Abstract

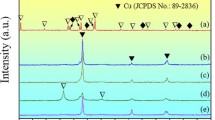

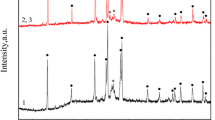

Copper (Cu) surfaces with bimodal nanoporosity can be used for a variety of applications. This research shows that bimodal nanoporous Cu surfaces can be fabricated by dealloying of an as-cast hypereutectic alloy Al75Cu25 (at.%) alloy, which solidifies as pre-eutectic Al2Cu (micrometre-scaled) and eutectic lamella of α-Al/Al2Cu (nanoscaled). The bimodal nanoporous Cu surface is a result of a microstructural length scale controlled dealloying process: In the beginning, the micrometre-scaled Al2Cu acts as a cathode enabling the preferential dissolution of α-Al (anode) for larger pores to form. Afterwards, the nanosize effect of α-Al overrides the intrinsic difference in electrochemical potential allowing for subsequent simultaneous dealloying leading to finer pores. The assessment of the in situ Synchrotron XRD data of the formation of bimodal nanoporous Cu surfaces revealed a two-stage kinetic process, closely related to the formation of bimodal pores during the microstructural length scale controlled dealloying process. The underlying rationales and implications are discussed.

Similar content being viewed by others

References

M. Stratmann and M. Rohwerder, Nature 410, 421 (2001).

J. Fu, Z. Deng, and E. Detsi, JOM 71, 1581 (2019).

F. Kertis, J. Snyder, L. Govada, S. Khurshid, N. Chayen, and J. Erlebacher, JOM 62, 50 (2010).

W. Liu, P. Cheng, S. Zhang, and S. Shi, Metall. Mater. Trans. A 51, 2236 (2020).

T. Song, M. Yan, and M. Qian, J. Porous Mater. 22, 713 (2015).

X. Wu, G. He, and Y. Ding, Chemsuschem 13, 3376 (2020).

S.Y. Han, J.A. Lewis, P.P. Shetty, J. Tippens, D. Yeh, T.S. Marchese, and M.T. McDowell, Chem. Mater. 32, 2461 (2020).

Y. Gao and Y. Ding, Chem. Eur. (2020). https://doi.org/10.1002/chem.202000471.

L.-M. Luo, W. Zhan, R.-H. Zhang, Q.-Y. Hu, Y.-F. Guo, and X.-W. Zhou, J. Catal. 381, 316 (2020).

Z. Yuan, X. Wang, J. Bin, C. Peng, S. Xing, M. Wang, J. Xiao, J. Zeng, Y. Xie, X. Xiao, X. Fu, H. Gong, and D. Zhao, Appl. Surf. Sci. 285, 205 (2013).

P. Zhu, Z. Wu, and Y. Zhao, Scr. Mater. 172, 119 (2019).

Z. Qi and J. Weissmüller, ACS Nano 7, 5948 (2013).

T. Song, M. Yan, and M. Qian, Corros. Sci. 134, 78 (2018).

Y. Zhang, X. Sun, N. Nomura, and T. Fujita, Small 15, 1805432 (2019).

T. Song, M. Yan, N.A.S. Webster, M.J. Styles, J.A. Kimpton, and M. Qian, Acta Mater. 168, 376 (2019).

T.B. Massalski, Bull. Alloy Phase Diagr. 1, 27 (1980).

L. León-Reina, M. García-Maté, G. Álvarez-Pinazo, I. Santacruz, O. Vallcorba, A.G. De la Torre, and M.A.G. Aranda, J. Appl. Crystallogr. 49, 722 (2016).

K.S. Wallwork, B.J. Kennedy, and D. Wang, AIP Conf. Proc. 879, 879 (2007).

R.B. Von Dreele, Powder Diffraction: Theory and Practice (London: The Royal Society of Chemistry, 2008), pp. 266–281.

A. Dursun, D.V. Pugh, and S.G. Corcoran, Electrochem. Solid State Lett. 6, B32 (2003).

Q. Zhang and Z. Zhang, Phys. Chem. Chem. Phys. 12, 1453 (2010).

O.K. Abiola, N.C. Oforka, and S.S. Angaye, Mater. Lett. 58, 3461 (2004).

P. Kwolek, B. Kościelniak, and M. Wytrwal-Sarna, Materials 13, 1946 (2020).

T. Song, M. Yan, Z. Shi, A. Atrens, and M. Qian, Electrochim. Acta 164, 288 (2015).

D.F. Swinehart, J. Chem. Edu. 39, 333 (1962).

P. Bandyopadhyay and C.U. Segre, http://www.csrri.iit.edu/mucal.html. Accessed 14 July 2020.

T. Song, Y.L. Gao, Z.H. Zhang, and Q.J. Zhai, Corros. Sci. 68, 256 (2013).

X. Wang, Z. Qi, C. Zhao, W. Wang, and Z. Zhang, J. Phys. Chem. C 113, 13139 (2009).

Z. Zhang, Y. Wang, Z. Qi, J. Lin, and X. Bian, J. Phys. Chem. C 113, 1308 (2009).

M. Avrami, J. Chem. Phys. 7, 1103 (1939).

A. Kolomogrov, Izv. Akad. Nauk SSSR. Ser. Matem 1, 355 (1937).

W.A. Johnson and R.F. Mehl, Trans. Am. Inst. Min. Metall. Eng. 135, 416 (1939).

M. Avrami, J. Chem. Phys. 8, 212 (1940).

M. Avrami, J. Chem. Phys. 9, 177 (1941).

J. Chen, J. Bai, H. Chen, and J. Graetz, J. Phys. Chem. Lett. 2, 1874 (2011).

R.J. Francis, S. O’Brien, A.M. Fogg, P.S. Halasyamani, D. O’Hare, T. Loiseau, and G. Ferey, J. Am. Chem. Soc. 121, 1002 (1999).

J.W. Christian, The Theory of Transformations in Metals and Alloys, ed. J.W. Christian (Oxford: Pergamon, 2002), pp. 529–552.

Acknowledgements

This project was supported in part by the Australian Research Council (ARC) through LP140100607. T. Song acknowledges the use of the Australian Synchrotron Powder Diffraction Beamline (Proposal ID: PD/7953 and PD/8856) and the RMIT University’s Microscopy and Microanalysis Facility, a linked laboratory of the Microscopy Australia. T. Song further thanks Dr Nathan A.S. Webster, Dr Mark J. Styles and Dr Justin A. Kimpton for their experimental assistance at Australian Synchrotron.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, T. Copper Surfaces with Bimodal Nanoporosity by Microstructural Length Scale Controlled Dealloying of a Hypereutectic Al-Cu Alloy. JOM 72, 4648–4656 (2020). https://doi.org/10.1007/s11837-020-04391-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04391-2