (2013).

M. Keddam, M. Kulka, N. Makuch, et al. “A kinetic model for estimating the boron activation energies in the FeB and Fe2B layers during the gas-boriding of Armco iron: Effect of boride incubation times,” Appl. Surf. Sci., 298, 155 – 163 (2014).

H. Planitz, G. Treffer, H. Konig, and G. Marx, “Zum Einfluss von Temperatur und Zeitauf die Erzeugung von Eisenboridschichten aus der Gasphase,” Neue Hutte, 27, 228 – 230 (1982).

I. Campos-Silva, M. Ortiz-Domínguez, H. Cimenoglu, et al., Surf. Eng., 27, 189 – 195 (2011).

I. Campos, J. Oseguera, U. Figueroa, et al., “Kinetic study of boron diffusion in the paste-boriding process,” Mater. Sci. Eng. A, 352, 261 – 265 (2003).

C. M. Brakman, A. W. J. Gommers, and E. J. Mittemeijer, “Boriding of Fe and Fe – C, Fe – Cr, and Fe – Ni alloys; Boride layer growth kinetics,” J. Mater. Res., 4, 1354 – 1370 (1989).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 30 – 34, May, 2020.

Rights and permissions

About this article

Cite this article

Keddam, M., Kulka, M. Mean Diffusion Coefficient Method in Studying Armco Iron Boriding Kinetics. Met Sci Heat Treat 62, 326–330 (2020). https://doi.org/10.1007/s11041-020-00562-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00562-9