Abstract

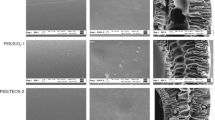

A series of industrial-scale 316L stainless steel membrane tubes (Φ60 mm × 1000 mm) was fabricated by wet spray coating three membrane powders (20 μm; 12 μm; 4 μm) onto a pre-sintered 316L stainless steel support tube, followed by sintering. The influence of the membrane powder size and spray coating times or number of spray coating layers on the structure and permeability of the as-sintered membrane tubes was analyzed in detail. A permeability model has been formulated according to the resistance-in-series model based on Darcy’s law. It is shown that the model can reasonably describe the permeability of as-sintered stainless steel membranes. A good balance between the filtration accuracy and the permeability can be achieved by fabricating an ultra-thin metallic membrane structure on the surface of a pre-sintered stainless steel support tube. The gas separation efficiency of the as-fabricated 316L stainless steel membrane reached 99.8% for the 0.3-μm dust particles. The as-sintered porous 316L membrane (Φ60 mm × 1000 mm) was used to filter hot gas mixtures of CO and C4NiO4 in continuous industrial operations for 4 months and demonstrated outstanding performance.

Similar content being viewed by others

References

P. Pandey and R.S. Chauhan, Prog. Polym. Sci. 26, 853 (2001).

L. Zhao, M. Bram, H.P. Buchkremer, D. Stöver, and Z. Li, J. Membr. Sci. 244, 107 (2004).

Z. Li, N. Qiu, and G. Yang, J. Membr. Sci. 326, 533 (2009).

S. Heidenreich, Fuel 104, 83 (2013).

S. Benfer, P. Árki, and G. Tomandl, Adv. Eng. Mater. 6, 495 (2004).

T. Van Gestel, H. Kruidhof, D.H.A. Blank, and H.J.M. Bouwmeester, J. Membr. Sci. 284, 128 (2006).

T. Van Gestel, D. Sebold, H. Kruidhof, and H.J.M. Bouwmeester, J. Membr. Sci. 318, 413 (2008).

Q.B. Wang, J. Wang, K. Yang, B.J. Yang, and H.P. Tang, Powder Metall. 59, 203 (2016).

Y. Lin, D. Zou, X. Chen, M. Qiu, H. Kameyama, and Y. Fan, Appl. Surf. Sci. 349, 8 (2015).

B.S. Institution, BS EN 779, Particulate Air Filters for General Ventilation. Determination of the Filtration Performance (London: BSI Standards Limited, 2012).

B.S. Institution, ISO 12103-1, Road Vehicles: Test Dust for Filter Evaluation—Part 1: Arizona Test Dust (London: BSI Standards Limited, 1997).

B. Ghanbarian, A.G. Hunt, and H. Daigle, Water Resour. Res. 52, 2045 (2016).

J. Hommel, E. Coltman, and H. Class, Transp. Porous Med. 124, 589 (2018).

Acknowledgements

This work was funded by the National High Technology Research and Development Program of China (2012AA03A610). The authors are grateful to Professor Ma Qian of Royal Melbourne Institute of Technology (RMIT University) for many insightful discussions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, K., Wang, J., Yang, B.J. et al. Fabrication of Industrial-Scale Porous Stainless Steel Membrane Tubes and Their Applications. JOM 72, 4576–4582 (2020). https://doi.org/10.1007/s11837-020-04392-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04392-1